International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

2

Ahmed AbouAlyazid, 3 Ibrahim Ahmed1 Researcher, Automotive and tractor engineering department, faculty of engineering, Helwan University, Egypt

2professor at Automotive and tractor engineering department, faculty of engineering, Helwan University, Egypt 2professor at Automotive and tractor engineering department, faculty of engineering, Helwan University, Egypt ***

Abstract - This research paper is about enhancing tribological behavior of ventilated disc brake by using (Cr3C275 % NiCr25 %) coating on the first disc and (Al2O3-87 % TiO2 13%) coating on the second disc to compare them with the plain disc with no coating to determine if this coating materials improve the coefficient of friction (µ) and brake force (Fb) with variable brake oil pressure and different initial temperatures after comparison it is concluded that the second disc with (Al2O3-87 % TiO2 13%) coating has the most low coefficient of friction and low final temperature than the first disc with (Cr3C2-75 % NiCr25 %) coating and The plain disc is the highest one.

First, the test rig is designed and constructed to examine the performance of the brake system. Second, two different coating layer are used on two brake discs. After that, some experimental tests are conducted on the three discs at different brake oil pressure at constant sliding speed and at different initial operating temperatures. Finally, comparisons between three brake discs are performed. Experimental results showed that the brake force (Fb) and the coefficient of friction (µ) of the second disc with (Al2O3-87 % TiO2 13%) coating is lower than the brake force and the coefficient of friction of the first disc with (Al2O3-87 % TiO2 13%) coating and the brake force (Fb) and the coefficient of friction (µ) of the first disc is lower than the brake force and the coefficient of friction of the plain disc with no coating.

Key Words: Coating, Ventilated disc brake, Brake force ( Fb), Friction coefficient(µ) , brake oil pressure.

Braking systems are undoubtedly the most important componentforroadsafetypurposes.

During the braking process, the heat generated by frictionbetweenthebrakepadsandthediscisnotquickly dissipated.Thismainlydependsongeometricalfeaturesand manufacturingmaterial.Consequently,numerousnegative effectsontheentirebrakemayarise[1].

Thebrakediscandlinings,mustmeettherequirementsof goodwearresistancestablecoefficientoffriction,reduced

noiseandreducedparticlematteremissions.Tomeetthese requirements, the temperature formed by the correct thermalconductivityandfrictionlayerformationconditions areoftenreferredtoaskeyfeaturesandisthereforecovered bymanystudies.

Thetribologicalbehaviorofthebrakefrictionmaterialsis controlledbythepropertiesofthefrictionlayerformedon thelininganddisccontactsurface.Theperformanceofthe system is very sensitive to the contact temperature. The coefficientoffrictionisrelativelyhigh,butmostimportantly it must be stable. In addition to the safety requirements, therearerequirementssuchaslonglifeandhighcomfort. The nature of the brake system differs significantly from many other tribological contact cases This tribological contact includes dry sliding contact at high speeds, high contactforcesandhightemperatures[2].

Ni-based NiCrBSi coatings are widely used in high temperature, corrosion and wear resistance applications. Hardnessandwearpropertiescanbeimprovedbyadding

Different powder properties into NiCrBSi coating powder. WiththeadditionofWCintoNiCrBSi,oneofthesepowders, highmicrohardness,highabrasionandcorrosionresistance hasbeenachievedwhichisthereasonwhyithasattracted attention of so many researchers. Nickel in the powder componentsof20NiCrBSi-WC12Coexhibitsagoodadhesion withitsexcellentwettability,andimprovesChrometribomechanical properties. Boron reduces the melting temperature and contributes to the formation of hard phases. Silicon increases the viscosity while lowering the meltingtemperature[3].

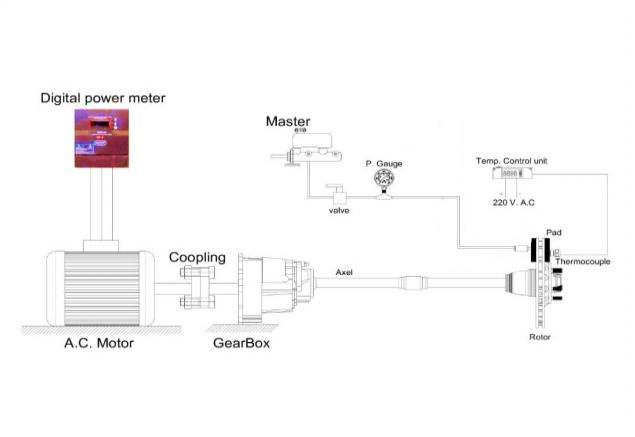

The brake test rig has two main objectives. The first objective is the ability to measure the generated brake poweroftheplaindiscbrake,thefirstdiscwith(Cr3C2-75% NiCr25 %) coating and the second disc with (Al2O3-87 % TiO213%)coating.atalloperatingparameters.Thesecond objective ofthe testrigisto generatetherequiredkinetic energythatcouldbeovercomebythebrakingsystem.The test rig is designed and constructed to achieve these requirements. Fig.1showsthemaincomponentsofthetest

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

rigwhichare discbrakesystemassembly,componentsof generationthekineticenergy.

The braking force is depending on two main parameters.Thefirstparameteristhenormalforceaffecting the brake pad. The second parameter is the coefficient of frictionbetweenthebrakepadsandtherotordisc.So,the normalforceisconsideredthemainfactorofgeneratingthe brakeforce.Henceitseffectonthebrakingprocesshastobe takenintoconsideration.Thegeneratednormalforcemust haveconstantvaluesduringthetestsaccordingtothe

AdiscbrakeofHyundaiExcelpassengercarisusedinthetest rig.Thisbrakingsystemisafloatingcaliperdiscbrake.The main components of this system are shown in Fig.1. It consists of floating caliper with its slave cylinder which containsahydraulicpistonofdiameter5.3cm,rotordisc,two brakepads,wheelbearing,fingerandhub.Thehydraulicpipe isconnectedbetweenthemastercylinderandthehydraulic piston.

The value of the oil pressure in the brake system is measured by using an oil pressure gauge. The pressure gaugeismountedinthehydrauliclinebetweenthemaster cylinder and the slave cylinder of the brake system. The normalforceiscalculatedasthemultiplicationofthepiston area of the slave cylinder and the magnitude of the oil pressure. Different values of the normal force are determinedaccordingtothevaluesoftheoilpressure. Four oil pressure values of 2.5, 5, 7.5, 10 bar are selected duringthetests.Accordingtoequation(3)thesevaluesof pressure equal normal forces of 550, 1100, 1650, 2200 N respectively. To insure that the normal force is constant duringthetests,acontrolvalvewasusedtoachievethisaim. Thevalvewasmountedintothehydrauliclinebetweenthe mastercylinderandtheslavecylinder.Thisvalveisopened toidentifytherequiredpressureanditisclosedduringthe test to insure that the pressure is constant as well as constantnormalforce.

AnA.Celectricmotorisusedinthetestrig,asshowninFig. (1). The electric motor is three phase type which has maximum power 10 Hp at 1500 r.p.m. In order to do the experimentsatvariousspeeds,agearboxwithdifferential unitofaHyundaiExcelpassengercarisinstalledbetweenthe electric motorandthebrakesystem.Thisgearboxandits differentialunithavereductionratiosof6.5,3.9,2.6,1.9,1.5 andareversereductionratioof6.8.

Where:

Thepistondiameteroftheslavecylinderequals(0.053m)

Thepistonareaoftheslavecylinderequals(2.2* m2)

Thenormalforcewhichaffectsthebrakepad.

Inthisworkthebrakepowerismeasuredbyusing digitalpowermeter.Thetypeofthedigitalpowermeteris Schneider PM 1200 which has range from 20 watt to 300 k.wattandhasaccuracy1%ofreadingforpowerandgives 60 readings per minute. The power meter measured the powerofthe electricmotor duringthe brakingprocessas thenormalforceaffectedthebrakepad.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Therotationalspeedoftherotordisc(slidingspeed)isalsoa very significant parameter in the braking process. The sliding speed of the braking system was measured by a digital tachometer which its type is (DT2234 ) and it has rangefrom5to100000r.p.mwithaccuracyof0.5%.The first aim of measuring the sliding speed of the braking system was to calculate the angular speed of the rotating discwhichwasusedwithbrakepowertocalculatethebrake torque. The second aim was to know the behavior of the brakesystemwithdifferentslidingspeeds.

The brake force and friction coefficient are most important parameters indicate the performance of disc brakeathightemperaturesinthiswork. Bycalculatingthe brake torque the braking force can be calculated as following:

(4)

Foradiscbrakesystemthereisapairofbrakepads,thus thetotalbraketorqueis: (5)

(6)

Where:

Thebrakeforcegeneratedatthecontactinterface(N)

Theeffectiveradiusofthebrakepad,equals0.089m

Theouterradiusofthebrakepad(m)

Theinnerradiusofthebrakepad(m)

Fromequation(10)thebrakeforceofthethreediscscanbe calculatedasfollow: (7)

Where: Thebrakeforce(N) Thebraketorque (N.m)

However the braking force is dependent upon the normal forceandthefrictioncoefficient,whichisderivedasbelow: (8)

Thecoefficientoffrictioncanbecalculatedasfollow: (9) (10)

Where: µ Thefrictioncoefficient.

The effect of the initial operating temperature is consideredduringthisworktoinvestigateitseffectonthe performanceoftheplaindisc,thefirstdiscwith(Cr3C2-75 %NiCr25%)coatingandtheseconddiscwith(Al2O3-87% TiO213%)coating.AthermocoupleofJ-typewasselected and is fixed in the brake pad to measure the friction temperatureatthecontactareabetweenthebrakediscand thebrakepad.Theoutputsignalofthethermocouplewas sent to the temperature control unit (thermostat). The temperature control unit is adjusted at a certain temperature.Asthebrakepadtemperaturereachestothe adjusted temperature of the control unit. Four initial operatingtemperaturesareselectedduringthetests.These valueswere38˚C,60˚C,80˚Cand100˚C.

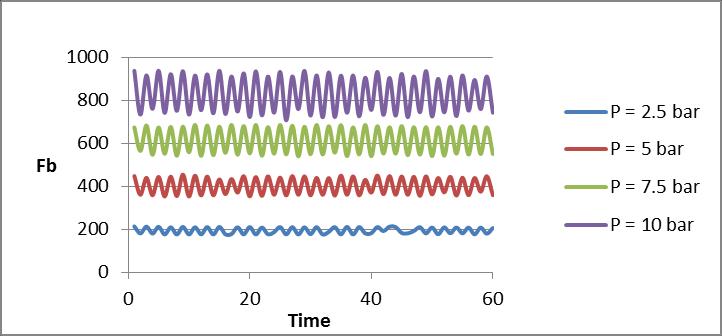

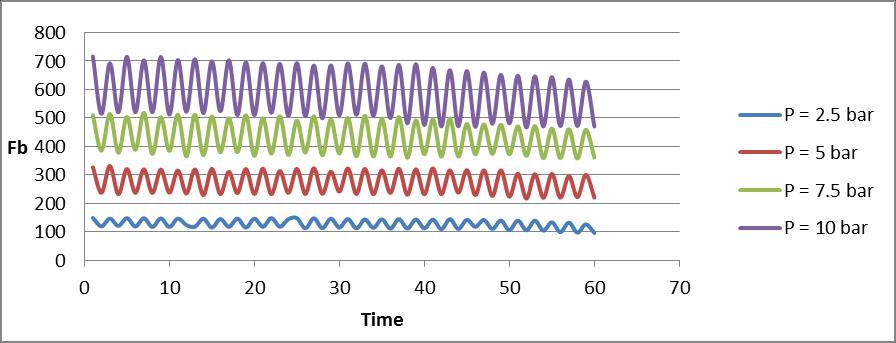

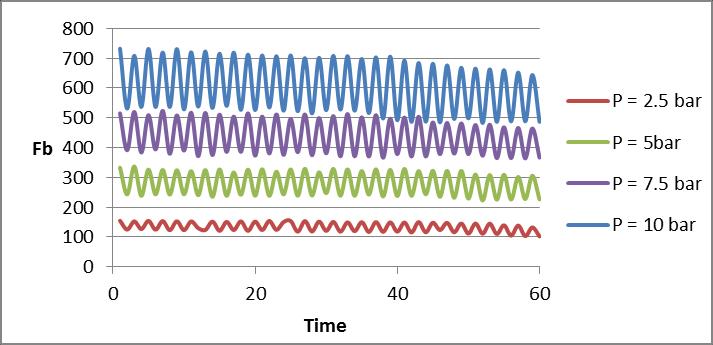

Theexperimentalworkiscarriedouttoinvestigatetheeffect of brake oil pressure at constant sliding speed and at differentinitialoperatingtemperaturesonthebrakeforce andfrictioncoefficientoftheplaindiscbrake,thefirstdisc with (Cr3C2-75 % NiCr25 %) coating and the second disc with(Al2O3-87%TiO213%)coating.Allexperimentaltests areconductedinthesameconditions60secondsofbraking. Thebrakepowerwasmeasuredeverysecondbythedigital powermeter.Theslidingspeed,thebrakeoilpressureand the initial operating temperature were measured during each test for the three brake discs. The brake force and frictioncoefficientofthethreediscswerecalculatedevery secondandplottedwiththebraketimeduringeachtest.

temperature 38˚C:

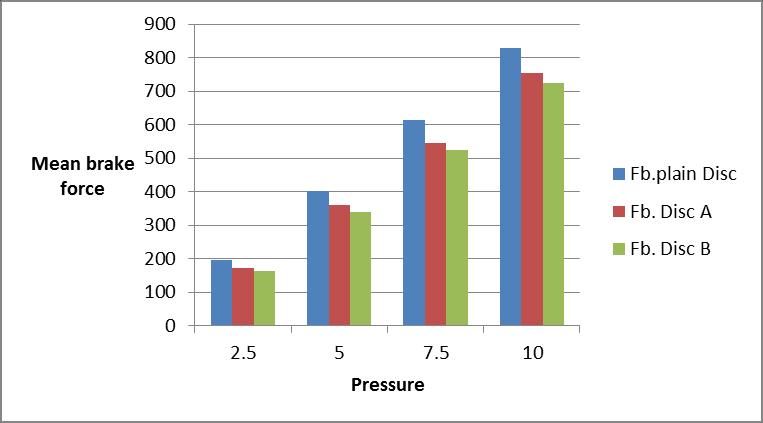

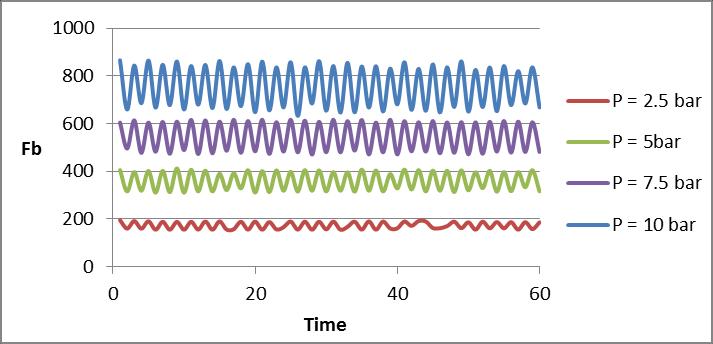

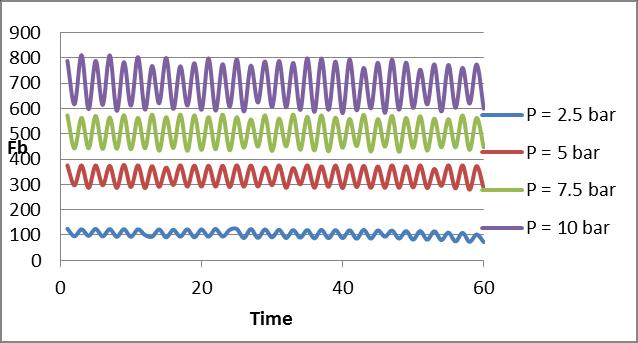

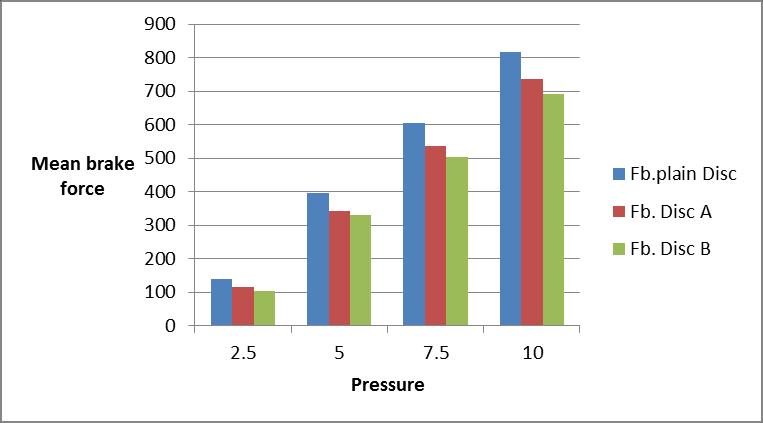

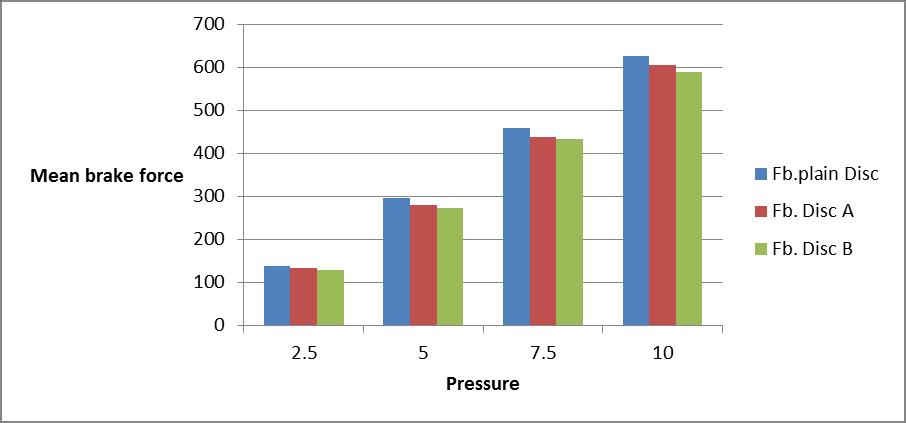

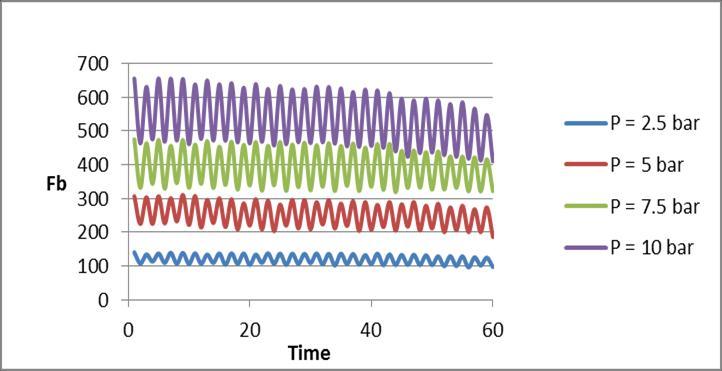

Theeffect ofbrakeoilpressureoftherotatingdisconthe brakeforces ofplaindisc,thefirstdiscwith(Cr3C2-75% NiCr25 %) coating and the second disc with (Al2O3-87 % TiO2 13%) coating at sliding speed 100 r.p.m and initial temperature38℃ispresentedinFig.(3),Fig.(4)andfig.(5). Theresultsshowedthat,thebrakeforcesofthethreediscs fluctuatewithnoidenticaltrendateachconstantbrakeoil pressurewiththebrakingtime.Thefluctuationofthebrake forceisduetothevariationofthefrictioncoefficientwith thebrakingtime.Alsoitcanbeseenthat,thebrakeforcesof thethreediscsareincreasedwithincreasingthebrakeoil pressure. The results presented in Fig. (6) Show the variation of the mean brake force of the three discs at differentbrakeoilpressure.Fromtheresults,itcanbeseen thattheincreaseofthebrakeoilpressurecauseanincrease ofthemeanbrakeforceofthethreediscs.Themeanbrake forces of the plain disc are 194, 403, 615, 830 N and the meanbrakeforcesofthefirstdiscwith(Cr3C2-75%NiCr25 %)coatingare173,360,545and755Nandthemeanbrake

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

forces of the second disc with (Al2O3-87 % TiO2 13%) coatingare162,338,523,722 atbrakeoilpressure 2.5,5, 7.5,10barrespectively.

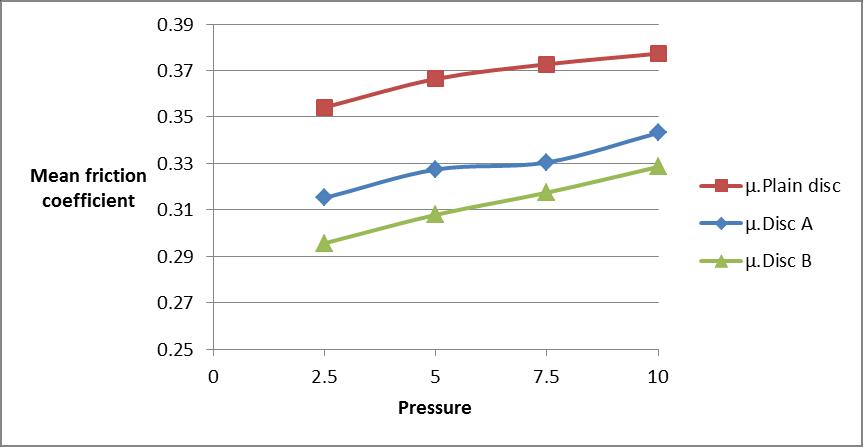

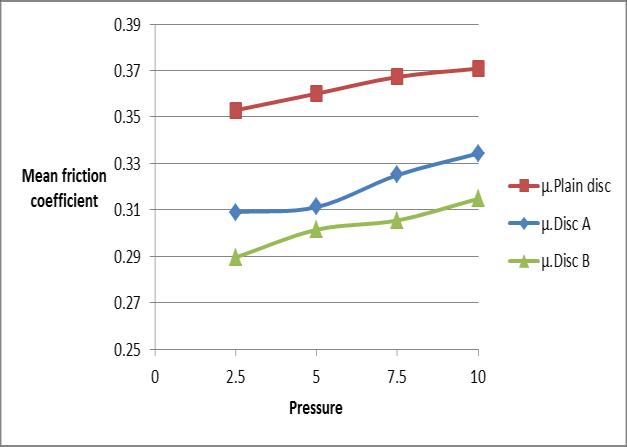

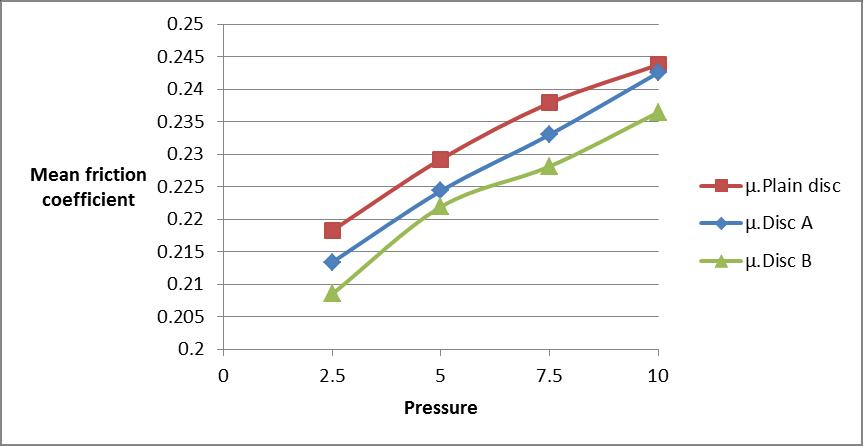

TheresultspresentedinFigure(7)showthevariationofthe meanfrictioncoefficientofthethreediscsatslidingspeed 100r.p.m andinitialtemperature38℃ atdifferentbrakeoil pressure2.5,5,7.5and10bar.Theresultsindicatedthat,the increaseofthebrakeoilpressurecauseanincreaseofthe meanfrictioncoefficientofthethreediscs.Theincreaseof brakeoilpressurefrom2.5barto10barcausesanincrease onthemeanfrictioncoefficientfrom0.354to0.377forthe plain disc and from 0.315 to 0.343 for the first disc with (Cr3C2-75%NiCr25%)coatingandfrom0.295to0.328for theseconddiscwith(Al2O3-87%TiO213%)coating.Also themeanfrictioncoefficientoftheplaindiscishigherthan themeanfrictioncoefficientofthefirstdiscandinthefirst discitishigherthantheseconddiscateachconstantbrake oilpressure

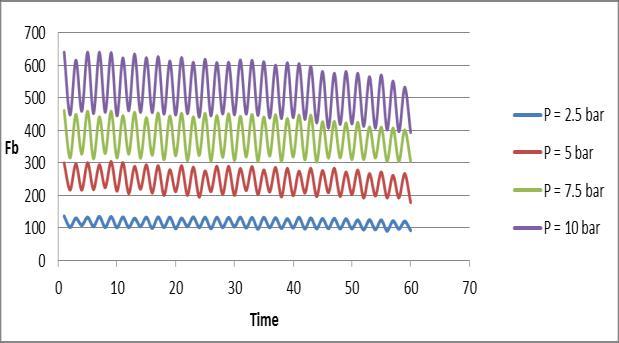

Fig.5 Effect of pressure on the brake force of the second disc at N = 100 r.p.m, T = 38˚ C

Fig.3 Effect of pressure on the brake force of plain disc at N = 100 r.p.m, T = 38˚C

Fig.6 Effect of pressure on the mean brake force of plain disc & first disc & second disc at N = 100, T = 38˚C

Fig.4 Effect of pressure on the brake force of the first disc at N = 100 r.p.m, T = 38˚ C

Fig.7 Effect of pressure on the mean friction coefficient of plain disc & first disc & second disc at N = 100, T = 38˚ C

3.2 Effect of brake oil pressure at sliding speed 100 r.p.m and initial temperature 60˚C:

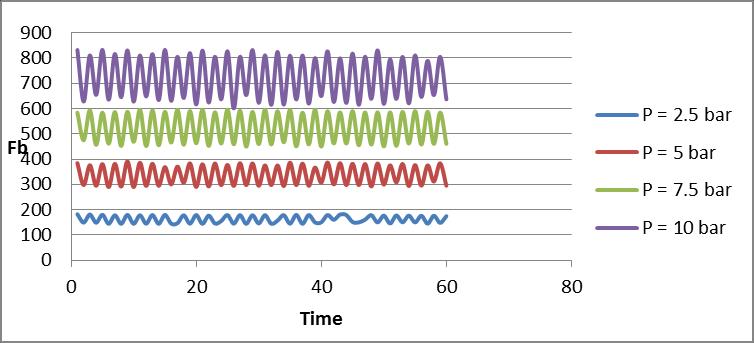

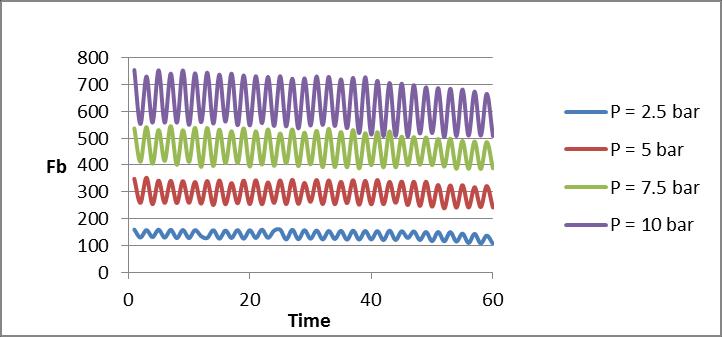

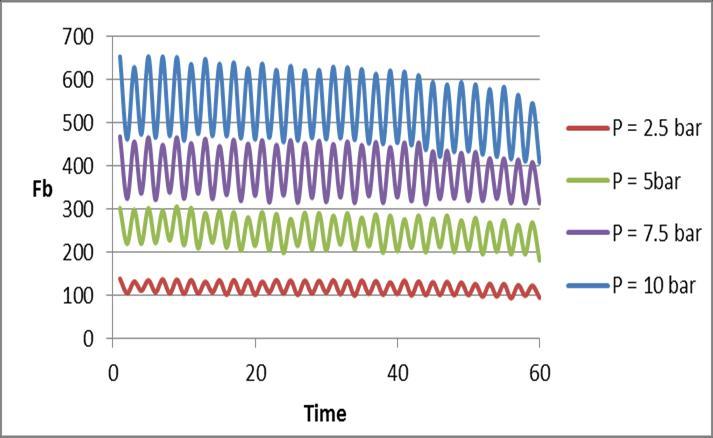

Figures (8),(9) and (10) explain the effect of the brake oil pressure of the three discs at sliding speed 100 r.p.m and initialtemperature60˚C.Theexperimentalresultsshowed that,theincreaseofthebrakeoilpressureofthebrakedisc leadstoincreasethebrakeforceofthethreediscs.Alsothe brake forces of the three discs fluctuate with no identical trend with the brake time at each constant brake oil

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

pressure. The fluctuation of the brake force is due to the variationofthefrictioncoefficientwiththebrakingtime.The effectofthebrakeoilpressureonthemeanbrakeforceof thethreediscsisshowninFigure(11). Fromtheresults,it canbeseenthattheincreaseofthebrakeoilpressurecause a increase of the mean brake force of the three discs. The meanbrakeforcesoftheplaindiscare139,396,606, 816 N andthemeanbrakeforcesofthefirstdiscwith(Cr3C2-75% NiCr25%)coating are114,342,536,735Nandthemean brakeforcesoftheseconddiscwith(Al2O3-87%TiO213%) coatingare104,331,504,692Natbrakeoilpressure2.5,5, 7.5 and 10 bar respectively. The mean brake force of the plain disc is higher than the first disc and also the mean brakeforceofthefirstdisc ishigherthanthemean brake forceoftheseconddisc.

Figure(12)Illustratetheeffectofthebrakeoilpressureon the mean friction coefficient of the three discs at sliding speed100r.p.mandinitialtemperatureof60˚C.Theresults indicatedthat,theincreaseofthebrakeoilpressurecausean increaseofthemeanfrictioncoefficientofthethreediscs Theincreaseof brake oilpressure from2.5 bar to10bar causes an increase on the mean friction coefficient from 0.352to0.37fortheplaindiscandfrom0.309to0.334for thefirstdiscwith(Cr3C2-75%NiCr25%)coatingandfrom 0.289to0.314fortheseconddiscwith(Al2O3-87%TiO2 13%)coating .Furthermore,themeanfrictioncoefficientof plaindisc ishigherthanthemeanfrictioncoefficientofthe firstdiscandthemeanfrictioncoefficientofthefirstdisc is alsohigherthanthemeanfrictioncoefficientofthesecond disc ateachconstantbrakeoilpressure

Fig.9 Effect of pressure on the brake force of first disc at N = 100 r.p.m, T = 60˚ C

Fig.8 Effect of pressure on the brake force of plain disc at N = 100 r.p.m, T = 60˚C

Fig.10 Effect of pressure on the brake force of second disc at N = 100 r.p.m, T = 60˚ C

Fig.11 Effect of pressure on the mean brake force of plain disc &first disc & second disc at N = 100r.p.m, T = 60˚C

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Fig.12 Effect of pressure on the mean friction coefficient of plain disc &first disc &second disc at N = 100 r.p.m, T = 60˚ C

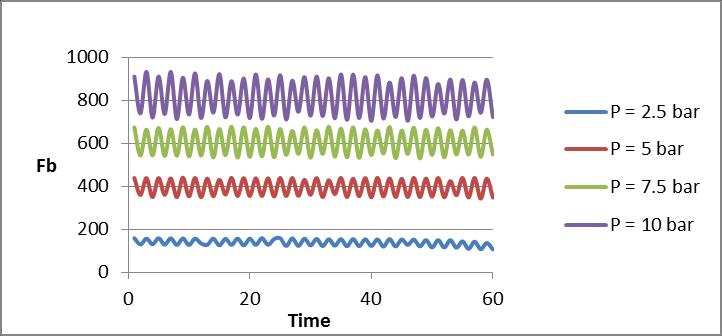

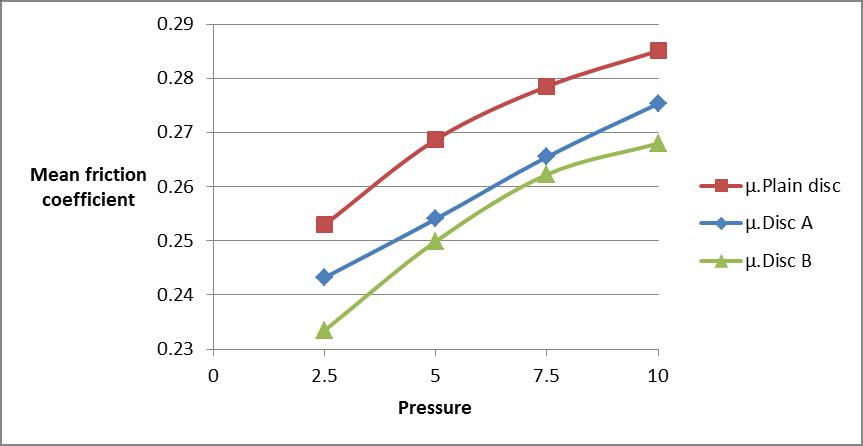

Figures(13),(14)and(15)explaintheeffectofthebrakeoil pressure on the brake forces of the three discs at sliding speed 100 r.p.m and initial temperature 80˚C. The experimentalresultsshowedthat,theincreaseofbrakeoil pressureofthebrakediscsleadstoincreasethebrakeforce of the three discs. Also the brake forces of the three discs fluctuatewithnoidenticaltrendwiththebraketimeateach constantspeed. Thefluctuationofthebrakeforceisdueto thevariationofthefrictioncoefficientwiththebrakingtime. Theeffectoftheslidingspeedonthemeanbrakeforceofthe threediscsisshowninFigure(16)fromtheresults,itcanbe seen that the increase of the brake oil pressure cause an increaseofthemeanbrakeforceofthethreediscs.Themean brakeforcesoftheplaindiscare139,295,459,627Nand the mean brake forces of the first disc with (Cr3C2-75 % NiCr25%)coatingare133,279,438,605Nandthemean brakeforcesoftheseconddiscwith(Al2O3-87%TiO213%) coatingare128,274,432,589Natbrakeoilpressure2.5,5, 7.5 and 10 bar respectively. The mean brake force of the plain disc is higher than the first disc and also the mean brakeforceofthefirstdisc ishigherthanthemean brake forceoftheseconddisc.

Figure(17)Illustratetheeffectofbrakeoilpressureonthe meanfrictioncoefficientofthethreediscsatslidingspeed 100 r.p.m and initial temperature of 80˚C. The results indicatedthat,theincreaseofthebrakeoilpressurecausean increaseofthemeanfrictioncoefficientofthethreediscs. Theincreaseof brake oilpressure from2.5 bar to10bar causes an increase on the mean friction coefficient from 0.252to0.285 fortheplaindiscandfrom0.243to0.275for thefirstdiscwith(Cr3C2-75%NiCr25%)coatingandfrom 0.233to0.268fortheseconddiscwith(Al2O3-87%TiO2 13%)coating .Furthermore,themeanfrictioncoefficientof plaindiscishigherthanthemeanfrictioncoefficientofthe firstdiscandthemeanfrictioncoefficientofthefirstdiscis alsohigherthanthemeanfrictioncoefficientofthesecond discateachconstantbrakeoilpressure.

Fig.13Effectofpressureonthebrakeforceofplaindiscat N=100r.p.m,T=80˚C

Fig.14Effectofpressureonthebrakeforceoffirstdiscat N=100r.p.m,T=80˚C

Fig.15 Effect of pressure on the brake force of second disc at N = 100 r.p.m, T = 80˚ C

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Fig.16 Effect of pressure on the mean brake force of plain disc &first disc & second disc at N = 100 r.p.m , T = 80˚C

Figure(22)Illustratetheeffectofthebrakeoilpressureon the mean friction coefficient of the three discs at sliding speed100r.p.mandinitialtemperatureof100˚C.Theresults indicated that, the increase of the sliding speed of the rotating disc cause an increase of the mean friction coefficient of the three discs. The increase of brake oil pressurefrom2.5barto10 bar causesanincreaseonthe meanfrictioncoefficientfrom0.218to0.243 fortheplain discandfrom0.213to0.242forthefirstdiscwith(Cr3C2-75 %NiCr25%)coatingandfrom0.208to0.236forthesecond discwith(Al2O3-87%TiO213%)coating .Furthermore, themeanfrictioncoefficientofplaindiscishigherthanthe mean friction coefficient of the first disc and the mean friction coefficient of the first disc is also higher than the meanfrictioncoefficientoftheseconddiscateachbrakeoil pressure.

Fig.17 Effect of pressure on the mean friction coefficient of plain disc &first disc &second disc at N = 100, T = 80˚ C

3.4 Effect of brake oil pressure at sliding speed 100 r.p.m and initial temperature 100˚C

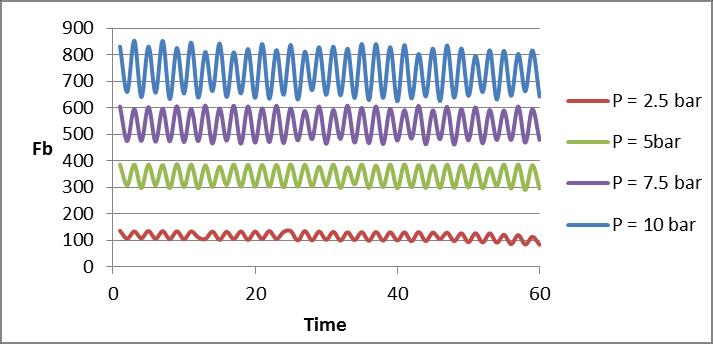

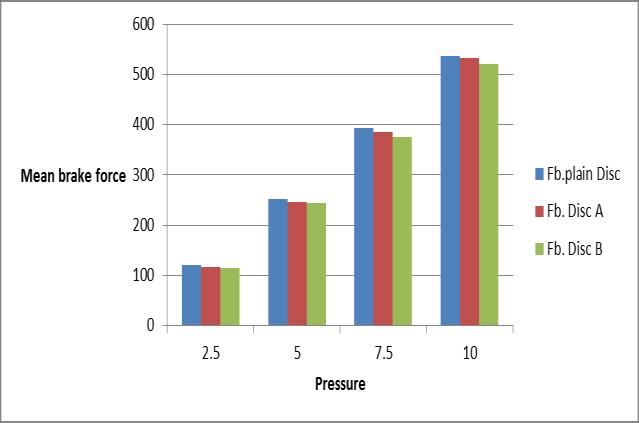

Figure(18),(19)and(20)explaintheeffectofthebrakeoil pressure on the brake forces of the three discs at sliding speed 100 r.p.m and initial temperature 100˚C. The experimentalresultsshowedthat,theincreaseofbrakeoil pressureleadstoincreasethebrakeforceofthethreediscs. Also the brake forces of the three discs fluctuate with no identicaltrendwiththebraketimeateachconstantspeed. Thefluctuationofthebrakeforceisduetothevariationof thefrictioncoefficientwith thebrakingtime. Theeffectof thebrakeoilpressureonthemeanbrakeforceofthethree discsisshowninFigure(21).Fromtheresults,itcanbeseen thattheincreaseofthebrakeoilpressurecauseanincrease ofthemeanbrakeforceofthethreediscs.Themeanbrake forces of the plain disc are 120, 252, 392, 536 N and the meanbrakeforcesofthefirstdiscwith(Cr3C2-75%NiCr25 %) coating are 117, 246, 384, 533 N and the mean brake forces of the second disc with (Al2O3-87 % TiO2 13%) coatingare114,244,376,520Natbrakeoilpressure2.5,5, 7.5 and 10 bar respectively. The mean brake force of the plain disc is higher than the first disc and also the mean brakeforceofthefirstdisc ishigherthanthemean brake forceoftheseconddiscateachconstantbrakeoilpressure

Fig.18 Effectofpressureonthebrakeforceofplaindiscat N=100r.p.m,T=100˚C

Fig.19Effectofpressureonthebrakeforceoffirstdiscat N=100r.p.m,T=100˚C

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

1- The brake force of the plain disc, the first disc with (Cr3C2-75 % NiCr25 %) coating and the second disc with (Al2O3-87%TiO213%)coatingvariesandfluctuateswith no identical trend with the brake time. This is due to the variationofthefrictioncoefficientwiththebraketime.

2-Theincreaseofthebrakeoilpressureincreasesthemean brakeforceoftheplaindisc,thefirstdiscwith(Cr3C2-75% NiCr25%)coating andtheseconddiscwith(Al2O3-87% TiO213%)coating.

Fig.20 Effect of pressure on the brake force of second disc at N = 100 r.p.m, T = 100˚ C

3-Theincreaseofthebrakeoilpressurefrom 2.5barto10 baratinitialtemperature38℃andslidingspeed100r.p.m increasesthemeanbrakeforceoftheplaindisc,thefirstdisc with(Cr3C2-75%NiCr25%)coating andtheseconddisc with(Al2O3-87%TiO213%)coating.Alsotheincreaseof the brake oil pressure from 2.5 bar to 10 bar at initial temperature60℃andslidingspeed100r.p.mincreasesthe meanbrakeforceoftheplaindisc,thefirstdiscwith(Cr3C275%NiCr25%)coating andtheseconddiscwith(Al2O3-87 %TiO213%)coatingandsoonatinitialtemperature80℃ and100℃

Fig.21 Effect of pressure on the mean brake force of plain disc &first disc &disc second at N =100 r.p.m , T = 100˚C

4-Theincreaseofthebrakeoilpressureatconstantsliding speed 100 r.p.m and at different initial operating temperature38,60,80,100℃increasesthe meanfriction coefficientofthe plaindisc,thefirstdiscwith(Cr3C2-75% NiCr25%)coating andtheseconddiscwith(Al2O3-87% TiO213%)coating.Butateachbrakeoilpressurethemean friction coefficient of the plain disc was greater than the meanfrictioncoefficientofthefirstdiscwith(Cr3C2-75% NiCr25%)coatingandthemeanfrictioncoefficientofthe first disc with (Cr3C2-75 % NiCr25 %) coating is greater thantheseconddisc with(Al2O3-87%TiO213%)coating.

5- At brake oil pressure 2.5, 5, 7.5, 10 bar and at sliding speed100r.p.mthemeanbrakeforceoftheplaindiscwith nocoatingwasgreaterthanthemeanbrakeforceofthefirst disc with (Cr3C2-75 % NiCr25 %) at the initial operating temperatures38,60,80,and100℃and alsothemeanbrake forceofthefirstdiscwith(Cr3C2-75%NiCr25%)coating was greater than the mean brake force of the second disc with(Al2O3-87%TiO213%)coatingattheinitialoperating temperatures38,60,80,and100℃

Fig.22 Effect of pressure on the mean friction coefficient of plain disc &first disc &second disc at N=100 r.p.m , T = 100˚C

After monitoringtheresultsofourexperimental work we cansaythatthemainconclusionsfromthepresentstudycan besummarizedinthefollowingpoints:

6-Theincreaseoftheinitialoperatingtemperaturefrom38 ˚Cto100˚Cdecreasesthemeanbrakeforceofthe plaindisc, thefirstdiscwith(Cr3C2-75%NiCr25%)coating andthe seconddiscwith(Al2O3-87%TiO213%)coating.

[1] Cómo citar:García-León, Ricardo; Flórez-Solano, Eder; Suárez-Quiñones, Álvaro (2019). Brake discs: A technologicalreviewfromitsanalysisandassessment. InformadorTécnico,83(2),000-000

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

[2] Investigation of tribological behavior of 20NiCrBSiW C12Cocoated brakediscbyHVOFmethodHalilKılıç and CenkMısırl.

[3] A.DEMIR,R.SAMUR,I.KILIÇASLANINVESTIGATIONOF THECOATINGSAPPLIEDONTOBRAKEDISCSONDISCBRAKE PAD PAIR Article in Metalurgija -Sisak then Zagreb

[4]

DepartmentofEngineeringScience,University West, 46132 Trollhättan, SwedenR & D Department, Automotive ComponentsFlobyAB,52151Floby, Sweden

Received: 7 August 2019; Accepted: 23 August 2019; Published:27August2019 OmkarAranke ,WaelAlgenaid,SamuelAweand ShrikantJoshi