International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

UTILIZATION OF LOCALLY OBTAINED MATERIALS IN PAVEMENT SUB-BASE

Abhay Chaudhary1

Abstract - The exhaustion of regular assets is a main pressing issue of the development business today, and the street fragment is no special case. Total interest is excessively perfect because of broad street development strategies, numerous energy-serious impacting, mining, squashing and transportation tasks, yet total interest rapidly evaporates and supply is restricted. Then again, capricious assets like modern waste, results, and locally usable unused materials cause ecological issues and overflows, yet they have Potentially utilized in street development. In this review, anendeavor was made to involve two sorts of materials in the roadbed: slag, a nearby and effectively open rock and steel squander material (moorum). The compound creation, piece of the stages, the substance of weighty and harmful metals in the slag and its filtering water were totally contemplated. Fitting tests and methodology are utilized to concentrate on the order and its other actual attributes. Traditional squashed total is likewise utilized along with slag or moorum to accomplish the ideal molecule size for use in a specific level, as determined by the Department of Transportation and Highways. The ideal extents of slag and moorum utilized in the sub-base are 80 and half, separately. On account of monads, the expected measure of concrete is likewise used to give the ideal strength. The actual properties of the material were considered. As per exploration, slagand moorumhave uncommoncharacteristics like sugar totals and can be utilized in roadbed and subgrade applications.

Key Words: Toxicity,UnconfinedCompressiveStrength, Slag,Moorum,XRDanalysis.

1.INTRODUCTION

The financial, modern, social and social development of a nationisgonebeforebystreetportability.Indiaasofnow has the second biggest street network on the planet. The Indiangovernment'ssignificantstreetdevelopmentprogram has achieved a fast improvement in the street area. Consistently,agreatmanykilometersofstreetsareimplicit India, either as metropolitan streets (under the National Road Development Program) or provincial streets (as per Pradhan Mantri Gramin Sadak Yojna). [May 2011 issue of HighwaysofIndia].Theupwardloadmovehappeningfrom the top (surface) to the base (substrate) of the asphalt structureisutilizedforthestreetparts:thesub-base,sublayer, sub-base and top (sub-base) layer. . A great (adaptable) asphalt framed by an extremely minimized granulargameplancomprisingofverymuchreviewedtotals thatcirculatecompressiveworryaboutabiggersurface.The

asphalt is upheld by the subfloor, which sits straightforwardlyunderneaththetoplayerandmovesthe loadtothelayersbeneath.Thesubfloor,situatedunderneath the subfloor, not just backings the asphalt structure and conveys traffic loads through the subfloor, however it likewisegoesaboutasaniceboundaryandgiveswaste.The mulch is typically comprised of two layers: a lower layer (channel)thatholdssoilimpuritiesbackfromsaturatingthe upper layers, and an upper layer (waste) comprised of a granularsupportmaterial (orGSB) thathelpschannel the dirt.waterleaksthroughthesurfacebreak.

Unbending asphalts commonly comprise of a concrete substantialpiecewithagranularbaseorunderlaymentfor seepage,siphoncontrol,solidifyingcontrolandsubsurface shrinkagecontrol,andfloorswellcontrol.Asfarasburden dispersion,unbendingasphaltisnotthesameasadaptable asphalt.Theholdingmaterialisutilizedinthebaseorbase layerofsemi-unbendingasphalts,givingahigherprotection from bowing than conventional adaptable asphalt layers. Totals, soil, or a mix of the two might be utilized for the reinforced base or subbase, with stabilizers, for example, lime, concrete, fly debris or business stabilizers added to giveproperstrengthlevel.Keepinginviewtheabove,efforts aremadetoutilizetheindustrialwasteorbyproductsatthe locallevel.Materialsavailabletoatleastpartiallyreplacethe natural aggregate in the base or sub-base application, as thesematerialsareavailableinhugequantitiesatanominal cost.theseingredientsmaynotmatchthedesiredstandards or specifications but may provide a possibility for their optimum use in road construction. Use of the above materialsmayresultinreductionofcanhelpinmeetingthe constructioncostofroads,qualityrequirementsandinstead Improvethestrengthanddurabilityofpavement.

The current review centers around the mix of locally accessiblehardslagormoorumwithcustomarysquashed totals(ofvariousostensiblesizes)foruseinthesubgradeor subgradeoftheasphalt.

Thegoalsofthisundertakingareasperthefollowing: Assessthesubstancearrangementoftheslagand its leachate, as well as the presence of dangerous components.

Assurance of actual boundaries of slag and investigationofreasonablenesstouseforsub-base layerofasphalt.

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page61

1M.Tech (Civil Engineering with specialization in Highway Engineering) Scholar, Maharishi University of Information Technology, LucknowInternational Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Lay out the actual properties of the locally accessiblehardsubflooranddecideitsadequacyfor useinthesubgradeorsublayeroftheasphalt.

Decidetheeffectofutilizinglocallyusableregular totalsandrocktosettletheconcreteinthebaseor subbase(hardunit).

Thissectioncentersaroundauditingafewlateexaminations on the utilization of slag and moorum in asphalts and sublayers. The properties of the slag,aswell asthe actual propertiesandstrengthboundariesoftheslagandmoorum, havebeenexploredindifferentexaminations.

1.1. Characterisation of slag

Fundamentaloxygenheater(BOF)steelslagisaresult of essential oxygen converters utilized in steelmaking. It tends to be halfway utilized as a street development material.Inspiteofthefactthatitisanoutwardlyengaging structurematerial,itsdrawnoutconductandrelatednatural resultsoughttobeassessedprecedinguse.Silicon,calcium, ironandcertainpossiblydestructiveorperceivedpoisonous mixtures, for example, chromium and vanadium, make up mostofBOFslag.

1.2. Chemical composition and phase analysis

X-beam diffraction (XRD), SEM joined with microanalytical examination of energy dispersive X-beam spectroscopy (EDS) and X-beam retention spectroscopy (XAS)aretheunderlyingstrategiesusedtodecideparticular stagestructuresaretrackeddownintheslag.

The X-beam diffraction strategy is a quick, nonhorrendous insightful instrument for deciding the gem structure, nuclear game plan, and stage piece of the substance under study. The slag was coarsely ground and examined with a Philips PW 3710 X-beam diffractometer utilizingCoKradiationat0kV(voltage)and0mAforthe XRD(current)technique.Diffractionpictureswereminedin the[8-90o]territorywithacountseasonof13s/step.

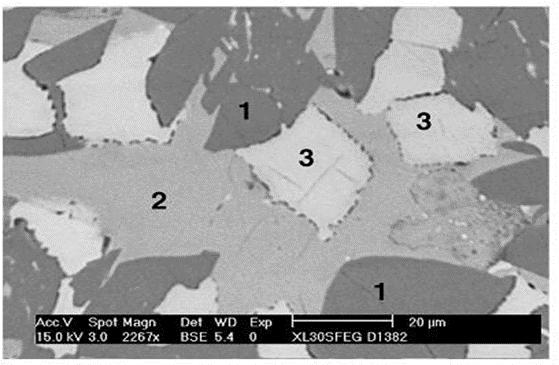

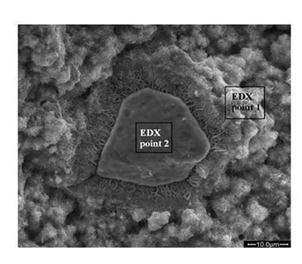

Theexaminingelectronmagnifyinginstrumentisone more indestructible apparatus for concentrating on the shapeandcreationoftests.Thestructureofthecomponents presentintheslagwasconcentratedonutilizingaPhillips SFEGcheckingelectronmagnifyinglens(SEM)(XL30)joined withanenergydispersivespectrometer(EDS)fromOxford Instruments.Itworksat15keVwithslagsizesfrom200to 500μm.Semi-quantitativeevaluationsofexplicitsegments weretriedutilizingacountseasonof60-200s/score.

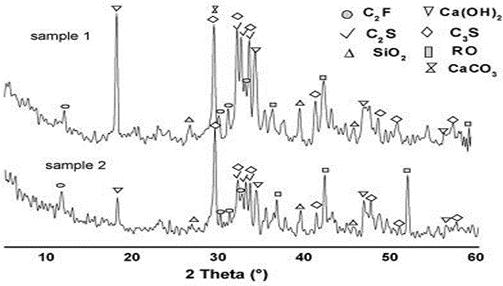

InChina,anothersortofroadbedmaterialcomprising ofsteelslag,flydebrisandgypsumhasbeenutilized.Steel slag, fly debris and phosphorus are utilized to decide the substance structure of unrefined components. Figure 2. showstheXRDexamplesoftwoslagtests(steelslag).

Figure 2. XRDpatternsofswordsedimentsamples( WeiguoShen.,etal.(2009))

Electricbendheater(EAF)steelslagisutilizedtosupplant regular totals in the foundation of malleable asphalt. The substanceorganizationofthetotals wasresolvedutilizing XRF(X-beamfluorescence)andtheharmfulpropertiesofthe EAF still up in the air by the ICPAES (Inductive Plasma Emission Spectrometer) technique for focuses starting degrees of weighty/poisonous metals [Pasetto and Baldo (2010)].

X-beam diffraction can be utilized to decide the mineralizationofhydration itemsinsteel slag.[Wangand Yan(2010)]utilizedTTR|||CuK1radiationdiffractometer with nickel channel (= 1.505), voltage 50 kV, current 200 mA. The microstructures were resolved utilizing SEM and thecomponentdisseminationwasrecognizedutilizingEDX.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

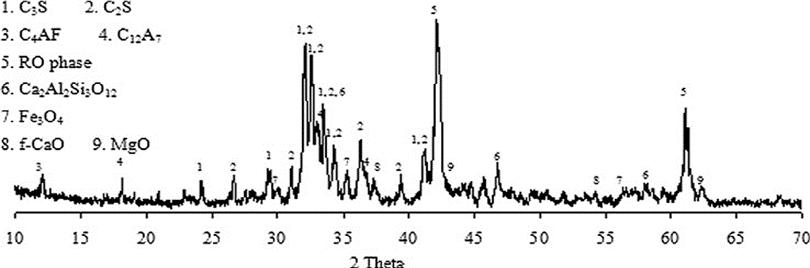

Figure 3. X-Raydiffreactionofsteelslag.(WangandYan (2010)).

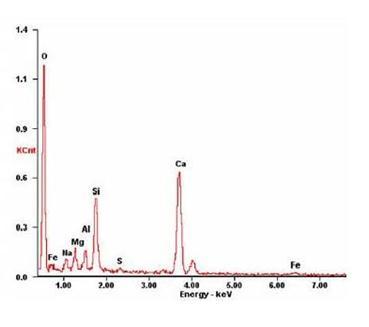

Figuse 4.( b). EDXresultofpoint1

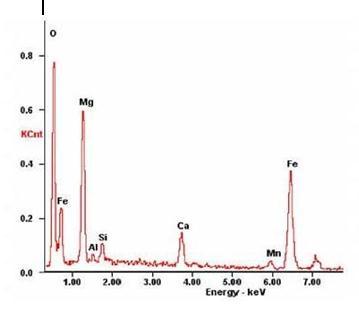

Figure 4.( a). SEMmorphologiesandEDXanalysisofthe hydrationproductsattheageofthe28days-SEMpicture (WangandYan(2010)).

ToassessthecompoundandmineralogicalportrayalsofLD slags and to distinguish the stages that are defenseless againstasphaltshakiness,afewscientificmethodologiesare applied[J.Waligora.,etal.(2010)].Themineralstagesfound intheslagwererecognizedutilizingaXraydiffraction(XRD) move toward utilizing a Bruker AXS D8 Advance diffractometerwithaCosource(K=1.79°),filteringrange2 [5-99.9°] with a stage of 0.005°/s at 25°C. To assess the substanceandmineralogical portrayalsofLDslagsand to distinguish the stages that are helpless against asphalt shakiness, a few scientific methodologies are applied [J. Waligora.,andpartners.(2010)].Themineralstagespresent intheslagweredistinguishedbyX-beamdiffraction(XRD) utilizinga BrukerAXSD8Advancediffractometerwith Co source(K=1.79°),examiningrange2[5-99.9]°]withastage of0.005°/sat25°C.

Figuse 4.( c).EDXresultofpoint2

2. MATERIAL AND METHODOLOGY

Priortobeingutilizedinthesubgradeorsubfloorofan asphalt, materials, whether normal totals, modern waste/results or locally usable assets, should meet the accompanyingprerequisites:meetdeterminedqualityand sturdiness necessities. Notwithstanding these tests, materialsthatarepossiblyhurtfultotheclimateshouldgo throughcompoundtestingandportrayaltodecidewhether theyareecologicallyadequate.Thesyntheticarrangement andpropertiesoftheslagwereexploredinthisreview.The actualnatureofslag,normallygroundtotalsandmoorumsis resolved utilizing proper guidelines, determinations and records. The testing methods utilized in this review are recordedunderneath.

2.1. Characterisation of slag

Thecompoundpieceandstagestructureofthenot entirely settled as a feature of the portrayal cycle. The presenceofweightyorhurtfulmetalsintheslag,aswellas leachate got from the slag, was researched. A few logical methodologies and their technique are momentarily investigatedfortheabovementioned.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page63

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

2.2. X-Ray Fluorescence

Theexampleishitbyahigh-energyessentialX-beam, making electrons be launched out from the inward shell. Higherenergyelectronsfromtheexternalshellwillleapto fill the hole, bringing about fluorescence radiation that fluctuateswiththesubstance.Subsequently,thepresenceof a specific part in the example can be resolved utilizing a locator.Theslagtestsweregroundtoacoarsepowdertoget a homogeneous blend prior to being broke down by a Xbeamfluorescencespectrometer.Thesyntheticstructureof the12slagtestswasdeterminedasaproportionoftheirall out mass. The substance arrangement and metallurgical characteristicsofthenotentirelysettledbybasicity,whichis characterizedastheproportionamongCaOandSiO2.

2.3.Physical Properties and Strength Tests

Inthisreview,anendeavorbecamemadetoapplyslag withinsidethebendyasphalt'ssub-baselayer.Asindicated byMoRTH(2013)prerequisites,ashutreviewing(GradingII forGranularSub-baseMaterials)becameutilizedforthemost minimal sub-base layer (or get out layer), and a typically uniformevaluating(GSBGradingIV)becameutilizedforthe higherlayer(seepagelayer).GSBgradeIVbeatentotalshave been settled with concrete to be utilized withinside the seepagelayerofthesub-base.Inallcases,extrememoorum becameusedwithinsidetheconcretebalancedoutpremise and the concrete settled sub-base clear out layer, reliable withtheGSBGradingIIofMoRTH(2013)detail.Table3.1 proposestheidealdegreesofGSBreviewingIIandIVsteady withMoRTH(2013)particulars,whichrelatetocustomaryIS strainersizes. Table 2.1. GradingforGranularSub-baseMaterials[Table 400-1,MoRTH(2013)specification].

GranularSub-baseMaterials)becameutilizedfortheleast sub-base layer (or get out layer), and a generally uniform reviewing(GSBGradingIV)becameutilizedforthehigher layer (waste layer). GSB grade IV beaten totals have been balanced out with concrete to be utilized withinside the seepagelayerofthesub-base.Inallcases,extrememoorum becameusedwithinsidetheconcretebalancedoutpremise and the concrete settled sub-base clear out layer, reliable with the GSB Grading II of MoRTH (2013) determination. Table3.1recommendstheidealdegreesofGSBevaluatingII and IV predictable with MoRTH (2013) determinations, whichrelatetotraditionalISsiftersizes.

WetImpactValue(%)= 2.5.

Combined Flakiness Index

Stripping and prolongation records were resolved utilizingapredeterminedlengthandthicknessmeasureas per IS: 2386 (Part I) - 1963. To begin with, the totals are gone through the sensoriometer to decide the joined strippingfile,andtheheavinessofthetotalsgoingthrough thesensoriometerisrecorded(A).Theheldmaterialisthen takencareoftothelengthmeasure,andtheheavinessofthe heldtotalsisrecorded(B).AsdisplayedinEquation2,the joined chipping list is communicated as a level of the completeweight.

CombinedFlakinessIndex(%)= 2.6.

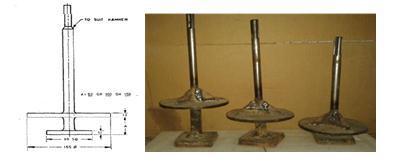

Cube Specimen

IS:4332(PartV)1970isutilizedtotestthecompressive strengthofconcretestablecubicexamples(15cm15cm15 cm).Materialwithagreatestsizeof37.5mmwasprocessed totheidealdampnesscontentandexamplesweredelivered atthepredeterminedmostextremedrythickness.Thesolid shapeiscompactedutilizingavibratinghammerconnected to three shufflers of foreordained level (as displayed in Figure.5.)forthreelayers(5cmeach).

2.4. Aggregate Impact Test

Inthisreview,anendeavorbecamemadetoapplyslag withinsidethebendyasphalt'ssub-baselayer.AsperMoRTH (2013) prerequisites, a shut evaluating (Grading II for

Figure 5. Tampersforusewithavibrationhammerfor unconfinedCompressiveStrengthTest[(IS4332(PartV)–1970)]

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

RESULTS AND DISCUSSION

Table 3.1. Presentsthesubstancepieceofthenotentirely settledbytheXRFstrategy.Thesubstancepieceofslag testswasassessedbytheXRFtechniqueasdisplayedin theTable.

Chemicalcomposition Percentage

SiO2 027.321

FeO 020.901 Al2O3 06.012 CaO 031.023 MgO 09.222 MnO 04.501 S 0.103 TiO2 0.642 K2O 0.142

Table 3.2. XRDpinnaclesoftheslagtestasanelementof position[2(degrees)]andrelative,notentirelysetin stonebytheprogramX'pertHighScore.

Position[2θ (degrees)]

Relative Intensity Matched by (References)

18.6299 65 83-0114;70-1435 26.6815 65.36 79-1910;17-0445;701435

29.4604 100 24-0027;71-2108;170445 31.4502 32.92 24-0027;17-0445 38.0265 55.2 83-0114;71-2108;701435 42.1184 26.82 70-1435

3. CONCLUSION AND FUTURE SCOPE

Inthiswork,anattempthasbeenmadetouseslagand locallyavilablehardmooruminvariouslayersofpavement roadbaseandsub-base.Theslagareusedinthestudyofthe well graded and can be used as a general aggregate constituent(upto80%oftotalaggregates)inthepavement roadsub-baseapplications(bothfilteranddrainagelayer). Resultshaveshownthatit notonlyhasspankingphysical propertiesandrequiredstrengthforusedinpavementroad sub-base and but is also environmentally secure. Locally availablehardmoorumareusedinthisstudycontainsextra fine materials and can be appropriate for closed or dense gradingapplications(baseorfilterlayerofsub-base)which

canchangetheconventionalaggregatesuptoamaximumof 50% by weight. The physical properties indulge the desideratumrequirements.Theminimumrequiredstrength rateforuseinaparticularlayercanbecognizablebyusinga smallamountofbinder(cement).Foraindividualcontent of binder , moorum has shown preferential strength than thatoftheconventionalcrushedaggregates.

The strength parameters considered in the study areCaliforniaBearingRatio(CBR)andUnconfined CompressionStrength(UCS).Apartfromthesetests the repetitive load triaxial test can also be performedtofindouttheimpactofdynamicloading in dissimilar layers, and the realistic resilient modulusvaluesmaybedetermined.

Thepermeabilityoftheslagandcrushedaggregate mixture can be determined specifically in the drainagelayerofthesub-basebyusingpropertests.

REFERENCES

Aiban,S.A.“UtilizationofSteelSlagAggregatesfor RoadBases”.Journaloftestingandevaluation34, no.1(2006):65.

IS: 2720 (Part 2), “Method of Test for Soils: DeterminationofWaterContent”,BureauofIndian Standards,NewDelhi,1973.

IS: 2720 (Part 5), “Test Method for Soil: DeterminationofLiquidandPlasticLimits”,Bureau ofIndianStandards,NewDelhi,1985

IS: 2720, (Part 8), “Methods of Test for Soils: Determination of Water Content – Dry Density Relationship by Heavy Compaction”, Bureau of IndianStandarda,NewDelhi,1983

IS: 2720, “Methods of Test for Soil (Part 16): LaboratoryDeterminationofCBR”,BureauofIndian Standards,NewDelhi,1987

IS:4332,“MethodsofTestforStabilizedSoil(Part V): Determination of Unconfined Compressive Strength of Stabilized Soil”, Bureau of Indian Standards,NewDelhi,1970

IS: 5640, “Method of Test for Determination of AggregateImpactValueforSoftCoarseAggregates”, BureauofIndianStandards,NewDelhi,1970

IRC:SP:89."Guidelinesforstabilizationofsoiland granularmaterialusingcement,limeandflyash", IndianRoadCongress,NewDelhi,2010

IS:2386(PartI),“MethodsofTestforAggregates for Concrete: Particle Size and Shape”, Bureau of IndianStandards,NewDelhi,1963

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page65

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page66

IS:2386(PartIII),“MethodsofTestforAggregates for Concrete: Specific Gravity, Density, Voids, Absorption,Bulk”,BureauofIndianStandards,New Delhi,1963