International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

1MTech Student Civil Engineering Dept. Jain college of engineering Belagavi, Karnataka, India 2Asst Prof. Civil Engineering Dept. Jain college of engineering Belagavi, Karnataka, India ***

Abstract - There is a huge demand for natural materials due to this scarcity of materials happenings. Many researchers worked on replacement of materials in concrete to construct eco-friendly and cost-effective building. Recently researchers worked on this and come with some materials like GGBS, Fly ash, Lime etc. here, an attempt is made to fly ash as partial replacement material with the application of polypropylene and steel fibres in it with different proportions. In this paper obtained experimental results are discussed and tabulated the same. Conclusion of this paper is, we can replace cement by fly ash and fibres enhances the strength property.

Key Words: Fly-ash, Polypropylene fibre, Steel fibre, propertiesofconcreteetc.

Concreteisbrittleandmoderatelyrobustincompressionbut weakintension.Itsusehasbeenlimitedduetothesetwo flaws.Theconcentrationofsilica,calcium,andironinthefly ash can be used to classify the FA. Category C fly ash developsasolidmaterialinthepresenceofwater,andafter aperiodoftime,itgainsstrength.Ingeneral,CategoryCFA containsmorethan10%lime(CaO).ClassCFAcontainsalot ofalkaliandsulphate.(SO4).ThisFAispozzolanicinnature andincludeslessthan5%lime(CaO).Flyashisprimarily keptincoalindustriesanddischargedinlandfills.[1]used flyashaspartialreplacementofcementup-to25%withthe application of fibre. fibrous by incorporating 1.5% Polypropylene fibreinto concrete Givinggood resultsand givinglessresultin2%fibreisaddedtotheconcrete[2].FA willincreasetheconcrete'stoughness.Inordinaryconcrete, flyashservesasnon-air entertainment [3]. theconcrete's compressive strength reinforced with 1.5 % mixed polypropylenefibresincreasedby17%.Splitconcretehasa 22%increaseinsplittensilestrength,24%increaseinsplit flexuralstrength,aswellasan11percentdecreaseinsplit elasticmodulusoverordinaryconcrete[4].Theshrinkage propertyofconcretewasstudiedby[5]andhasgivenfuture scope to study the, mechanical properties of concrete. However,inthisstudy,testinvestigationswerecarriedout toseehowreplacingcementwith20%flyashandadding1.5 %polypropyleneandvaryingproportionsofsteelfibres(0.5, 1, 1.5, and 2 % by volume of concrete) affected the workability,strength,anddurabilityofM30concrete.

2.1 Cement: ThecementemployedinthisstudyisJKSuper cement of 53 grade OPC, which complies with IS code IS: 12269-2013.

Fig 1: Cement.

Table 1: Cement properties. Sl. No Particulars Test outcomes

Brand JKSuperCement

Sp.Gr. 3.18

Initialsettingtime 40minutes

Finalsettingtime 125minutes

Finenesstest 5.00%

The coarse aggregates are made from crushed BasaltrockandcomplywithIS:383.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Fig 2: 20mm Size Aggregate.

Table 2: 20mm aggregate properties.

Particulars GGBS Sp.Gr. 2.67 Waterabsorption 0.38% Shape Angular Finessmodulus 3.49 Confirmingtotable2ofIS 383:1970 20mm

2.4 Fine Aggregates: Sandismadeutilizingarock-on-rock crushingprocedurethatemploysstate-of-the-artplantand machinerywithcutting-edgetechnology.IS:480sieveshave beenusedtocollectriversand.

Fig 4: Fly-Ash

Table 4: Fly-ash properties

Characteristics Fly Ash % Specificgravity 2.1 Fineness 3% Silica 62 Al2O3 23 Cao 5

2.6 Super Plasticizer: Super plasticizers utilized in the currentstudytoimprovetheworkabilityofconcrete.

Fig 3: Fine aggregate.

Table 3: Properties of Fine aggregate.

Properties Sand Sp.Gr. 2.64 FinenessModules 2.88 Waterabsorption 1%

2.5 Fly-Ash: FAisutilisedtoreducethecostofPCC while also improving its performance. FA to Portland cement replacementratiosrangefrom1:1to1.5:1.Lowcalcium,low silicacontentclassFdryflyashfromR.T.P.Ssilosadhering toIS:3812(Part1)-2003wasemployed

Fig 5. Super plasticizer

2.7 Polypropylene Fibre: Polypropylene (PP) is a thermoplasticpolymerthat isutilized in a several uses or widerangeofapplications.

Fig 6: Polypropylene fiber

value:

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Table 5: Physical Properties of PP (As per test report).

SL.NO Properties Dimensions

1 Length 6mm 2 Diameter 10mm

2.8 Steel Fibre: The fibres utilised are hooked end fibres with the parameters shown below, as provided by the manufacturer.

Fig 7. Steel fibre

Table 6: Properties of Steel fibre

Sl. No Property Values

1. Length,Lf 30mm 2. Df 0.6mm 3. AspectRatio, 50 4. Vf 0.5%

2.9 Water: Normal water is used for experimental works having IS standard pH. The concrete mix is mixed with potablewater.pHlevelsshouldbeintherangeof6to7.

Basicjournalsarefollowedtolookforwardforcollectionof materialsandfollowedbytestsconductedonfuturescopes suggestedbyresearchers.Here,investigationswerecarried out to see how replacing cement with 20% fly ash and adding1.5%polypropyleneandvaryingproportionsofsteel fibres(0.5,1,1.5,and2%byvolumeofconcrete)affected theworkability,strength,anddurabilityofM30concrete.

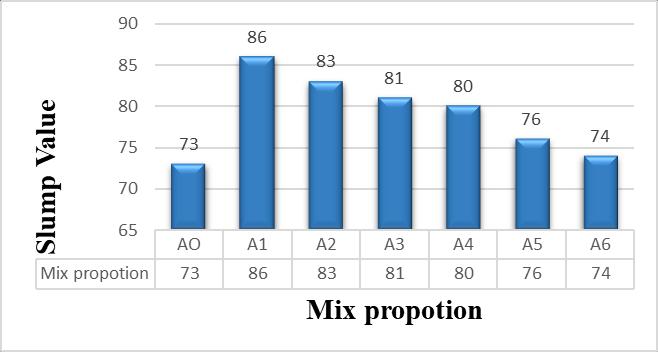

ThistypeoftestingwasusedinaccordancewithIS11991959.

value:

Table 7: Slump test results.

Mix Proportion Sample 1 (Slump)

AO 73

A1 86 A2 83 A3 81 A4 80 A5 76

When20%ofthecementintheconcreteisreplacedwithFA, the workability of the concrete improves compared to regularconcrete.Aftera20%partialreplacementofcement byFAresultsinaslump,theworkabilityofamixtureof1.5 %polypropylenefibresandincreasing%agesofSteelfibres steadilydecrease(0.5,1,1.5and2%).

The objective is to find the Compressive Strenght of the concete for 7, 14 and 28 days and Cube mould (150 X150mm),tampingrodeandCtmmechinearerequiredto performthistest.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Fig. Compressive testing

Tab. 8: Compression test results

Mix Proportion

7 days strength 14 days strength 28 days strength N/mm²

AO 31.54 38.89 44.56

A1 30.07 36.59 43.41 A2 30.81 36.86 46.84 A3 31.82 38.41 47.61 A4 33.04 39.73 48.99 A5 30.24 37.87 43.29 A6 28.03 32.49 41.69

The compressive strengths of hybrid fibres reinforced concretegeneratedbyreplacingcementwith20%FAand adding1.5%polypropylenefibrestogetherwith1%steel fibresarefoundtobethegreatest(MixProportionA4).Asa result,evenatlowwatercontent,theconcreteachievesgood bondingstrengthandstrength.

Thistestwasconductedtoexaminethesplittensileproperty ofcylinderspecimen.Andthetestwasconductedfor7and 28 days of curing period, obtained results are tabulate below,

Fig 11. Split tensile test

Tab. 9: Split tensile results

Mix Proportion

7 days strength 28 days strength N/mm²

AO 2.69 3.8

A1 2.4 3.2

A2 2.83 4.02

A3 2.94 4.05

A4 2.99 4.18 A5 2.63 3.72 A6 2.42 3.5

The highest value is found in the SPT strength of hybrid fibresreinforcedconcretegeneratedbysubstitutingcement with 20% fly ash and adding 1.5 % polypropylene fibres together with 1% steel fibres (Mix Proportion A4). As the amount of steel fibre combined with polypropylene fibre increases, the split tensile strength decreases. With the additionof1.5%polypropylenefibresand1%steelfibres, the split tensile strength is 4.18 at 28 days and 2.99 at 7 days,basedonthenumberofdaysasareference.

Theflexuraltestwasconductedfor7and28daysofcuring onbeamofsize700x150x150mm.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Fig 12. Beam casting

Tab 10: Flexural test results

Mix Proportion

7 days strength 28 days strength N/mm²

AO 3.38 4.44

A1 3.08 4.33 A2 4.21 5.81 A3 4.09 5.33 A4 4.62 6.04 A5 3.73 5.21 A6 3.44 4.92

FLX strength of HFRC made by substituting cement with 20% fly ash has been found to be higher when 1.5 % polypropylene fibre and 1% steel fibre are added. The % increase in Flexural strength after adding 1.5 % polypropylenefibreand1%steelfibreis6.04at28daysage strengthand4.62at28daysagestrengthcomparedtothe referencenumberofdays.Flexuralstrengthisreducedwhen steelfibresareaddedinexcessof1%combinedwith1.5% polypropylenefibres.

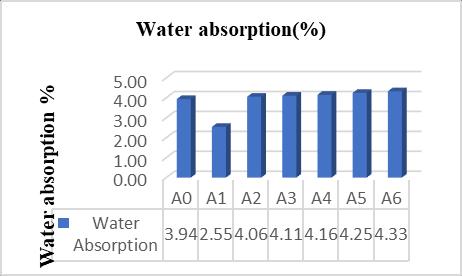

Thetestwascarriedouttoseehowmuchwaterisabsorbed byconcretewhenitisreplaced20%partialreplacementof cementbyFAresults

Whenconventionalconcreteiscomparedtoconcretemade with 20% fly ash in water absorption experiments, the maximumamountofwaterabsorbedislargerfortraditional concrete.Whencomparedtoflyashconcrete,hybridfibre reinforcedconcretehasahigherwaterabsorptionrate.Due tothevacanciesgeneratedbythehybridfibres,thisisthe case.

When 20% of the cement is replaced by fly ash, the concrete'sworkabilityimprovesby20%comparedto standard concrete. The workability reduces as the proportion of fiber increases, as evidenced by the resultsofaslumptest.

Thehybridfibercombinationof1.5%polypropylene fiber and 1% steel fiber achieves the highest compressivestrength.Thecompressivestrengthofthe concreteis33.04,39.73and48.99N/mm2after7,14, and 28 days, respectively, which is higher than traditionalconcrete.Asaresult,theA4mixproportion isthebestmixproportion.

Insplittensilestrength,hybridfibercombinationswith 1.5 % polypropylene fiber and 1 % steel fiber have higher split tensile strength values of 2.99 and 4.18 N/mm2for7and28days,respectively.

Flexuralstrengthvaluesof4.62and6.04N/mm2for14 and 28 days were observed for hybrid fiber combinationsincluding1.5%polypropylenefiberand 1 % steel fiber. The fibers serve a crucial function in improvingthebeam'sbendingstrength.

Inawaterabsorptiontest,thehybridfibercombination of 1.5 % polypropylene fiber and 2 % steel fiber absorbsthemostwater(A6).

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

[1] A.M Shende, A.M Pande, M.Gulfam Pathan “EXPERIMENTAL STUDY ON STEEL FIBER ON REINFORCED CONCRETE FOR M-40 GRADE”, International research journal of engineering and Science,Vol-1,Sept-2012.

[2] Avinashjoshi,Pradeepreddy,PunithkumarandPramod hatker “EXPERIMENTAL WORK ON STEEL FIBER REINFORCED CONCRETE”International Journal of Scientific&Engineeringreserch,Volume-7,Octomeber2016.

[3] Ch Saketh M. Manoj “STATISTICAL ANALYSIS OF POLYPROPELENE FIBER REINFORCED CONCRETE”,InternationalJournalofAdvancedreserch ideasandinnovationstechnology,Vol-3,2017.

[4] Divya SDharam,AswathyLal“STUDYOFEFFECTOF POLYPROPYLENEFIBERINCONCRETE"International researchjournalofengineeringandtechnology,Vol-3, june2016.

[5] MilindV.Mohod“PERFORMANCEOFPOLYPROPYLENE FIBER REINFORCED CONCRETE” IOSR Journals of MechanicalandCivilengineering,Vol-12,Feb-2015.

[6] NavileshJ,RahulBK,ShankarB.K,Shivakumarpatil“A STUDY OF HYBRID FIBER REINFORCED CONCRETE”,International research journal of engineeringandtechnology,Vol-4,June-2017.

[7] Prof., Dr. Hamed M. Jassim, Dr.Abdulkader G. Anwer “EXPERIMETAL STUDY ON POLYPROPYLENE FIBER REINFORCEDCONCRETE”InternationalJournalofR&D in engineering science and management,Vol-4, July2016.

[8] Rudraswamy M P, Dr. B.R Patagundi, Dr. K.B Prakash “ON INVESTIGATION OF SHRINKAGE CHARECTERISTICS OF HYBRID FIBER REINFORCED CONCRETEPRODUCEDBYUSINGFIBEROFDIFFERENT ASPECT RATIO”International Journal of Advanced reserchinengineeringandtechnology,Vol-11,2020.

Mr.JainulHabidPNReceivedtheBEin civil Degree from ACS College of engineering Bangalore in the year of 2020andcurrentlypursuingMTechin ConstructiontechnologyinJaincollege of engineering Belagavi, Karnataka, India.

Prof. Mahaboobali Nadaf received BE CivildegreeandMTechdegreeinCAD StructuresfromSDMCollegeofEngg.& Technology,Dharwad.Hehas2Years of Professional experience as site engineer, 6 Years of Professional experienceasPlanningengineerand6 Years of Professional experience in Teaching. He is Presently working as AssistantprofessorinCivilengineering department in Jain College of Engineering,Belagavi.