International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 p-ISSN: 2395-0072

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 p-ISSN: 2395-0072

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net

1 M. Tech Student, Dept. of Civil Engineering, St. Joseph’s College of Engineering and Technology, Palai, Kerala, India

2Assisstant Professor, Dept. of Civil Engineering, St. Joseph’s College of Engineering and Technology, Palai, Kerala, India ***

Abstract - A stiffened plate is an extension of the beamcolumn in which an effective width is added to the beam. Stiffeners are used to resist lateral loading of a plate & are usually made from the rolled shapes integrally welded to the plate. They are used as structural part of ships, submarines & bridges. This project deals with the nonlinear and linear analysis of stiffened plate using ANSYS. A stiffened plate has been analyzed to find out its ultimate strength. An experimental determination of ultimate strength of stiffened plate has also been done in this project. It also includes the linear buckling of stiffened plate without stiffener. The stiffened plate has been analyzed with and without stiffener to get to know about the importance of stiffener. Stiffeners are secondary plates or sections which are used to stiffen the primary elements. The economical design of plate can be obtained by using stiffeners instead of increasing thickness of plate. Also, plates with varying number of stiffeners and stiffened plate under transverse loading condition have also been considered in this project.

Key Words: Stiffened plate, Stiffeners, Lateral loading, Ultimatestrength,Linearbuckling,Transverseloading.

The widespread usage of stiffened parts in engineering began in the nineteenth century and it was used in steel platesforthehullofships,steelbridgesandalsoinaircraft structures. Stiffeners are used to withstand the extremely directionalloads,anditintroducedifferentloadwayswhich may provide protection against harm and crack growth beneathboththetensileandcompressiveloads.Thegreatest advantage of using stiffeners are the increased bending stiffness of the stiffened panel with a minimum of extra materialwhichmakesthestructuresperfectforout-of-plane loadsandalsofordestabilizingthecompressiveloads.Usage ofstiffenedplategivesmorebenefitslikelessmaterialusage, low cost, better performance etc. Nowadays, the importance forstructureswith highstiffnessisincreasingday byday. Oneamongsttheeasiestwayofachievingitisbyusingthe stiffeners. Innumerous mechanical structures are manufacturedfromstiffenedplates.Thesestructuralparts maybeoutlinedastheplatesstrengthenedbyoneoragroup of beams or ribs on one side or both aspects of the plate. Thereforethestiffenedplateunitsaremanufacturedfrom plateparts,ontowhichtheloadingsareahavebeenapplied.

Thebeam partsare connectedtoa distinctspacinginoneor bothdirections.Thefabricoftheplateandalsothefillermay be same or totally different. Compared to the unstiffened plates, the advantage of using stiffened plate is their high stiffnesstoweightquantitativerelation.Becauseoftherise in overall stiffness of the system, stability characteristics have been increased. Thus these structurally economical elementshavetheadditionalbenefitoffabricsavingsaswell astheyareeconomictoo.

Anotheradvantageofexploitationofstiffened plateisthattheycanbemanufacturedthroughaneasyand simpleprocess.Hence,it'snotasurprisethatsuchstructural elementsfoundawide-spreadutilizationwithinthetrendy branches of civil, mechanical, structural and construction engineering.Stiffenedplatesaresubjectedtomanyformsof loading conditions in their operating surroundings. For instance,thestiffenedplateissubjectedtolateralorcross loadwithinthecaseofbridgedecks.Ontheoppositehand, the longitudinal bending of the ship hull exert a longitudinal in-plane axial compression on the plates. The loading conditions on an element may be of 2 types: static and dynamic. Static masses are invariant of time and dynamic masses varieswiththe time. So thedesignersshouldkeepin mindthese2aspectsofloadingwhilethedesigningprocess.

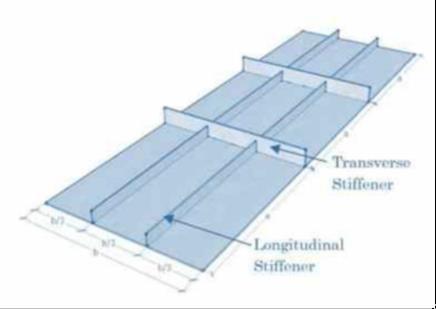

Fig-1:Stiffenedplate

Themainobjectiveofthisstudyis: • Toanalyzethestiffenedplate.

International Research Journal of Engineering and Technology (IRJET)

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net

• To apply the cases of loading and boundary conditionsforasimplysupportedplatewithstiffeners.

• Tofindouttheultimatestrengthofstiffenedplate.

Review of literature

Validation of ultimate strength of stiffened plate

An experiment on ultimate strength of stiffened plate

Linear buckling of stiffened plate without stiffener Analysis (linear) of stiffened plate with one stiffener

Analysis of stiffened plate subjected to uniform

transverse load

Interpretation of results

The stiffened plate has been analyzed linearly and nonlinearlyinordertofindouttheultimatestrengthofthe stiffenedplate.

• Thematerialusedisaluminumalloy.

• Stiffenedplateisofsize440*590mm

• Dimensionofstiffener–590*28mm

• Youngsmodulus=73700MPa

• Tensileyieldstrength=324MPa.

• Compressiveyieldstrength=324MPa.

• Tensileultimatestrength=471MPa.

• Compressiveultimatestrength=471MPa.

• Initialyieldstrength=299MPa.

• Meshsizegiven=0.02m

• Poisson'sratio=0.33

• Densityofaluminumalloy=2780kg/m³

• Thicknessofstiffenedplate=2.2mm

• Thicknessofstiffener=2.8mm

• Distancebetweenstiffener=167mm

e-ISSN: 2395-0056 p-ISSN: 2395-0072

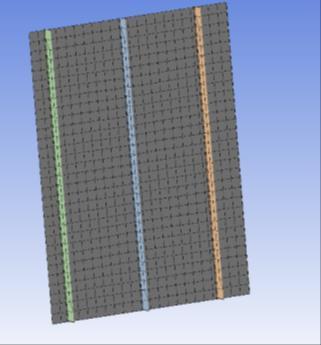

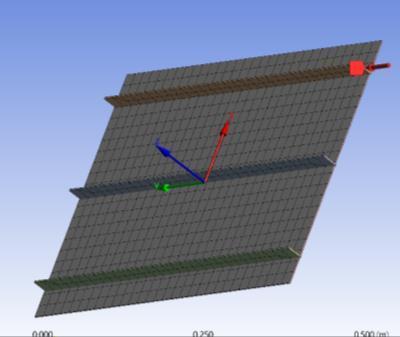

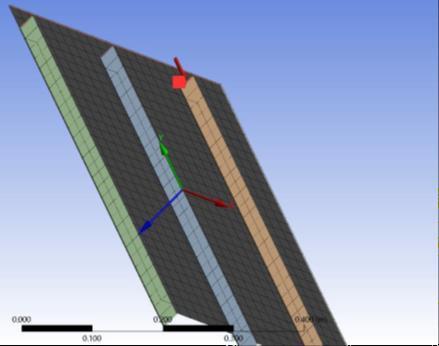

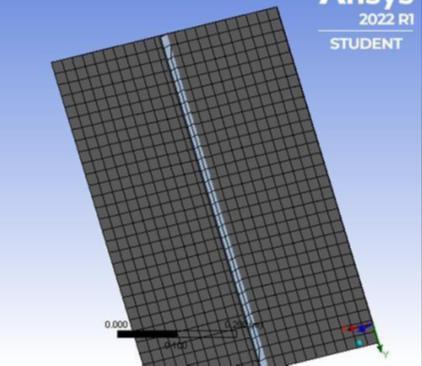

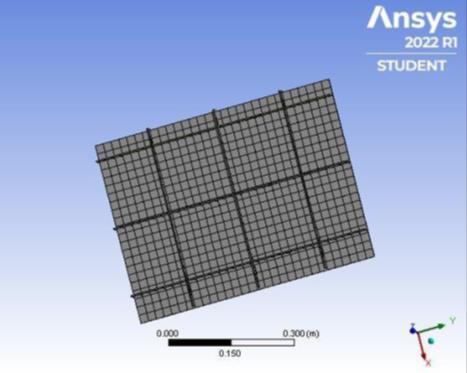

The model of stiffened plate is created using ANSYS software. In this study, the ultimate strength of stiffened plate is being carried out. Here, the thicknessof stiffened plate is taken as 2.2mm and the thickness of stiffener is takenas2.8mm.Themeshsizeofthemodel=0.02m.

Fig-2:Meshedmodel

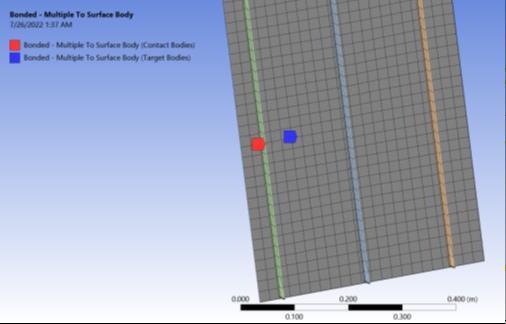

The stiffened plate and stiffeners are connected by the bondedtypeofconnection.Itisdonebyusingthemanual contact region option found in ANSYS software. If the connectionbetweenthestiffenersandstiffenedplateisnot given,itsurelyaffectstheloadingsgivenandthuswewon’t get the required deformation for the stiffened plate. So providingconnectiontoboththegeometriesareverymuch important.

Fig-3:Connections

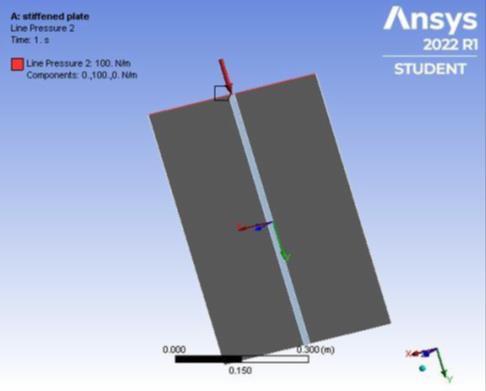

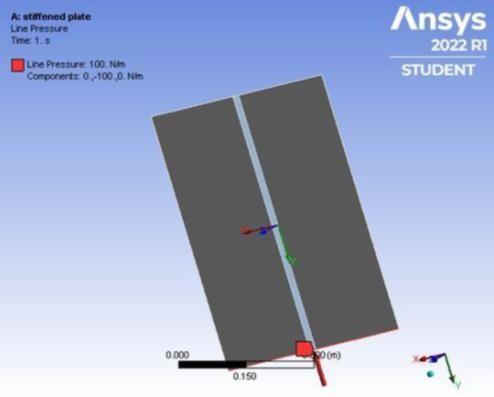

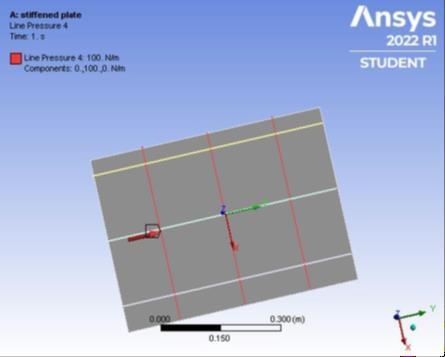

Theloadisgivenasacompressiveloadonboththeedges ofthestiffenedplate.Theloadisappliedonboththeedges of stiffened plate as well as on the stiffeners. The load givenis100N/m.

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net

Fig-4:Loadontop

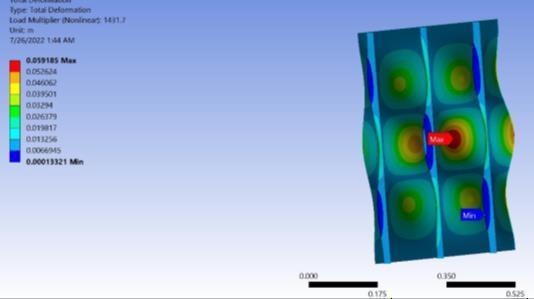

Inthisstudy,thetotaldeformationwasfoundout.Inthis case,linearanalysisofstiffenedplatewasbeingcarriedout. Thevalueoftotaldeformationobtainedis0.059185m.The figurebelowshowsthedeformedmodel ofstiffened plate withstiffener.Onapplyingload,boththestiffenedplateand stiffenerarebeingdeformed.

e-ISSN: 2395-0056 p-ISSN: 2395-0072

method.Thefigurebelowshowstheforcereactionappliedto thestiffenedplate.

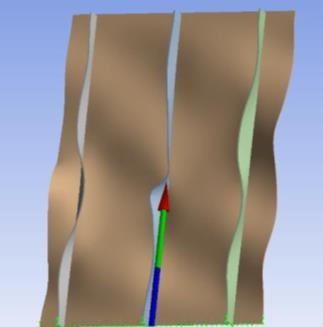

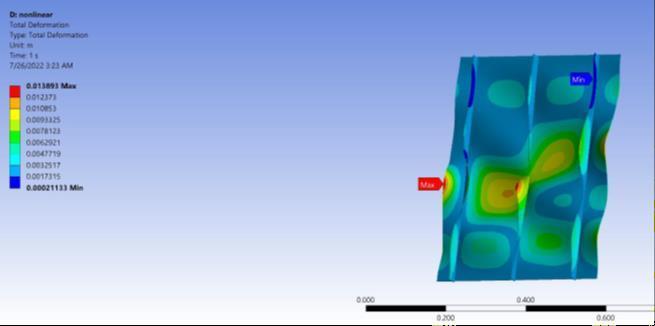

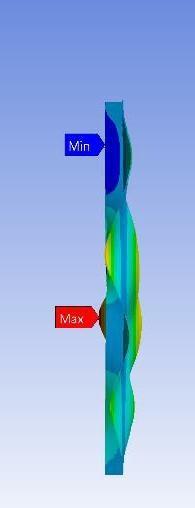

In this study, the total deformation was found out using nonlinear method here. In this case, nonlinear analysis of stiffened plate was being carried out. The value of total deformation obtained is 0.013893 m. The figure below showsthedeformedmodelofstiffenedplatewithstiffener. Onapplyingload,boththestiffenedplateandstiffenerare beingdeformed.

Fig-8:TotalDeformation

Thisisthenonlinearcaseofthevalidation.Here,same material properties and dimensions are used as in linear analysis.Theonlydifferenceisthatitisanalyzedinnonlinear

Fig -9: Deformed shape of stiffener © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 p-ISSN: 2395-0072

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net

• Materialused:aluminumalloy

• Stiffenedplateisofsize440*590 mm

• Dimensionofstiffener–590*28 mm

• Thicknessofstiffenedplate=2.2mm

• Thicknessofstiffener=2.8mm

• Distancebetweenstiffeners= 110mm stiffenedplateisof440*590mmandstiffenerisof 590*28mm.

The figure below is the stiffened plate made of aluminum. This stiffened plate is kept on a Universal TestingMachine (UTM). Then UDLof36kN/mwas

appliedontopofstiffenedplateandfixedsupportwas givenonthebottomportionofstiffenedplate.The

Fig -12: Applying Load on UTM

Fig -10: Stiffened plate

Fig -11: Stiffened plate

Fig -13: Deformation of stiffened plate

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 p-ISSN: 2395-0072

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net

•

•Materialused–Aluminumalloy

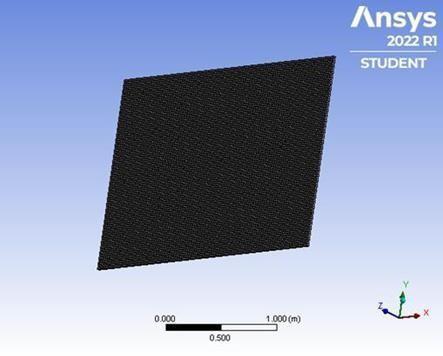

•Sizeofstiffenedplate=2500*1800mm

•Ultimatetensilestrength=537MPa

•Ultimateyieldstrength=489MPa

•Young’sModulus=72GPa

•Poisson’sratio=0.34

•Density=2795kg/m

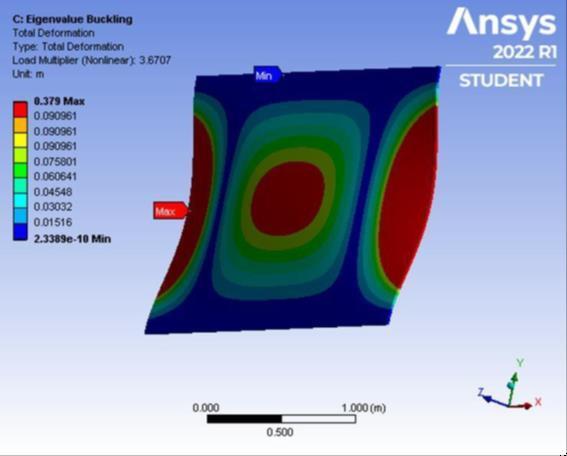

Fig-16:LoadsGiven

TheValueofdeformationobtained(forplatehaving thickness20mm)=0.379m.

Fig -14: Meshed model

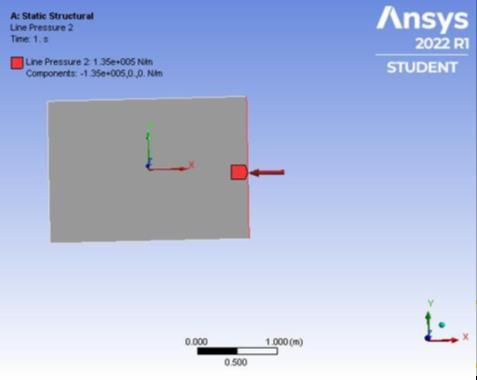

Here,theloadisgivenonbothedgesofstiffenedplate.A

Fig-17:Totaldeformation

• Materialused–aluminumalloy

•Stiffenedplateisof440*590mm

•Dimensionofstiffener–590*28mm

•Young'smodulus=73700MPa

•Tensileyieldstrength=324MPa.

•Compressiveyieldstrength=324MPa.

•Tensileultimatestrength=471MPa.

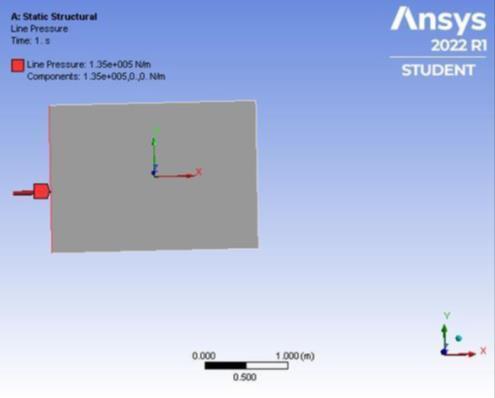

Fig-15:LoadsGiven

•Compressiveultimatestrength=471MPa.

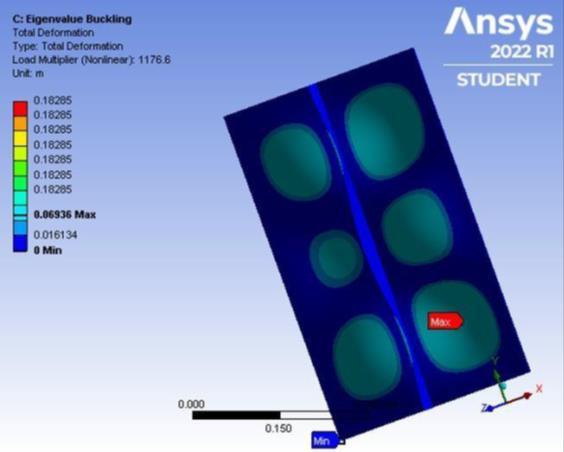

bare plate or a stiffened plate without stiffener is being consideredhere.Linearanalysisisdoneinthisstudy.The loadgiven=135kN. © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page735

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 p-ISSN: 2395-0072

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net

Initialyieldstrength=299MPa.

Meshsize=0.02m

Poisson'sratio=0.33

Densityofaluminumalloy=2780kg/m³

Thicknessofstiffenedplate=2.2mm

Thicknessofstiffener=2.8mm

Fig-20:LoadGiven

Thevalueoftotaldeformationobtained=0.18285m

Fig-18:Meshedmodel

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 p-ISSN: 2395-0072

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net

• Tensileultimatestrength=471MPa.

•Compressiveultimatestrength=471MPa.

• Initialyieldstrength=299MPa.

• Meshsize=0.02m

• Poisson'sratio=0.33

•Densityofaluminumalloy=2780kg/m³

•Thicknessofstiffenedplate=2.2mm

•Thicknessofstiffener=2.8mm

Fig-22:Meshedmodel

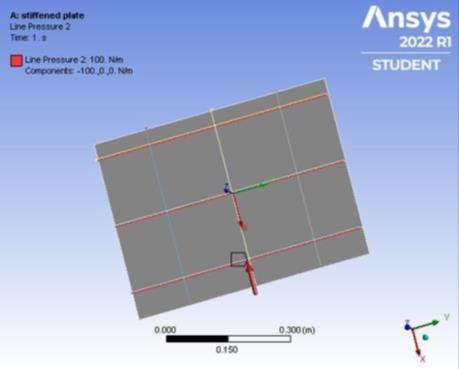

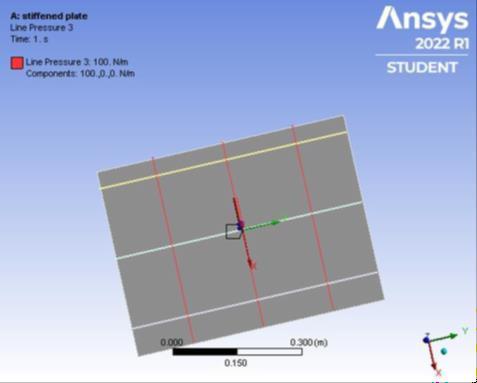

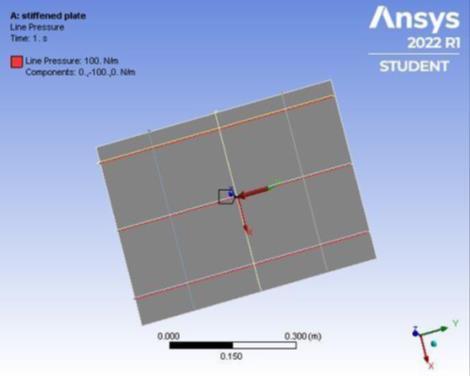

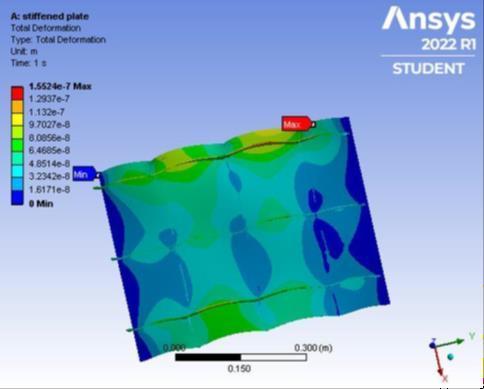

TheLoadappliedtostiffenedplatewithlongitudinaland transversestiffener=100N/m.

Fig-23:LoadsGiven

Fig-24:LoadsGiven

Fig -25: Loads Given

Fig -26: Loads Given

Thedeformationvalueobtainedforstiffenedplatewith longitudinalandtransversestiffeners=1.5524eˉ⁷m.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 p-ISSN: 2395-0072

[2] A. Aruljothi; (2020),” Analyzing the Buckling Strength of Stiffened SteelPlates with Longitudinal StiffenersSubjectedTo Uniaxial Compression”, Journal of Xi'an University of Architecture & Technology, Vol. 12, Issue: 07, pp. 149 – 153, 2020.

[3] Rodrigo R. Amaral; Grégori S. Troina; Cristiano Fragassa; Ana Pavlovic; Marcelo L. Cunha; Luiz A.O. Rocha; Elizaldo D. dos Santos; Liércio A. Isoldi; (2020),” Constructal design method dealing withstiffened platesand symmetryboundaries”, Theoretical &Applied Mechanics Letters, pp. 366 –376, 2020.

Fig -27: Total deformation

Thisprojectwasconductedtofindouttheultimatestrength ofstiffenedplatewithandwithoutstiffener.So,itwasfound that adding stiffeners to the stiffened plate increases the strength and less amount of material is required for such plates when compared to plates with no reinforcement. Thus, it makes an economical structure. It also improves resistanceandrigiditywithrespecttoitsweight.Therefore the economical style of plate will be obtained by using stiffeners rather than increasing the thickness of plate. Stiffeners facilitate in stiffening the first components. It absolutelywasfoundthatsizeofsubpanel,formandsizeof filler and range of equi-spaced stiffeners affects the important buckling strength of stiffened plates having longitudinal stiffeners. By increasing the cross sectional momentofinertia,therigidityofstiffenerswillberaised.

In this study, stiffened plates with varying thicknesses were analyzed in ANSYS software. So it was foundthatstiffenedplatehavinglessthicknessgivesalmost equal deformation when compared to a stiffened plate havinggreaterthickness.Thatis,thestrengthcharacteristics ofa stiffenedplateis notdependentonthicknessofplate. Also, analysis of stiffened plate with varying number of stiffeners were also conducted in this project. So it was foundthatthestrengtheningeffectofstiffenersdecreasesas the number of stiffeners increases. As the number of stiffenersincreases,theultimatestrengthvaluedecreases.

[4] Guangping Zou; Yuyang Wang; Qichao Xue; Chunwei Zhang; (2019),” Buckling Analysis of Sandwich Plate Systems with Stiffening Ribs: Theoretical, Numerical, and Experimental Approaches”, Advances in Civil Engineering, pp. 1 – 14, 2019.

[5] Murat Ozdemir; Ahmet Ergin; Daisuke Yanagihara; Satoyuki Tanaka; Tetsuya Yao; (2018),” A new method to estimate ultimate strengthofstiffened panels under longitudinal thrustbasedonanalyticalformulas”,Marine Structures,pp.510 -535, January 2018.

[6] Amar N. Nayak; Laren Satpathy; Prasant K. Tripathy; (2018),” Free vibration characteristics of stiffened plates”, International Journal of Advanced Structural Engineering, pp.153 – 167, June 2018.

[7] S. Jeya Pratha; V. Paulson; R. Santhanakrishnan; (2018),” Experimental studies on effect of stiffener configuration on compressive strength of stiffened panels”, International Journal of Mechanical and Production Engineering Research and Development (IJMPERD),Vol.8 Issue:06, pp. 681 – 690, Dec 2018.

[8] D. Quinn; A.Murphy; W.McEwan; F.Lemaitre; (2009),” Stiffened panel stability behavior and performance gains with plateprismatic sub-stiffening”,Thin-WalledStructures,pp.1457 – 1468, 2009.

[1] Chen Jiaqi; ZhongYifeng; LuoQiushi; Shi Zheng; (2021),” Static and dynamic analysis of Isogrid Stiffened Composite Plates (ISCP) using equivalent model based on variational asymptotic method”, Thin-Walled Structures, pp. 1 –15, March 2021.