International Research Journal of Engineering and Technology (IRJET)

Volume:09Issue:09|Sep2022 www.irjet.net

e-ISSN: 2395-0056

p-ISSN: 2395-0072

Volume:09Issue:09|Sep2022 www.irjet.net

e-ISSN: 2395-0056

p-ISSN: 2395-0072

1st NiteshGohil Student, Department of Mechanical Engineering Thakur College of Engineering and Technology Mumbai,India

3rd DeepDoshi Student, Department of Mechanical Engineering Thakur College of Engineering and Technology Mumbai,India

Abstract The paper discusses the concept of creating an insu- lated lunch box that limits the heat transfer with its surrounding. In addition to limiting the heat transfer, the concept also proposes a method with which heat can be added to the system. This, in turn, prolongs the period where edibles can be stored at thedesired temperature. A Thermoelectric Cooler is incorporated which makes possible the inception of two separate compartments in the lunchbox which stay at different temperatures to make possible the storage of hot as well as cold food inside a single lunchbox. Due to the increasing importance of healthy and warm food, one can have midst the work, the paper ascertains theneed to understand the potential working mechanism of this project. This concept can possibly change the conventional way of carrying food by introducing an additional cold compartment to store the food in addition to a hot one. The design of the prototype is discussed. Various electronic components to be usedare discussed and the working of the prototype is explained.

Index Terms Portable Food Storage, Thermos Tiffin, Electric Tiffin, Heated Lunchbox, Cooled Lunch Box, Fresh Food Storage, Peltier module, TEC or Thermo-electric cooling, Heat Pump.

In our daily life, there are many appliances that weuse seamlesslytoderivetheworkfromthembecausetheyarevery convenient.OneofthemostusedproductsisaThermosFlask. For people who work away from home, the food or fluids theycarrytoeatlatercaneasilygettoroomtemperatureonly withinafewhours;rancidinthecaseofhighoilcontentfood. Therefore,Vacuumflasksareutilizedtokeepbeveragesfresh andhotorcoldforextendedperiods.Thermosflaskswere inventedin1892bySirJamesDewarasaresultofhisradical research in the field of cryogenics. By evacuating the air

2nd AkshatShukla Student, Department of Mechanical Engineering Thakur College of Engineering and Technology Mumbai,India

4th VinayVerma Student, Department of Mechanical Engineering Thakur College of Engineering and Technology Mumbai,India ***

betweenthetwochambersinaflask,astateofpartialvacuum can be created; such was his observation. He refused to patentit.Itwasnotuntil1904thattwoGermanglassblowers, ReinholdBurgerandAlbertAschenbrenner,discoveredthat itcouldbeusedtokeepfoodandbeverageshotorcoolfor a longer amount of time and can be used in daily use. They termeditasThermos [1].Duetoitsdesign,thethermosflaskis abletokeephotfoodhotand,coldfood,cold.Astheparadigm shifted,itbecamewidelyused.

In the age of scientific advancement, there is anenergy reduction race. How can one increase efficiency? We are coming to the realization that there is an urgent need to reduceenergyusageanddeliversuitableoutcomesinavery sustainableway.Thermosflaskscameinvariousshapesand sizesgiventhattheyensuredthestorageofmultiplekindsof food and beverages. Later, flasks with double-wall vacuum insulationwereavailablecommercially.Thevacuuminsulated thermosflasksthatareusedbythemassestodaystilllackin theirabilitytolimitheattransferthroughlongperiodsoftime. Empirically,itcanbewitnessedthatifathermoswere tobe filled with coffee for later consumption, the flask can only keepthetemperatureconstantforasmalltime.Afteranhouror two,theheatinevitablygetsoutrenderingthecoffee bland. Thisproblemisinherentbecauseoftheconstructionof the vacuumflask.Thespaceinsidethedouble-wallinsulation is definitelyevacuatedbuttheouterwallstillhastoconnectat somepointwiththeinnerholdingcompartment.Thisallows forheattransferthroughconduction.Alittlebylittletheheat seepsout,theedibleseventuallyreachroomtemperatureand theydonotcomeoutasfreshaswasexpected.Somemight suggestsimplytooverheatthecoffeebeforepouringitinto theflaskbutthatcanonlybedonewiththiscase.Whataboutthe otherbeverageswhosetastegetsdestroyedduetothehigh temperature?Andinthecasewhenacoldbeverageneedstobe stored, a layman cannot supercool a beverage at home. To combatthis,itisnecessarytodeviseasystemthatcannotonly keepenergyinsidethesystembut,whennecessary,addenergy

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page965

e-ISSN: 2395-0056

Volume:09Issue:09|Sep2022 www.irjet.net p-ISSN: 2395-0072

toit.Thispaperexploresanideawithsuchacontraptionthat cansuitthiscase.

Uponlookingforsuchproducts,itcanbenotedthatmostof theproductswhicharebeingusedaresimpleThermosflasks withoutanyabilitiestoaddenergytothesystem.Diggingin furtherwefindabouttheeffortsthatwerebeingputinthisfield tofurtherexpandthecapabilitiesofaThermosFlask.Ref[2] startedoffbypresentinganelegantsolutiontominimizethe heatlossfromthecupsorfluidcontainers.Itisasystemfor retainingorcontrollingthetemperatureofthefluid.Suitable forallkindsofenvironments,itcomprisesofaheatsinkwitha thermoelectricdevice.Thethermoelectricdeviceisattached tothebottomsurfaceofthecup.Suchaplacementmaximises theheattransferbysheercontact.

Ref[3][4]dealwithasimilarproblemofheataddition.The solutionprovidedwasrathertraditional.Beginetal.2008had proposedanideathatincludedafoodchillingdevicethathada cylindricalbodywithanouterwall,aclosed-end,andanopenend.Thisdevicecandipinanycontainer,filledwithice,which willcooldownthefoodforlaterreheatingandserving.Meanwhile,Palenaetal.2011patentedasimilardesign,acontainer thatcanfillup,exceptthecontainernowhadarechargeable, self-heating supersaturated salt solution. A potential triggermeantaprocessofcrystallization,whichessentially isanexothermicprocess[4].Thesereviewsconcludedthat theyhadatremendousdrawback.Theycompromisevolume, eitherwheretheyaretobeinstalledorfittedin. However, they addressed the problem statement accurately by providingasolutionforheatingandcoolingabeverageinthe flask.Ref

[5]wasproposedin2013and,itisbyfarthemostrelevant patenthereinregardtoourconceptofunifyingbothheating andcoolingprocessessimultaneously.However,itelaborately explainstheheatadditionprocess,butthereisnomentionof coolingthefluiddown.Itonlybalancesthetemperatureof thefluid.Itisanactivelyheatedmug.Themugcaninclude manyheatingelementsthatheatasurface.Themugalsouses thefunctionalityofwirelesspowerchargingasamethodto deliverpowertotherespectivemodule.Theoverallcircuitry canbeturnedofforonbasedontheusage.

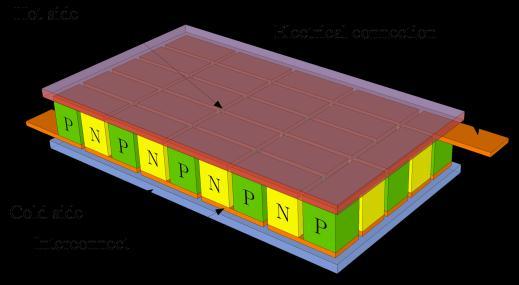

Fig.1.PeltierElementSchematic[6].

“The Peltier circuit, the basic element of the cooling thermoelectric cell, consists of semiconductors p-type and n-type connected in series with copper plates. The copper plates, on both sides, are thermally bonded to each other through ceramic plates, but are electrically insulated. In termsofelectricity,semiconductors areconnectedinseries with each other, however with respect to thermal in parallel.”[7].

Thermoelectric Coolers (TEC) work on the principle of PeltierEffectwhichstatesthatwhentwodifferentmetalsare subjected to a voltage potential, a temperature gradient is inducedattheirjunction.Peltiermodules,inessence,actlikea heatpumpwhichcancreatetemperaturedifferenceswithin the range of 70°C across both sides with no movingparts whichprovetobeessentialinmanufacturingsmallsystems withlimitedspace[8].

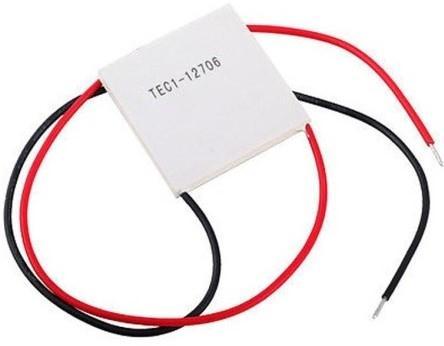

Fig.2.TEC1-12706Module.

TEC1-12706isa4cm 4cmmodule.Itisratedfor60Wand worksat12voltstill6A[9].127inTEC1-12706standsforthe 127thermocouplesitconsistsofwhilethe06signifies its 6 Amperecurrentrating.

e-ISSN: 2395-0056

Volume:09Issue:09|Sep2022 www.irjet.net p-ISSN: 2395-0072

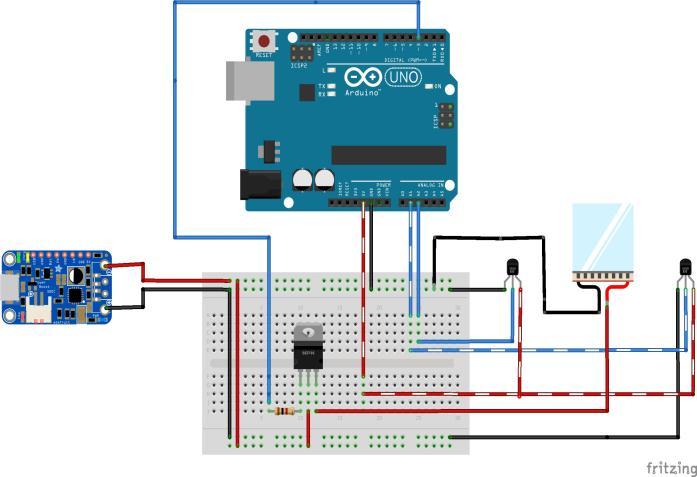

ArduinoUno is a prototyping boarddeveloped inorder to simplydevelopingprototypingcircuitsforallusers.Arduino isanopen-sourceplatformwhichprovidesMCUboardsfor makingprototypingcircuits.ArduinoUnohasacircuitbase andasoftwarecompatibilityofC#andC++[10][11].Arduino hasahugescopeofapplication.Itisoftenusedinalldomains fromdefence,healthcaretosmarthomes[12].

Usingadigitalbus,theKY-001allowsthemeasurementofa rangeoftemperatures.ItconsistsofaDS18B20single-bus temperaturesensor,aLEDandaresistor.DS18B20isawidely useddigitaltemperaturesensor.Itischeaptomanufactureand hashighprecision.ItiscompatiblecompletelywithArduino Uno[13].

OperatingVoltage:3-5.5V.

TemperatureMeasurementRange:-55to125°C Accuracy: ±0.5°C[5].

TheTIP120isaNPNTransistor.Itswitchesuploadto60V, apeakcurrentratingof8Aandcontinuouscurrentof5A.Itis verysuitableforourprojectasitcanbeusedformediumto highpowerdemandingelectronicslikeDCmotors andhighpowerLEDs[14].

The XY-016 power module can act as a multipurpose voltagebooster.ItisoftenusedinvariousprototypesandDIY projects.Ithasbeenobservedtohaveavoltagerangefrom 5.5VDCto28VDC,uptopeak2A [15]

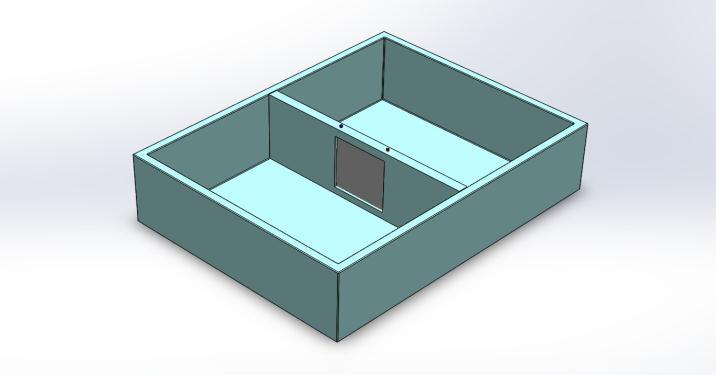

Container (the body) of the lunchbox can be made from Stainless steel or Aluminium having two compartmentsdividedbyawallwhichisusedtomountthePeltiermoduleas showninFig.2.

Volume:09Issue:09|Sep2022 www.irjet.net

Fig.7.IllustrativemodeloftheLunchBox.

Thebodyofthetiffincanbedoublewalledintroducinga vacuum between the walls to provide further insulation whichcanincreasetheefficiencyandpreventheatdiffusion tothesurroundingsbynearlyafactoroften.Theinsulation ofthedividerwalliscriticalsinceignoringitwillnullifythe temperature gradient introduced by the TEC module renderingthesetupuseless.

Thelidoftheboxistobemadesuchthatitisolatesthe compartments from ambient atmosphere and each other whenclosedtominimizeheattransferfromthesystem.

TEC1-12706 works in the range of 5-12V. However, to attain a suitable temperature and have the independence ofvarying it based on the feedback, it becomes necessary to supply12Vinitially.Forthesakeofportabilityandeasy access totheenduserwhowouldmakethemostuseofthis product

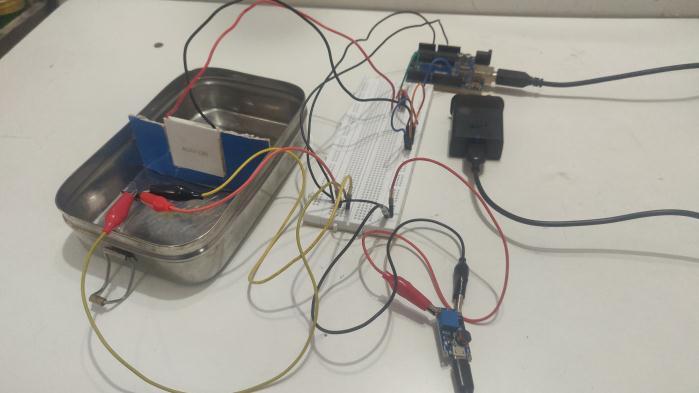

Fig.8.Developedprototypesofar.

Whenoutdoors,feeding12Vdirectlywouldnotbefeasible. TheubiquityoftheSmartphoneshasgiventhisworldaneasy accessof5VfromanACadaptereverywhere.Makinguseof this,thisprototypemakesuseofaDC-DCStepUpconverter

e-ISSN: 2395-0056

p-ISSN: 2395-0072

whichtakesaninputfroma5VUSBchargerandstepsitupto 12Vforthisapplication.

Tocontrolthetemperatureinsidethelunchbox,thepowerto theTECmoduleneedstobecontrolledactively.Thisisdone with the help of the prototype friendly MCU, Arduino Uno. Arduinoactsasabrainforthisprototype,ittakesananalog input from the temperature sensor KY-001mounted inside thecompartmentanddetermineswhetherto supplyvoltage to the Peltier module or not. The temperature ranges are specifiedwhileprogramming.Ifthethresholdtemperature is surpassed and the temperature sensor demands cooling, ArduinosendsaPulse-WidthmodulationsignaltotheTIP120 Darlington Transistor. TIP120, based on the input voltage provided by the Arduino varies the 12V supply itreceives fromtheDC-DCStepUpmoduleandsuppliesittothePeltier for the pumping of heat. This process continues until the desired cooling/heating is reached. When the temperature sensor measures more heat than desired, Arduino stops the supplyofvoltagetoTIP120therebylimitingthetemperature. Afterthis,thesystementersmaintenancemodewhereasupply oflowvoltagetotheTECmoduleisconductedtomaintainthe temperaturerequiredbythesystem.

Pulse-widthmodulationisamethodtoextractanalogoutput fromadigitalsignal.Unlikedigitalsignalswhicharebinary in theirnature,analogsignalshavearangeofvaluesbetweentheir OnandOffexpressions.Pulse-widthmodulationdoesthisby chopping up the signal into discrete parts [16]. The square wavedsignalisbrokenintomanypartsby rapidlyswitching thevoltagesupplyon and off.This on and offmotionresults inasquarewavethatisonforaspecificamountoftime,andofffor a specific amount of time. The result of this process is an averagevoltagewhichactsastheanalog outputofthedigital signalthatismodulated.

Volume:09Issue:09|Sep2022 www.irjet.net

Fig.10.SimplifiedCircuitSchematic.

ADVANTAGES

1) Provisionofacoldcompartmentinadditiontoahotone.

2) Increasedenergyefficiencysincetheemergenceofcold compartment is a by-productofpumping heattotheother compartment.

3) FreshfoodforprolongedtimeunliketraditionalThermos wherethereisnoadditionofenergyintothesystem.

4) Can act as a portable food storage while keepingthe qualityoffoodessentiallythesame.

5) Quickresponsetotheheatdemanded.

1) Introductionofan electrical system makes itdifficult to manufacture.

2) Larger than conventional lunchboxes since heavy insulationisrequired.

3) Manufacturing is difficult since vacuum insulation is difficulttoachieve.

4) Difficulttoisolatebothcompartmentssinceheattransferis encouraged due to the temperature gradient across the sides.

