International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

1M.Tech Scholar, Eklavya University Damoh M.P.

2Assistant Professor Eklavya University Damoh M.P.

3 AssistantProfessorEklavyaUniversityDamohM.P. ***

Abstract - Recycled Aggregate Concrete (RCA) is a concrete product made from recycled aggregate in whole or in part from natural aggregates. The purpose of this study is to characterizeACRandcompareit toconcretebasedonnatural aggregates2. Recycled concrete aggregate has also been described as "the most innovative development in concrete structures in decades". Not only does it conserve nonrenewable resources, it has been proven to be economically and environmentally beneficial. rice paddy. In this study, conventional grade 43 Portland cement was used, and the weight percent of recycled aggregate partially replacing natural aggregate was 0%, 10%, 20%, 30%, 40%, and 50%. Concrete blocks and columns are molded and laboratory tested. In order to determine the optimal replacement rate, mechanical property tests such as compression tests and tensiletests wereconducted. Theresultsshowthattheoptimal rateofreplacingrecycledaggregatewithnaturalaggregateis 30%. Replacing up to 30% can achieve the same strength as conventional concrete. Above 30%, the resulting strength tends to decrease.

Key Words: Workability, Compressive Strength, Tensile Strength,SilicaFume.

Today the concrete industry consumes a lot of natural resources.Thiscausesgreatdamagetotheenvironmentand homeland.Thelesscementandnaturalaggregatesusedto makeconcrete,thelessimpactithasonthe environment. Rising landfill costs and scarcity of natural resources for aggregate are driving the use of construction waste as an aggregatesource.Sustainablebuildinghasbecomeamajor concern with building practicesharming the future ofour planet.Thisisbecausetheconstructionindustryconsumesa large amount of natural resources and produces a large amount of waste. High raw material consumption in the constructionindustryhasbecomeoneofthemaincausesof environmentaldestruction,pollutionofthemotherlandand depletion of mineral resources. Over 165 million tons of natural aggregates are used in civil and industrial constructioneachyear.TheUKcurrentlygeneratesaround 109 million tonnes of construction and demolition waste. About60milliontonsofthiscomesfromconcrete.Sources ofrawmaterialssuchascoarseaggregate,sandandcement

are disadvantageous as these resources cannot cover the high demand in the construction industry. The use of recycled aggregates can therefore be one of the key initiativestoachievesustainableconstruction.

Asrecycledaggregate(RA) isincreasinglyrecognized and acceptedasaviablealternativetonaturalaggregate(NA),it is important to understand recycled concrete aggregate. HowdoesRACcomparetoconventionalconcrete?Through propermixdesignandtheintroductionofdifferentformsof aggregateanddifferent super plasticizers, itis possible to influencetheperformanceofstructuralconcreteandobtain thesamestrengthasconcrete.Ican.Correspondingnatural aggregates (NAC), or sometimes improved, where coarse aggregatesgenerallyhavesuperiorstrength,durability,and weather ability, and are free of surface impurities such as sludge,manure,andorganicmatter.Itisimportantthatthe particles are not chemically absorbed in an acceptable amount and will not affect the hydration of cement and waterandtheadhesionofcementpowder.Aggregatescan beclassifiedbyweight,rocktypeandshape

All materials used in the concrete mix are essential, but cement is often the most important as it is usually the delicatelinkinthechain.Thefunctionofcementisfirstlyto bindsandand rock togetherand secondlyto fill thevoids betweenthesandandrock particlesintoa compactmass. Althoughitaccountsforonlyabout20%oftheconcretemix volume, it is the active ingredient in binders and the only scientifically controlled concrete component. Variation in thatamountaffectsthecompressivestrengthoftheconcrete mix.Grade43ordinaryPortlandcement(OPC)wasusedfor allconcretemixesinthisstudy.

Aggregate is a matrix or primary structure consisting of relatively inert coarse particles. Coarse aggregates are mainlyusedtoaddbulktoconcrete.Theprimaryfunctionof fine aggregates is to help create a uniform, workable

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

concretemix.Thefineaggregatealsohelpsthecementpaste to keep the coarse aggregate particles in suspension. This effect promotes the ductility of the concrete mix and prevents the separation of coarse and coarse aggregates duringtransportation.Aggregatesmakeupabout75%ofthe concrete body, so its impact is very significant. The propertiesoftheseparticlesgreatlyaffecttheperformance ofconcrete.

IS: 383-1970 determines fine aggregate when passing 4.75mm IS sieve. Fine aggregates are often referred to as sand-sized aggregates. In this study, locally available riverbed sand was used. The percentage passing the 600 micron sieve is 62.35. Sand corresponds to classification zone-IIIaccordingtostandardIS383-1970.

