International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

1M.tech Final Year Student, Dept. of Civil Engineering, GNIOT, Greater Noida, U.P, India 2Assistant Professor, Dept. of Civil Engineering, GNIOT, Greater Noida, U.P, India ***

Abstract - Glass is one of the world's oldest and most commonly used materials. Glass has a fairly short shelf life in its current condition. Reusing this waste in construction materials is one alternative for safe environmental and economic disposal. The waste glass will be used tosubstitute fine aggregate in the following proportions: 0%, 10%, 20%, 25%, 30%, 40%, and 50%. This study will go over properties such as compressive strength. Another attempt was made to replace coarse aggregate with steel slag because there is a growing interest in using waste materials as alternative aggregate materials and significant research is being conducted on the use of many different materials as aggregate substitutes such as coal ash, blast furnace slag, and steel slag aggregate. By altering the quantity of steel slag, different concrete mixtures were created Steel slag is to be substituted for coarse aggregate in the following proportions: 0%, 10%, 20%, 30%, 40%, 50%, 60%, 70%, 80%, and 90%. Compressive strength of concrete to be reviewed, as well as another attempt at combined replacement by replacing both fine aggregate and coarse aggregate with waste glass powder and steel slag, while maintaining the optimum replacement of glass powder constantand varying the percentage replacement of steel slag with coarse aggregate in proportions of 0%,10%,20% up to 80%, and thus finding the combined optimumreplacement of coarse and fine aggregates with steel slag and waste glass powder in terms of compressive strengthofconcrete.

Key Words: Steelslag,Wasteglasspowder,compressive strength,Superplastisizer,Partialreplacement,Combined replacement.

Today, concrete is the most often utilised construction material.Inall fieldsofmodernconstruction,concrete has risen tothe rank ofa key building material.It's difficultto think of another construction material that is as versatile asconcrete.Whenstrength,durability,impermeability,fire resistance, and absorption resistance are necessary, concreteistheidealmaterialtouse.

Concreteismadefromacombinationofcement,sand, coarse material, and water. Today, global warming and environmentaldestructionhavebecomeobviousproblems in recent years, and concern about environmental

concerns, as well as a transition from the past's masswaste, mass-consumption,and mass-productioncultureto azero-emanationsociety,isregardedascrucial.Glassdoes notnormallyaffecttheenvironmentsinceitdoesnotemit pollutants, but it can hurt humans and animals if not handled safely, and it is less environmentally beneficial because it is non-biodegradable. As a result, the development of new technologies was necessary. Glass encompassesawiderangeofchemicalvariations,including soda-lime silicate glass, alkali-silicate glass, and borosilicate glass. Steel slag might also be utilised as a partialsubstituteforcoarseaggregate.Byeffectivelyusing these by-products, which would otherwise be discarded, good environmental conditions will be achieved. Because of its mechanical strength, stiffness, porosity, wear resistance, and water absorption capacity, steel slag particles are already employed as aggregates in asphalt pavingroadmixtures.Thefeasibilityofusingsteelslagasa replacement for traditional concrete is being researched. Whencomparedtoordinaryconcrete,thetestfindingsfor workabilitylevelsandstrengtharealsothesame.

One of the oldest man-made materials is glass. It is made in a variety of forms, including packaging or containerglass,flatglass,andbulbglass,allofwhichhavea limited life in their manufactured forms and must be recycled to be reused in order to prevent environmental concernscausedbystockpilingordisposalinlandfills.The building sector has demonstrated outstanding forms such as package orcontainer glass, flat glass,and bulb glass,all ofwhichhavebenefitedfromtherecyclingofindustrialbyproducts and garbage, including waste glass resources. Quantities of waste glass have increased rapidly in recent decades due to rapid industrialization and significant improvementsinlivingstandards;however,themajorityof these waste quantities are not recycled but rather abandoned, causing serious problems such as waste of naturalresourcesandenvironmentalpollution.

Aggregates account for around 70-75 percent of the overallvolumeofconcrete.Tofulfiltheworldwideneedfor

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

concrete in the future, an alternative material in construction that may fully or partially replace natural aggregate without altering the properties of fresh and hardenedconcreteisrequired.Thepropertiesofaggregate have an impact on the durability and performance of concrete

1. To investigate the compressive properties of a cubeafter7and28daysofcuring.

2. M40 grade concrete mix design with varying proportions of steel slag and waste glass powder replacement

3. To investigate the growth of concrete strength by the percentage replacement of glass powder with wasteglasspowderandsteelslag.