5) Additionofelectronicsandvacuumleaveslessspacefor actualfoodstorage.

6) Bulkier and Heavier than traditional food storage solutions.

e-ISSN: 2395-0056

p-ISSN: 2395-0072

7) Food in the hot compartment may get very dry if the boxisnotsealedwellandthewatercontentmanagesto evaporateout.

• The weight can be trimmed down by using lightweight composites.

• Materials with lower thermal conductivity can help to betterisolatethetwocompartments.

• UsageofembeddedelectronicswithsmallPCBswillhelp in reducingthesizeandcostoftheproduct.

• Properrubbersealingwithair-tightlockscanbeusedto avoidtheproblemofevaporation.

The simultaneous heating and cooling in a single unit is unlikeanyothercommerciallyavailableproductandseems more efficient than just utilizing the heat or just the cold andrejectingthecounterpart.Itshowsgreatpotentialandcan change the way people look at packed food. However, manufacturing seems to be a major challenge and more research is needed regarding its efficiency and feasibility. Preventingenergylossfromthesystemprovestobeamajor challenge in the prototype. Electric components can be substitutedforminutecircuitsthatcanfitonthebottomof thelunchbox.Moreresearchregardingitsthermalefficiency isrequiredtobecarriedout.

1) Wisniak,Jaime.”JamesDewar Morethanaflask.” (2003).

2) Schafer, Chris. ”Thermoelectrically heated/cooled cupholder system.”U.S. Patent No. 7,089,749. 15 Aug.2006.

3) Begin, Jason Ernest, and Robert Grant McRorie III. ”Rechargeable Food Chilling Device.” U.S. Patent ApplicationNo.12/105,167.

4) Palena,Travis,MorrisTorseth,andMarkE.Beatty. ”Rechargeable self- heating food container.” U.S. PatentNo.7,942,145.17May2011.

5) Alexander, Clayton. ”Heated or cooled dishwasher safe dishware and drinkware.” U.S. Patent No. 8,618,448.31Dec.2013.

e-ISSN: 2395-0056

Volume:09Issue:09|Sep2022 www.irjet.net p-ISSN: 2395-0072

6) Michbich, “Peltier Element”, Wikimedia Commons, the free media repository, Sep 2020, https://commons.wikimedia.org/w/index.php?titl e=File:Peltierelement.png&oldid=465186740

7) P Kolber, D. Perczy n´ski, K. Peszyn´ski, and B. Landowski, “EF- FICIENCY TESTING OF THERMOELECTRIC COOLING CELL BASED ON PELTIER MODULE,” pp. 14–17, 2018, doi: 10.21495/91-8-381.

8) TellurexCorporation. (n.d.). Questions about thermoelectric cooling. University of Toronto. https://www.physics.utoronto.ca/ phy326/xrf/APPENDIX%20E.pdf

9) “Peltier Element TEC1-12706,” Peltier Element TEC1-12706- MikrElektronika Thermoelectric, Peltier Modules Online Catalog DigiKey Electronics. [Online]. Available: https://www.digikey.com/catalog/en/partgroup/ peltier-element-tec1-12706/94615.[Accessed:19Sep-2021].

10) M. Banzi, “Getting Started with Arduino,” O’Reilly Online Learn- ing. [Online]. Available: https://www.oreilly.com/library/view/gettingstarted-with/9780596155704/.[Accessed:19-Sep2021].

11) Arduino,”Arduinouno.”

12) Kaswan, Kuldeep Singh, Santar Pal Singh, and Shrddha Sagar. ”Role of Arduino in real world applications.” Int. J. Sci. Technol. Res 9.1 (2020): 1113-1116.

13) Sarma, Shrutidhara, and Jang Ho Lee. ”Developing efficient thin film temperature sensors utilizing layered carbon nanotube films.” Sensors 18.10 (2018):3182.

14) “TIP120 – Darlington NPN Transistor,” Components101. [On- line]. Available: https://components101.com/transistors/tip120pinout- datasheet-equivalent. [Accessed: 19-Sep2021].

15) Macfos, “Buy XY 016 Step UP DC DC 5V/12V/28V power module w/ micro USB,” Robu.in Indian Online Store RC Hobby Robotics. [Online]. Available: https://robu.in/product/xy-016-2a-dcdc-step-up-5v- 9v-12v-28v-power-module-withmicro-usb/.[Accessed:19-Sep-2021].

16) Barr,Michael.”Pulsewidthmodulation.”Embedded SystemsProgram-ming14.10(2001):103-104.