International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Pastay1 , Mahaboobali Nadaf 2

1M.Tech Student Civil Engineering Dept. Jain college of engineering Belagavi, Karnataka, India 2Asst Prof. Civil Engineering Dept. Jain college of engineering Belagavi, Karnataka, India ***

Abstract - The aim of this study is to look at the mechanical and durability qualities of hybrid fiber reinforced concrete made with Fly Ash, RHA, and LP as partial replacement of cement Pozzolanic materials, on the other hand, improve strength over time. RHA is a pozzolanic substance with high reactivity. When RHA is mixed with OPC, it not only strengthens the concrete. At low replacement levels and later in life, using a ternary blend of OPC, RHA, and FA improves the mortar's strength dramatically. FA and RHA are both very good at improving mortar corrosion resistance.

Key Words: Rice Husk Ash, Fly Ash, Lime, Polypropylene, Mechanical Properties etc.

In today's construction sector, concrete has become an unavoidableconstructionmaterial.Thisisoneofthebiggest environmental threats. Supplementary Cementitious Materials(SCMs)areusedinconcretetoreducetheamount ofcementused,whichhelpstosolvetheproblem.Itnotonly benefits the economy and the environment, but it also improves the characteristics of concrete. Because the majority of SCMs are by-product materials from the industrial andagricultural sectors,usingtheminconcrete hasbeenshowntobeacost-effectivealternativetodisposal. TheCalcium-Silicate-Hydrate(C-S-H)gelgivesstrengthto concrete, whereasthe Ca (OH)2inhydratedcementpaste degradesconcretequality.Itisanunfavourablematerialthat reducesthestrengthoftheconcrete.WhenSCMsaremixed withPortlandcementconcrete,theamorphoussilicainthe SCMs combines with additional Calcium hydroxide to produce C-S-H gel, gives concrete strength and minimises permeabilitywhilealsoincreasingtheconcrete'slongevity. Becauseofthepozzolanicandfillereffects,addingSCMsto concreteimprovesitscharacteristics.TheadditionofSCMs to Portland cement concrete improves the strength and durability of the finished product[1]. Studied HFRC SCCs withahighvolumeofcoarseFA[2].Monoandhybridsteel fibres with hooked ends and straight steel fibres were employed[3].Thedurabilityofglassfibrewasalsostudied [4].ThedurabilityqualitiesoffibrillatedPPfibrereinforced highperformanceconcretewerecarriedout[5]Accordingto muchresearch,thequalitiesofblendedcementconcreteare improvedbytheseingredients[6]

1.Tocomparethemechanicalpropertiesofconcretein monoandhybridformwithsteel,carbon,andfibrillated polypropylenefibre(PP).

2.ToseehowSCMsaffectthemechanicalpropertiesof mono-fibre and hybrid fibres added into concrete duringlongercuretimes.

3. To determine the durability properties of concrete with the best mono and hybrid fibres, such as water absorption,sorptivityandRCPTtests.

SampleIndividually,0.25percentand0.5percentofPP andcarbonfibresisaddedtoconcrete.Whencarbonfibres aremixedwith polypropylenefibresina hybridform, the total weight fraction of cementitious materials is kept between0.25and0.5percent.Steelfibreswillbemixedwith mono PP fibre, mono carbon fibre, and carbon-PP hybrid fibre systems at 0.5%, 1%, and 1.5% volume fractions, respectively.Curingtimesfortheconcretespecimenswillbe 28days andtherequiredtestsforstrengthanddurability testsarecarriedoutafterthat.

OPC 53 grade JK SUPER cement is employed for experimentalinvestigation.Varioustestswerecarriedoutto know the properties of cement. The results obtained are showninthetablebelow.

Table -1: Resultsofcement

Tests conducted Results IS Standards

Std.consistency 31% 35%

Initialsetting 32mins 30mins

Finalsetting 290mins 600mins Sp.Gravity 3.11 3.1

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

The fine aggregate employed was sand collected from the local distributors and passed through a 4.75mm sieve.ThesandmetIS383-2016gradingZoneII.

Table -2: TestResultsofF.Agg.

Finenessmodulus 3.3 Sp.Gravity 2.65 Waterabsorption 1%

Coarse aggregates are selected which meets the requirementsofISspecifications.Varioustestsareconducted toknowthepropertiesofCAwhichwereangularinshape andfreefromdirt/oil.

Table -3: TestResultsofC.Agg.

Particulars Results

Finenessmodulus 3.91 Sp.Gravity 2.75 Waterabsorption 0.43%

ClassFFlyAshwasobtainedRaichurThermalPowerStation and chemical properties are almost similar to RHA with SpecificGravityof2.4.

TheRHAemployedinthisexperimenthadthecompositionas showintableandishavingspecificgravityas2.3asspecified bythedistributor.

Inthisexperiment,alocallyavailableLimepowderisused and is having specific gravity as 2.8. Table 11 shows the chemicalcompositionofLimepowder

Table -4: Limestonepowderproperties

Chemical Composition

%

SiO2 6.83

Al2O3 4.14

CaO 55.71

Fe2O3 4.5

Hookedendfibres(steelfibres)areused.Selected fibersarehavinglengthof35mm,0.45mmasdiameterand aspectratioof78.Ithastensilestrengthrangingfrom800to 1000MPa.

Fig –2:Steelfiber

ThelengthofPPwas6mm,thedia.-0.04mm,thespecific gravitywas0.91,andthestrength(tensile)wasbetween350 to450MPa.

CarbonfibreswithaL=12mmandadiameter=11microns wereusedinthisexperiment.Accordingtothemanufacturer, the carbon content was 95% and the tensile strength was 4300MPa

Fig -1:RHA

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

2. MIX DESIGN.

Table 5 – Shows mix proportion Mix proportion Cement F. Agg C.Agg 1 1.73 3.11

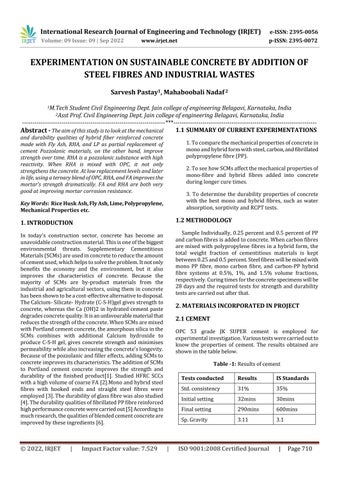

Slumpconetestwasusedtochecktheworkability ofcementfollowingthestandardprocedureoftest.

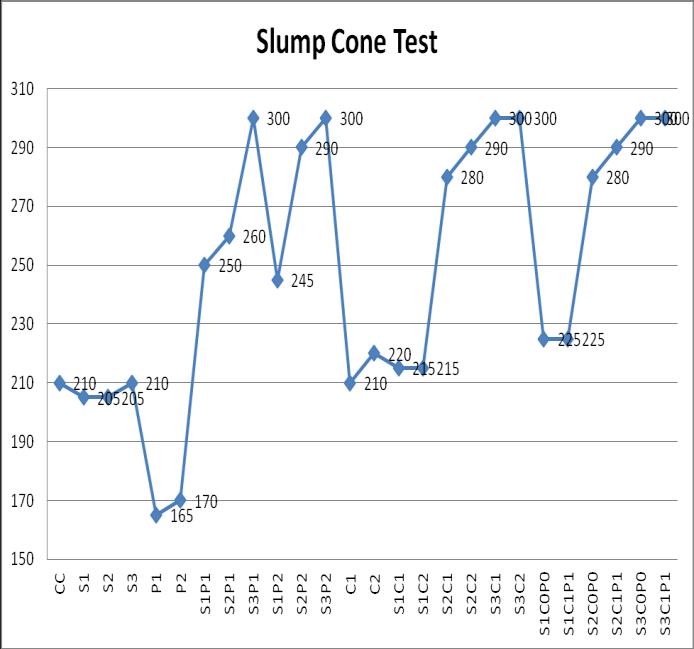

TheVee-BeetimeforSteelPolypropyleneHybridFiber ReinforcedConcrete(SPHFRC)variedbetween12and 63seconds.

Steelfiberadditionsof0.5,1,and1.5percentincreased theVeeBeetimeby5,15,and36seconds,respectively.

The Vee Bee time increased by 1 and 4 seconds for polypropylene fibers at 0.25 percent and 0.5 percent, respectively.

CarbonFiberReinforcedConcretehadaVee-Beetimeof 2to5seconds(CFRC).

Inthecurrentinvestigation,theVee-BeetimeforSteelCarbonHybridFiberReinforcedConcrete(SCHFRC)was between13and69seconds.

TheVee-BeetimewasincreasedwhenfibrillatedPPfiber wasaddedtotheSCHFRCmix.Ata1.5percentvolume fractionofsteelfibers,workabilityisreducedandfiber ballingoccurs.Asaresult,workabilityisfurtherreduced, and a balling effect of fibers occurs, resulting in a concrete mix that is not fully compacted.This effectis stronger in Steel-Carbon-Polypropylene Hybrid Fiber Reinforced concrete (SCPHFRC) mixes than in Steel Carbon Hybrid Fiber Reinforced Concrete (SCHFRC) mixes

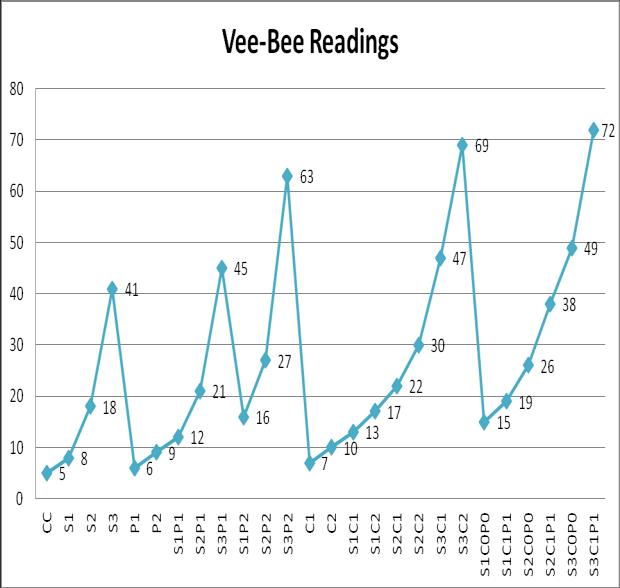

ThistestwasconductedinaccordancewithIS5161999.Thisiscarriedouttoknowthecapacityofconcreteto withstandloadsbeforefailure.Thestandardsizeofthecube is used to cast the concrete. Tests were conducted for differentintervaloftime7,28and56daysofcuring.

Fig –3:Resultsofslumpcone

3.2 VEE-BEE CONSISTOMETER TEST.

Fig –5:ShowsresultsofComptest.

Fig –4:ResultsofVee-Beetest

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Incomparisontonormalconcrete,

Compressive strength improvement in SFRC increased by 15.93%, 28.29%, and 26.12% for concrete mixes containing 0.5%, 1%, and 1.50% volumepercentageofsteelfibers,respectively.

The maximum compressive strength gain in a 1% steelfiberblendis28.29percent,8.54percentina 0.25percentPPfiberblend,and29.06percentina 0.25percentcarbonfiberblend.

WhencomparedtomixS1,thehybridmixesS1P1 and S1P2 show significant beneficial synergy. Strengthenhancementovercontrolconcreteisupto 22.24% in S1P1 and 25.22% in S1P2 mixes, comparedto15.95%inS1.

ThecompressivestrengthimprovementinS1C1is 30.60% at 28 days, and the compressive strength improvementinS1C2is35.74%.

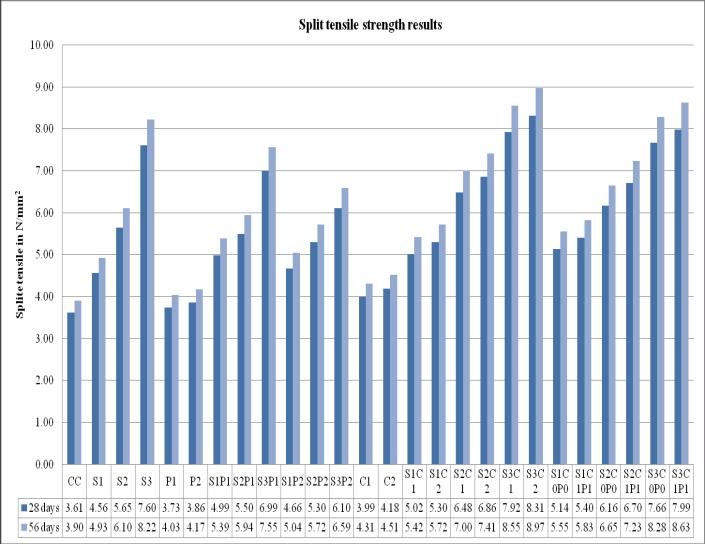

Fig –6:ShowsresultsofSplittensiletest.

At0.5percentvolumefractionofsteelfibers,only S1C0P0 and S1C1P1 mixes exhibit a greater beneficial synergy impact than S1C1 and S1C2 mixes.ThemaximumstrengthofthemixesS1C0P0 andS1C1P1at28daysisincreasedby32.17%and 40.54%,respectively,whencomparedtothecontrol concrete.

Forthepercentagesemployed,thesplittensilestrengthof steel, PP, and carbon in mono form increases with fiber content.Italsoincreasesforsteel-carbonhybridFRCinterms of percentages used. However, when polypropylene is utilizedinahybridformwithmorethanacertainpercentage ofsteelfibers,thesplittingtensilestrengthdecreases.

However, at 1 percent and 1.5 percent volume fractions of steel fiber, all other SCPHFRC blends exhibit negative synergy when compared to all SCHFRC mixes. Compressive strength is lower in S2C0P0 to S3C1P1 mixes than in S2C1 to S3C2 mixes.

ThistestisfollowedonUTMandthespecimenishaving specificationslike150mmdia,300mmasheight.Testsare conducted in accordance to IS 5816-1999. The casted specimens are tested at an interval of 28 and 56days of curing.

Due to fiber hybridization, a significant beneficial synergyisobservedinthemixesS1P1andS1P2when 0.5percentsteelvolumefractionisused.

Fromtheabovetable,thestrengthofotherhybridfiber mixes S2P1to S3P2 islower than that of mono fiber mixes S2 and S3. At higher fiber dosage ratios, hybridization is less effective in increasing splitting tensile strength as it is in compressive strength. In comparisontotheconventionalconcrete,thestrength enhancement in the hybrid mix S1P1 is up to 38.06 percent, 29.17 percent in the S1P2 mix, and 26.39 percentintheS1mix.

At28days,thesplittingtensilestrengthimprovement in SCHFRC mix S1C1 is 38.89% andin mixS1C2 itis 46.67%comparedtocontrolconcrete.Whentheresults are compared to SPHFRC, SCPHFRC, and SCHFRC systems, only the mix of S1C0P0 and S1C1P1 at 0.5 percentvolumefractionofsteelfibersshowsapositive synergisticeffect.

The highest percentage increases are 42.22 % and 49.44 % for the S1C0P0 and S1C1P1 combinations, respectively.

At 1% and 1.5 % volume fractions of steel fibers, SCPHFRC mixtures exhibit a negative synergy as comparedtoSCHFRCblends.TheSCHFRCmixeswere morepowerfulthantheSCPHFRCmixtures.Chenand Liu(2005)reporteda similardiscoveryinwhichthe

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

carbon-steel hybrid fiber combination outperformed thecarbon-PP-steelfibercombination.

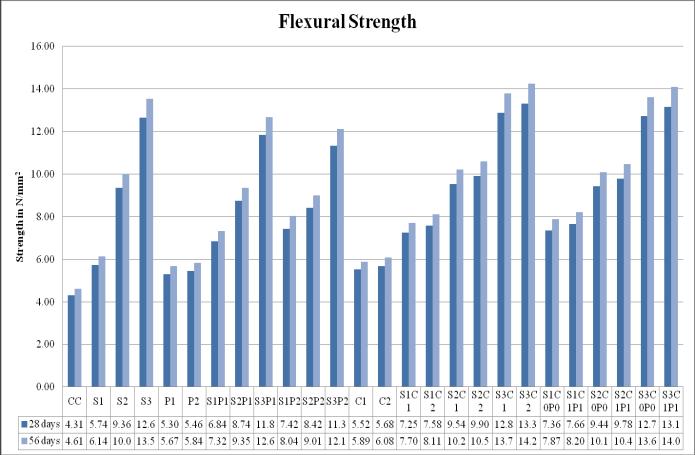

Fig –7

At28days,thestrengthofmixS1is33.18percentmore thanthatofthecontrolconcrete.WhenPPisaddedto thismonosteelmix,thestrengthincreasesby58.70% inthemixS1P1and73.55%inthemixS1P2compared tothecontrolconcreteafter28days.

FlexuralstrengthislowerinhybridmixesS2P1,S2P2 andS3P1,S3P2thaninmonomixesS2andS3at1% and 1.50% volume fractions, respectively. This reductionisduetotheincreasednumberoffibersin the matrix, which causes higher porosity and the formationofweakinterfacezones.

Theinsertionoffiberscompletelychangesthefailure characteristics. The specimen does not fail suddenly aftertheinitialcrackingoccurs.Therandomlyoriented fibersthattraversethefracturedportionpreventcrack propagationandsectionseparation.

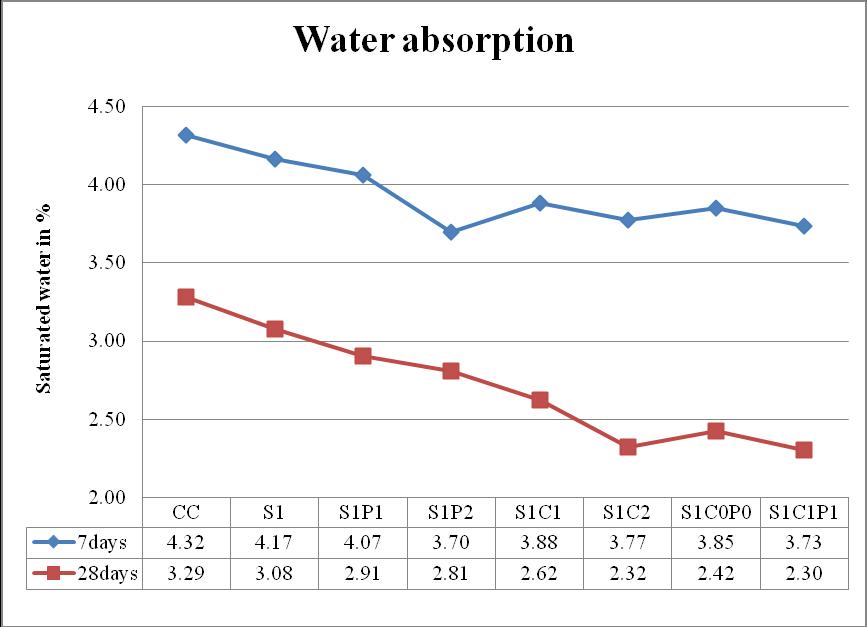

AccordingtoASTMC642-97,thewaterabsorption testwasdoneoncubespecimens Testwascarriedoutat7 daysand28daysinterval

Thewaterabsorptionwasfoundoutusing Formula

Fig –8:ShowsresultsofWaterAbsorptiontest.

At7and28days,thewaterabsorptionpercentagein the control mix is 4.32 percent and 3.33 percent, respectively. Saturated water absorption in mono and hybrid fibrous mixtures is lower when comparedtoconventionalconcrete.Theapplication offibersreducestheabsorptionofwaterinconcrete.

Waterabsorptionislowerduringthe28dayswhen compared to the 7 days. This reduction in water absorptioniscausedbythepresenceofpozzolanic elements in the mix. At all curing times, water absorptioninSPHFRCmixislowerthaninSFRCmix.

Workabilityreducesasfibredosageincreasesinboth mono and hybrid fibre types. Given the workability standards, the maximum volume percentage of steel fibre advised for hybrid combinations should not exceed0.5percent.

At0.5percentsteelvolumefractionproducesagreater positiveeffectinthemixesS1C0P0(0.5percentsteel+ 0.125percentcarbon+0.125percentPP)andS1C1P1 (0.5percentsteel+0.25percentcarbon+0.25percent PP) for all mechanical properties. At 28 days, the maximum compressive, split tensile and flexural strength of the mix S1C1P1 (0.5 percent steel + 0.25 percentcarbon+0.25percentPP)increasedby40.53 percent,49.44percent,and77.73percent,respectively, comparedtotheconventionalconcrete.

Whencomparedtoconventionalconcreteat28days, the maximum compressive, split tensile, and flexural strength of the mix S1C1P1 (0.5 percent steel + 0.25 percent carbon + 0.25 percent PP) at 90 days is increased to 67.68%, 77.78%, and 116.71%, respectively.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

The maximum compressive, splitting tensile, and flexural strength of the S1P2 (0.5 percent steel + 0.5 percent PP) mix improved by 25.22 percent, 29.17 percent,and73.55percent,respectively,after28days whencomparedtothecontrolconcrete.

The best SCHFRC hybrid combinations mechanical propertiesareS1C1(0.5percentsteel+0.25percent carbon) and S1C2 (0.5 percent steel + 0.5 percent carbon).Whencomparedtoconventionalconcrete,the maximum compressive, split tensile and flexural strength at 28 days are improved by 35.74 percent, 46.67percent,and75.87percent,respectively,inthe mixS1C2(0.5percentsteel+0.5percentcarbon).

At 28 days, the water absorption percentage in the controlmixis4.32.Waterabsorptionislowerinmono and hybrid fibrous mixtures as compared to conventionalconcrete.Theminimumwaterabsorption inS1C1P1(0.5 percentsteel +0.25percentcarbon+ 0.25percentPP)at7and28daysis3.74percentand 2.31percent,respectively.

When compared to all other hybrid mixes, the beam with mix S1C1P1 (0.5 percent steel + 0.25 percent carbon+0.25percentPP)hasabetterpositivesynergy effect at 0.5 percent volume fractions of steel fibres, whereas mix S2C2 (1 percent steel + 0.5 percent carbon) performed well at 1 percent volume of steel fibres.Themaximumultimateloadcarryingcapacityof thebeamisincreasedbyupto51.98%inS1C1P1(0.5 percentsteel+0.25percentcarbon+0.25percentPP) at0.5percentvolumefractionsofsteelfibresandupto 75.95%inS2C2(1percentsteel+0.5percentcarbon) at1%volumefractionsofsteelfibres.

[3] Juenger,MCG,&Siddique,R2015,„Recentadvancesin understandingtheroleofsupplementarycementitious materials ataraja, MC, Nagaraj, TS & Basavaraja, SB 2005, „Reproportioning of steel fibre reinforced concretemixesandtheirimpactresistance‟,Cementand concreteresearch,vol.35,no.12,pp.2350-2359.

[4] Mohammadi,Y,Carkon-Azad,R,Singh,SP&Kaushik,SK 2009,Impact resistance of steel fibrous concrete containing fibres of mixed aspect ratio‟, Construction andBuildingMaterials,vol.23,no.1,pp.183-189.

[5] Uygunoglu,T2011,„Effectoffibertypeandcontenton bleedingofsteelfiberreinforcedconcrete‟,Construction andBuildingMaterials,vol.25,pp.766-772

ISCodesUsed

•IS:10262:2009(Specificationforconcretemixdesign).

• IS: 456: 2000 (Plain & Reinforced concretecode of Practice).

• IS: 383:1970 (Specification for coarse & fine aggregate).

When compared to the normal beam, the energy absorption capacity of the mix S1C1P1 (0.5 percent steel+0.25percentcarbon+0.25percentPP)israised by117percent,anditisincreasedby226.67percentin themixS2C2(1percentsteel+0.5percentcarbon).

Asaresult,itisdeterminedthataddingsteel,carbon, andfibrillatedpolypropylenefibreinhybridformcan considerably improve the qualities of quaternary blendedconcretewithSCMs.

[1] Saraswathy, V & Song, HW 2007, „Corrosion performance of rice husk ash blended concrete‟, Constructionandbuildingmaterials,vol.21,no.8,pp. 1779-1784.

[2] Lothenbach, B, Scrivener, K & Hooton, RD 2011, „Supplementary cementitious materials‟, Cement and ConcreteResearch,vol.41,no.12,pp.1244-1256.