International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

1Master of Technology in Civil Engineering, Lucknow Institute of Technology, Lucknow, India

2Assistant Professor, Civil Engineering, Lucknow Institute of Technology, Lucknow, India ***

Abstract - Foam is unambiguously entrained in the significantbasedslurryormortarthatisproducedatadensity of 400 kg/m3 to 1950 kg/m to create Cell Light Weight Concrete (CLWC), a design material exhibiting features of cement. CLWC is appropriate material, despite its strength beingexceptionallylesswhendivergedfromtheconventional concretehowevercanbeusedintheplanswhicharepresented tonon-loadbearing,astherehasbeenawidespreadneedfora construction material that transports successfully in the future. The packaging wall and its heat-shielding properties makeitusefuleveniftheyare notcentraltotheproductitself; thisissosincetheproductislessheavythanaverage. Because ofitsweakness,materialssuch asflyflotsamandjetsam,silica fume, etc. are added to the CLWC during construction. Inadequate knowledge of CLWC's features and security has severely restricted its applications. Concrete, fine amounts, coarseaggregates,silicaseethe,flyrubbishasadmixtures,and aluminumpowderasanairentrainingexpertareallrequired to develop lightweight concrete. Silica haze and fly rubbish completely change the mix's explicit qualities. Lightweight concrete has compressive and flexural strengths that are on par with those of regular concrete. The primary benefits include a lesser need for dead weight, which may lead to increased production rates and lower costs in handling and transport. In the grand scheme of things, it will be seen as a crucial and flexible material in development right now. The uses include, but are not limited to, multi-story homes and floors, prestressed ranges, section walls, building tops, and a great many other components. Compressive strength, water absorption, the thickness of valuable materials, and using water content to provide necessary cohesiveness between water and cement are among the most notable features of lightweight concrete. It maintains consciousness despite exposure to massive gaps and dramatic changes in scenery. Excessive water use may cause significant run-off from aggregates toward the film layer, which can weaken the structure.

Key Words: Foam, Fly ash, Silica, Cellular Lightweight Concrete,Cement.

Theproductionofconcreteentailscombiningsand,water, and concrete following a predetermined ratio, with the assistance of hardening the mixture unpredictably. These

three components will always be combined in this exact proportion.Concretemaybeusefulinensuringtheeffective completionoflarge-scaleconstructionprojects.Tobemore specific, when a greater portion of these substances are mixed to form a mass that could be poured to incline towardsdesignorworkspacework,thistakesplacewiththe assistanceofutilizingthereactionofconcreteandwaterand various components within side the all to form solidified concrete.Thistakesplacetoformasolidifiedconcretemass. To put it another way, when a bigger fraction of these ingredients are mixed to produce a mass that might be pouredtoslanttowarddesignorworkstationlabor,thisis referredtoas"pouring."Totalsandwaterhavethepotential toexertsomecontroloverthesignificancebymodifyingor solidifying it with the appropriate components or admixtures,respectively.Thiswouldhavetheaddedbenefit ofbringingtheexcellentandvariousconnectedpropertiesof thesignificantbackuptodate.Totalsandwaterwouldalso have the potential to exert some control over the signs themselves.Cement-basedhousingrequirestheuseofthe component that must be kept in mind for mixing. This component is highly vital for the building of dwellings. Additionally, the Cellular Lightweight cement (LWC) itself implies "fragile in weight," which may be normally in a generalsenselessinaddedweightandisconsistently20% to 40% lighter than the regular weight concrete. This is becausetheLWCismadeofadifferenttypeofmaterial.This is because the LWC is constructed using a unique kind of material, which accounts for the difference. This is a significantadvantagethatshouldnotbeignored.Theusage oflightweightcement,whichisexhibitedasamajorkindbut issensitiveinweight,minimizestheamountofweightthatis considered to be sluggish. Although lightweight cement is displayedasasignificantkind,itissensitiveinweight.This isbecauselightweightcementisdelicateintermsofweight yet is considered to be an important kind. The particular componentsthatareusedtomakelightweightcementmay varybasedontheareaorlocationandthesourcesthatare available in that place. This may be the case because the precisecomponentsusedtomakelightweightcementmay vary.Becausethesourcesthatareaccessibleinthatareaare subject to change, this can be the case. The three most essential head substances for increasing the usage of lightweight concrete are lightweight coarse total, air entraining informed authority, and admixtures. The term "lightweightcoarsetotal" refersto thekindoflightweight aggregatethatwillbediscussedhere.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

It is a common misunderstanding that these components become inert or dormant after they have been combined withappropriatedevelopmentconcrete;however,thisisnot thecase.Materialslikeascrushedshakes,rock,andsandare examplesofthiscategory;theyareoftenemployedinstead oftotalsthatexistnaturallyintheenvironmentthroughout the building process. Cement is normally made up of anywherebetweenseventy-fiveandeighty-fivepercentofa componentwhichisknownasafullcomponent.Inaddition to its form and size, the presence of toxins, its capacity to survive being pounded, and the quantity that is assessed mayallplayaroleindeterminingthequalitiesofcement.

look out for them may reasonably anticipate discovering. TheUltra TechCement ofthe43grade OPCisusedin the preparation of the cast areas of strength for the sample. Concretesthatisdrivenbywaterandconcretesthatarenot drivenbywaterarethetwouniquecategoriesthatmaybe usedtoclassifycementmaterials.Theseclassificationsare based on the distinct coagulation and crystallization mechanisms that are inherent to each kind of concrete. Concretesthatare beingpushedbypressureandare now setting and hardening are said to concentrate hydration responses,whichmeansthattheywantwater.Ontheother hand,non-water-drivenconcretesessentiallyreactwithgas and may simply set when exposed to air. This kind of concreteisnotdrivenbywater.

In the process of mixing concrete, key mixtures may have admixturesaddedtothem.Admixturesareatypeofmaterial thatmaybeaddedtokeymixtures.Thisadditionisonlya smallpercentageofthetotalmassofconcrete.Whenmixed withthecustomaryhugecombinations,thisisdonetocreate agenuinelyastoundingdifference Eventhoughthemethod of developing admixtures may be inorganic and conventional,theattributesthatareproducedforthemare in no way comparable to those that are developed for minerals.Itisboththebeginningandtheconclusionofthe procedure,aswellasacriticalcomponentforthelargestill additionofintegratingresponsibilitiestoraisethecement's multiplequalities.Additionally,itisasignificantcomponent of the process. Because of the substances that they are associatedwith,theadditivesarefrequentlyreferredtoby namessuchaswater-reducing,water-preventing,speeding up, water-preventing and speeding up, water-diminishing andspeedingup,andsuperplasticizer.Thesenamesareall derived from the features that the additions confer to the material.

Concrete is by a significant margin the most important componentofcement;inthesensethatitmovestowardthe functionoftheenclosingvehicleforthevariousornamental aspects.Concreteisthemostessentialcomponentofcement. Concrete will be made up of concrete in addition to other solidcomponentsthataregeareduptotakeonthechallenge offusingparticlesofrobustmattertoproduceasomewhat weighty mass. Their primary function is to bind the fine (sand)andcoarse(cornmeal)materialparticlestogether; consequently, their constituents are calcareous concretes thatincludemixturesoflimeastheirprimarycomponent. Becausetheirprimaryfunctionistobindthefineandcoarse materialparticlestogether,theirconstituentsarecalcareous concretes.Thevastbulkoftheimportancemaybeattributed toregularPortlandcement(OPC).OrdinaryPortlandCement may be found in the following grades: 33 Grade (IS269:1989), 43 Grade (IS8112:1989), and 53 Grade (IS12669-1987).The43-Gradeconcretesare,forthemost part,thetypesofthingsthatalmostanybodywhokeepsa

The garbage that is collected electrostatically or directly fromtheexhaustgasesofcoal-finishedpowerplantsisoften referredtoascrushedfueldebris.Thiswastealsogoesby thenameofcrushedfueldebris.Thefakepozzolanathatis seenmostcommonlyismadeupofcrushedfuelwaste.The particles of fly trash are spherical and have an extraordinarilyhighfineness:themajorityoftheparticles have an evaluation between 1 micrometer and 100 micrometers,andthespecificsurfaceareaofflyjunkisoften statedintheregionof250to600m2/kg.Flydebristhathas beengiventheclassificationofClassCisconsideredtobea high-limewaste.Thistrashcomesfromlignitecoalandmay have a lime percentage that is as high as 24 percent. Depending on the amount of time that has passed, the compressivestrengthofflyashmayvaryanywherefrom7.1 MPato47.5MPa.Thiscanhappenanywherefromonedayto threehundredsixty-fivedays.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

severalfactors,includingthecorrectvolumes,proportioning, and mixing of the elements, as well as the collection, transporting, and setting of those ingredients. It has been foundthatthewater-significantlevelplayskeypartsinthe essentialcombination,strength,settingtime,andusefulness of the large. [Citation needed] [Citation needed] The less water and temperature that is utilized during the setup process, the more advantageous and expedient it will be fromtheverybeginning.Thewater-significantdegreesthat fallbetweentherangeof0.45and0.5aretheonesthatare usedthemostoften.

In many instances, it is the delayed appearance of large materialsthathavealreadybeguntoharden.Inotherwords, itisadelayedappearance.Pozzolanawasthenamethatwas firstgiventothissubstancewhenitwasoriginallydescribed. Inadditiontothis,itisadvisedasbeingmoremoderatethan regularsilicasmokeorcementedsilicasmoke,anditisthe ultimateresultofthedevelopmentofsiliconandferrosilicon compoundsfromhigh-moderatequartzandcoalinlowercurve electric heaters. In addition to this, it is advised as beingmoremoderatethanregularsilicasmokeorcemented silicasmoke,anditistheultimateresult.Inadditiontothis, it is recommended since it is considered to be milder in comparison to regular silica smoke or cemented silica smoke.Thefollowingamountsofsilicaconcentrationare,in general, reflective of normal silica levels: silicon metal includes94–98%silica,whileferrosiliconhas90%silica.13 In the majority of instances, the specific gravity of silica seetheissomewhereinthe neighborhood ofaround2.20; nevertheless, it is possible for the specific gravity to be significantlyincreasedifthereisamuchsmallerquantityof silicapresent.

Afterallofthenecessaryproduction,andauditshavebeen carriedout,apersonmaygetahigh-qualityandreasonably pricedbasiccomponentthatislightinweightandisreferred toaslightweightcementbyaddingadmixturessuchassilica smokeandflyash,forexample.Ifallotherpossibilitieshave been investigated and ruled out, a correct proportioning blendingofconcrete,sand,silicasmoke,aggregates,andFly garbage bin may be used to produce high compressive mettle.Itwillhaveasmallerdeadstoreinthecenterportion, higher resilience to fire and strength, and a cheaper total costwhencomparedtonormalcement.Additionally,itwill be stronger. The severe nature of concrete is a result of

Fortheblocktest,twodistinctsortsofmodelsareused,each ofwhichhasconsiderableareasofstrengthforeither150x 150 x 150 mm or 100 x 100 x 100 mm, depending on the dimensions of the whole object. For this evaluation, solid forms with dimensions of 100 millimeters on each of the three axes are employed. After seven days of lightning, twenty-eightdaysofrestoring,andfifty-sixdaysofrestoring, themodelsareputthrougha pressuretestingmachineso that they can be examined more thoroughly. The bearing surfacesofthetestingmachinewillbecleaned,andanyloose sandorotherdebriswill beremovedfromthesurfacesof themodelthataregoingtobeincontactwiththepressure plates. In addition, the bearing surfaces of the testing machine will be cleaned. The model must be organized in suchawaythattheheapisappliedonthechatsidesofthe significantregionsofstrengthfortheascast.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Thetestshouldbebasedonthemodelthatwascreatedafter themitigatingconditionwaseliminated.Thiswill prevent surface drying, which can lead to a reduction in flexural strength.Placethemodelonthestackingfocuses.Thehandcompletedsurfaceofthemodeloughtnottobeintouchwith stackingfocuses.Thiswillassuregoodcontactbetweenthe modelandstackingpoints.Centrethestackingframework like the applied force. Bring the block exerting force in contactwiththemodelsurfaceatthestackingplaces.Using loadsthatarebetween 2and6percent ofthe insaneload that was calculated. Using leaf-type sensor gauges with a lengthofatleast25mm,determinewhetherornotanygap betweenthemodelandthestoreapplyingorsupportblocks is more important or not for each of the gauges. These gaugeshaveadiameterof0.10mmandathicknessof0.38 mm.

ranges anywhere from 20 to 40 percent lighter. This propertyoftenaccountsforthebulkofthedecreaseinadded weight,whichiswhytheword"lightweight"relatestothe material'sintrinsicqualityofbeing"lowinweight."Theterm "lightweightconcrete"referstoanessentialkindofbuilding materialthatislightinweightandgetsridofexcessweight inthismanner.

Normal (Mix 1) Mix 2 Mix 3

Figure-04: Flexural Strength

One of the key criteria that helps to identify cellular lightweightconcreteistheadditionalweight,whichisalso referredtoastheself-weightofthematerial.Becausefoam was present, there were fewer important forms to begin with, which in turn led to a decrease in the quantity of concrete that was necessary to produce those forms. In additiontothis,theuseofadecreasedlightweightcomplete has a sizeable impact on the quantity of concrete that is essentialfortheproductionofthoseforms.

Theweightdifferencebetweenordinaryweightconcreteand cell lightweight concrete, also known as LWC, generally

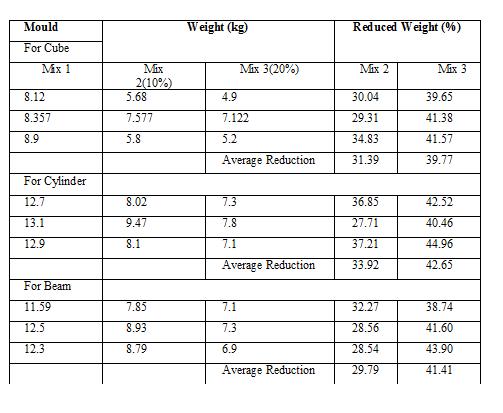

Ithasbeensuggestedthatbecauseblends2and3eachhave 20%offoamaddedtothem,theprocessofaddingthefoam shouldbedoneintwodifferentsteps.Whencomparedtothe regular or standard significant mix, it was shown that lightweight concrete had a reduction in self-weight that variedfrom30.9%to33.92%and29.79%.

The goals of this endeavor are to reduce the quantity of unused extra material, minimize the pressure that is imposed on an arrangement, make it easier to set up and maintain, make progress more swiftly toward new development,andattainahighcompressivestrength.When the appropriate quantities of concrete, sand, silica smoke, aggregates, and flying debris are combined in the appropriateproportions,theycanimparthighcompressive stresstotheessential.Itwillstrengthentheresistancetofire andstrengthwhileminimizingthedeadheapofthecritical area,andwhencomparedtoregularcement,itwillbemore cost-effective than regular cement. Concrete's zones of strength are produced by utilizing suitable aggregates, followingtheproperproportioningandmixingprocedures, bringingtheconstituentpartstogether,andtransportingand setting them. It has been found that the ratio of water to cementplaysasignificantpartintheprocessofformulating thecriticalmix,inadditiontohavingasignificantimpacton

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

thevalue,settingtime,andstrengthoftheconcrete.Inmost circumstances,celllightweightconcreteisanalternativeto normalcementthatislighterinweight.Foamisrequiredfor themanufacturingprocess,andbetween10and20percent of silica smoke and fly, trash is incorporated into the materialthroughouttheprocess.Mix2hasatotalof10%of thesignificantweightcontributedbyadmixtures,whereas Mix3hasatotalof20%ofthesignificantweightcontributed by admixtures. This is because silica smoke and fly litter each contribute 10% and 20% of significant weight, respectively.Inthisapproach,Mix2resultsinalowstarting settingtime,quickacquisitionofcompressivestrength,more noticeableweakness,andamazingcomfortwhencompared toMix3.Inaddition,thebeginningsettingtimeofMix2is muchshorter.ThisisbecauseMix2hasagreaterquantityof admixtures that are significantly contributing to the substantial, and silica smoke and fly trash are both acceleratingadmixtures.

1. M.Awana&C.Kumar.(2017).ManishAwanaandCK. No Title. Int Conf Emerg Trends Eng Technol Sci Manag Cell Light Concr 241–246

2. Selvaprasanth P, Kumar SM, Indumathi M. DEVELOPMENT OF LIGHTWEIGHT CONCRETE USING PUMICE STONE. Int Res J Eng Technol Publishedonline2008.AccessedAugust30,2022. www.irjet.net

3. S. Nandi, A. Chatterjee, P. Samanta, & T.Hansda (2016). No Title Cellular Concrete & its facets of application in Civil Engineering. Int J Eng Res http://www.ijer.in/ijer/publication/v5si1/09.pdf

4. A.Bhosale,N.Zade.P.,Sarkar,P.,&R.Davis.(2020). Mechanical and physical properties of cellular lightweightconcreteblock masonry.Construction andBuildingMaterials,248,.

5. A.Gupta. & M.Rathore (2016). No Title.” ComparativeStudyandPerformanceoflightweight concrete. Int Interdiscip Conf Eng Sci Manag December, 228–232.

6. H.Hansika . & A.Nanayakkar. (2019). No TitleInvestigation on Properties of Cellular Lightweight Concrete Blocks with Bottom Ash. MERCON 2019. Proceedings, 5th Int Multidiscip Moratuwa Eng Res Conf 424–429 https//doi.org/101109/MERCon20198818756

7. D.Jain,A.K.Hindoriya,.,&S.S.BhadauriaSS(2019). No Title Evaluation of properties of cellular light weight concrete. AIP Conf Proceedings, 2158(September).

https://doi.org/10.1063/1.5127158

8. Pravin.(2015)\.NoTitleAnInvestigationonFoam ConcreteWithQuarryDustReplacementforFiller inMixDesign".13(1),570–581. Journal,I,TechnolE, Sci C, B

9. R.Karolina., &Y.G.C. Sianipar (2018). No Title The utilization of stone ash on cellular lightweight concrete. OP Conf Ser Mater Sci Eng

10. S..Raees,G.M.Shahid,S.AyyanM.S.,Anas,P.A.Hafiz &AA(2008).No Title. Cell Light Weight Concr Int Res J Eng Technol. ”, 3212, 3212–3216. www.irjet.net

11. M.A. Rasheed & SSP (2018). No Title Behavior of hybrid-synthetic fiber reinforced cellular lightweight concrete under uniaxial tension –Experimental and analytical studies. Construction and Building Materials. https://doi.org/10.1016/j.conbuildmat.2017.12.09 5

12. J.Thumrongvut, S.Seangatith , T.Siriparinyanan & S.Wangrakklang(2016).NoTitle. AnExp BehavCell Light Concr steel Sq tube columns under axial compression.

13. J. Thumrongvut , P.Tiwjantuk,. (2018). No Title Strengthandaxialbehaviorofcellularlightweight concrete-filled steel rectangular tube columns underaxialcompression.MaterialsScienceForum. https://doi.org/10.4028/www.scientific.net/MSF.9 41.2417