Coarse aggregate is defined as retained by a 4.75 mm IS sieve.Coarseaggregateisoftenusedintwoormoresizesto increasethedensityoftheresultingconcretemix.Twotypes of aggregates with different sizes were used in this study. Detailsofthecontentsareasfollows.

Aggregatepassing20mmsieve

Aggregatepassing10mmsieve.

Coarse aggregate is defined as retained by a 4.75 mm IS sieve.Coarseaggregateisoftenusedintwoormoresizesto increase the density of the resulting concrete mix. Two aggregates of different sizes were used in this study. The detailsofthecontentsareasfollows.

Crushed granite with nominal sizes of 10 mm and 20 mm wereusedasnaturalcoarseaggregate.

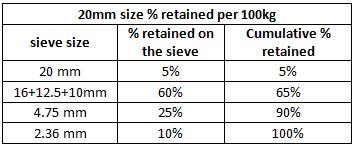

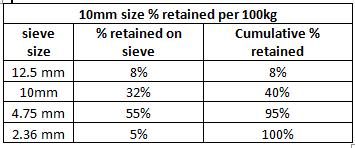

Concretewastesofthematerialtestinglaboratorywereused ascoarseaggregates.Bothnaturalandrecycledaggregates followedthesamegradingandthesameisshowninTable1 &Table2

Table-1: Cube Compressive Strength at 28 days for 20 mm Size of Aggregate

Table-2: Cube Compressive Strength at 28 days for 10mm Size of Aggregate

Thetermsmicrosilica,condensedsilicafume,andsilicafume are commonly used to describe ferrosilicon, a by-product extractedfromsiliconoff-gases.Othermetal alloymelting furnaces.However,thetermsfumedsilicaandmicrosilicic acid are used for high quality concentrated silica fumes suitableforuseinthecementandconcreteindustries.The term silica fume was used in European standards. Silica fumes were first detected in Norway in 1947 when the Environmental Protection Agency began filtering blast furnaceexhaustgases.Mostofthesefumesconsistedoffine compositionswithahighproportionofsilica.Thepozzolanic reactivity of silica has been well known and has been extensivelystudied.Over3000publicationsonfumedsilica andfumedsilicaconcrete.AASHTOM307PerASTMC1240, silica fume can be used as an additional cementation material to improve strength and durability. Silica fume consists of fine particles with a specific surface area approximatelysixtimesthatofcement,astheparticlesare much finer than cement particles. Therefore, it was found thattheporespacedecreasedwhensilicafumewasmixed into concrete. Silica fume is a pozzolana because it is reactive, like volcanic ash. Its effects include strength modulus, ductility, sound absorption, vibration damping capacity,wearresistance,porosity,strengthofbondingwith rebar,shrinkage,permeability,resistancetochemicalattack, reductionofalkali-silicareactivity,andcreeprate.,whichis related to corrosion resistance. Embedded rebar, freezethaw resistance, coefficient of thermal expansion (CTE), specific heat, defect dynamics, thermal conductivity, dielectrics.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Drinking water is generally sufficient for use on concrete. Waterfromlakesandstreams,whichareusuallyinhabited by marine life, is also suitable. Sampling is not required whenwaterisobtainedfromtheabovesources.Ifthewater issuspectedofcontainingsewage,minewater,wastefrom factoriesorcanningfactories,itshouldbeusedforconcrete unless tests give satisfactory results. Water from such sources should be avoided as low water levels and intermittenthazardouswastedischargesintoriverscanalter thewaterqualityandfiberdispersityof blendscontaining shortmicrofibers.thereis.Drinkingwaterwasusedasitwas deliveredtothebuildinglaboratoryofourresearchinstitute. Thewaterusedformixingandcuringmustbecleanandfree of hazardous levels of oils, acids, alkalis, salts, sugars, organics,orsubstancesthatcouldharmconcrete..According to IS: 456-2000, drinking water is generally considered sufficient for mixing and hardening concrete. Therefore, drinkingwaterwasusedforthepreparationofallconcrete samples.

