International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Abstract - A hybrid vehicle is a vehicle that uses two or more distinct types of power The basic principle in hybrid vehicles is that different engines work better at different speeds; An electric motor is more efficient at producing torque, or rotational power, and a combustion engine is better at maintaining a high speed than a typical electric motor. Switching from one to the other in time while accelerating yields gains for both parties in terms of energy efficiency, which translatesinto greaterfuel efficiency.

It also includes other means of storing the energy of pressurized fluids in hydraulic hybrids. Hydraulic power conversion and storage provide exceptional energy density and efficiency, making it ideally suited to renewable powertrain design. It is especially effective in city traffic conditions, is characterized by frequent stops, coasting and long idle periods. In addition, emissions are reduced, particularly at idling and at lower speeds, compared to conventional powered vehicles. This paper reviews the latest developments inthisfield.

Key Words: hydraulic hybrid vehicle, Parallel hydraulic hybrid,accumulator,reservoirandpump/motorunit.

Becauseofthevolatilityinthepriceofcrudeoil,thepriceof gasoline has risen. As a result, Hybridization is used as a techniquetoimprovetheoverallfuelefficiencyofavehicle. Ahybridvehicleisonethatusesacombinationofpropulsion sources to create motive power. Normally, the vehicle is poweredbyaninternalcombustionengine(ICE)thatburns fossilfuels.Thepoweristransferredtothewheelsthrough thetransmissionsystembywayofamechanicaldrivetrain Whenasecondpowersourceisaddedtotheexistingone,it's known as a "hybrid" vehicle. Electrical, chemical, or other sourcesofadditionalpowercanbeused.Powerstorageand productioncanbehydraulic,flywheeloperated,oranyother method.

Hybridization occurs for a variety of reasons. The major causesofthishaverecently been environmental pollution and gasoline savings. The exhausts of traditional automobilescontaminatetheairinlargecities,necessitating an alternative source while the other serves as a working mediumorenergyreservoir,allowingthesystemtobemore flexible. Hydro-mechanical and power assist systems the term"architectural"isalsousedtodescribethesestructures. Systems in series, parallel, and power-split configurations [1].

The Hydraulic Vehicle has several advantages such as Improving Vehicle performance, hydraulic fluid power is simpletouse,Improvedfueleconomy,hydraulichybridsmay achieve efficiencies of up to 70% when compared to conventional hybrids, which havean efficiency ofless than 40%Reducing pollutant emissions, hydraulic hybrids offer more than 40% reduction in carbon dioxide emissions becauseofthelesserneedtooperatetheengine[3]. Ahybrid vehicleisabletoreducevehiclelossesinfourways,makesure theengineisrunningsmoothly,downsizingtheengine,using regenerativeenergytobrakeandshuttingengineoffwhennot needed[3-7].

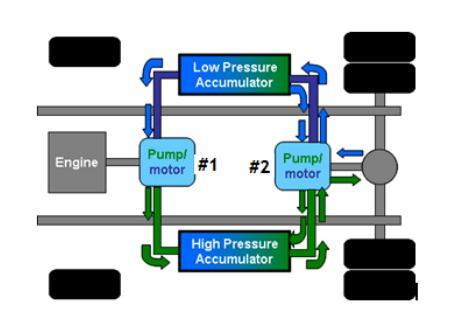

In the series hydraulic hybrid vehicle design, the typical gearboxanddrivingshaftareeliminated,asshowninFigure. Thehydraulicpump,whichismechanicallyattachedtothe engine, converts the engine's mechanical power into hydraulic power. The accumulator is then charged or immediatelychargedbythehigh-pressurehydraulicfluid. The fluid is sent to the wheel-end pump/motor, which movesthevehicleforward.Itisfeasibletousethissetupto thevehicle'sgroundspeedandenginespeedareseparated. As a result, it is possible to at its torque-speed map, the engine should be managed at its most efficient efficiency regime.Furthermore,Whenthebrakesareengagedorthe vehicle comes to a complete stop, the engine may be switchedoff.Thepowerwasturnedoff[4].Thestructureof SHH is shown in Figure1. The main component is the accumulator, Pump /motor unit and tank (low pressure accumulator). Accumulator is energy storage unit. Pump /motor is connected to the ICE to refill the accumulator. Pump/motor2isconnectedtothedriveshafttopropelor slowthevehicle.SinceDuetotheseparationoftheinternal combustionenginefromthedriveshaft,higherefficiencycan be achieved through operation The motor only has the torqueandspeedrequiredformaximumefficiency[5].

Sincethe1970s,aseriesofHHTshavebeeninvestigatedfor decades.Thedevelopmentofthissystemwasthemainfocus ofthestudyontheseriesHHTintheearlyinvestigations.A mechanicalbypassinparallelwithaserieshybridhasbeen investigated,withfuel improving from17% to22%when compared to a traditional series hydraulic hybrid [8]. Simulating a series of HHV for passenger cars revealed

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

significant fuel savings and the potential to be applied to real-worlddesign[9].

fuel economy of 93 mpg with engine idling and 110 mpg with engine shut-downs [18]. Simulation work has been done on the engine power management based on the conditionofthechargecontrol,whichispartoftheseries hydraulic hybrid for a light truck, and fuel economy projectionsfortheoptimizedsystemsuggestfuelsavingsof morethan50%whendrivingthroughcitytraffic[19].

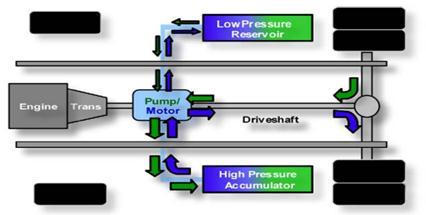

Figure1-1:Aserieshydraulichybridconfiguration[6].

Volvo introduced prototype work on series hydraulic hybridswithCumuloHydrostaticDriveintheearly1990s. For dynamometer testing, a bus was employed with a trapezoidaldrivingcycle.Estimateda48%decreaseinfuel consumption[10].EPA,Eaton,andUPS,togetherwithother industry partners, fitted a UPS delivery truck with series HHTin2006,andduringfieldtesting,fuelsavingsof60%to 70%wereachieved[11].

In recent studies, FTA, Altair, and Parker partnered each other to develop a series HHT for city buses with a more efficientengineandreducedvehiclemass.Thehybridbus showed fuel improvement of 29% over the most efficient electrichybrids,47%overtheidenticalnonhybridbus,and 109%overtheconventionalcitybus[12].Severalsimulation studiesontheseriesHHThavebeenconductedinorderto assess performance and fuel savings. With the Federal UrbanDrivingSchedule(FUDS)cycle,aserieshybrid in apassengercarwassimulatedandafueleconomyof60mpg wasreached[13].

Powerbondgraphapproachhasbeenappliedtopredicting thedynamicresponsecharacteristicsofaseriesHHT[14]. Fuel economy of the medium truck with a series HHT showed improvement of the fuel economy by 72% and reduction oftheparticulate emissionby 74%compared to theconventionalbaseline,whichwasstudiedbysimulation and the engine-in-the loop (EIL) techniques [15]. The performance of a rule-based, SDP, and MPC energy managementstrategyhasbeenstudiedforaseriesofHHTs usingdifferentdrivingcyclesandmodelparameters[16].

Based on the simulation, a topological study of a series of hydraulichybridrefuse-collectingvehicleswasperformed, revealingfuelsavingsofupto14%[17].

ThereareseveralstudiesforthecontroloftheseriesHHT; For the FUDS driving cycle, Johri and Filipi provided optimized supervisory control for a series of HHTs with a

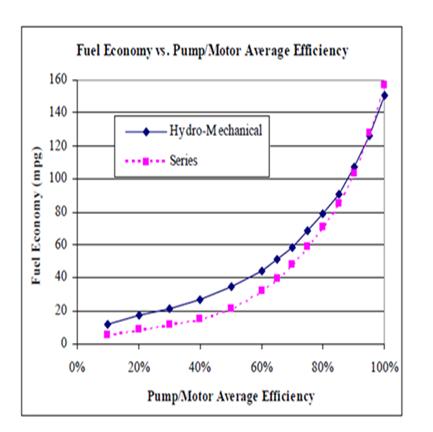

AmodelpredictivecontrollerwasstudiedforaseriesHHV to improve a fuel economy [20]. A neural network power management was investigated for series HHTs to reduce averagefuelconsumption,anditshoweda12%reduction. When compared to a baseline constant control strategy, therewasa26%reduction[22].Inaddition,Strategiesfor managingseriesenergyanopen-circuitsetupwasusedto researchHHTs[24].Theprosandconsofopenandclosed circuits of series HHTs have been studied in terms of the weight of hydraulic components [25]. An A series hybrid drivetrainismodelledandcomparedtoahydro-mechanical hybrid drive train in operation. The U.S. Environmental ProtectionAgency'sUrbanDynamometerDrivingSchedule theexcellentfuelefficiencyisdemonstratedbythehydromechanical system. Despite the economy's potential, development work in the field is required Pump/motors withgreatefficiencyatlowspeeds[26].

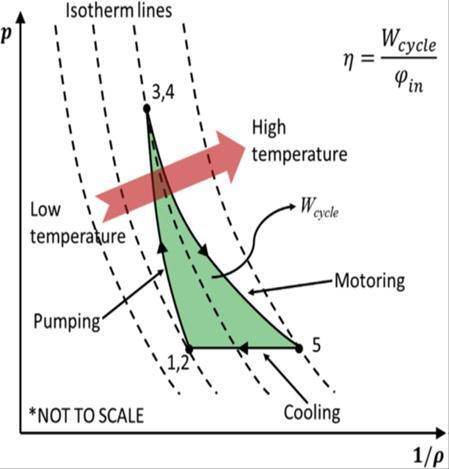

A simulation model based on lumped parameter thermodynamic analysis was used to investigate the transmission of a series of HHV. A thermal model was developed in order to capture the very transient thermal phenomena. The unstable system comes in a variety of forms. The model was put to the test. Measurement data fromanHILtestrigwasusedtovalidatethemodel.TheFTP72 driving cycle is being tracked. The simulation findings suggest that there is a They show a high connection with measured data and suggest that the approach given here provides useful information on the temperature environment.Hydraulichybridsystembehaviorthethermal model is a useful tool used to determine the system's thermalstabilityandpackagingoptimizationpriortovehicle production,ofcomponentsandcoolingsystemdesign[27].

Thehydraulichybridvehicle(HHV)isa novel technology that is being developed to increase road vehicle fuel economy. Thistechnology alsohasdisadvantages,such as poorenergydensityandnoabilitytoconnecttothepower grid.Thegoalofthisstudyistoassessanewapproachfor upgradingHHVtechnology.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

prototypeofthepowersplitHHTswascreatedandpatented in1980forapassengercar,indicatinga100%fuelsavings [32]. By simulating various transmissions of power split HHTsforcitybuses,theywereabletoimprovefueleconomy by5%forahydrostaticpowersplittransmissionand14% for a compound power split transmission. And 28% for a HHTwithacompoundplanetarypowersplit.Comparedto thebaselinebus,thegeartrain[33].

Figure 2: The fuel economy predicted by the simulation fortheseriesandhydro-mechanical

Aftertheyear2000,KumarandIvantysynova[34]suggested anHHTforapassengercarwithanoutputcoupledpower splitapplication.Thedynamic analysisandcontroller ofa powersplitHHTwerestudiedforapassengervehicle[35]. Peugeot and Bosch Rexroth developed an output coupled powersplitHHTforapassengercaranddemonstratedfuel savings up to 45% in 2013 (Hybrid Air, an innovative full hybridgasolinesystem).Also;Onadynamometertestrig,a power split HHT for medium duty cars showed a fuel efficiency improvement of 19 percent for the Baltimore driving cycle and 52 percent for the New York City Compositecycle[36].

Apowersplit HHThasbeensimulatedandcomparedtoa power split hydrostatic transmission for system optimization[37].Addtothere,StelsonandRamdanAhigh levelofpowerSplitHHThasbeenstudiedforacitybus[38].

Figure3: Thermodynamic diagram of the transmission of theseriesHHV[27].

Theairsystemcanbechargedthroughgridplug-inorbythe internal combustion engine with the addition of an air systemtoHHV(ICE).Thenovelsystemhasthepotentialto considerablyincreasetheenergydensityofhydraulichybrid vehicleswhilealsoallowingthemtoplugin.Thisresearch develops a parallel hybrid simulation model for the new system based on a symbolic programmed created in MATLAB/Simulink[2]

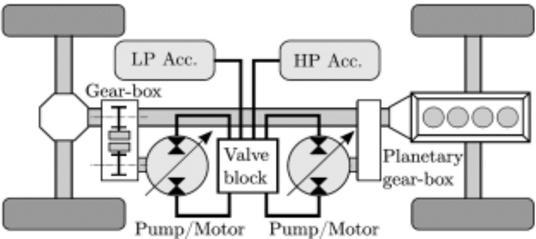

Thepowersplitpowertraindesign,asshowninthefigure, combinestheconvenienceofapurehydrostaticpowertrain (theabilitytoruntheengineatitsmostefficientpoints)with the high overall transmission efficiency of a hydro mechanical powertrain using a planetary gear train arrangementtoprovidethebenefitsofbothlayoutswhile minimizing their disadvantages. [29, 30,31]. The first

Figure 4:power-splithydraulichybridVehicles[28].

Figure shows a hydro-mechanical (parallel) powertrain concept that retains the traditional transmission and driveshaft system intact while adding a hydraulic pump/motor unit in parallel to the mechanical path to absorband/orreducevibrations.Providehydraulicpower to/fromthemechanicalsystem.Thearchitecturedoesnot allow for decoupling. Hence, the engine cannot be started becausetheenginespeedisdifferentfromthegroundspeed. Controlledinthemostefficientmannerpossible.When,on the other hand, the relative sizing is such that the more efficientmechanicaltransmissiontransmitsalargeamount of electricity. The overall fuel efficiency of the hydromechanical path is better than the hydrostatic path when comparedtothehydrostaticpath.Forsomedrivecycles,a parallel powertrain may be preferable to a series powerplant.[39,30,40].

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

differentsuggestedparallelhydraulichybridpowertrainfor the Family of Medium Tactical Vehicles (FMTV) [52]. Toulson used modelling and simulation to investigate a parallel HHT for small road vehicles in urban driving conditions [53]. Several authors employed simulation to explore the energy management of parallel HHTs for fuel savings, with refuge vehicles achieving fuel savings of around 20% as compared to conventional automobiles [54,55]. For the control of the system, Wu and coworkers proposedapowermanagementstrategythroughadynamic programmingforaparallelHHTforamedium-sizedelivery truck,whichyieldedthepotentialfuelsavingsof47%[65].

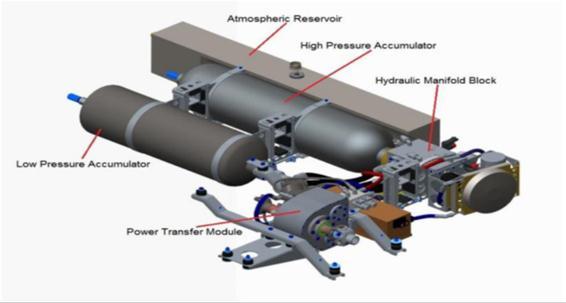

The energy management problem in a hydraulic hybrid vehicle is solved using a model predictive control (MPC) approach.Totransmitenergybetweenthemechanicaland hydraulic domains, MPC employs a variable displacement pump/motor combination, as well as a high-pressure accumulatorforenergystorage[41].Theround-tripenergy storageefficiencyofaparallelHHTwastestedbyutilizingan experimental setup for the construction of the prototype, whichexhibitedaroundtripefficiencyofover50%.andafter thestudy,theyachievedtheround-tripefficiencyof66%in theimprovedtestrig[42].

In a subsequent study, with the aerodynamic drag of the flywheeltakenintoaccount,aroundtripefficiencyof75% was reached [43]. In the early 1980s, MAN produced a parallelHHTprototypethatshoweda25%reductioninfuel consumptionwhencomparedtoaconventionalbus[44].

Mitsubishi Motors' braking storage system and reduced engine resulted in a 30 percent reduction in fuel consumption[45].TheCanadianNationalResearchCouncil created a parallel HHT for a bus, which showed a 17 % reduction in fuel usage when compared to the 13 regular buses [46]. In 2000s, Ford, Eaton, and EPA advanced a parallelHHTforSUV,whichpresentedfuelsavingsof24% [47].EatondevelopedarefugetruckwithaparallelHHTin 2008,resultingina30%fuelsavings.Experimentationand simulation were used to investigate a hydraulic power systemthatcanbeeasilyinstalledinregularbusesinrealworld tests, it demonstrated a 28% reduction in fuel consumption[48] InEarlysimulationstudiesDuetoalack ofcomputationalcapabilities,theprecisionoftheresultsis limited.AparallelHHTforabuswasexploredandconfirmed inasimulationexercisewithasmalldeliveryvan,indicating possiblefuelsavingsof25to30%[49].

AparallelHHTforapassengercarhasbeensimulatedusing threedistinctdrivingcycles,withfueleconomyupto64mpg attainableforurbandrivingcyclesbutlittlegainforhighway drivingcyclesduetothelackofregenerativebraking.When comparedtocitydriving[50].Asadesigntool,asimulation ofHHTswithbondgraphhasbeendevelopedtoexploitthe system'sperformanceandefficiency[51]. After2000,Filipi and et al. conducted a comprehensive investigation of a

Insimulation,acontroltechniqueforoptimalbrakeenergy recoverywaspresentedforaparallelHHT,andtheresults showedthat42.7percentofthebrakeenergywasrecovered [57]. For a parallel HHT with an urban driving cycle, the optimal energy distribution with a fuzzy torque control approachwasinvestigated[58,59,60].

The front-mounted parallel HHT has been analyzed for control strategies and system optimization [61] is a new hydraulic hybrid vehicle with wheel motors that improve vehiclepowerandefficiency.Thevehicle'ssimulationmodel isconstructedinthefuture.Thesettingsofthesystemare set in accordance with the requirements for power performance A smaller engine with a lower peak power outputischosen.byafactorof11.96%Experimentsonthe designed model are used to calibrate and verify the simulation model. Bench test Parameterized simulation resultsshowthattheaccelerationtimeofthevehicleis0–100 km/h. When compared to a normal car, the planned vehicle'stimeisreducedby36.3percent,from19.63to12.5 seconds.Thetopspeedofthevehicleis140km/h,andthe maximumgradeabilityis29%.WhenitcomestotheWhen theengineissettoeconomymode,fuelconsumptiondrops by35.59percent,from15to9.66Lperhour.100km[62].

The multi-objective optimization function in this article is optimizedusingtheantcolonyalgorithm.ThePHHVsystem parameterscanberesolvedusinganantcolonyapproach. Becauseithasaquicksearchconvergence,it'sagoodmatch problem.speed,concurrentcomputations,andanefficient solutiontheauthenticityandcorrectnessofthesimulation findings are demonstrated. The ant-based multi-objective optimization approach an algorithm for colony formation

The method of multi-objective optimization is capable of locatingthebestsolutionsitesinatimelymannerIfyou're looking for one of the major components of a hydraulic hybridcar,gonofurther.Increasetheoverallperformance ofthevehicle[63].

The hydraulic hybrid is a great teaching tool for thermodynamics, fluid mechanics, and vehicle dynamics basics.AMATLAB/Simulinkapplicationwasbuilttomodel the performance of hydraulic hybrid and conventional vehicles.Modelinformation,showstudentexercisesthatare organized by level and course, and give an example

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

evaluation of the simulation tools and associated tasks' effectivenessinimprovingStudenteducation[64].

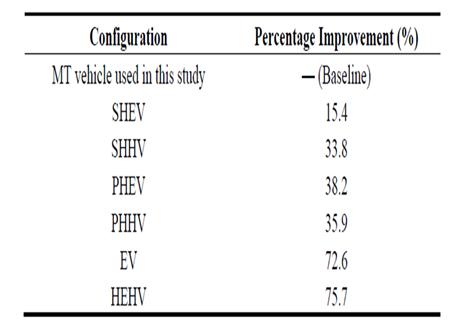

ThisstudyadoptedMATLABSimulinktoconstructcomplete HHV and HEV models for backward simulations. New European Driving Cycles were used to determine the changes in fuel economy and, the experimental results revealedthat,regardlessofwhethertheUDCorEUDCwas used, then HEHV had the best energy-conservation performance(average,NT$0.631/km).Table1showsthat, fortheMTvehicleusedinthisstudy,theHEHVpresenteda 75.7% improvement in economic savings is presented in Table2[67].

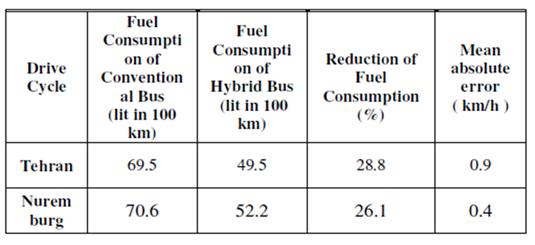

InMATLAB/Simulink,afeedforwardmodelforthehybrid powertrainwasconstructed.Themodelwassimulatedusing arule-basedapproach.Atacticforcontrolincomparisonto thetraditionalmodelshowsaminimum26%reductionin fuel consumption for Hybrid hydraulic technique. Furthermore,theeffectivenessofincomparisontoregular buses, hybrid buses are acceptable. The parallel hydraulic hybridmodelthatwascreatedthebuscanalsobeutilizedto runadditionalsimulations.Puttinginplacemorecomplex controlstrategies[66].

According to simulation findings from the constructed numericalmodelforthevehiclebrakingmode,thepressure in the high-pressure accumulator reached its maximum value during vehicle braking and the accumulator was chargedbyroughly85%.Accordingtosimulationfindings fromthegeneratednumericalmodelforthevehiclestarting mode,thehydraulicmotorisabletoovercomethetorque requiredtostartthecar,indicatingthatthestoredenergyin the high-pressure accumulator is adequate to start the vehicle.

The developed hydraulic hybrid system was shown to be capable of producing, storing, and reusing energy for all driving regimes for the chosen delivery van, resulting in energysavings[68].InthisworkAmethodfordevelopingan energy management plan was presented and applied to a small heat and power unit (SHHV). The model predictive controlframeworkwasusedtocreateanonlinesystemin thismanner.Optimalcontroliscapableoftrackingadesired motorspeedwhileinmotion.Enforcingefficientpowertrain functioning.Thisresearchestablishedarigorousframework forselectinggoalfunctionsandoptimizingenergyuseina hydraulichybridvehicleusingarecedinghorizonapproach.