4. To investigate the densities of concrete with varyingpercentagesofglasspowderandsteelslag replacement.

5. Determinethebestdoseofglasspowderandsteel slag.

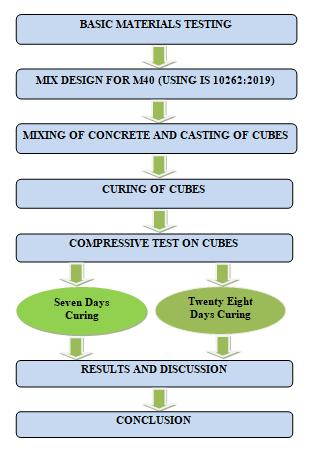

TheBasictestsareperformedonvariousmaterials such as OPC43 grade cement, fine aggregate, coarse aggregate, and steel slag to determine their acceptability for use in the production of concrete. Concrete mix proportionsarealteredtoallowfortheuseofsteelslagas apartialreplacementforcoarseaggregateandwasteglass powder as fine aggregate replacement separately . The cubes were formed by substituting coarse aggregate with 0%, 10%,20%,30%,40%, 50%,60%, 70%and 80% steel slag, respectively. While 0%, 5%, 10%, 20%, 25%, 30%,40% and 50% for fine aggregates replacement. Specimens are cast in accordance with the mixdesign,andtestsareperformedfollowingappropriate curing. The tests are compressive strength of cubes (150mmx150mmx150mm),that are then compared tothe conventionalconcrete.

After determining the optimal replacement of coarse and fine aggregate, maintain the fine aggregate optimum replacement constant while altering the coarse aggregate replacement by 10% upto 80%. Following castingofcubes,curingandtestingwouldtakeplace.

The laboratory performed basic tests on cement, coarse aggregate, fine aggregate, and steel slag, and the resultswillbeusedinconcretemixdesign

3.1 Cement Test Results

CementUsed : ACCOPC43Grade

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

SN Test Conducted on cement Result

IS 8112 Requirement

1 Normal Consistency 34% -

2 Specificgravity 3.15

3 Initialsetting time 35Min Shallnotbeless than30min

4 Finalsetting time 320Min Shallnotbe greaterthan600 min

SN Test Conducted on Fine aggregates Result IS Recommendations

1 Fineness Modulus 2.52 ZoneII(IS383-1970)

2 Specificgravity 2.68

3 Water Absorption 1% Shallnotexceed3% (BS812-2)

Fine aggregate is defined as aggregate that passes through a 4.75 mm sieve. It is made from locally available river sand that is free of organic impurities. This inquiry makesuseofsandthathaspassedthrougha4.75mmfilter andhasbeenkeptona150micronISsieve.

Beforeweighingandstrivings,thesamplemustbe brought to an air dry state. This can be accomplished by dryingatroomtemperatureorheatingatatemperatureof 100C to 110C. The air dry sample must be weighted and sieved sequentially on suitable sieves, beginning with the biggest. Before using the sieves, be certain that they are clean.

The main component of concrete is coarse aggregate. They provide body to the concrete, minimise shrinkage,andhaveaneconomicinfluence.Oneofthemost critical aspects in generating workable concrete is a suitable gradation of coarse aggregate. In this experiment, the coarse material was crushed aggregate that had been

passed through a 20mm IS filter. IS-383-1970 compliant aggregates were used. Crushed aggregate improves strength owing to angular particle interlocking, but spherical aggregate enhances flow because to lower internalfriction.Longaggregatesareundesirable.

The basics test was conducted on the coarse aggregate in laboratory, the included Specific gravity test, water absorption test, bulk density test, fineness modulus test and etc are conducted before going to design a mix proportionandresultshowsionTable3

SN

1 Type Crushed

2 SpecificGravity 2.73 3 BulkDensity 1813.12kg/m 3 4 Fineness Modulus 7.208

5 Water absorption 0.5%

3.4

Glass powder is madefromwasteglasscollectedfrom Gurugramretailers.Glasswasteisadurablematerial.Glass powder must be pulverised to the right size before being mixedintoconcrete.Glasspowdercrushedina ballfor30 to60minutesproducedparticlesizessmallerthan4.75mm inthisstudy.

This recipe calls for basic oxygen furnace slag from Jindal Steel Works Pvt. Ltd. in Sandur Village, Bellary District, Karnataka, India. Fluxes (limestone and/or dolomite) are used as fuel in blast furnaces together with cokeintheproductionofironandsteel.Carbonmonoxide is created when coke is burnt, converting iron ore to molten iron product. Fluxing agents remove impurities, andslagisgeneratedduringtheseparationofmoltensteel.

Although almost all steel slag’s are air-cooled, contemporary slag manufacturing technology cannot always offer quick cooling,which mightaffectslag quality. As a result, it is not always appropriate for future use, which is why quality monitoring of steel slag manufacturingisrequired(Cerjanetal1995,NationalSlag Association 1982). Due to their high density, steel slags have long been employed as protective armour stones for rivers,seaandcoastal erosionschemes,anddifferentland reclamationprojects,yetacertainpercentageofgenerated

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

steel slag is still discharged (National Slag Association 1982). The primary issue with steel slag aggregate is its expansivenatureandunfavourablereactivity. TheCharacteristicsofSteelslagsarefollowing.

design were carried out according to specified code book andobtainedresultsobtainedgivenbelow

Table4MixRatioproportion

Water Cement Fine aggregate Coarse Aggregate

171liters 400kg 799kg 1110kg 0.40 1 2 2.77

CEMENT: SAND: AGGREGATE = 1:2:2.77

5.1

Cubes are cast using moulds measuring 150mm x 150mm x 150mm. The moulds have been cleaned, but the corners have been oiled. All interior surfaces receive one layerofcuttingoil

Itisapowerfulwaterreducingagentinconcreteagent in concrete. The superplastisizer used to reduced water 20%-30%henceavoidbleedinginconcrete.

The recently issued Bureau of Standards (BIS) amended code on "Concrete Mix Proportioning-Guidelines" IS 10262-2019 brings relief to many construction industry stakeholders, notably those involved in concrete manufacturing.

Previously, the fourth edition of IS 456, published in2000,wasasmallstumblingpointinthecodeofpractise for "Plain and reinforced concrete."Aligning IS 10262and IS456intermsofconcreteproducingmaterials,minimum cement content, minimum water cement ratio, and minimumgradeofconcreteforvariousexposurescenarios satisfies the need to align these two standards. The new standard is applicable to ordinary and standard concrete grades (as defined in IS 456- 2000). The code has been updatedtosuitcurrentwatercontentandcoarseaggregate proportioning practices in concrete mixes. The mix mix

The moulds are filled in three layers, with each layer around one-third the depth of the mould. Every layer is compressed by applying 25 blows with a tamping rod equally throughout the whole cross section for members. The top surface of the moulds is levelled and left for 24 hours after filling and compacting them. The cubes, cylinders, and prism are then taken from the mould and kept for the requisite curing period. The water should be pure and free of impurities. The water should be changed everythreedaystoattainthebestbenefits.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

The cubes were cured in a water container filled with fresh, drinkable water that was devoid of any pollutants. After the curing period is through, all of the specimens shouldberemovedanddriedforoneday,becauseoptimal results need thorough drying. Before the test, the specimens'surfacesshouldbecleanedusingacompression testing machine (CTM)and a universal testing machine (UTM).

study. The compressive strength of ordinary concrete cubes and concrete cubes containing a fraction of Waste Glass was investigated. The cubes are put through their paces on a 3000KN compressive testing machine. The weightwasappliedtothecubeinsucha waythatthetwo opposingsidesofthecubewerecrushed.Itisdocumented atwhatloadthecontrolspecimensfail.

Thecompressivestrengthofconcreteisoneofitsmost important characteristics. Concrete is designed to resist compressive stress in most structural applications. The compressive strength of regular concrete cubes and concrete cubes with a fraction of Waste Glass was investigated in this study. The cubes are tested in a 3000 KNcompression-testingmachine.Theweightwasapplied to the cube in such a way that the cube's two opposing faces were crushed. The force at which the control specimens fracture is recorded. The compressive strength is computed as the average of 3 cubes. Compressive strengthisestimatedbydividingtheloadbytheareaofthe specimen.

Amongthemostimportantcharacteristicsofconcreteis itscompressivestrength.Concreteisdesignedtowithstand compressive stress in most structural applications. In this

Fig.4Performingthecompressivetestoncubesin compressiontestingmachine

Theaverageofthreecubesisusedtocalculatecompressive strength. The compressive strength of a specimen is estimatedbydividingtheloadbytheareaofthespecimen.

Table4Glassreplacementcompressivestrengthfor Sevendays

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Table5SteelSlagreplacementcompressivestrengthfor Sevendays

SN % of Steel Slag

Load(KN) Compressive Strength

1 0 593.87 26.39 2 10 615.40 27.35 3 20 698.07 31.02 4 30 719.00 31.95 5 40 754.00 33.51 6 50 767.33 34.10 7 60 779.00 34.62 8 70 662.66 29.45 9 80 543.00 24.13

Table6CombinedReplacementcubescompressive strengthforSevenDays

SN % of Slag % of Glass Load(KN) C/S

1 0 20 732 32.54 2 10 20 746 33.17 3 20 20 758 33.70 4 30 20 779 34.63 5 40 20 793 35.26 6 50 20 807 35.85 7 60 20 747 33.23 8 70 20 700 31.14 9 80 20 607 26.98

Table7CombinedReplacementcubescompressive strengthfor28Days

SN % of Slag % of Glass Load(KN) Compressive strength

1 0 20 920 40.91 2 10 20 959 42.63 3 20 20 988 43.92 4 30 20 1002 44.54 5 40 20 1010 44.91 6 50 20 1025 45.57 7 60 20 960 42.69 8 70 20 905 40.23 9 80 20 785 34.91

6.1 Graph representation of Compressive Strength of cubes

Compressive strength of cubes for WGPReplacement (7 days Curing)

Compressive Strength ( N/mm2)

0 10 20 25 30 40 50 0 5 10 15 20 25 30 35 0 20 40 60

Percentage of replacement(WGP)

Graph1SevendayscompressivestrengthforWasteglass powder

Graph 1showtheeffectofreplacingfineparticleswith wasteglasspowderonhardenedconcretepropertiessuch as compressive strength. It is found that the compressive strength of seven dayscubes improves initiallyup to 20% replacement, but as we increase the replacement by glass powderafter20%,thecompressivestrengthdecreases.As a result, we discovered that the ideal proportion of glass waste powder replacement with fine particles in concrete mixis20%.

Compressive Strength ( N/mm2)

Compressive strength of cubes for Steel Slag Replacement (7days Curing) Series1

30

20

10

Series1 Series2 0

40 0 50 100

Percentage of replacement(Steel Slag)

Graph2.SevendayscompressivestrengthforSteelslag replacement

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page987

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Abovegraph2showsthattheindividualreplacementof coarse aggregates with steel slag at different replacement i.e. 0% (Convential Concrete), 10%,20%,30%, 40%, 50%, 60%, 70%, and upto 90%. The compressive strength test was carried out on seven days cubes and the results suggest that the strength of concrete initially increasing upto 60% replacement after that strength gets decreases. Basedontheresultsobtainedtheoptimumreplacementof coarseaggregateswithsteelslaginconcretemixis60%

Hence, We observed that optimum percentage of Steel slagreplacementwithCoarseaggregatesinconcretemixis 60%.

Above Graph 3 & Graph 4 Shows that the optimum percentageofreplacementofsteelslaginconcreteat7and 28-days compressive strength is 50% with 20% replacementofglasspowder.

Thetestwasperformedon(54+51)cubeswithvarying percentage replacement, and the final output results are shown in Tables 4-7 On behalf of table data graphs have been plotted between percentage of replacement and compressivestrength.Itssuggestthattheinitially strength gainandaftersomereplacementitdecreasesdown.

7 days and 28 days compressive strength comparsion

Percentage of steel slag

Percentage of replacement(Steel Slag)

Graph3Sevendayscompressivestrengthforcombined replacement

Graph5Comparisongraphbetween7daysand28days compressivestrength

Above 5 shows that comparison between 7 days 28 days compressive strength for combined replacement. Where,

[Graph8.5Series17dayC/s,Series2–28dayC/s]

The inclusion of waste glass content in the concrete mix enhances the compressive strength of the mix with 20% waste glass powder, according to the results of the tests. When concrete mixes containing 10%, 20%, 30%, 40%, and 50% waste glass powder are used, the compressive strengthincreasesby21.82percentwhencomparedtothe standard mix.On 7 days of testing, the optimal replacementofsteelslagascoarseaggregateis60%.

Graph428dayscompressivestrengthforcombined replacement

While compressive strength increased by 31.18 percent when compared to the standard mix. Furthermore, the test was conducted on combined replacement while maintaining fine aggregate replacement constant at 20% and altering steel slag as coarse aggregate replacement in the sequence of 0%,20% upto ,80%. Furthermore, the test results indicate that the best percentage for mixed replacement while preserving 20% waste glass powder is 50%, while the optimum percentageforcoarseaggregatereplacementis50%.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Theprimarypurposeofthisstudyistolookatthe effects of waste glass and steel slag content on the properties of concrete mixes when used as a partial substituteforfineandcoarseaggregates,respectively.This aim was achieved by determining the effects of adding waste glass powder and steel slag on the fresh characteristicsofconcretemixes,aswellasresearchingthe effects on the hardened concrete properties. Choosing the best waste glass and steel slag content to employ as a partial replacement within the concrete mix, focusing on concrete mixes with optimal waste glass and steel slag contents by measuring their compressive strength. These goals were met by performing a conventional series of compressive strength tests. The output outcomes of this laboratory programme demonstrated credible data points andfuturestudyobjectives.

After putting in the effort,obtained the following results: optimal replacement of fine aggregate with waste glass powder, optimal replacement of coarse aggregate with steel slag, and optimal percentage of combined replacementofcoarseaggregateandfineaggregate,which werediscussedintheconclusionsection

The research findings may lead to the following conclusions,whicharesummarisedbelow.

1) There is a 21.82 percent improvement in compressive strength for concrete mixes containing10%,20%, 30%, 40%,and 50% waste glass powder as compared to conventional concretemixesafter7daysofcuring.

2) Thereisafallincompressivestrengthinconcrete mixtures containing 30%, 40%, and 50% waste glass powder. GP mix concrete for a 7-day curing period.

3) For 7 days curing of concrete, concrete mixes containing10%,20%,30%,...upto80%steelslag have a 31% improvement in compressive strength when compared to standard concrete mixes.

4) There is a reduction in compressive strength in concrete mixes containing more than 60% steel slagascoarseparticles.

5) The combined replacement forsteel slag found best at 50 percent while maintaining waste glass powder constant throughout 20 percent and

varied steel slag as a coarse aggregates partial replacement.

6) Thedensityofconcretereducesastheproportion ofglasspowderincreases.

7) The use of recyclable waste glass in concrete reducesbuildingcosts.

8) This substance can lessen the environmental consequencesoftrashandthemaximumquantity ofsandmining.

1) Study of mechanical properties of concrete likeflexuralstrength&splittensilestrength.

2) In a concrete pavement research, coarse particleswerereplacedwithsteelslag.

3) Investigation of the fresh characteristics of concrete after the substitution of glass powderandsteelslag.

4) The investigation of the environmental impacts of such waste generated (Glass and Steelslag)

5) Data collection,suchasslagwastecreatedby steelplants.

6) Combined replacement of Coarse Aggregate and Fine Aggregate with keeping Coarse aggregatereplacementconstant.

7) Study of compressive strength with different gradeofconcretemix

8) Study of compressive strength with different watercementratio

9) Useofglasspowderasreplacementofcement andstudyofpozzolanicproperty

10) Glass powder and steel slag replacement to studythefreshconcreteproperties

We would like to express our heartfelt gratitude to our director, Dr Dhiraj Gupta whose presence as the head of the institute provided me with a very tranquil atmosphere and inspiration, resulting in the timely completionofthisProject.

We are grateful to Dr. Rajesh Sharma, our esteemed Head of Department, for his inspiration, appreciation,andcooperationthroughouttheProject.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

We have the tremendous honour and huge pleasure of expressing our heartfelt thanks to our project leader Prof. Shreeja Kacker for his advice and assistance in all Mages of this Project. She takes her time going through the books and providing the valuables. Her cooperation and efforts aided us in finishing on time; it was a very pleasant and rewarding experience working underhersupervision.

We gratefully thank all other staff members and non-teachingemployeesfortheirassistanceincompleting thisProjecteffectively.

Last but not least, I'd like to express my heartfelt gratitude to my beloved Mother and my deceased father(who died last December‘May Almighty Grant him thehighestlevel intheheaven’), fortheirsignificant roles inmy lifeand their innumerable sacrifices for meand my siblings.Manythankstomybrothersfortheirhelpandfor beingtruebrotherswhenIneededitthemost.

1. Ravikumar H, Dr. J.K. Dattatreya and Dr. K.P Shivananda. “Experimental Investigation on Replacement of Steel Slag as Coarse Aggregate in Concrete” Journal of Civil Engineering and Environmental Technology ISSN : 2349-8404; Online ISSN : 2349-879X; Volume 2, Number 11 (2015):58–63

2. Zahid Rasool Bhat, Abhishek Gupta and Girish Gharma. “Effect of Steel Slag as Partial ReplacementofCoarseAggregateinM35Gradeof Concrete” International Journal of Engineering andTechniques-Volume4Issue3,(2018).

3. S. Piraimathi. “A study on concrete properties using steel slag as partial replacement of coarse aggregate” Global journal of engineering science andresearchesISSN2348–8034(2017)

4. G.C.Behrera and R.K. Behera. “A study on properties of self compacting concrete with slag as coarse aggregate” International Research Journal of Engineering and Technology (IRJET) eISSN:2395-0056Volume:03Issue:01(2016)

5. K.Thangaselvi. “ Strength and Durability of ConcreteUsingSteelSlagasaPartialReplacement of Coarse Aggregate in Concrete” International Journal of Advanced Research Trends in Engineering and Technology (IJARTET) Vol. 2, Issue7(2015)

6. R. Rajendran. M. E.Mubarak Ali, P.Nagendran, T. Subash and D. Vasudevan. “An Experimental

Study on M30 Grade Concrete by Partial Replacement of Coarse Aggregate as Steel Slag and Fine Aggregate as Crumb Rubber” International Journal of Engineering Research & Technology(IJERT)ISSN:2278-0181(2018).

7. Dr. K. Chinnaraju, V.R. Ramkumar, K. Lineesh, S. Nithya, and V. Sathish.“Studyonconcreteusing steel slag as coarse aggregate replacement and ecosand as fine aggregate replacement” IJREAT International Journal of Research in Engineering & Advanced Technology, Volume 1, Issue 3,( 2013)ISSN:2320–8791

8. Nandini Suri. “Experimental investigations on partial replacement of steel slag as coarse aggregates and eco sand as fine aggregate” International Journal of Civil Engineering and Technology(IJCIET)Volume7,Issue5,(2016),pp. 322–328.

9. Mr. Yogesh Sharad Vatkar and Mr. Vaibhav KhanderaoKamble.“UtilizationofCrushed Waste Glass Powder as Partial Replacement of Fine Aggregates in Concrete” International Journal of Engineering Science and Computing ISSN 2321 3361(2021).

10. Vijaykumar G. Sawant. “Experimental InvestigationofWasteGlassPowderasthePartial Replacement of Sand in Making Concrete” IRE Journals Volume 1 Issue 11 ISSN: 2456-8880 (2018).

11. J.Premalatha and R.Srinivasan. “Properties of Concrete with Waste Glass Powder (Gp) as Fine Aggregate Replacement” International Journal of RecentTechnologyandEngineering(IJRTE)ISSN: 2277-3878, Volume-8, Issue-2S11, September 2019

12. SurajPMishra,KalpanaDThakur,VickyNGupta Partial Replacement of Fine Aggregate by Glass Powder in Concrete International Journal of Engineering Research & Technology (IJERT) ISSN:22780181 (Vol.9Issue02,February-2020)

13. Sarfaraz Nawaz Kittur, Md Nayeemuddin Ahmed, Rahimansab Kushtagi, Vinod Patagar and Vidyadhar.N “partial replacement of fine aggregate by waste glass powder in concrete” InternationalResearchJournalofEngineeringand Technology (IRJET) e-ISSN: 2395-0056 Volume: 07Issue:07p-ISSN:2395-0072(2019).

14. IS 10262: 2019 Concrete mix proportioningguidelines(SecondRevision)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

15. IS4562000PlainandReinforcedConcrete–Code forPractice(Fourthrevision)2007

16. “Solid Waste Management” United nation environmentprogramme.

17. M.S.Shetty, “CONCRETE TECHNOLOGY” Theory andPractice..[11] I000

18. MLGambhir“Concrete Technology”Theoryand PracticeFifthEdition2013MagrawHillEducation privatelimited.

Md Rehan, M.tech (Civil) Final Year Student, GNIOT, Greater Noida I’ve completedmy B.E in civil from VTU Belagavi in 2017 and have worked in the construction sector for over 4 years.

Ms. Shreeja Kacker, has completed her M.E in Structures from BIT Mesra, Ranchi in 2015 and has more than 6 years of industrial as well as academic experience She is currently workingasanAssistantProfessor in GNIOT, Greater Noida and is pursuing her PhD from Jamia MilliaIslamia