International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

SUNNY KUMAR1 , ER. ANOOP SHARMA2

1PG Student, Department of Civil Engineering, S.S.C.E.T, Badhani

2 ASSISTANT PROFSSOR, Department of Civil Engineering, S.S.C.E.T, Badhani ***

Calciumrichandsilicarichwastematerialsareabundantlyavailableinmanycountries.Thesewastesendedinawaste dump therebypollutingenvironmentandendangeringthelivesofthepeoplelivingwithinthevicinity.CalciumcarbideresidueCCR andcoconutshellashCSAaresuchwastesproduceasresultofindustrialandagriculturalactivities.Utilizingthesewastesfor stabilization purposes may result in providing a product with adequate strength for construction purposes. In this research, CCRandCSAwereemployedinstabilizingCI,CSAwasfixedat20% inCIrespectivelyusingindexpropertiestestsandthen CCRwasvaried(i.e.0.5,1.0and1.5%).StandardproctortestresultsshowedgeneraldecreaseinMDDvaluesandincreasein OMC values whichmay beobvious asthe specificgravityof the additivesis lessthanthat of the soil.UCS resultsindicated a tremendousimprovementinthestrengthofthesoilwiththeimprovementofupto1.59timesthestrengthofthevirginsoils at 7 days curing period and CBR results Showed Enhancement in the strength of the soil with the improvement of up to 2.1 times the strength of the virgin soils at 7 days curing period with combination of S+1.5%CCR+20%CSA respectively. Hence CCRandCSAcanbeemployedforexpansivesoilstabilizationsubjecttofurtherresearches.

Keywords: Clay soil, Calcium carbide, Blackcottonsoil, Standard proctor, CBR Test, Unconfined strength test (UCS)

Therearevarioustypesofsoilswhichshowvolumechangesduetochangeinthemoisturecontent.Thiscausesmajordamage topropertyconstructedonit.Thesesoilscontainmineralssuchasmontmorillonitethatarecapableofabsorbingwater.When they absorb water their volume increases. One of the biggest necessities in the developing countries is to provide proper roadway network by conventional method. Hence it is necessary to go for suitable method of low cost road construction followedbyaprocessofstagedevelopmentoftheroads,tomeetthegrowingneedsofroadtraffic.

Goodquality of subgrade soil is preferable for durable road but not alwaysavailable for highway construction. The highway engineersdesigningaroadpavementfaceweakorunsuitablesubgrade.Inthissituationimprovementinthepropertiesofthe existing soil by addition of some other materials can be adopted which is otherwise known as “soilstabilization”. Soil Stabilization:

Soil stabilization means the improvement of the stability or bearing capacity of a poor soil by the use of compaction; proportioningandtheadditionofsuitablestabilizersoradmixtures.Soilstabilizationincludeschemical,mechanical,physicochemical methods to make the soil stabilized. This process basically involve excavation of soil, this is an ideal technique for improving of soil in shallow depth, as in pavements. Stabilization method may be categorized as two main types: (a) improvementofsoilpropertiesofexistingsoilwithoutusinganytypeofadmixture;and(b)improvethepropertieswiththe admixtures.

Thecommonlyusedadmixturesforthestabilizationofclayeysoilhavebeenreportedintheliteraturearecement,lime,flyash, ricehuskash,furnaceslagorinthecombinationofmorethanoneadmixture.Flyash,ricehuskashandfurnaceslagareadded duetotheabundanceofpozzolanicmaterials(SiO2 andAl2O3)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Soil is taken from for this exploration work. The measure of soil is taken around 150 kg of locally accessible clayey soil (CI) wasgatheredandairdriedinopenranges.Thesuperfluous materialslikerocksandvegetativematterwereexpel physically from soil. The irregularities are available in soil are additionally broken with the assistance of wooden sledge and after that sievedthrough4.75mmstrainertoconcentraterockpart.Bythentheearthillustrationwasovendriedfor24hoursat100°C beforeitwasmixedwithCalciumCarbideandGroundGranulatedBlastFurnaceSlagusingitfortrials.Thepropertiesofsoil usedaregivenbelowintable1.

TableNo.1Propertiesofsoil:

S.NO. PROPERTIES RESULTS 1. LiquidLimit 47% 2. PlasticLimit 21.11% 3. PlasticityIndex 25.89% 4. OptimumMoistureContent 17.5% 5. MaximumDryDensity 16.2kN/m³ 6. SpecificGravity 2.67 7. IndianSoilClassification CI 8. Californiaratiotest 2.2% 9. Unconfinedcompressionstrength 240.05 kN/m2

B. Calcium Carbide Residue: TheCalciumCarbideResidueisusedinthisresearchwastakenfromLocallymarket. TableNo.2ChemicalcompositionofCalciumCarbideResidue

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

ThematerialCoconutshellashwastakenlocalmarket.

TableNo.3chemicalcompositionofCoconutshellash

S. No Name of constituent Percentage

1 SiO2chemicalcompositionofCoconutshellash 37.97 2 Al2O3 +Fe2O3 39.60 3 CalciumOxide(CaO) 4.98 4 Magnesiumoxide(MgO) 1.89 5 SO3 0.71 6 Na2O 0.95 7 P2O5 0.32

The soil take up in the proposed study was gathered from local area. Right off the bat the soil knots were broken with the assistanceofawoodenhammerandafterthatairdried.Atthatpointsoilwasgonethroughfromsifter4.75mmandafterthat gatheredinpacks.Theamountofsoilrequiredisthenovendriedat105˚Cfor1day.

Various tests that were performed in the laboratory to attain the desired objectives 1. Pycnometertest(Specificgravity). 2. Casagrande’stest(Liquidlimit). 3. Threadtest(Plasticlimit). 4. Modified proctortest(OMCandMDD) 5. CBRtest. 6. UCStest

InpresentworktheratioofCalciumCarbideResidueutilizedwas1.0,1.5and2.0%andCoconuthellAshwas15,20and25%.

Here,S=Soil,CSA=CoconutshellAsh&CCR=CalciumCarbideResidue.

value:

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

1. STANDARD PROCTOR TEST:

TableNo.1MDDandOMCforsoil–CSA–CalciumCarbidemix

S. No. Proportion Soil : CSA: Calcium Carbide MDD (kN/m3) OMC (%) 1. 100:0:0 16.20 17 2 79.5:20:0.5 16.75 18.6 3 79:20:1.0 17.40 19.3 4 78.5:20:1.5 17.06 18.8

GraphNo.1Graphsrepresentingthecurvesthatareobtainedfromstandardproctortestforsoil–CoconutShellAsh-Calcium Carbidemixture

14.5 15 15.5 16 16.5 17 17.5 18 18.5 19 19.5 20 100:00:00 79.5:20:0.5 20:01.0 78.5:20:1.5

A. Unconfined Compression Strength Test

MDD (kN/m3) OMC (%)

TableNo.2ResultsofUCSofCoconutshellAshandCalciumcarbide Clayey Soil :CSA: CC Curing Period (Days) UCS (kN/m2) 100:00 7 240.05 79.5:20:0.5 7 321.43 79:20:1.0 7 357.61 78.5:20:1.5 7 381.73

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

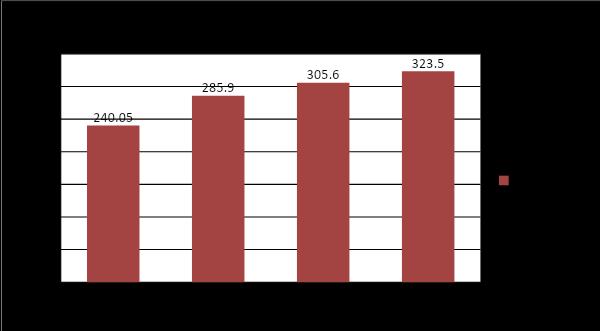

GraphNo.2UCSValueofClayeysoilofCoconutshellAshandcalciumcarbide

B. California Bearing Ratio Tests

TableNo.3ResultsofCBRofRiceHuskAshandNylonFibreMixwithSoil

CS: CSA: CC CBR (%) 100:00:00 2.2 79.5:20:0.5 4.1 79:20:1.0 4.3 78.5:20:1.5 4.6

4

GraphNo.3CBRPercentagesofClayeysoil,RiceHuskAshandNylonFibre 2.2

3

2

1

4.1 4.3 4.6 0

5 100:00:00 79.5:20:0.5 20:01.0 78.5:20:1.5

CBR (%)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

MODIFIEDPROCTORTEST:.

WithCoconutShellAshkeptconstantat20%MDDdecreaseswithanadditionofCalciumCarbidecontentinsoiland CoconutShellAshmix.ThereasonbehindofsuchbehaviourisCoconutShellAshislighterinweightandithashigh waterabsorptionpropertiesbecauseofpresenceofcalciumoxideandhenceOMCincreaseswithincreaseofCoconut ShellAshcontent.

TheCBRvalueofvirginsoilis2.2anditincreaseto2.1timeswhenCoconutShellAsh20%andCalciumCarbide1.5% isaddedtovirginsoil.ThisenhancementinCBRmaybebecauseofthegradualformationofhydrationcompoundsin thesoilduetothereactionbetweenthestabilizersandtheessentialsparticlepresentinthesoil.

• The UCS value of virgin soil also improves considerably with expansion of Coconut Shell Ash 20% and Calcium Carbide 1.5%. The value increases from 240.05kN/m² to 381.73kN/m² with addition of Coconut Shell Ash and CalciumCarbide.

• The reason behind of this when Coconut Shell Ash and Calcium Carbide comes in contact with water, pozzolanic reactionstakesplaceduringthecuringperiod.

1. TheC.B.RvalueincreaseswithincreaseofCalciumCarbidealongwithfixedquantityofCoconutShellAsh.Itincreased 2.1timesfromtheuntreatedsoil.

2. The optimum value of Coconut Shell Ash and Calcium Carbide required for soil stabilization is 20% and 1.5% by weightofsoilrespectively.

3. Unconfined compressive strength increases with increase of quantity of Calcium Carbide and with fixed quantity ofCoconutShellAsh.ThevalueofUnconfinedcompressivestrengthisincreased1.59timesfromtheuntreatedsoil.

1. Balaraba wade isah and S. Mary rebekahsharmila (2015) “Soil Stabilization Using Calcium Carbide Residue and Coconut Shell Ash” Journal of Basic and Applied Engineering Research Print ISSN: 2350-0077; Online ISSN: 23500255;Volume2,Number12;April-June,2015pp.1039-1044.

2. F. Okonta, Innocent kafodya (2018)“Effects of natural fiber inclusions and pre-compression on the strength properties of lime-fly ash stabilised soil” Elsevier (Construction and building materials) Volume 170,10 May 2018, Pages737-746

3. P B Madakson, D.S Yawas and A. Apasi (2012) “Characterization of Coconut Shell Ash forPotential Utilization in Metal MatrixComposites for Automotive Applications”. International Journal of Engineering Science and Technology (IJEST)ISSN:0975-5462Vol.4No.03March2012.

4. Utsev, J.T Taku, J.K (2012) “Coconut Shell Ash As Partial Replacement of Ordinary Portland Cement In Concrete Production”.Internationaljournalofscientific&technologyresearchvolume1,issue8,September2012ISSN:22778616

5. B.R. Phanikumar, Ravideep Singla (2016) “Swell-consolidationcharacteristicsoffibrereinforcedexpansivesoils”

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

6. Dr. Siddhartha Rokade, Rakesh Kumar, Dr. P.K. Jain(2017) “Effect of Inclusion of Fly-Ash and Nylon Fiber on StrengthCharacteristicsofBlackCottonSoil”.EJGEVol.22[2017].

7. Hesham A. H. Ismaiel (2013) “Cement Kiln Dust Chemical Stabilization of Expansive Soil Exposed at El-Kawther Quarter,SohagRegion,Egypt”.

8. M.Heeralal, G.V. Praveen(2011) “ A study on effect of fiber on cement kiln dust stabilized soil”. JERS/Vol. II/ Issue IV/October-December,2011/173-177

9. M.K. Rahman, S. Rehman & O.S.B. Al-Amoudi(2011) “Literaturereviewoncementkilndustusageinsoilandwaste stabilizationandexperimentalinvestigation”.

10. Kameshwar Rao Tallapragada, Anuj Kumar Sharma, TarulataMeshram(2009) “laboratoryinvestigationofuseof synthetic fiberstominimizeswellinexpansivesubgrades”.IGC2009,Guntur,INDIA

11. Pallavi, Pradeep Tiwari, Dr P D Poorey(2016) “Stabilization of Black Cotton Soil using Fly Ash and Nylon Fibre”. IRJETVolume:03Issue:11|Nov-2016

12. Indian Standard Code IS2720-16,IS2720-10.

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page60