Water-reducingandset-retardingadmixturesarepermitted inordertoincreasetheworkabilityoftheconcreteandto extendthetimeofdischargefrom60to90minutes.These admixtures are permitted and often required for superstructureconcrete.Chemicaladmixturesandmineral admixturesasdefinedbyASTMC494areasfollows:

Super plasticizer CONPLAST SP 430 is a chloride free workabilityretentionadmixturebasedonselectedorganic polymers.Designedtoprovideworkabilityretentionwhere rapid workability loss is caused by high ambient temperaturesortocompensatefordelaysintransportation. Itisparticularlysuitedtoconcretemixescontainingmicro silica.Silicafumewasusedasamineraladmixture.Itactsas afillermaterial,andgivestheearlystrengthtotheconcrete couldchangeduetolowwaterorbyintermittentdischarge of harmful wastes into stream. The water used was the potablewaterassuppliedinthestructureslaboratoryofour institute.Waterusedformixingandcuringshouldbeclean andfreefrominjuriousamountsofoils,acids,alkalis,salts andsugar,organicmaterialsorothersubstancesthatmaybe deleterioustoconcrete.AsperIS:456-2000potablewateris generallyconsidered satisfactoryfor mixing andcuring of concrete. Accordingly potable water was used for preparationofallconcretespecimens

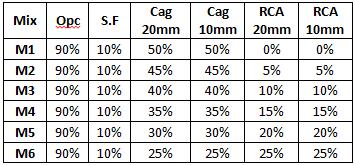

Differentquantitiesofmaterialsandthemixproportionsof thematerialsforeachmixisshowninTable3

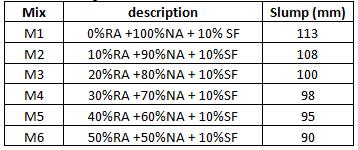

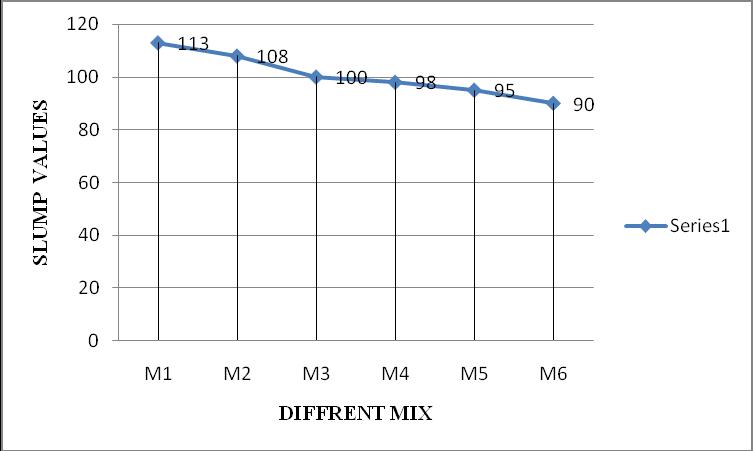

Slumptestisthemostcommonlyusedmethodofmeasuring theconsistencyofconcreteSlumptestwascarriedoutonall theconcretemixesintheconcretelaboratory.Thistestwas veryusefulindetectingvariationintheuniformityofamix ofgivenproportions.ItalsogivesanideaofWatercement ratio to be used for different mixes. Fresh unsupported concreteflowstoandsinkingintheheighttakesplace.This verticalsettlementisknownasSlump.Concreteissaidtobe workable if it can be easily mixed, compacted and easily finished. The results of all slump values of all mixes are showninTable4Theinternalsurfaceofmouldwascleaned thoroughlyandfreefrommoistureandanyconcretebefore commencing the test. The mould was placed on rigid, horizontalandnon-absorbentsurface.Themouldfilledin4 layers,eachapproximatelyonequarteroftheheightofthe mould. Each layer shall tamper with 25 strokes. After leveling the top, the mould was removed from concrete immediatelybyraisingitslowlyinaverticaldirection.This allowstheconcretetosubsideandslumpshallbemeasured bymeasuringthedifferencebetweentheheightsofmould andhighestpointofthespecimenbeingtested.

Table-4: Slump Values for Different Concrete Mixes

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

From Table 4, it can be seen that the slump value is decreasingwithincreaseintherecycledconcretepercentage inthemix.Thisis becausetherecycledaggregatesabsorb more water than the normal aggregates because of the presenceofdustandthemortaronthesurfaceofrecycled aggregates. All slump values were maintained in between 90-110mmbyvaryingthedosageofsuperplasticizer.