The general architecture and tools that have been establishedthemethodslaidoutherecanandwillbeusedto investigate alternative architectures in a controlled environment.

Table 1:COMPARISONOFFUELCONSUMPTIONFOR CONVENTIONALANDPHHBUSES[67].

Alargenumberofdrivingcycles.Inparticular,architectures that make use of Regenerative braking is an option to explore.Thecurrentresearchfoundthatitisthereforethat theaccumulatorshouldbeconsideredwhenoptimizingthe efficiency of the powertrain. Brakes with a regenerative system.Theadditionalefficiencywillbeevaluatedinfuture investigations. Improvements that can be made using the proposedenergysource[69].

Table 2:Percentageimprovementineconomicsavings [67].

The optimum power management algorithm for a midhybridhydraulictruckisItisformulatedandsolvedusing dynamicprogrammingtechnologytoreduceit.Theresultsof forward-looking improvements in DP are used to extract them.Suboptimalrulesforpowersplittingandgearshifting, feasiblecontrollers.Thenewrulesareverydifferentfrom typical hybrid strategies. Electric vehicles often use hydraulic motors as their only source of power. Process derivedfromDP.Theresultsenableimprovedfueleconomy

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

for the hydraulic hybrid truck above. The conventional isotopeisbetween28%and47%[70].

TheefficiencyoftheHHVaccumulatorinchargingoperating conditionsaswellasmixeddischargewereinvestigatedin the hybrid Parallel-HHV design model. An optimization modeliscreatedbasedontheoperatingconditions.Asthe best objective method for energy management, greatest efficiencycombination,resultinginoptimalmixing.Working circumstancesforenergy-efficientautomobiles,andthebest Control laws are in place. Fuel economy is a complicated blendofenergy-savingstrategies.Theconclusionsarebased onsimulationsofNEDCsettingsforvehicles.Impliesthat,in comparison to standard fuel use, based on 33.12% of models,whichindicatesthattheyhavebetterFuelstorage and its implications in hybrid parallel hybrid systems strategyforenergyoptimization[71].

The goal of this paper is to develop a control strategy for optimal brake energy recovery for a parallel hydraulic hybrid vehicle in which the torque coupler's shifting schedule and braking force distribution are the most importantimpactfactors,basedonathoroughexamination ofbrakingcharacteristics.Thevehiclesimulationmodelsare created using the software Advisor 2002, which has been validated through road tests. According to the simulation results,42.7%ofthebrakeenergycanbecapturedinthe hydraulic hybrid car, whereas 41.6 percent of the brake energycanbecapturedintheelectrichybridvehicle.Whena typicalcarbrakes,tractionenergyissquandered.Asaresult, theoptimalenergycontrolapproachinahydraulichybrid vehicle, brake energy recovery is particularly useful in boostingtheefficiencyofbrakeenergyrecovery[72].

improvedthepotentialforbrakingregenerativepowerThe torquecontrolisfuzzy.Thestrategyreasonablydistributed thepropulsionenergy.Becauseofthedistancebetweenthe powersources,thefueleconomyimproved.andadaptability to different working conditions, and minimized the disadvantage of the accumulator’s lower energy which providedapracticalandfeasiblemethodfortheimproving fueleconomyofthehydraulichybridvehicle[73].

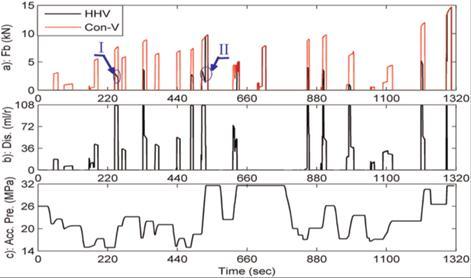

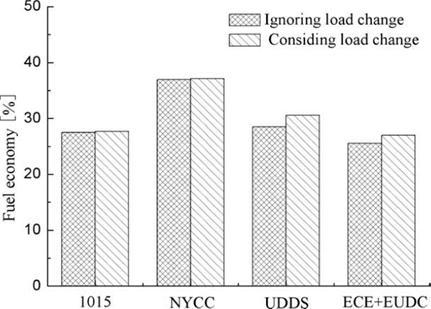

S.Hui,andet.al.hadprovedthatAnewtypeofconfiguration is investigated in this study. A PHHV test is presented. A fuzzy-based torque control strategy It is built using the optimization results according to the torque distribution among the engine, hydraulic pump, and transmission The motorandhydraulicpump,andthevehicleloadchange.We are introduced to the fuzzy torque control strategy for realizingfueleconomytothefullest.Thesimulationresults show That the new configuration of PHHV effectively

Factor value:

Figure 8:ImpactsofloadchangingonPHHVfueleconomy [73].

Filipi and et.al. [74] proved that Fuel economy and emissionsweresimulatedtoshowcomparisonsbetweenthe PHHB and conventional bus. Simulations of a parallel hydraulichybridbusshowed30%improvedfueleconomy, whichwassimilartorealroad-testingresultsof28%.Italso reducedregulatedemissions,showninFigure8,atpe=85bar over one simplified driving cycle. Control strategies were optimizedbyusinganNLPQLalgorithmforimprovingfuel economyandregulatedemissions,andperformanceswere improved significantly (FC: 11.5%, CO: 9.2%, HC: 13.2%, NOx: 5.6% and PM:8.1%). Optimum parameters can be selected to meet the fuel economy demand of custom and standardemissionsregulations,whicharefinallytransferred todesignobjectives[74].

In this paper, a scientific survey on hydraulic hybrid vehicle, due to their importance in reducing fuel consumption and reducing pollutants. Where the following three types parallel hydraulic hybrid System, Series Hydraulic Hybrid Systems and Power Split Hydraulic Hybrid Systems. Focused on parallel hydraulic hybrid System for ease application in practice and theory Wheretheresultsmentionedinthescientificsurveyfound to reduce fuel consumption by more than 28%, as well as reducingpollutants.

[1] S. Nawaz, J. Strobel, A. Ghafoor, Y. Lu, and V. R. Balakrishnan, “Thesis / Dissertation Acceptance,” PurdueUniv.,vol.9,p.176,2011

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

[2] T. M. Nguyen, “The University of Toledo College of Engineering,” Comp. Gen. Pharmacol., no. August, p. 2200,2009.

[3] T.Liu,X.Zhang,W.Yang,G.Fan,Y.Wang,andJ.Jiang,“A StudyonParameterOptimizationofParallelHydraulic HybridVehicle,”vol.2,no.1,pp.4426–4429,2010.

[4] I. P. Fulfillment and S. K. Molla, “SYSTEM MODELING ANDPOWERMANAGEMENTSTRATEGYFORASERIES HYDRAULICHYBRIDVEHICLEtheGraduateSchoolof theRequirementsfortheDegreeofAcceptedby:”no. May,2010.

[5] T. M. Nguyen, “The University of Toledo College of Engineering,” Comp. Gen. Pharmacol., no. August, p. 2200,2009.

[6] Amin Mohaghegh Motlagh, Mohammad Abuhaiba, Mohammad H. Elahinia, and Walter W. Olson: “HydraulicHybridVehicle”EnvironmentallyConscious Transportation,Ed,ByMyerKutz.JohnWilyInc.,2007. ISBN:978-0-471-79369-4.

[7] E.R. Toulon “Evaluation of a Hybrid Hydraulic Launch AssistSystemforuseinSmallRoadVehicles”Proc.of IEEE International Symposium on Industrial Electronics,ISIE2008,Cambridge,UK,June2008.

[8] Heggie, W. S., and R. Sandri. 1980. “An Energy Saving Hydro-Pneumatic Power Plant for the Automobile.” JournalofFluidControl12(4):1–20.

[9] Elder, F. T., and D. R. Otis. 1973. “Simulation of a HydraulicHybridPowertrain.”ASME(73-ICT-50):1–6.

[10] Hugosson, C. 1993. “Cumulo Hydrostatic Drive A Vehicle Drive with Secondary Control. In 3rd ScandinavianInternationalConferenceonFluidPower, Linkoping,Sweden.

[11] Wendel, G. R. et al. 2007. “Hydraulic Hybrid Vehicle System Panel.” In Michigan Clean Fleet Conference, Detroit,MI,USA.

[12] Heskitt, M., T. Smith, and J. Hopkins. 2012. Design & DevelopmentoftheLCO-140HSeriesHydraulicHybrid LowFloorTransitBus.

[13] Wu,P.,F.J.Fronczak,andN.H.Beachley.1985.“Fuel Economy and Operating Characteristics of a Hydro pneumaticEnergyStorageAutomobile.”SAETechnical Papers:851678.

[14] Ramachandran, R., S. S. Hiremath, and M. Singaperumal.2010.“PowerBondGraphModelingof Series Hydraulic Hybrid System.” In International Conference on Fluid Mechanics and Fluid Power, Chennai,India.

[15] Filipi, Z., and Y. J. Kim. 2010. “Hydraulic Hybrid Propulsion for Heavy Vehicles: Combining the Simulation and Engine-In-the-Loop Techniques to MaximizetheFuelEconomyandEmissionBenefits.”Oil & Gas Science and Technology – Revue de l’Institut FrançaisduPétrole65(1):155–78.

[16] Deppen,T.O.,A.G.Alleyne,J.J.Meyer,andK.A.Stelson. 2015. “Comparative Study of Energy Management StrategiesforHydraulicHybrids.”JournalofDynamic Systems,Measurement,andControl137(4):41002

[17] Soriano,F.,J.M.Moreno-Eguilaz,J.Alvarez,andJ.Riera. 2016.“TopologicalAnalysisofPowertrainsforRefuseCollecting Vehicles Based on Real Routes – Part I: HybridHydraulicPowertrain.”InternationalJournalof AutomotiveTechnology17(5):873–82.

[18] Johri, R., and Z. Filipi. 2010. “Low-Cost Pathway to UltraEfficientCityCar:SeriesHydraulicHybridSystem withOptimizedSupervisoryControl.”SAEInternational JournalofEngines2(2):505–20.

[19] Kim,Y.J.,andZ.Filipi.2007.“SeriesHydraulicHybrid Propulsion for a Light Truck –Optimizing the Thermostatic Power Management.” SAE Technical Papers:2007-24–0080.

[20] Vu,T.-V.,C.-K.Chen,andC.-W.Hung.2014.“AModel Predictive Control Approach for Fuel Economy Improvement of a Series Hydraulic Hybrid Vehicle.” Energies7:7017–40.

[21] Pundir, BP." Engine Emissions and Air Pollution" IndianInstituteofTechnologyKanpur.EngineEmission course.August.2017.

[22] Sprengel and Ivantysynova 2017. “Neural Network Based Power Management of Hydraulic Hybrid Vehicles. “International Journal of fluid Power 18(2): 79–91.

[23] Pundir, BP." Emission Standards "Indian Institute of TechnologyKanpur.EngineEmissioncourse.8/2017.

[24] Deepen,T.O.,A.G.Alleyne,J.J.Meyer,andK.A.Stelson. 2015. “Comparative Study of Energy Management StrategiesforHydraulicHybrids.”JournalofDynamic Systems,Measurement,andControl137(4):41002.

[25] Cross, M., and M. Ivantysynova. 2011. “Practical ConsiderationsforPump/MotorSelectioninHydraulic HybridVehicles.”InProceedingsofthe52ndNational ConferenceonFluidPower20112,LasVegas,NV,USA.

[26] J.D.VanDeVen,M.W.Olson,andP.Y.Li,“Development of a Hydro-Mechanical Hydraulic Hybrid Drive Train withIndependentWheelTorqueControlforanUrban PassengerVehicle,”2003.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page944

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

[27] M David Burghardt; “Engineering Thermodynamics withApplication”,ThirdEdition,1986.

[28] C. Di Lorenzo, N. Andretta, A. Rossetti, and A. Macor, “Studyandoptimizationofaparallelhydraulichybrid systemforheavyvehicles,”vol.05009,pp.1–15,2021.

[29] Pourmovahed, A., Vehicle Propulsion Systems with a Hydraulic Energy Storage: A Literature Survey. International Journal of Vehicle Design, 1991. Vol. 12(4):p.378-403.

[30] Hewko,L.O.andT.R.Weber,HydraulicEnergyStorage Based Hybrid Propulsion System for a Terrestrial Vehicle.1990.Vol.4:p.99-105.

[31] Kumar, R. and M. Ivantysynova. An Optimal Power Management Strategy for Hydraulic Hybrid Output CoupledPower-Split Transmission.inProceedingsof the ASME 2009 Dynamic Systems and Control Conference.2009.Hollywood,California,USA.

[32] Shiber, S. 1979. “Automotive Energy Management System.” In National Conference on Fluid Power, Chicago, IL, USA, 141–47. 1980. “Multi-Mode Transmission.”:USPatent4196587.

[33] Bowns, D., N. Vaughan, and R. Dorey. 1981. “Design Study of a Regenerative Hydrostatic Split Power Transmission for a City Bus.” In IMechE Hydrostatic Transmissions for Vehicle Application, Coventry, England,29–38.

[34] Kumar, R., and M. Ivantysynova. 2009. “An Optimal Power Management Strategy for Hydraulic Hybrid Output Coupled Power-Split Transmission.” In ProceedingsoftheASMEDynamicSystemsandControl Conference,Hollywood,CA,USA,299–306.

[35] Kumar,R.andM.Ivantysynova“TheHydraulicHybrid Alternative for Toyota Prius – A Power Management Strategy for Improved Fuel Economy.” In 7th International Fluid Power Conference, Aachen, Germany,2010

[36] Cheong, K. L., Z. Du, P. Y. Li, and T. R. Chase. 2014. “Hierarchical Control Strategy for a Hybrid HydroMechanical Transmission Power-Train.” In American ControlConference,Portland,OR,USA,4599–4604.

[37] Lammert, M. P., J. Burton, P. Sindler, and A. Duran. 2014. “Hydraulic Hybrid and Conventional Parcel DeliveryVehicles’MeasuredLaboratoryFuelEconomy onTargetedDriveCycles.“SAEInternationalJournalof AlternativePowertrains4(1):2014-01–2375.

[38] Macor, A., A. Benato, A. Rossetti, and Z. Bettio. 2017. “Study and Simulation of a Hydraulic Hybrid Powertrain.”EnergyProcedia126:1131–38.

[39] Ramdan,M.I.,andK.A.Stelson.2016.“OptimalDesign ofaPower-SplitHybridHydraulicBus.”Proceedingsof theInstitutionofMechanicalEngineers,PartD:Journal ofAutomobileEngineering230(12):1699–1718.

[40] Next Energy. http//www.nextenergy.org/industrial service/hybridhydraulics.asp.2008[cited2008/07/02].

[41] Ven,J.D.V.d.,M.W.Olson,andP.Y.Li.Developmentofa Hydro-Mechanical.

[42] T.O.Deppen,S.Member,A.G.Alleyne,S.Member,andJ. Meyer, “A Model Predictive Control Approach for a ParallelHydraulicHybridPowertrain,”pp.2713,2011.

[43] Dunn,H.,andP.Wojciechowski.1972.“High-Pressure Hydraulic Hybrid with Regenerative Braking.” In 7th Intersociety Energy Conversion Engineering Conference,SanDiego,CA,USA,989–95.

[44] “Energy Storage and Conversion Efficiency in a Hydraulic/Gas–Turbine Hybrid.” In ASME 1974 International Gas Turbine Conference and Products Show,Zurich,Switzerland:ASME.

[45] “EnergyRegenerationandConversionEfficiencyina Hydraulic-Hybrid,1975.

[46] Dewey, C., F. Elder, and D. Otis. 1974. “AccumulatorCharged Hydrostatic Drive for Cars Saves Energy.” HydraulicsandPneumatics:180–83.

[47] Martini, S. 1984. “The M.A.N. Hydro bus: A Drive ConceptwithHydrostaticBrakeEnergyRecovery.”In International Symposium on Advanced and Hybrid Vehicles,Glasgow,UK,27–34.

[48] Nakazawa,N.,Y.Kono,E.Takao,andN.Takeda.1987. “Development of a Braking Energy Regeneration SystemforCityBus.”SAETechnicalPapers:872265.

[49] Davies, A. S. 1987. “Fuel Economy and Emissions PotentialofaCityBus,RegenerativePowertrain.”SAE TechnicalPapers:872267.

[50] Kepner, R P. 2002. “Hydraulic Power Assist – A Demonstration of Hydraulic Hybrid Vehicle Regenerative Braking in a Road Vehicle Application.” SAETechnicalPapers:200-01–3128.

[51] Liu, G.-Q., Y.-C. Yan, J. Chen, and T.-M. Na. 2009. “SimulationandExperimentalValidationStudyonthe Drive Performance of a New Hydraulic Power Assist System.”In2009IEEEIntelligentVehiclesSymposium, Xian,China,966–70.

[52] Buchwald, P., H. Christensen, H. Larsen, and P. S. Pedersen. 1979. “Improvement of City Bus Fuel Economy Using a Hydraulic Hybrid Propulsion

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page945

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

System aTheoreticalandExperimentalStudy.”SAE TechnicalPapers:790305.

[53] Tollefson, S., N. Beachley, and F. Fronczak. 1985. “StudiesofanAccumulatorEnergy-StorageAutomobile DesignwithaSinglewithaSinglePump/motorUnit.” SAETechnicalPapers:851677.

[54] Pease,G.,andJ.M.Henderson.1988.“Simulationofa HydraulicHybridVehicleUsingBondGraphs.”Journal of Mechanisms, Transmissions, and Automation in Design110:365–69.

[55] Filipi,Z.etal.2004.“CombinedOptimizationofDesign and Power Management of the Hydraulic Hybrid Propulsion System for the 6 X 6 Medium Truck.” International Journal of Heavy Vehicle Systems 11: 372–402.

[56] Toulson, R. 2008. “Evaluation of a Hybrid Hydraulic LaunchAssistSystemforUseinSmallRoadVehicles.” In IEEE International Symposium on Industrial Electronics,Cambridge,UK,967–72.

[57] Bender, F. A., T. Bosse, and O. Sawodny. 2014. “An Investigation on the Fuel Savings Potential of Hybrid Hydraulic Refuse Collection Vehicles.” Waste Management34(9):1577–83.

[58] Bender, F. A., M. Kaszynski, and O. Sawodny. 2013. “Drive Cycle Prediction and Energy Management Optimization for Hybrid Hydraulic Vehicles.” IEEE TransactionsonVehicularTechnology62(8):3581–92.

[59] Wu, Bin et al. 2002. “Optimization of Power ManagementStrategiesforaHydraulicHybridMedium Truck.” In Proceeding of the 2002 Advanced Vehicle ControlConference,Hiroshima,Japan.

[60] BINWU,CHAN-CHIAOLIN,ZORANFILIPI,HUEIPENG AND DENNIS ASSANIS 2004. “Optimal Power Management fora Hydraulic HybridDelivery Truck.” VehicleSystemDynamics42(734):23–40.

[61] Zhang, Z., J. Chen, and B. Wu. 2012. “The Control Strategy of Optimal Brake Energy Recovery for a ParallelHydraulicHybridVehicle.”Proceedingsofthe InstitutionofMechanicalEngineers,PartD:Journalof AutomobileEngineering226(11):1445–53.

[62] Hui, S., J. Ji-Hai, and W. Xin. 2009. “Torque Control Strategy for a Parallel Hydraulic Hybrid Vehicle.” JournalofTerrmechanics46(6):259–65.

[63] Hui,S.,andJ.Junqing.2010.“ResearchontheSystem ConfigurationandEnergyControlStrategyforParallel HydraulicHybridLoader.”AutomationinConstruction 19(2):213–20.

[64] Hui,S.,Y.Lifu,andJ.Junqing.2010.“Hydraulic/electric Synergy System (HESS) Design for Heavy Hybrid Vehicles.”Energy35(12):5328–35.

[65] Yan,Y.,G.Liu,andJ.Chen.2010.“IntegratedModelling andOptimizationofaParallelHydraulicHybridBus.” InternationalJournalofAutomotiveTechnology11(1): 97–104.

[66] H.Zhou,Z.Xu,andL.Liu,“Designandvalidationofa novel hydraulic hybrid vehicle with wheel motors,”vol.103,no.1,pp.125,2020,doi:10.1177/003685 0419878024.

[67] T.Liu,X.Zhang,W.Yang,G.Fan,Y.Wang,andJ.Jiang,“A StudyonParameterOptimizationofParallelHydraulic HybridVehicle,”vol.2,no.1,pp.4426–4429,2010.

[68] M. Schumack, M. Elahinia, C. Schroeder, and W. Olson,“AC20081088:AHYDRAULICHYBRIDVEHICLESIM ULATIONPROGRAMTOENHANCEUNDERSTANDINGOF ENGINEERINGFUNDAMENTALS,”2008.

[69] Elder, F. T., and D. R. Otis. 1973. “Simulation of a HydraulicHybridPowertrain.”ASME(73-ICT-50):1–6.

[70] Elder, F. T., and D. R. Otis. 1973. “Simulation of a HydraulicHybridPowertrain.”ASME(73-ICT-50):1–6.

[71] V. Esfahanian, M. Reza, H. Yazdi, A. Safaei, and M. Esfahanian, “Design and Modeling of a Parallel HydraulicHybridBus,”no.February,2012.

[72] D. Brnčić and G. Gregov, “NUMERICAL SIMULATION STUDY OF PARALLEL HYDRAULIC HYBRID SYSTEM FORADELIVERYVAN,”vol.6168,pp.21–28,1991.

[73] T.O.Deppen,A.G.Alleyne,K.A.Stelson,andJ.J.Meyer, “Optimal Energy Use in a Light Weight Hydraulic HybridPassengerVehicle,”vol.134,no.July2012,pp. 1–11,2013,doi:10.1115/1.4006082.

[74] B.Wu,C.Lin,Z.Filipi,H.Peng,andD.Assanis,“Vehicle System Dynamics: International Journal of Vehicle Optimal Power Management for a Hydraulic Hybrid Delivery Truck,” no. October 2013, pp. 37–41, doi: 10.1080/00423110412331291562.

NeamaH. Yousef,hasBScinIndustrial Education in 2018, and acting as a researcherassistantandDemonstrator at Automotive Technology Dept., Faculty of Technology and Education, HelwanUniversity,Cairo, Egypt.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page946