International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Karthika C. R .1 , Nikhil R.2

1 PG student, Dept. of Civil Engineering, Universal Engineering College, Thrissur, Kerala 2Assistant Professor, Dept. of Civil Engineering, Universal Engineering College, Thrissur, Kerala. ***

Abstract - At the joint point of the X-braced system, a new seismic resistant system with a braced ductile shear panel (BDSP) was installed. Numerical study revealed that the BDSP performs the function of ductility and energy absorption while the X components continue to be elastic. A novel type of steel shear wall called shear panels combined with bracing eliminates heavily distributed stresses placed on main beams and columns.

The findings of an experimental program that compared shear panels with and without stiffeners are presented in this paper. The stiffening rib spacing as well as the specifications and dimensions of the shear panel thickness were taken into account. The maximum load-carrying capability of BDSPs can be strengthened by the addition of strengthening ribs. ANSYS 2021 R2 software was used to model, evaluate, and design the following. This study has shown that shear panels with stiffeners had outstanding ductility as well as appropriate hysteretic behavior, which increases the scatter of induced seismic energy.

Key Words: Earthquake resistant structures, Bracing, Energy dissipation, Finite-element method, Cyclic loading, Stiffening ribs, etc

Instrongseismicareas,metalshearpanelsareanefficientmeansofresistingseismicforcesandarefrequentlyutilizedto withstandwindorearthquakepressures.Theenhancementinstructuralenergydissipationcapacitybroughtonbythestable hystereticbehavioristhemainadvantageofferedbytheusageofmetalshearpanels.Manyresearchershaveexperimentally investigateda varietyofshearpanelsmadeofvarious metals,including purealuminum,low-yield-strengthsteel,regular carbonsteel,andstainlesssteel.Prominentbenefits,includingpreferableductility,highinitialstiffness,andhighlateralloadcarryingcapacity,havebeennoted.

Thesteelplatewithvariousopeningforms,includingcircle-,ring-,andauxetic-shaped,wasinitiallyproposedandexamined fromamechanicalperspective.Thispaperincludesacomparativeexperimentalprogramontwotypesofsteelshearpanels withandwithoutstiffeners.Thestiffeningribspacingaswellasthespecificationsanddimensionsoftheshearpanelthickness weretakenintoaccount.Theultimateload-carryingcapacitywasgreatlyimproved bytheadditionofstrengtheningribs. ANSYS2021R2softwarewasusedtomodel,evaluate,anddesignthefollowing.

AtotalofsevenBDSPspecimensweremodeled,analysed,anddesignedusingANSYS2021R2software.TheBDSPwasusedas themajorlateralforceresistingcomponentfortheprototypebuilding,whichwasselectedanddesignedaccordingtothe designapproachintheChineseseismiccode.ModelsofBDSPwithandwithoutstiffenerswerefabricated.BDSPstiffeningribs weremodeledinSpecimens2-7withvaryingnumbersofribsandthicknesses.Detailedinformationaboutthetestspecimensis listedinTables1and2.

ThegradeofthesteelpanelforallthespecimenswasmadeofQ345Bwithnominalyieldingstrengthof331.22MPa.Table1. Showsthepropertiesofsteel.Thespecimentypesandtheirdimensionalparametersarelistedintable2

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Table -1: Propertiesofsteel

Steel

Thematerialused- Q345B

Yieldstrengthfy -331.22Mpa

Poisson’sratio-0.3

Bilinearproperty

Table -2: Specimenparameters

Specimen No.

Specimens type Thickness of shear panel

Thickness of flange Thickness of Stiffening ribs

1. BDSPwithoutstiffeners 3 6 -

2. BDSPwith2H2V 3 6 3 3. BDSPwith2H2V 3 6 6 4. BDSPwith2H2V 3 6 12 5. BDSPwith2H2V 3 6 3 6. BDSPwith2H2V 3 6 6 7. BDSPwith2H2V 3 6 12

In specimens 2–7, equally spaced ribs were arranged in two and three rows along the horizontal and vertical directions, respectively.Toachievetheshearpanelyieldingpriortothefailureofthesurroundingcomponents,thebraces,loadingframe, andshearpanelswerefabricatedusingtheChinesestandard–conformantQ345Bsteel.

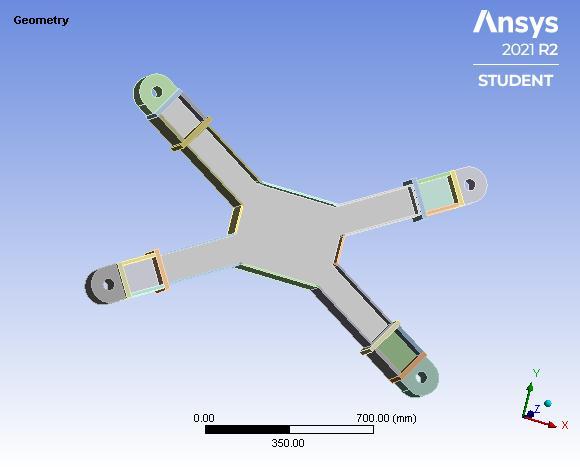

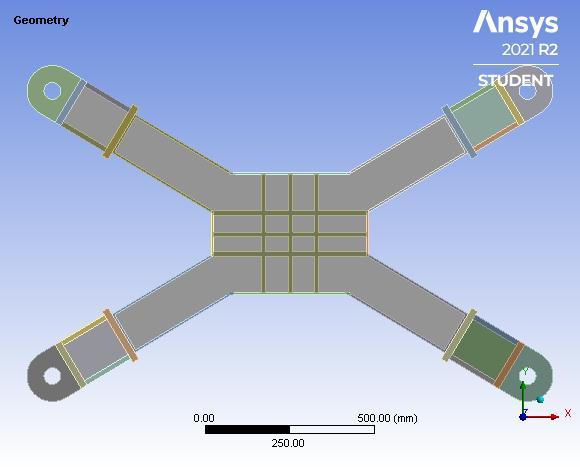

Fig -1:GeometryofBDSPwithoutstiffeningribs

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

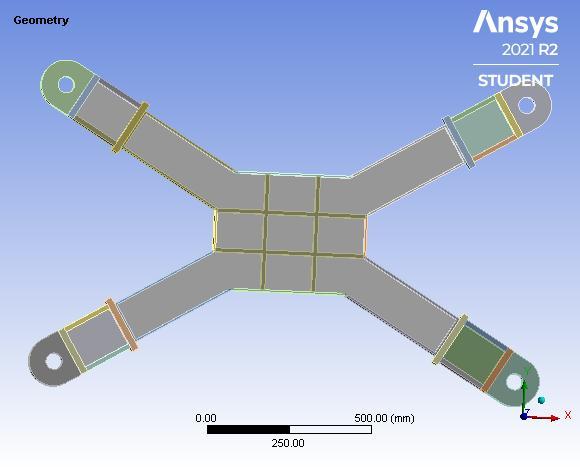

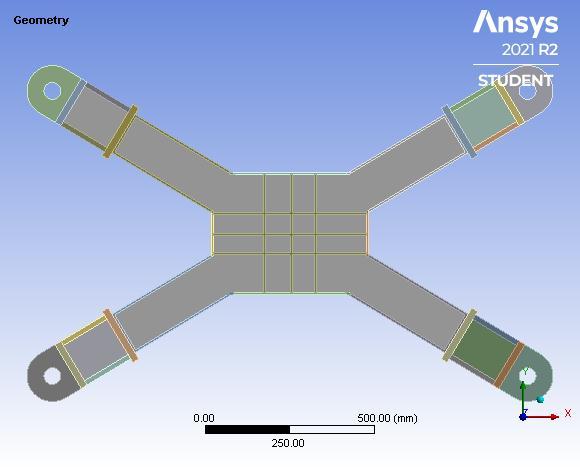

Fig -2:GeometryofBDSPwithstiffeningribs2H2V-3mm

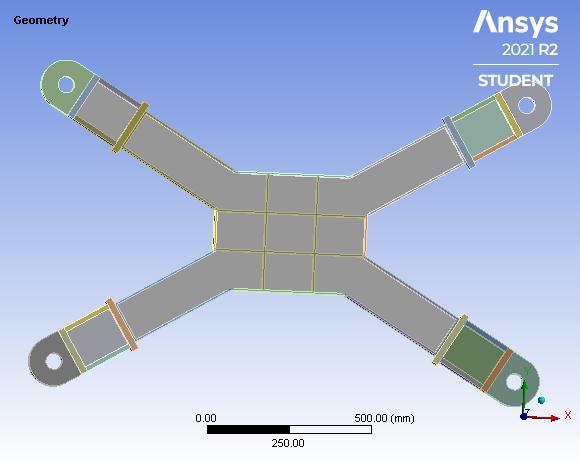

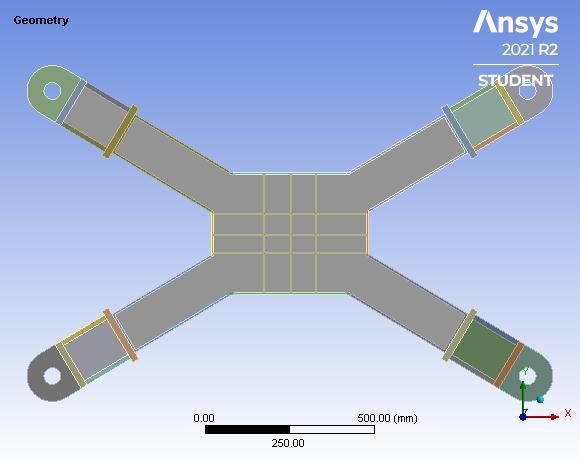

Fig -3:GeometryofBDSPwithstiffeningribs2H2V-6mm

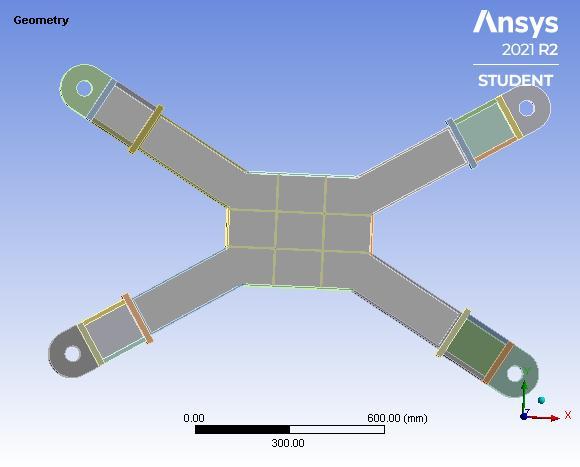

Fig -4:GeometryofBDSPwithstiffeningribs2H2V-12mm

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

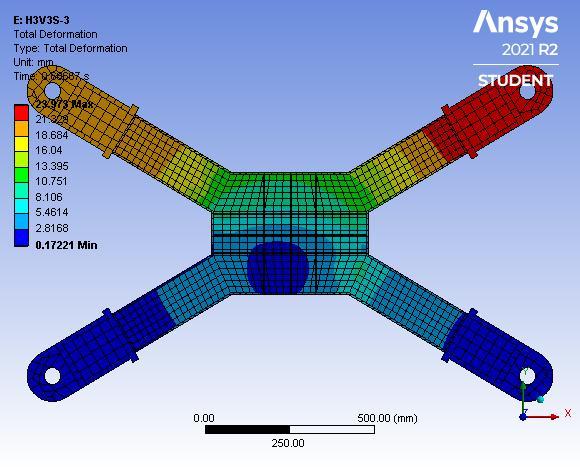

Fig -5:GeometryofBDSPwithstiffeningribs3H3V-3mm

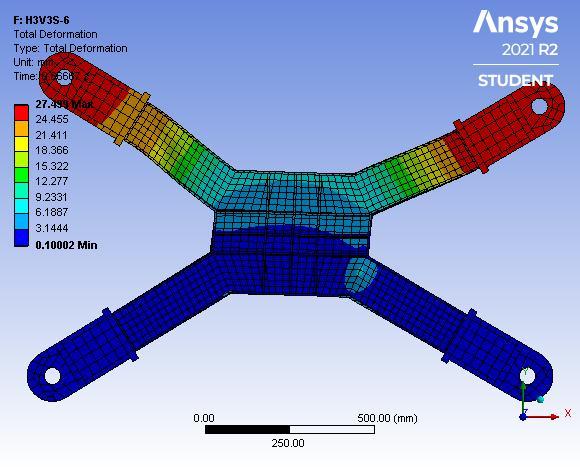

Fig -6:GeometryofBDSPwithstiffeningribs3H3V-6mm

Fig -7:GeometryofBDSPwithstiffeningribs3H3V-12mm

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

ANSYSworkbench2021R2wasusedtodevelopthethree-dimensionalBDSPmodel.Total7modelsarepreparedforthe study,1modelpreparedwithoutstiffeningribsand6modelswithdifferentarrangementsofstiffeningribswith3mm,6mm,and 12mmthicknessofribs.Theeffectivespecimenamongthesespecimensundercyclicloadingisnoted.Andalsofoundthepanel optimizationofBDSPwithoutandwithstiffeningribs.

Thebracedductileshearpanel(BDSP)systemwasmodeledinANSYSWorkbench2021R2.Forthepaneloptimization,theBDSP with&withoutstiffeningribswerealsomodeled.Thestiffeningribswereprovidedwith2&3numbers,andspecimensmodeled withstiffeningribsthicknessof3mm,6mm&12mmrespectively.Theanalysisconductedhereinwasessentiallyacyclicloading.

TheANSYSworkbench2021R2softwarewasusedtomodelallthespecimensfornonlinearanalysis.SOLID186fromtheANSYS librarywasusedfor3-DfiniteelementmodelingoftheBDSPsmodels.AllthemodelsarestudiedusingANSYSworkbench2021 R2undercyclicloading.Firstly,theloadisappliedonthetopflanges,andinthenextstepeccentricloadingwithaneccentricityof 25mmisappliedtothestructure.

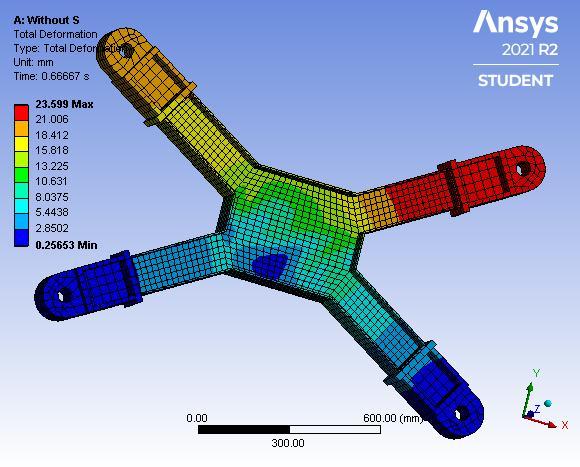

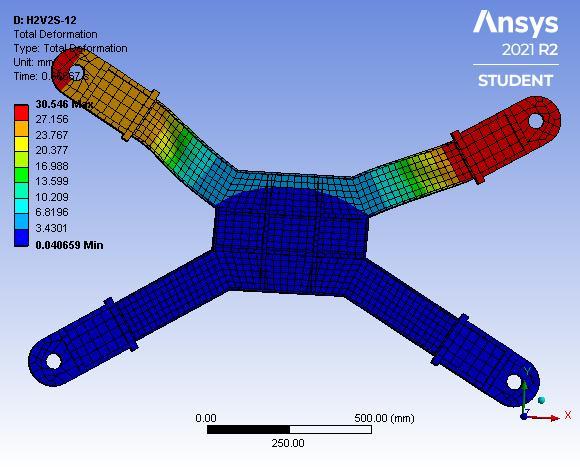

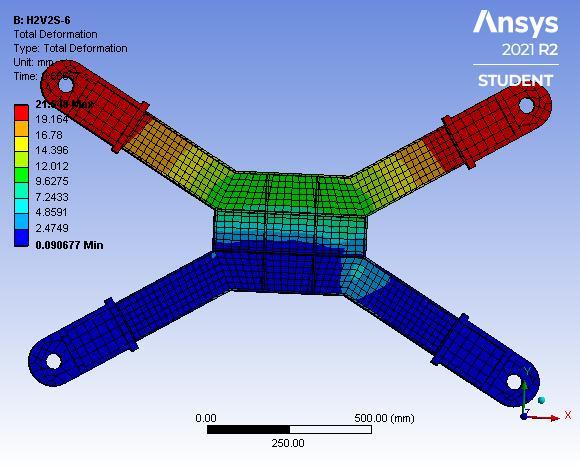

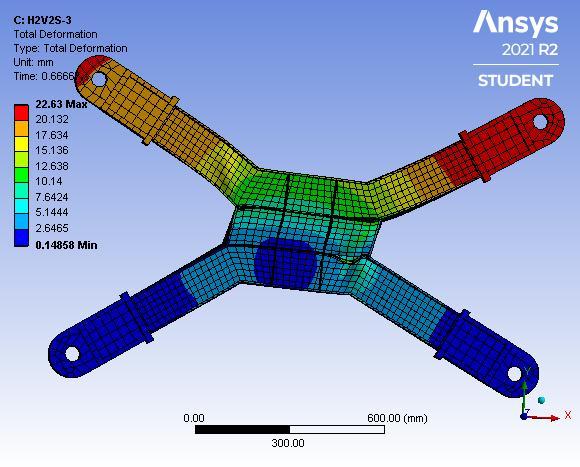

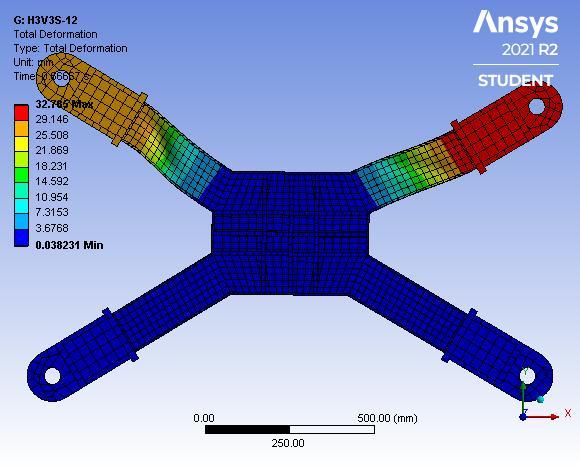

ApathiscreatedalongtheentireBDSPwiththelowersideoftheBDSPasstartingpointandtheuppersideoftheBDSPasan endpoint.Thetotaldeformationofallthebestmodelsalongthepathandgraphicalrepresentationareshowninthefiguresgiven below.

Fig -8:TotaldeformationofBDSPwithoutstiffeningribs

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

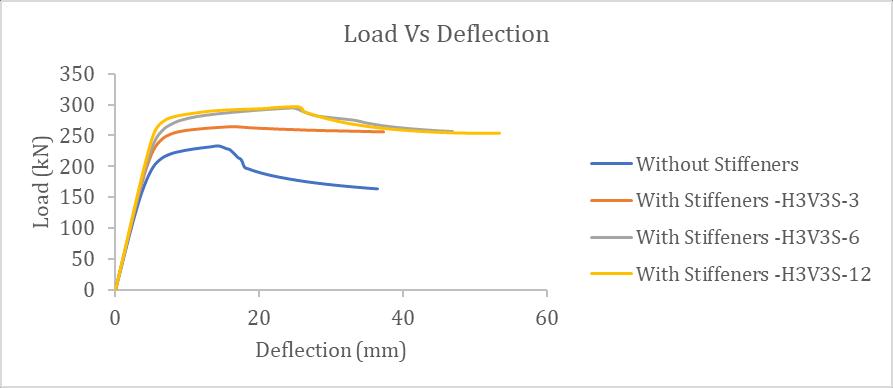

Chart -1:LoadVsDeflectioncurvewithoutstiffenersandwithstiffenersof2H2V

Chart.1 shows the load Vs deflection curve of BDSP without stiffeners and with stiffeners of 2H2V. In that BDSP without stiffeners, the ultimate load and ultimate deflection show very little effectiveness. When comparing 2H2V stiffeners with thicknessesof3mm,6mm,and12mm,theultimateloadandultimatedeflectionaregreaterforstiffenerswithathicknessof12 mm.

Table -3: Percentagedecreaseinloadofwithoutstiffenersandwithstiffenersof2H2V MODELS DEFLECTION LOAD % DIFFERENCE IN LOAD

WithoutStiffeners 14.313 234.07 1

WithStiffeners-H2V2S-3 12.639 257.47 9.997009442

WithStiffeners-H2V2S-6 23.108 280.71 19.92566326

WithStiffeners-H2V2S-12 23.168 299.15 27.80364848

Fromtable3,theultimateloadandultimatedeflectionvaluesforstiffenerswith2H2Vwith3mm,and6mmthicksarelessthan thatof12mmthickstiffeners.Theultimateloadandultimatedeflectionfor2H2Vwith12mmthickis299.15kN&23.168kN.

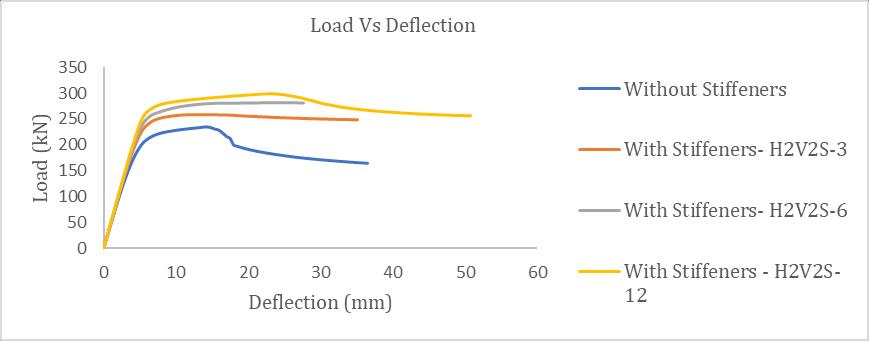

Chart -2:LoadVsDeflectioncurvewithoutstiffenersandwithstiffenersof3H3

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Table -4: Percentagedecreaseinloadofwithoutstiffenersandwithstiffenersof3H3V MODELS DEFLECTION LOAD % DIFFERENCE IN LOAD

WithoutStiffeners 14.313 234.07 1

WithStiffeners-H3V3S-3 16.451 263.9 12.74405092

WithStiffeners-H3V3S-6 24.772 295.68 26.32118597

WithStiffeners–H3V3S-12 24.99 297.49 27.09445892

Fromtable5.2,theultimateloadandultimatedeflectionvaluesforstiffenerswith3H3Vwith3mm,and6mmthicksareless thanthatof12mmthickstiffeners.Theultimateloadandultimatedeflectionfor3H3Vwith12mmthickis27.094kN&24.99 kN.

Bycomparingtable5.1&table5.2,Theultimateloadandultimatedeflectionvaluesforstiffeners12mmthickshownearlythe samevalueswhencomparedwithboth2H2Vand3H3V.Sointhecaseoftheincreasingthicknessofstiffeningribsin3H3V,no furtherimprovementsoccur.

Using metal shear panel dampers, it was demonstrated that it had good low-cycle fatigue properties and super seismic behavior.Theshearpanelthicknessspecificationsanddimensions,aswellasthespacingofthestiffeningribs,weretakeninto considerationinordertoreducedamagetoallstructuralcomponentsotherthanthesacrificialpanelsduringearthquakes.The ultimateload-carryingcapacitywasgreatlyimprovedbytheadditionofstrengtheningribs.Thedatawillalsobeutilizedto forecasttherealductilityandenergydissipationcapacityofvariousgeometriesbyaddingadamageandfailurecriteriontothe finiteelementmodel.Bracedductilethinshearpanelswithstiffeningribsexhibitthebestpaneloptimization.Theultimateload andultimatedeflectionare higher forBDSP withstiffenersascomparedtoBDSP without.Thishasa greatercapacityfor haulingloads.Theultimateloadandultimatedeflectionarehigherforstiffenerswithathicknessof12mmwhencomparedto stiffenerswiththicknessesof3mm,6mm,and12mm.Theultimateloadandultimatedeflectionarehigherfor3H3Vstiffeners withathicknessof12mmwhencomparedtostiffenerswiththicknessesof3mm,6mm,and12.Whencomparedwithboth 2H2Vand3H3V,stiffeners12mmthickexhibitalmostthesamevaluesforultimateloadandultimatedeflection.Thereare thereforenofurtheradvancementsinthecaseofthethickeningstiffeningribsin3H3V.TheoutcomesshowthattheBDSP systemhasthepotentialforreducingstructures'lateraldisplacements.

[1] DavideGiannuzzi(2015). "BracedDuctileShearPanel:NewSeismic-ResistantFramingSystem”, AmericanSocietyofCivil Engineers,JournalofStructuralEngineering

[2] GuohuaSunetal.(2021), "Cyclicbehaviorofaninnovativebracedductilethinshearpanel ’’, Sciencedirect,Volume32

[3] Guohua Sun et al. (2021), "Cyclic testing of an innovative self- centering X- braced ductile shear panel’’, Science direct,Volume244

[4] JunxiaZhaoetal.(2014). “Anoveltypeofanglesteelbuckling-restrainedbrace’’,EarthquakeEngineering&Structural Dynamics

[5] Zaid A. Al-Sadoon (2020). "New Buckling-Restrained Brace for Seismically Deficient Reinforced Concrete Frames”, AmericanSocietyofCivilEngineers,JournalofStructuralEngineering,Volume146,Issue6