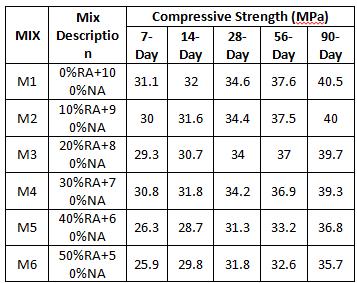

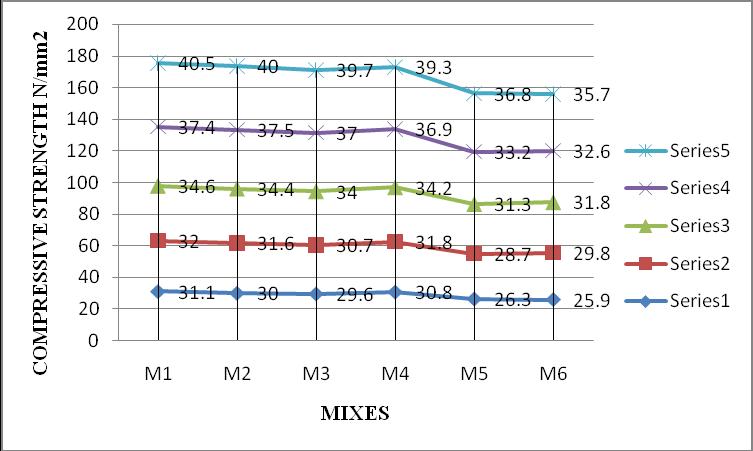

Cubesofsizes150x150x150mmwerecastforstrength testing.Thesecubeswerecuredfor7,14,28,56and90days andtestedinCompressiontestingmachinehavingacapacity of200T.Thespecimenswereallowedtodryinsunlightfor1 dayandareplacedcentrallyinthetestingmachineandthe loadwasappliedcontinuously,uniformlyandwithoutany shock. Mixes cured at different ages are presented and discussed in this section. The compressive strength test resultsofallthemixesatdifferentcuringagesareshownin Table–5.Variationofcompressivestrengthofallthemixes withcuringageisshowninFig.–2

Fromtheabovetestresultsandthegraphicalchangesshown in Table 4.4 and Figure 4.2, it was observed that the split tensilestrengthresultsforM2,M3andM4werecomparable to mixture M1. This shows that the split tensile strength results of recycled aggregate concrete with 30% replacement of natural aggregate with recycled aggregate show the same value compared to normal aggregate concreteorconventionalconcrete.After30%exchangei.H. With 40% and 50% substitution of NA for RA, there is an irregular behavior in the values of the cleavage tensile strength.Thepercentstrengthlossfromthe0%RAblendto the30%RAblendwas5.01%.Fromtheabovetestresults andthechangesinthegraphsshowninTable4.4andFigure 4.2,itwasobservedthatthecleavagetensilestrengthresults ofM2,M3andM4werecomparabletoblendM1.Thisshows thatthesplittensilestrengthresultsofrecycledaggregate concrete with30% replacementof natural aggregate with recycledaggregateshowthesamevaluecomparedtonormal aggregate concrete or conventional concrete. After 30% exchange,i.e.

The greater water absorption capacity of recycled aggregatehasalargeeffectonthewateraddedtothe mix,whichcanaffecttheworkabilityoftheconcrete.

Up to 30% same compressive and tensile strength as conventionalconcretecanbeachievedreplacingnatural aggregatewithrecycledaggregate.Butaccordingtothe overall study, the values of compressive strength and fractional tensile strength decrease with increasing substitutionofrecycledaggregate

Increasingtherecycledaggregatecontentbeyond30% hasaneffectnegativelyonthecompressivestrengthof recycled aggregate concrete. The reduction in compressivestrengthafter28daysisabout10%when using50%recycledaggregate.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Separation tensile results also show a tendency to decreasecompressivestrengthbeyond30%replacing recycledaggregate.

The pore filling capacity of silica fume improves the mechanical properties and durability of recycled aggregate concrete. The use of silica fume to partially replacecementreducesthewaterabsorptioncapacityof recycledaggregateconcrete.

[1]AASHTOM307ASTMC1240.“StandardSpecificationfor Silica Fume Used in Cementitious Mixtures”, American Society for Testing and Materials, Annual Book of ASTM Standards, Volume04.02, West Conshohocken, Pennsylviania.

[2]Ajdukiewicz,A.,andKliszczewicz,A.(2002).Influenceof recycledaggregatesonmechanicalpropertiesofHS/HPC, 24,269–279.

[3]Asamoah,M.,andAfrifa,R.O.(2010).Astudyofconcrete propertiesusingphylliteascoarseaggregates.Materialsand Design,31(9),4561–4566.

[4] ASTM standards C 1585-04 "Standard test method for measurementoftherateofadsorptionofwaterbyhydraulic cement concrete", American Society for Testing and Materials, Annual Book of ASTM Standards, Volume04.02, WestConshohocken,Pennsylviania.

[5]BritishStandard,BS1881-208:1996“Recommendations for the determination of the initial surface absorption of concrete”,BSI389ChiswickHighRoadLondonW44AL

[6]BritishStandard,BS812series,“Describesmethodsfor determiningtheflakinessindexofcoarseaggregate”,BSI389 ChiswickHighRoadLondonW44AL

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal