International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

1

Abstract - Buffeting noise, a common phenomenon observedinmovingvehicles,isanacousticresponseduetothe differenceinaerodynamicsaroundopeningslikesunroofsand sidewindows.Thereductionoftheresultantacousticnoisehas been the area of interest of aerodynamicists. The research workofthisprojectaimstoestablishthebasisforthedesignof a deflector that solves the problem of sunroof buffeting noise in a three-dimensional simplified car model. This will be executed through Computational Fluid Dynamics (CFD) numericalsimulationtechnology.Thepressurecharacteristics of buffeting noise at different speed conditions are to be analyzed. The pressure distribution around the sunroof will helpestablishanefficientdesignforadeflector.TheDetached Eddy Simulation (DES) method is chosen for this analysis because it is conventionally used for acoustic-based studies. Additionally, since the conditions at maximum noise are intendedtobemodelled,compressibilityisincorporatedinthe fluid model. The domain around the car model will be constructedtoreplicateathree-dimensionalwindtunnel,and the boundary conditions will be assigned accordingly. The observations obtained about buffeting will be used to brainstormthedesign,sizingandpositioningofthedeflector.

Key Words: Aeroacoustics, CFD, Detached-Eddy simulations, Buffeting, Virtual Wind Tunnel, Car sunroof, Sunroof deflectors

Theunpleasant,low-frequency,high-sound-pressure-level noise observed around sunroofs and side windows of moving vehicles is termed as buffeting. The occurrence of thisphenomenonisdependentonvariousfactors,primary onesbeingvehiclespeedandgeometry.Ithappenswhenthe airparticlesaroundthegeometrycollidewiththesurfaces andothergeometries.Everyvehiclehasacriticalspeedand condition at which buffeting occurs. Generally, a sound intensitylevelgreaterthan110dBandafrequencyofless than20Hzcharacterizebuffeting[1].

Thespecimenusedfortestinginthisprojectisan extensionoftheAhmedbody.Thissimplifiedcarmodel is simulated in a 3-D virtual domain. In order to replicate a windtunnelforthisdomain,twosetsofinletswereused,a pressureinletandvelocityinlet.Thesimulationsarecarried out for two primary cases at different velocities- closed sunroof and open sunroof. As previously stated, buffeting

value:

***

occurs at a critical speed, and the aim of this project is to studyanddemonstratethesame.

1. Study on the sunroof buffeting suppression with a notchedflatdeflector[2]:Thispaperhasimplementeda simulationmethodtoinvestigatethesunroofbuffeting phenomena of the vehicle with castled deflector with velocity range of 30 km/h-90 km/h. At 70 km/h, the maximumbuffetingoccurred,withamagnitudeof135.9 db.Anotchedflatdeflectorwasusedinsteadofacastled deflectortodecreasebuffeting.Theresultsrevealeda considerable reduction in sound pressure, with buffetingnoisedroppingto97.9db.

2. The Effect of a Sheared Crosswind Flow on Car Aerodynamics [3]: The aerodynamic parameters of a DrivAermodelinfastbackandsquarebackform,subject to a crosswind flow, with and without shear, were analyzedusingaCFDsimulationinthiswork.Theyaw simulationwasperformedwitha10°yawangleandone shearflowexponent.Ithasbeenobservedthatthecar experiences similar forces and moments in both the cases when the mass flow in the crosswind over the heightofthecarisidentical.

3. Aerodynamics of High-Performance Vehicles [4]: The purpose of this research is to improve the racing vehicle'sexteriorfluiddynamicsandtoinvestigatethe notion of various aerodynamic properties and their effects on racing automobiles. Aerodynamically, race cars are designed to reduce drag, reduce vehicle resistance,andincreasedownforce.Althoughdownforce isutilizedtoofferstabilitywhendrivingthroughturns, drag forces limit maximum speed and affect fuel consumption. The effect of aerodynamics on various racing car parameters and CFD has been reviewed in thiswork.

4. Assessing the Effects of Shear and Turbulence During the Dynamic Testing of the Crosswind Sensitivity of RoadVehicles[5]:Thisresearchfocusesontheissueof crosswindsensitivityatgreaterspeedsaswellasweight reduction in modern cars. The fluctuation in vertical velocityprofileaswellastheturbulenceseveritywithin the gust were considered using a generic squareback model. Because there was less variance in turbulence

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

intensityandtheverticalvelocityprofilewasvaried,the resultsshowedasignificantdifferenceinaerodynamic stressonthemodel.

5. Wind tunnel tests and aerodynamic numerical simulations of car opening windows [6]: The article focuses on the aerodynamic drag caused by varying window opening levels in both the wind tunnel and aerodynamicnumericalsimulation.Theresultsofboth approacheswereanalyzed,andsuggestionsfordrivinga caratamoderatepaceinthesummerwereoffered.It was discovered that when the car's air conditioner is turned on, it consumes more gasoline than when the car'swindowsareopenataspeedlessthan90km/h.

6. Computational study of flow around a simplified car body [7]: The flow around the Ahmed body was explorednumericallyforthebaseslatanglesof25and 35degreesinthisresearch.Thetransitionofthewake to completely three-dimensional behavior is not recreated for slant angle 25°, although the twodimensional behavior of the flow is accurately anticipatedforslantangle35°.

7. Computationalaero-acousticanalysisofapassengercar with a rear spoiler [8]: This research proposed a numericalmodelbasedonaCFDtechniquetoestimate theflowstructurearoundapassengerautomobilewith a wing-type rear spoiler. The CFD solver used in this investigationisAnsysFluent(19.2).Theaerodynamic liftcoefficientcanbereducedbyinstallingaspoilerwith anadequateangleofattack.Additionally,installingan endplatemighthelptodecreasenoisefrombehindthe vehicle.Itisobviousthatapassengervehicle'svertical stability and noise reduction may be enhanced. Eventually, the most appropriate spoiler design's aerodynamics and aeroacoustics are introduced and examined.

8. Experimental and numerical study of the flow field aroundasmallcar[9]:Themainobjectiveofthiswork istocomprehendtheflowfieldanddoanaerodynamic analysis on a small car. CFD Fluent is used to do the numericalsimulationinordertodeterminethevehicle's drag force as well as the flow field. Particle image velocimetry (PIV) is then used to investigate the flow fieldsurroundingthevehicleinawindtunnel.Whenthe computational and experimental flow fields are compared,theyrevealanexcellentmatch.

9. Experimental and computational study of vehicle surfacecontaminationonagenericbluffbody[10]:The goal of this work is to give an experimental and numerical(CFD)investigationofmethodologiesusedto describevehiclesurfacepollutioncausedbyrearwake aerodynamics. The contamination is investigated in a windtunnelundercontrolledconditionsusingatypical bluff body (the Windsor model.) CFD results were

obtainedutilizingparticletrackingtechniquesandboth stableRANSandunsteadyURANSsolvers.SteadyRANS doesnotcorrectlycapturethewakestructures,which hasanimpactoncontaminationprediction.Thelargescalewakeunsteadinessfoundintheexperimentaldata isrecoveredbyURANS,butthediscrepancybetweenthe experimental and computational contamination distributionsremainsessential.

10.Computational study of the unsteady flow structures around two vehicles [11]: This research exhibits the evolutionoftwovehiclemodelsaswellastheimpactof various unstable aerodynamic circumstances on the vehicle'shandling.Whenacarmovesathighspeeds,the pressure imposed on the back-end changes unexpectedly,whilstthepressuresurroundingthefront remainsrelativelyconstantpressure,temperature,Mach number, and velocity The flow around the minivan exhibits quasi-periodic vortex shedding, resulting in a significantincreaseinsurfacepressure.Intheinstanceof thepick-uptruck,thesurfacepressurerevealsanarchlike shapeIrjet Template sample paragraph .Define abbreviationsandacronymsthefirsttimetheyareused in the text, even after they have been defined in the abstract.AbbreviationssuchasIEEE,SI,MKS,CGS,sc,dc, and rms do not have to be defined. Do not use abbreviations in the title or heads unless they are unavoidable.

Thissectionexplainstheprocessthatwasadoptedtocarry out the simulations. After creating the geometry of the specimenandthedomain,theentiremodelwasmeshedon theAnsysWorkbench.Thismeshedfilewasthenimported on Ansys Fluent for the analysis. The following sections explaintheprocedureindetail

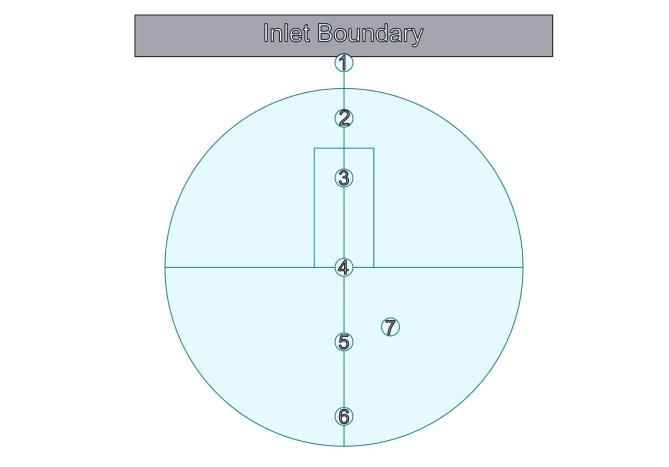

Forthepredictionofvelocityatdifferentlocationsinthe X-direction,severalpointsarecreated,atwhichtheflowisto bemonitored(alsocalledprobepoints).Thesameisshown inFig3.

An unsteady simulation is run for two values of input velocities, namely at 60 km/h and 100 km/h wind speed. Thecarmodelconsideredwithoutsunroof(alsoreferredto as the closed case) represents non-buffeting simulation, whilethecasewherethesunroofisopen(alsoreferredtoas opensunroofcase)representsbuffetingsimulation.

Itmaybenotedthattheboundaryconditionsforboththe cases are the same and have been tabulated (Table 2). A scaleresolvingdetachededdysimulationisselected.Further implementationoftheDetachedEddysimulationSpallartAllmaras (DES-SA) model on Ansys Fluent 19.2 has been implemented.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Solver Pressure-based,unsteady, least square cell based gradientscheme Fluidmaterial Airasidealgas

Timeformulation Second-orderimplicit

Turbulencemodel DES-SA (SA production vorticitybased)

Pressure-velocitycoupling SIMPLEC

Pressurediscretization Second-order

Momentumdiscretization Bounded central differencing

Modified turbulence viscosity Second-orderupwind

Energydiscretization Second-orderupwind

WiththesolversetupsettingsfromTable1,thesimulations wererunfor60km/hand100km/honaclosedandanopen sunroofcase

Boundary label Boundary condition Value

Nozzleinlet Velocity inlet (magnitude, normal to boundary)

U = 60 km/h, 100km/h

Tunnelinlet Pressureinlet Gauge pressure =0Pa

Tunneloutlet Pressureoutlet Gauge pressure =0Pa

Tunnel top, floor,sides Euler’s wall (No slipcondition) NA

InANSYSFluent,operatingpressureiskeptat101325Pa. Tostudythephenomenaofbuffetingforsuchcavityusing computational fluid dynamics can be more efficient by adding compressibility in the fluid modelling. Compressibilitypreciselypropagatesthepressurewavesat

the local speed of sound in the flow field. This ensures accurate interaction between solid body and fluid. This interactiondeterminesbuffetingfrequencyandpropagation ofresultantpressurewavesinsidethecavityvolume.

Each speed case for buffeting simulation is first run-in steadystatemodefor14400iterationsandthenunsteady state. Unsteady state simulation provides time dependent results.Atimestepof0.005iscalculatedtoruntheflowas desiredfrequencyrangeis0-50Hz.Withineachtimestep12 number of maximum iterations are allowed. The total numberoftimestepswere1200.Thethreepressureprobes arelocatedinsidethecarvolumeviz.(-0.36,0,1),(-0.56,0, 1)and(-0.76,0,1).

These vertices are defined to be vertex average with static pressure as a recording parameter. The pressure fluctuation meets gradual stability with increase in time. After 1200-time steps, 100 samples are noted on above mentioned3vertices.Toenableaero-acousticanalysis,Fast Fourier Transformation (FFT) with Hanning window is utilized.Soundpressurelevelisdefinedas: wherePisthesoundpressureofthenoiseinPa,andP0is thereferencepressureequalto2x10-5 Pa.

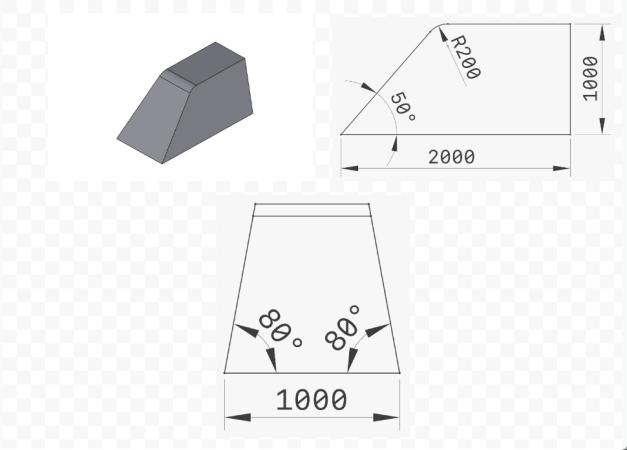

The geometric dimensions of the simplified car model withoutsunroofareusedforexperimentalinvestigationof buffetingnoiseasshowninFig1.

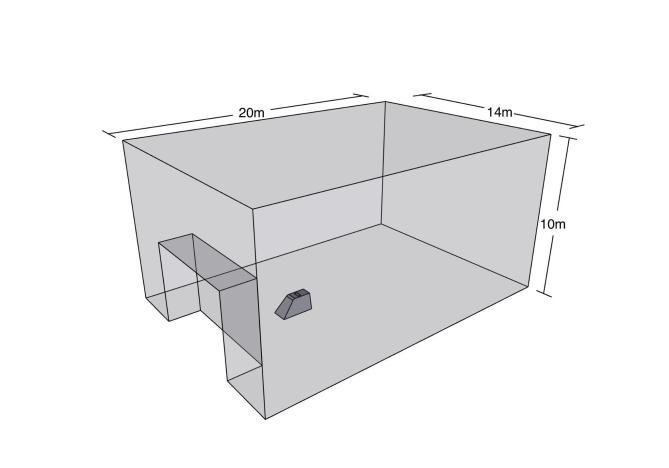

Forourstudy,wehaveconstructedavirtualwindtunnel with suitable size as given in Fig.2. To carry out volume discretizationaswellassurfacediscretization,ANSYS19.2is engaged

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Fig-1: (clockwise)Isometric,side,andfrontviewsof specimenforcasewithoutsunroof

Fig-3:Pointsatwhichtheflowisintendedtobemonitored 3.4 Simplified car model analysis with sunroof

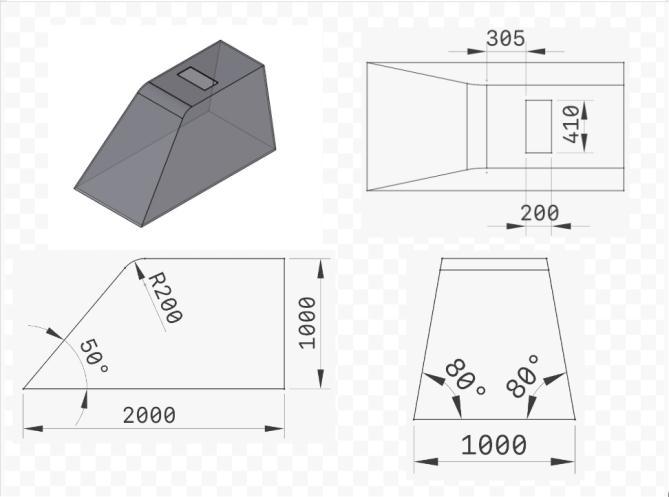

Thegeometricdimensionsofthesimplifiedcarmodelwith sunroofareusedforexperimentalinvestigationofbuffeting noiseasshowninFig1.

Fig-2: Geometryofchosendomain

2. MeshInformation

Thesimplifiedcarmodelisplacedinvirtualwindtunnel as given in Fig3. In this discretization process, hexacore, tetrahedral and prism elements were selected. A layered meshconsistingof20prismlayersisgeneratedtocapture boundarylayerphenomenaprecisely.Thefirstcellheightof 0.00025mandauniformgrowthratioof1.15areinserted. While doing discretization, researchers have kept in their mindthatthegridnearthemodelisfineandawayfromthe modeliscoarse.Toachievethisdesiredformofmesh,three spheresofinfluenceareused. Thedomainissaidtobefluid zoned,andthesimplifiedcarmodelissaidtobesolid.

Thetotalmeshcountisapproximately8millioncells.For accurate prediction of velocity and pressure near the boundarywallsofmodel,prismlayersareused.

Fig-4: (clockwise)Isometric,top,frontandsideviewsof thespecimenforopensunroofcase

InFig4,toinvestigatethebuffetingphenomenonanopen sunroof of dimension (410mm x 200mm) is created. The thicknessofthecarmodelis10mm.

The entire discretization process of without sunroof car modelispreciselyfollowedforthiscase.Although,avolume meshisgeneratedinsidethemodeltocreateaprobepoint insidethemodelandtoallowthefluidtoenterthecavity. Thetotalmeshcountforthiscaseis10millioncells.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

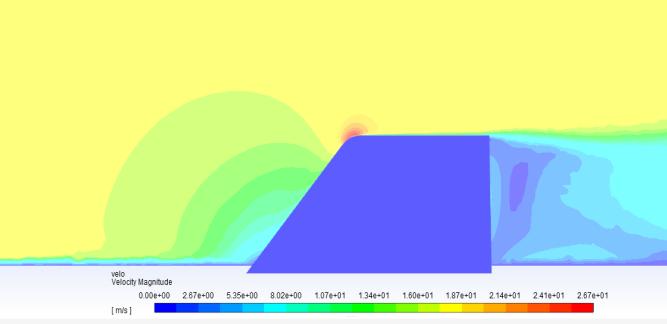

A. Toanalyzetheflowoverthemodel,acutplanealigned withtheplaneandy=0isdisplayed.

closedsunroof

Thevelocitymagnitudesinclosedcarmodelareanalyzed quantitativelyusingseveralprobepointsmentionedinFig3. Thiscaseissimulatedasaprecursortotheprimarycaseof interest,i.e.,whenthesunroofisopen.Thebuffetingnoise insidetheclosed-carmodelisnotinthescopeofthispaper. Thebuffetingsimulationiscarriedoutat60km/hand100 km/h. The results of the simulation for closed case at a velocityof60km/hispresentedinFig.5.

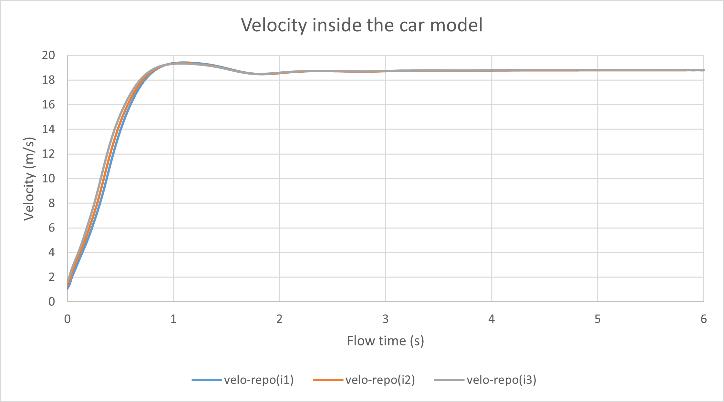

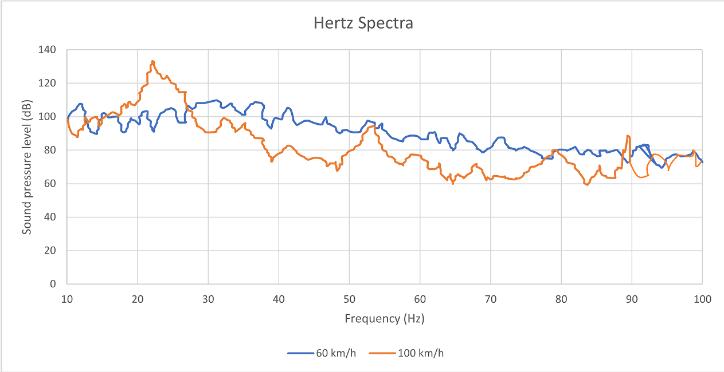

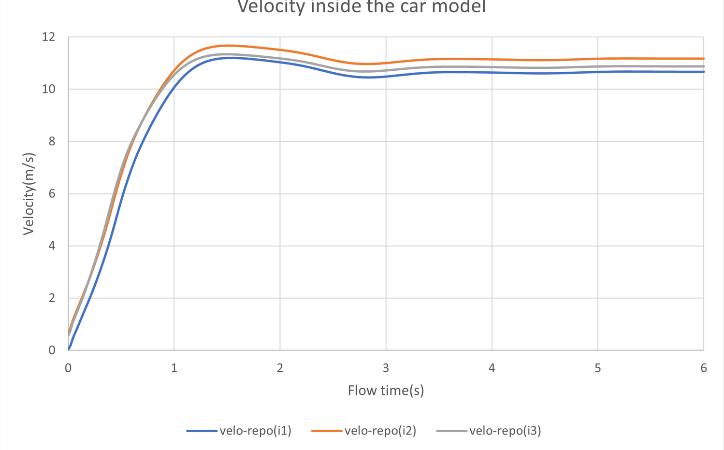

Upon establishing a visual and quantitative representation of the velocity flow around the selected geometry,thecasefortheopensunroofwassimulated.The velocityprofilesofthesimulationarepresentedinFig.6and 7.Tounderstandtheoscillatorybehavioroftheopencase, thefrequencyspectraatboththeaforementionedspeedsare plotted,whichmaybeseeninFig.8.

Fig-7: Velocityprofileforopensunroofcaseat100km/h

Fig-6: Velocityprofileforopensunroofcaseat60km/h

Fig-8: FFTplotofopensunroofcaseatvelocities60km/h and100km/h

ItisevidentfromthegraphinFig.8,thathighbuffeting noiseiscapturedwith60km/hvelocity.Thereasonbehind lowbuffetingat100km/hisduetomostoftheflowrushes over the cavity with weak stream coming inside the car model.

Thedependencyofbuffetingonthevelocityofthevehicle has been demonstrated and it may be inferred that each vehiclehasacriticalspeedatwhichbuffetingismostlikely to occur. As previously mentioned, the geometry of the vehicle also plays an important role in determining the occurrenceofbuffeting.

Theexistingpapergivesrisetothestudyofmodellinga sunroof deflector that can efficiently overcome buffeting. The same methodology followed in this paper may be followedtounderstandtheflowaroundthenewspecimen, thatconsistsofadeflector.Thesize,location,orientationand shapeofthedeflectormaybedeterminedbycreatingand checkingvariouscases.

This paper would not have been possible without our projectmentorProf.Dr.DevabrataSahoo.Wearegrateful forhissupport,guidance,andencouragementthroughthe courseoftheproject.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

We also sincerely thank the Head of Department, AerospaceEngineeringatMITSchoolofEngineering,MITADTUniversity,Pune.

[1] Zhang, Q.; He, Y.; Wang, Y.; Xu, Z.; Zhang, Z. (2020)‘Computational study on the passive control of sunroofbuffetingusingasub-cavity.’ Appl. Acoust,159, 1–9

[2] Y. et al. (2019) ‘Study on the sunroof buffeting suppressionwithanotchedflatdeflector’, INTER-NOISE 2019 MADRID - 48th International Congress and Exhibition on Noise Control Engineering

[3] Howell,J.,Forbes,D.,Passmore,M., &Page,G.(2017). ‘The Effect of a Sheared Crosswind Flow on Car Aerodynamics.’ SAE International Journal of Passenger Cars - Mechanical Systems, 10(1), 278–285. https://doi.org/10.4271/2017-01-1536

[4] Kshirsagar,V.andChopade,J.V.(2018)‘Aerodynamics of High-Performance Vehicles’, International Research Journal of Engineering and Technology,5(3),pp.2182–2186. Available at: https://www.irjet.net/archives/V5/i3/IRJETV5I3502.pdf

[5] MacKlin, R., Garry, K. and Howell, J. (1997) ‘Assessing theeffectsofshearandturbulenceduringthedynamic testingofthecrosswindsensitivityofroadvehicles’, SAE TechnicalPapers,(412),pp.27–40. doi:10.4271/970135

[6] Zhang, Y. C., Zhao, J., Li, J., & Zhang, Z. (2012). ‘Wind tunneltestsandaerodynamicnumericalsimulationsof caropening windows.’ International Journal of Vehicle Design,62.https://doi.org/10.1504/ijvd.2012.045923

[7] Guilmineau, E. (2008). ‘Computational study of flow around a simplified car body.’ Journal of Wind EngineeringandIndustrialAerodynamics,96(6–7),1207–1217. https://doi.org/10.1016/j.jweia.2007.06.041

[8] Tsai,C.H.,Fu,L.M.,Tai,C.H.,Huang,Y.L.,&Leong,J.C. (2009). ‘Computational aero-acoustic analysis of a passengercarwitharearspoiler.’ Applied Mathematical Modelling, 33(9), 3661–3673. https://doi.org/10.1016/j.apm.2008.12.004

[9] Dobrev, I. et al. (2017) ‘Experimental and numerical studyoftheflowfieldaroundasmallcar’, MATECWebof Conferences, 133, pp. 0–3. doi: 10.1051/matecconf/201713302004.

[10] Kabanovs, A. et al. (2016) ‘Experimental and ComputationalStudyofVehicleSurfaceContamination onaGenericBluffBody’, SAE Technical Papers, (April) doi:10.4271/2016-01-1604.

[11] Tutunea,D.,Bica,M.andDima,A.(2014)‘Computational Study of the Unsteady Flow Structures Around Two Vehicles’, Journal of Industrial Design and Engineering Graphics, 9(1), pp. 13–16

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |