International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

1M.TECH (CCT) Student, Civil Engineering Dept, Jain College of Engineering, Belagavi, Karnataka, India.

2 Assistant Professor, Civil Engineering Dept, Jain College of Engineering, Belagavi, Karnataka, India ***

Abstract – Nowadays engineers are coming up with the important question of building on soils, to explain or describing about the loads withstanding with support the loads mislead administration during execution of projects or explanation with useful life of a product of the structure. In many parts of India, soil contain different and delicate portions particularly sediment element of the object. In this experimentalinvestigation, the stabilizationofsoilstartswith the selection of type of soil and collection of data about the particular soil which are required to stabilize the soil. Experiments were conducted to dictate the geotechnical features of the lithomargic soil and the tests are performed as per relevant codes. Changes intheirpropertieshavestudiedby blending the soil sample with silica fume, glass powder and quick lime powder and ends with the comparison on selected soil and the conventional soil.

Key Words: Stabilization,Lithomargicsoil

Soilistheimportantfactororpartofabuildingstructure whichultimatenecessaryfortheinfrastructure. Themajor taskforthecivilengineersisthedesignandexplanationof embankments and basis on faint and unfavorable soil especiallyfororganizationengineer.Theperformanceofthe characteristicsoftheprogressivesoilmainlydependsonthe natureofthefinesexistedinthesubstance.

Lithomargic soil available at an insight of few meters belowfromthegroundlevelanditislocallyknownasshedi soil. This shedi soil is very un-useful for structure use endeavor.Thebalanceofslopestabilityongrounddepends onthisshedisoil.

Thetermstabilizationisdefinedasthesynthesizingand joining materials accompanying a soil to upgrade sure characteristics of the soil. The mechanism contains the integrating of soils to gain a sought step or joining of commerciallyfreesupplementsmaychangethestep,pattern orpliancy,oractasacoverforagreementofthesoil.

Themainobjectivesofthisstudyareasfollows

Tostudythechangeofgeotechnicalproperties(suchas CBR, Atterberg limits, permeability, bearing capacity,

OMC and MDD, particle size distribution) of the Lithomargicclaybeforeandafteraddingadditives.

To discuss the strength characteristics of soil after stabilization.

Manyresearchesareunderprocessfordevelopmentof differenttypeofsoiltomakeuncapablesoiltocapableone withgoodbearingandwithstandcapacityforconstruction purpose

Kalantarietal.[1] Examinedtheinfluenceofutilizingwaste stone powder and produce in sustaining earth soil in laboratory.TheworkshopteststhatincludeAtterberglimits, grain size analysis, standard supervisor compaction tests, looseconfiningtestandCaliforniabearingratiotests.After the test the results shows that plasticity decreases with changing optimum liquid essence and also highest dry densityofclaysoil.

B.Michaeletal. [2] Expressedhisideasaboutthepreserving impactofgratedglassonclaysoil.Damagedglasspowder usedforaddingtostabilizedsoilinvariabledimensionslike 1%,2%,5%,10%and15%inadditionto15%cementby pressure of the soil sample. The miscellaneous tests were completed. According to obtained results, the soil sample capturedconsentedtogroup-6soilsacknowledgedasfairto feeblesoiltypeinagreementsadvantageousasleakageand substitutegradematerial.

Thestabilizationofsoilstartswiththeselectionoftypeof soilandcollectionofdataabouttheparticularsoilwhichare required to stabilize the soil with correct percentage of differentadditivesandfollowedbydifferenttypesoftestson particularsoilandendswiththecomparisononselectedsoil and the conventional soil the complete procedure is explainedinthefollowingflowchart.

Materialsused:Lithomargicsoil,Silicafume,

BasicTests:Specificgravity,Grainsizeanalysistest,Liquid test, Plastic limit, Standard Proctor test, Unconfined compressiontest,Californiabearingratiotest.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

2.3.

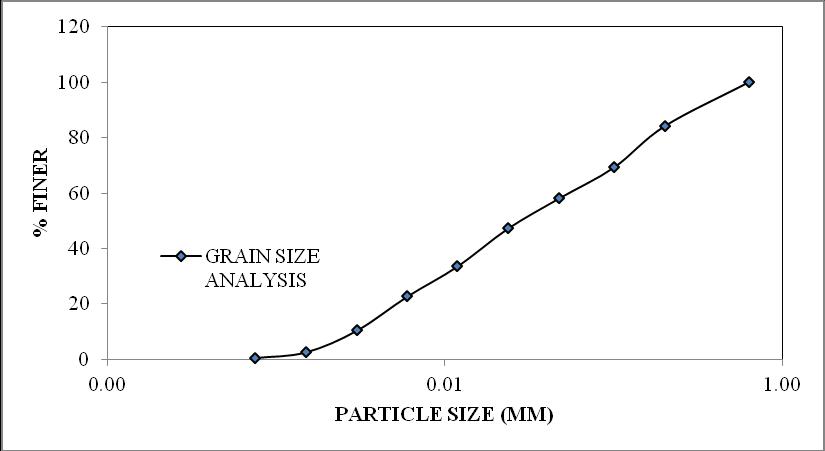

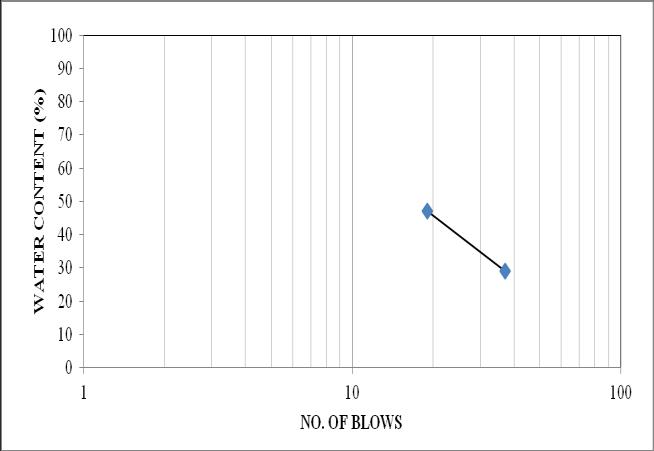

2.3.1 Observation of Lithomargic soil: Theclayaccessed fromthelocationproventoachievedifferentgeotechnical features. The result is produced in the table 1. Different geotechnical features like grain magnitude distribution, specificgravity,consistency limit,compactiontraits,shear substancecomponentsetc.aretabulated

Table -1: BasicgeotechnicalpropertiesofLithomargicsoil

PARAMETERS

RESULT

GRAVEL% 25 SAND% 68

SILTANDCLAY% 18&14 COEFFICIENTOFUNIFORMITY (Cu) 16.207

COEFFICIENTOFCURVATURE(Cc) 0.69

TYPEOFSOIL SANDYSOIL (Cu>6andCc<1)

GRADE POORLYGRADED

SPECIFICGRAVITY 2.76

OMC% 16

DRYDENSITY(g/cc) 1.64 CBR% 5.79 UCC(kg/cm2 0.1582

LIQUIDLIMIT% 45 PLASTICLIMIT% 16

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

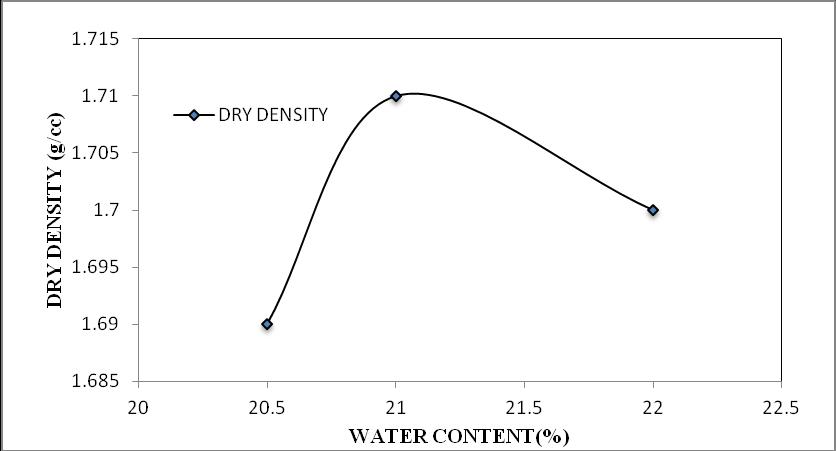

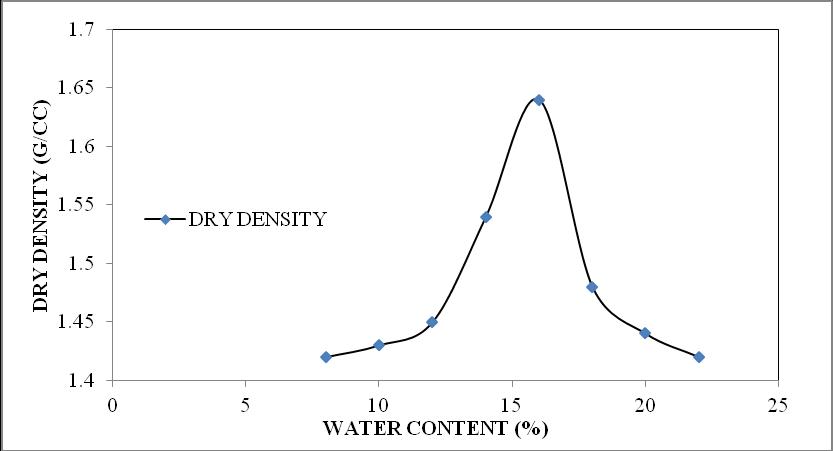

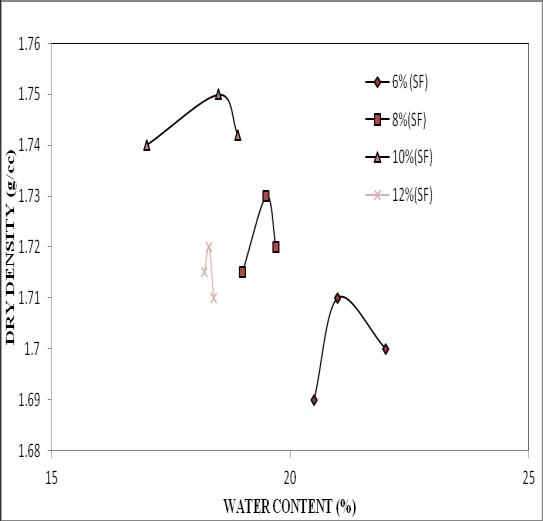

a) Effect of Silica fume on Compaction Characteristics of Shedisoil:TheaccuratepreliminaryProgrammehasexisted anticipate the determination compaction characteristics with an immediate effect for shedi soil with a various amountofsilicafumesaregiveninthebelowtable2

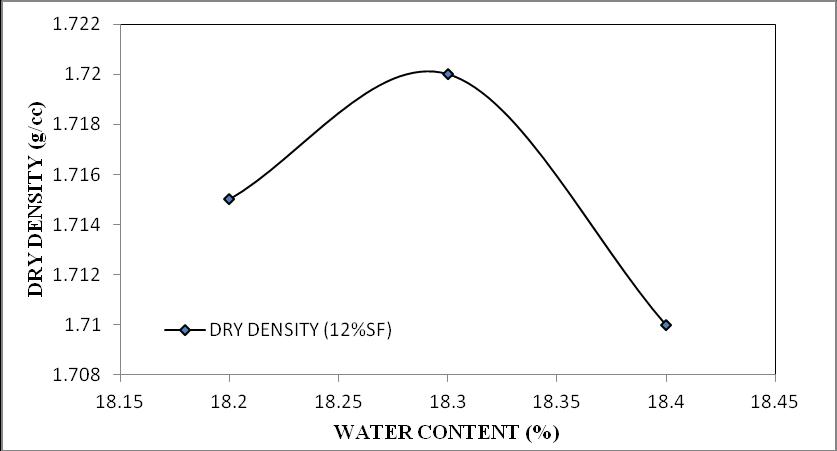

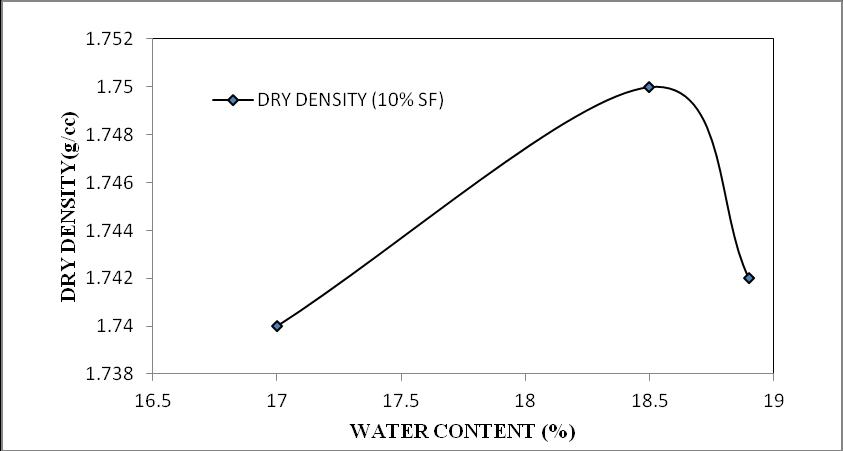

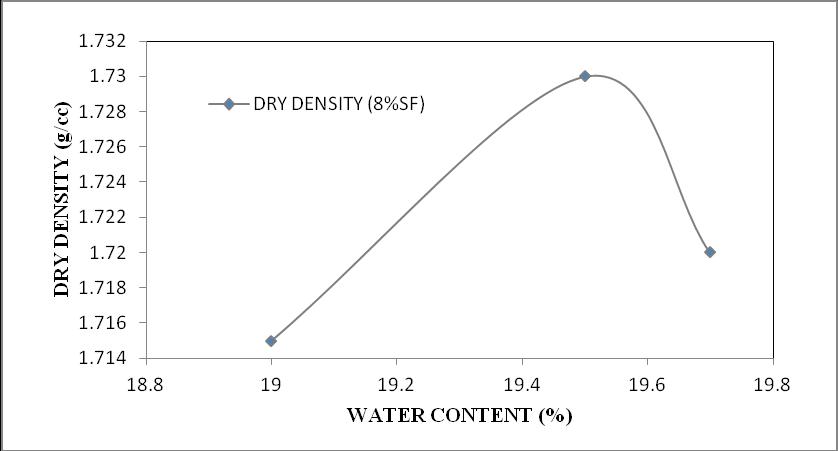

ThecompactiontestwasconductedonShedisoilaloneand ShedisoiltreatedwithvariouspercentageofSF.Theultimate drymassofShedisoilseparatefoundexpected1.64g/ccand bestmoisturecontent16%.Onadditionofdifferent%SFto Shedisoil, the ultimate dry mass maximizes with the increases in SF percentage and decreases in optimum moisture content as SF percentage increases as shown in table3andfigure6,7,8,9&10

Table -2: ExperimentalProgrammeforCompaction characteristicsshedisoil

Mixture Testconducted Shedisoil Compaction Shedisoil +6%to12%SF compaction

Table -3:CompactionCharacteristicsofShedisoilwitha differentpercentageofSilicaFume.

MIXTURE OMC (%) MDD(g/cc)

Shedisoil+6%SF 21 1.71

Shedisoil+8%SF 19.5 1.73 Shedisoil+10%SF 18.5 1.75 Shedisoil+12%SF 18.3 1.72

Chart -6:Compactioncurveforshedisoilwith4%SF

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

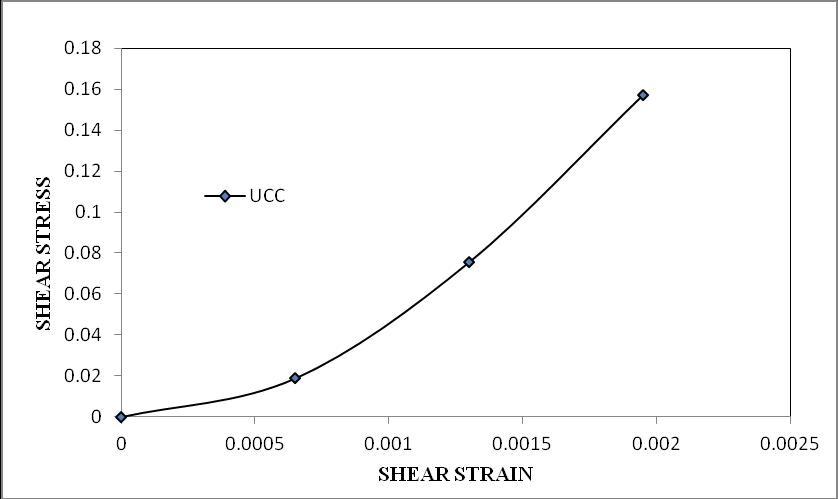

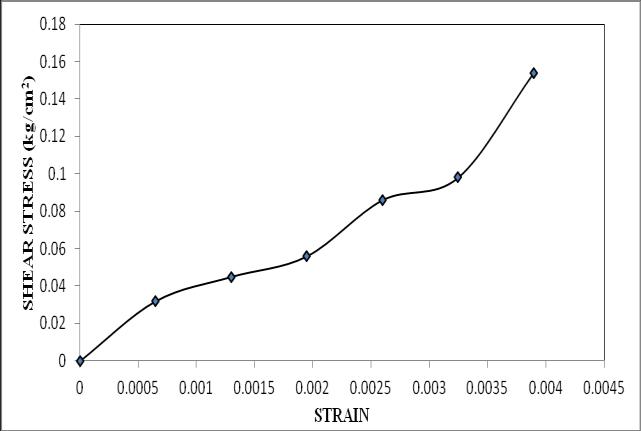

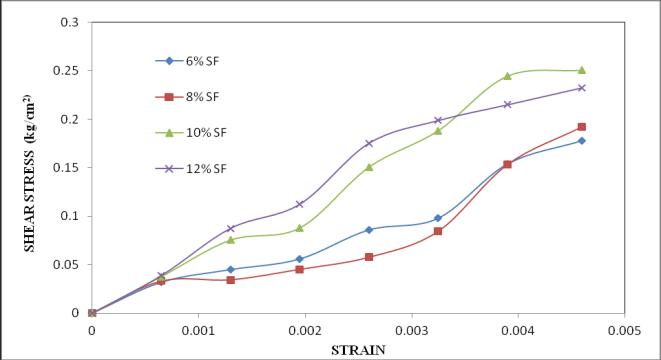

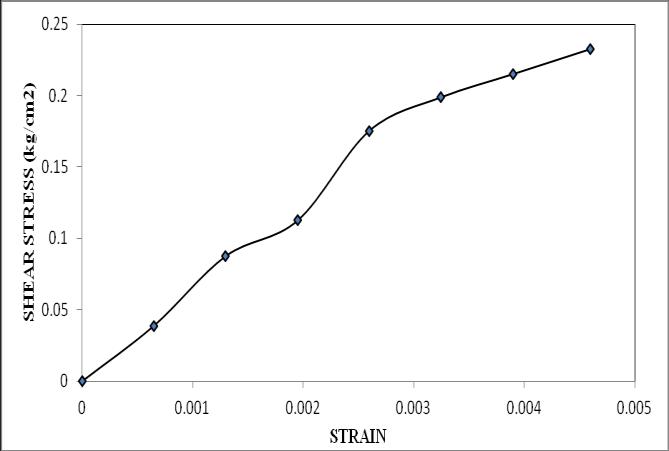

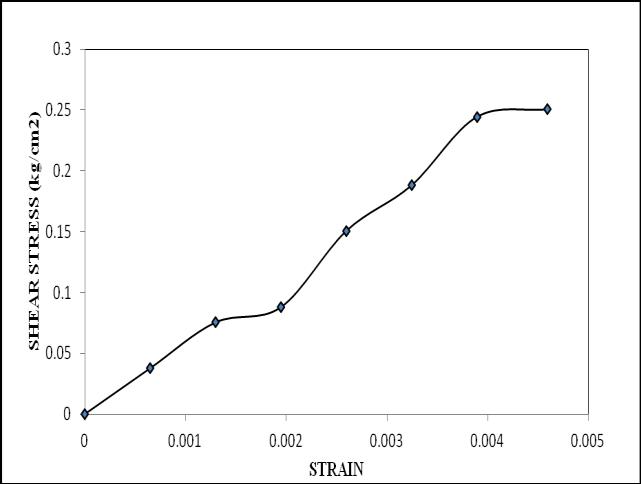

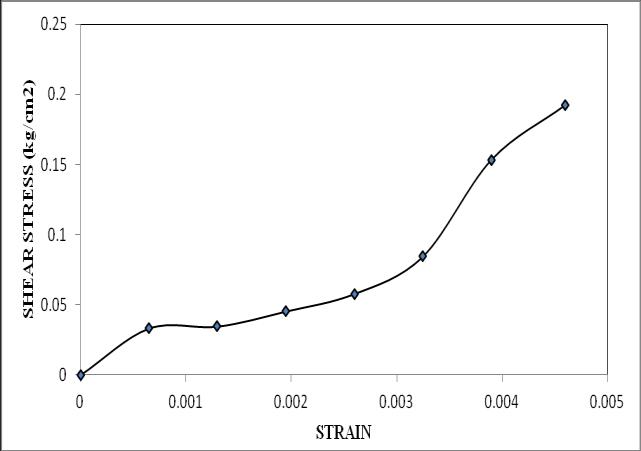

As seen from Table 1, the loose compressive strength of Shedi soil unique on instantons experiment was 0.1582 kg/cm2 respectively. On addition of 6 % to 12 % of Silica fume to Shedi soil, the energy maximized up to 10 % of Silicafumeadditionsonimmediatetesting.

Chart -7:Compactioncurveforshedisoilwith8%SF

ReducinginthepowerofShedisoilactedwithSilicafume further10%additionismaybeduetotheformoftheShedi soilisagitatedtoagreaterextentaccompanyingtheincrease ofSilicafume.Hence,10%addingofSilicafumetheShedi soil has existed preferred as the optimum portion. The alternative of loose compressive strength of Shedi soil doctoredwithdifferentquantityofSilicafumefornext,are showninTable5&Figure11,12,13&14.

Table -4:ExperimentalProgrammeforstrength characteristicsShedisoil.

Mixture Test Curing periods in days

Shedisoil+6%to12%SF UCS Immediate

Table -5:UnconfinedcompressivestrengthofShedisoil treatedwithvariouspercentagesofSilicafume

Chart -8:Compactioncurveforshedisoilwith10%SF

MIXTURE UCS(kg/cm2)

SHEDISOIL 0.1582

SHEDISOIL+6%SF 0.178

SHEDISOIL+8%SF 0.1924

SHEDISOIL+10%SF 0.2505

SHEDISOIL+12%SF 0.2325

Chart -9:Compactioncurveforshedisoilwith12%SF

Chart -11:StressStrainbehaviorshedisoilwith6%SF

Chart -10:ComparisonofCompactionCurvefordifferent %ofSFeffectsofSilicafumeonstrength

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Table -6: ExperimentalProgrammeforstrength characteristicsShedisoil

Shedisoil+6%to12%SF CBR Immediate

Chart -12:StressStrainbehaviorshedisoilwith8%SF

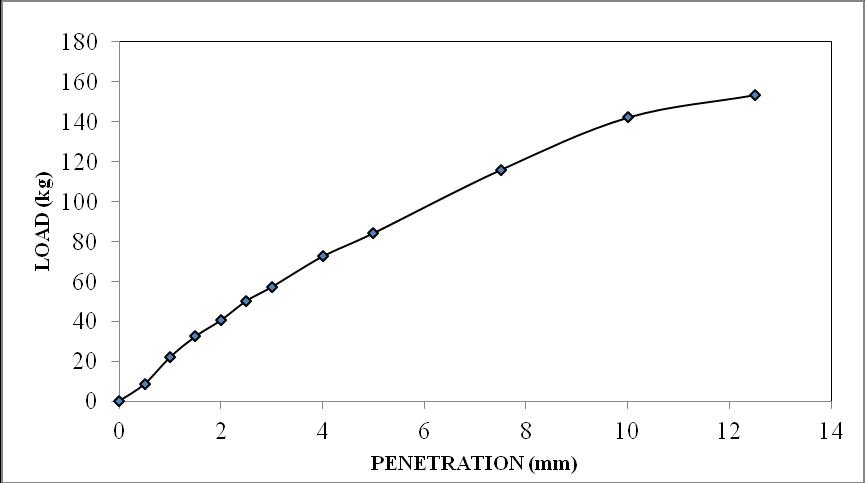

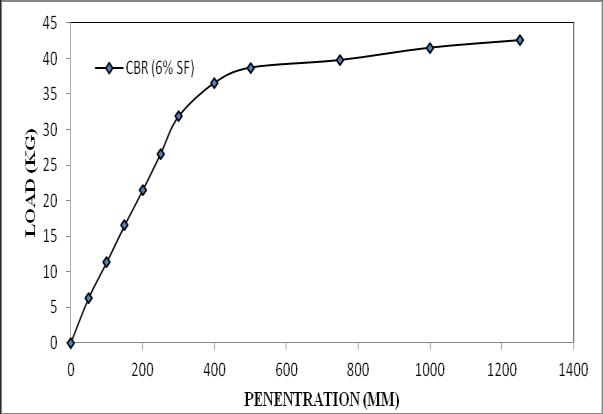

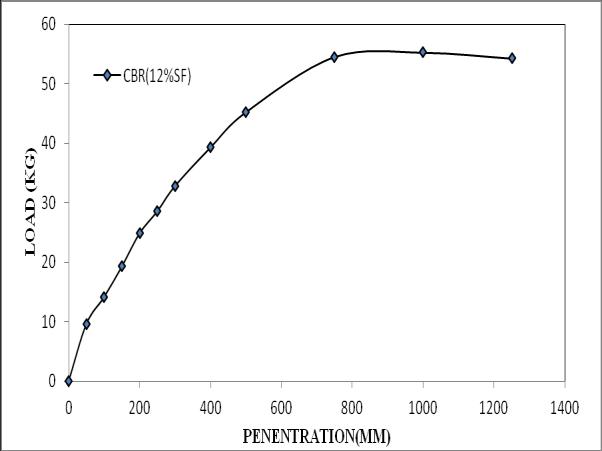

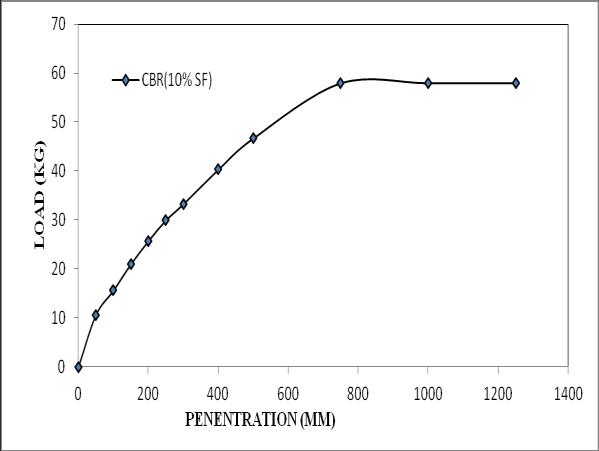

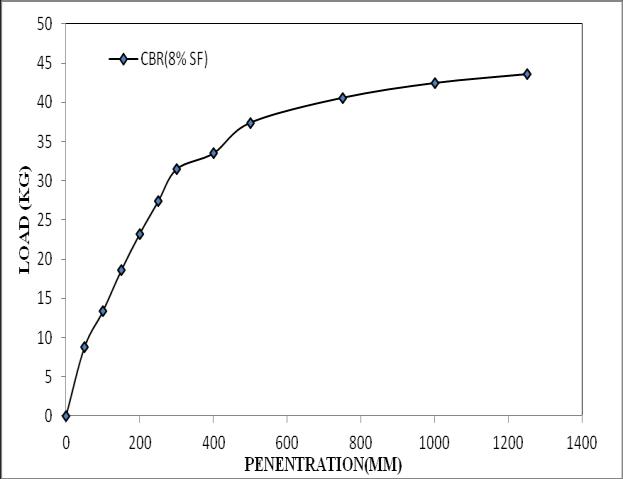

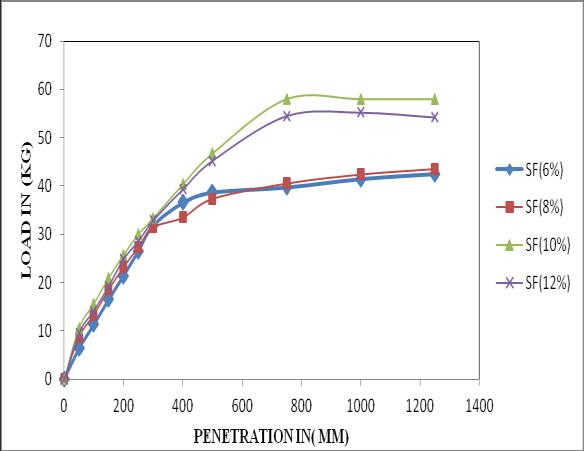

AsseenfromTable5theCBRofShedisoilaloneontesting,it was 5.79%. On addition of 6 % to 12 % of Silica fume to Shediclay,theCBRvalueincreasesupto10%ofSilicafume onrecenttesting

ThereduceintheCBRValueofShedisoilconsideredwith Silicafumebeyond10%additionofSilicaseethe.Hence,10 % addition of Silica fume to the Shedi soil has existed preferredasthebestportion.ThevariationofCBRvaluesin ShedisoiltreatedwithvariouspercentagesofSilicafumefor immediate,areshowninTable7andFigure16,17,18&19.

Table -7:CBRValueswithdifferent%ofSilicafume COMBINATONS /PENETRATION(mm)

CBRVALUES 2.5 5

Chart -13:StressStrainbehaviorshedisoilwith10%SF

SHEDISOIL 5.79 4.98

SHEDISOIL+6%SF 6.023 5.820

SHEDISOIL+8%SF 6.34 6.258

SHEDISOIL+10%SF 7.28 7.10 SHEDISOIL+12%SF 6.9 6.864

Chart -14:StressStrainbehaviorshedisoilwith12%SF

Chart -16:CaliforniaBearingRatio(Unsoaked)

Chart -15:UnconfinedCompressiveStrengthofShedisoil actedwithdifferent%ofSFimpactsofSilicaseetheon Californiabearingratio:

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Dependupontheresults,discussionsanddetailedanalysis of the data obtained from the exploratory outcomes the subsequentdecisionshavebeendrawn,

TheincreaseinSFpercentagestotheshedisoil,which in turn improves the strength, increases dry density and also improves the shear strength. Thus, use of silica fume will be beneficial to lithomargic soil in improvingtheirsoilproperties.

Inclusion of various percentage of Silica seethe, to Shedi Soil, strength (0.2505kg/cm2) and CBR value (7.28%)increasesupto10%duetopseudo-cohesion orfrictionofSilicaFumethereafterstrengthdecreases. Hence,10%Silicaseethewasdeliberateasbest.

The stress-strain curve become to a greater extent confinedandshowsmaterialisticbehaviorwithhigher stresscarryingcapacityatlowerstrainrate. Whenit reaches to peak stress the failure of the samples compactedatdryofoptimumarebrittleinnature.

TheShedisoilpreservedwithSilicafumecanbeused as a sub grade material for construction of flexible pavements in country roads with depressed traffic capacity.

For laying economical local pavements, lightly intoxicated buildings like residential constructions whicharenotinadditionto2floorsthesubstituteof clay soil with admixtures may be decided apiece builder.

Theconsolidationcharacteristicsofsoilscanbefound byreplacingSilicafume

TheSilicafumecanbereplacedwithadifferentaspect ratiofordifferenttypesofsoils.

[1] Armin Roohbakhshan, BehzadKalantari“Stabilization of ClayeySoilwithLimeand WasteStonePowder”ASCE,No.207, pp.165–173in2013.

[2] J. Olufowobi, a. Ogundoju, b. Michael, O. Aderinlewo “Claysoilstabilisationusingpowderedglass”Journalof EngineeringScienceandTechnologyVol.9,No.5(2014) 541–558.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

M.Ramakrishna M.TECH(CCT)Student, CivilEngineeringDept, Jain College of Engineering, Belagavi,Karnataka,India.

RajashekharMalagihal AssistantProfessor, CivilEngineeringDept, Jain College of Engineering, Belagavi,Karnataka,India

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |