International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

1Janmejay Tiwari PG Scholar (Industrial Engg. & Management) 2Nitin Yedmewar

(Asst. Prof.)Assistant Professor, Dept. of Mechanical Engineering, Takshshila Institutes of Engineering & Technology, Jabalpur, (M.P) ***

Abstract- These days, market requests have inspired the industries to give quick and solid assistance to meet clientdemandsthataretouchyintheirnecessitiesinthis sense, the production network of the executives has cultivated extraordinary premium as far as organization methodologies to remain worldwide business. Supplier selection is a basic action inside the organization of the production network. It is viewed as a complicated issue given that it includes various viewpoints, for example, the choices to alternatives, the numerous standards required as well as the group of decision-makers with different opinions. In this sense, the writing reports a few strategies to help in this troublesome movement of choosing the best provider.. This research work expects to introduce a contextual analysis that incorporated the methodology of the Topsis Method as a multi-criterion decision-making tool (MCDM) for the supplier selection andpositioningofthebestoptionfortheIndianrailline followingsystem.Aget-togetherorganizationdevotedto the production of a railway tracking system global positioningframeworkneedstocollectafewpartsinits production line. Determination of providers is considered a multi-criteria issue in the field of decision-making. Following pre-assessment to identify potential suppliers of the packaging, five suppliers were foundthatcouldeasilysupplythematerial intheregion where the assembly company is established. A group decision (GD) with two decision-makers has been integrated.TheGDhasbeendeterminedtoevaluatefive suppliersforthecomponentsupplyinRailwayindustry.

quality goods merchandise without providers that can fulfill the ideal need in a seriously competitive climate. The businesses of organizations depend on suppliers so theycanconveyqualitylabourandproductsmakingthe course of assessment and choice of providers a fundamental capacity of the business. To keep an upper hand, the business ought to, along these lines, take on a deliberate assessment model for provider choice while deciding potential and appropriate accomplices. (Karamasa,Cetal2021).

Theselectionofsuppliersisasignificantachievementin the progress of the plan and the executives of earth's feasiblestockchains.Thevastmajorityofthedisplaysin supplier determination depend on the joining of fluffy hypothesis withcustomary MCDM techniques. Theissue of supplier determination is one of the main issues instore network the executives, which straightforwardly influences the presentation of makers. This makes the courseofcreatingandputtingtoutilizeanotherdynamic strategy for the choice of a supplier a significant angle undertaking of the association. Even though there are quitealargenumberoffluffyMCDMstrategiesthathave been utilized to settle the supplier determination issue, the greater part of them don't consider the chief's restrictedobjectiveconduct(Banaeianetal.,2018)

: MCDM, TOPSIS Method, Supplier Selection,IdealBest,IdealWorst,Alternatives.

The buying system is one of the essential elements of a business,andthechoiceoftherightsupplierisoneofthe main parts of this interaction. This cycle straightforwardly influences the creation costs, item quality, and obtainment cycles of the ventures. It isn't workable for organizations to deliver low-cost, high-

Supplier improvement exercises can happen in three structures. The main structure could be the aggregation of data about the Supplier, the assessment of the Supplier's exhibition, and the unidirectional arrangement of express data about the Supplier's assessment results. The subsequent structure could be the arrangement of specific and inside and out specialized, process, or administrative information. The third structure could be the intuitive sharing of implied informationthroughthetradeofhumanresourceswhich are the representatives of the purchaser and provider firm. During supplier improvement, dependence on essential suppliers has driven purchasing firms to be

International Research Journal of Engineering and Technology (IRJET)

e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

more associated with their provider's exercises. The exercises give suppliers a potential chance to enhance theircapacities(FriedlandWagner,2012).

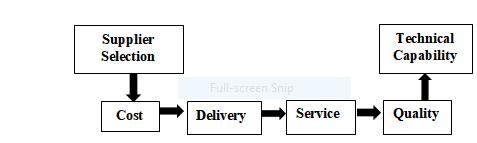

1. COST: While the unit cost of the material isn't ordinarily the sole rule in supplier choice, the absolute expense of possession is a significant element. All out the cost of ownership incorporates the unit cost of the material, instalment terms, cash rebate, requesting cost, conveying cost, coordinated factors costs, upkeep costs, and other more subjective costs thatmaynotbeeasytoevaluate.

:

Expulsion of openness to foreign currency changesasfarasestimating,

2. DELIVERY: During the determination stage, in some cases, associations need an organized method for assessing evaluate suppliers. This can be especially hard when the rules incorporate not simply quantitative measures (like expenses and on-time delivery rates) but other, more subjective elements, like administration strength or dependability. A supplier’s determination scorecard might be utilized as a choice help instrument. The assessment group will dole out a load to the various classes and foster a mathematical score for every supplier in every classification, consequently fostering the last presentation score.

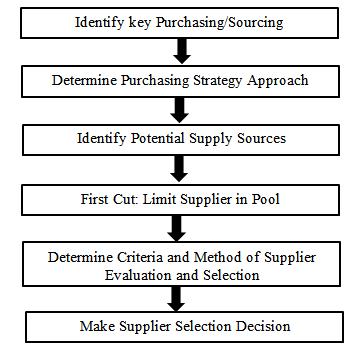

Supplier assessment and choice is one of the key hierarchical capacities required for effective business development and advancement. It is basic, along these lines, that the acquirement proficient executes viable cycles for qualifying Suppliers and deciding the honour ofbusiness.Todaywewillframefiveessentialphasesof effective obtaining. Also, we will investigate how Supplier responsiveness and capacity can be assessed andhowthesequalitiesshouldbejoined.

3. SERVICE: Providers should have the option to back up their items by offering great types of assistance when required. For instance, when item data or guarantee administration is required, providers should answer on a convenientpremise.

4. QUALITY AND RELIABILITY: Qualitylevelsof the acquirement thing ought to be a vital element in supplier determination. Item quality ought to reliably meet indicated necessities since it can straightforwardly influence the nature of the completed merchandise. Other than dependable quality levels, dependability additionallyindicatetoothersupplierattributes. For instance, is the supplier's conveyance leadtime solid? Any other way, creation might need tobeinterruptedonbecauseoflackofmaterial. 5. TECHNICAL CAPABILITY: Surveyingapotential supplier's administration capacity is a

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

convoluted, however significant stage. The various parts of the executive’s capacity incorporate the administration's obligation to ceaseless cycle and quality improvement, its general proficient capacity, and experience, its capacity to keep up with positive associations with its labour force, and its ability to foster a nearerworkingrelationshipwiththebuyer.

[Source: BLC 304/05 Procurement Management]

Supplier selection is considered as the main advance over inventory network the executives, which helps in lessening the expenses, work on the quality and convey theitemsontheschedule,inthismannersupportingthe extraordinary tension in the present worldwide contending climate. Numerous analysts have done their examination of provider determination and assessment, the cycles which decide the outcome of any store network, and proposed ground-breaking thoughts and strategiesfortheequivalent.

The examination project followed a subjective methodology with an exploratory view on the premise that the particular theme with regards to the railway industry. Supplier Selection is one of the subjects of interest,butthereisashortageofexplorationintherail route industry. Integra Engineering India Limited (IEIL) recruit supplier for giving part in the rail line global positioning framework, for this reason, we consider philosophy for supplier determination which is TOPSIS technique. TOPSIS (Technique for order preference by similarity to ideal solution) strategy is called an ideal arrangement. It is a different characteristic dynamic technique. This strategy is to develop the positive ideal solution and negative thought answers for the issues of different traits and utilizations the two benchmarks of being near the best arrangements and being far away fromtheshortidealsolutionastherulesofassessingthe plausible activities. "Positive ideal solution" and "negativeidealarrangement"arethetwoessentialideas ofTOPSISstrategy.Theallegedidealarrangement(noted asx+)istheideal arrangement(project),Inthisprocess, alltheattributesapproachtobestalternatevalueyetthe short optimal arrangement (noted as x-) is the most exceedingly awful (project) in theory. The standard of positioning ventures is to contrast every elective undertakingandx+ andx-.Assumingoneoftheactivities isnearx+anddistantfromxsimultaneously,then,atthat Point. It ought to consider the thorough appraisal of the Supplier Selection's capacity. Each record is a trait. So, it'saregularmultipleattributedecision-makingquestion

to sort Supplier judgments. And afterward, the TOPSIS techniquecanbeappliedtosortforsupplierchoice.

The literature review is the fundamental necessity for any research technique, as dealing with past writing shows the way, approach, and current progress on any exploration point. In this research, paperwork is to be furtherdevelopedSupplierchoiceprocedureforrailway tracking components following parts and pick best options with the assistance of TOPSIS and MCDM approaches. Railway capacity improvement basic approaches are followed: upgrading or expanding infrastructureforimprovingoperationalfeaturesonthat system.In eachapproachanalysis,thedifferentcapacity and methodology involve technically, furthermore, improving, as well as characterizing and ordering the limituse,areintroduced.

Sunil Kumar C. V. et al (2017) Inthepresentsituation, the author describes viewpoints and their comparing strategic policies in managing the suppliers that have been unfathomably changed and are developing at a quickerrate.Indeed,evensuppliers'explicitinvestments are committed to creating and adjusting the suppliers' capacities to meet the developing necessities of the end customers. Thus, in this review, an even-minded overview serious survey was conducted in the Indian assembling industry to investigate the connections among the boundaries to SDPs. The review has extensively consolidated the noticeable hindrances starting from various sides (for example provider, maker,producersupplier,andouterclimate)andgavea premise to a maker to direct the Supplier Development actually

Biswas, Tapas Kumar et al. (2020) This author has described the impact of supplier selection in all manufacturing industries during the COVID-19 pandemic,whetherallemergencyitemsandservicesare unavailable. The supply chain has been confronting differentobstacles.Thisresearchhasrecognizedthefive fundamental barriers to the production network, for example, absence of manpower, neighborhood regulations requirement, absence of transportation, shortageofunrefinedsubstances,andlackofincome for Indian manufacturing sectors during the lockdown. This paper proposed a system in light of a fluffy scientific ordered progression process (Fuzzy-AHP) with the utilization of triangular fuzzy numbers for the pairwise comparison matrices. It has been seen that the absence of manpower is a higher weight barrier than others. Additionally, the administrative ramifications of the outcomes are likewise given, which will be valuable for

International Research Journal of Engineering and Technology (IRJET)

e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

assembling areas to take reasonable choices to beat thesebarriers.

Kathirvel, P et al (2019). In this research, the author focusedontheIndianthermalpowerheavyindustryand distinguishes supply chain activity. Specialist keeps up with maintainability of supply chain management for reducingthe barriersofeconomicstability,social ethics, and environmental conservation, and this exploration help to evaluate the supplier of thermal power heavy industry given their presentation of The MCDM instrument TOPSIS is utilized to rank the supplier in thermal power heavy industry. The research likewise creates healthy competition among the providers and furtherdevelopsexecution.

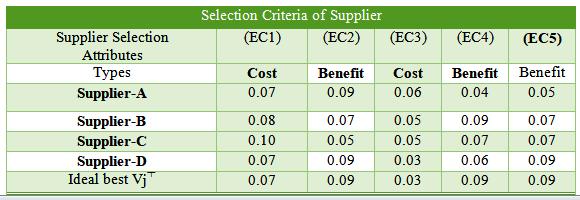

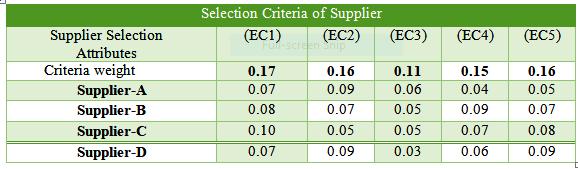

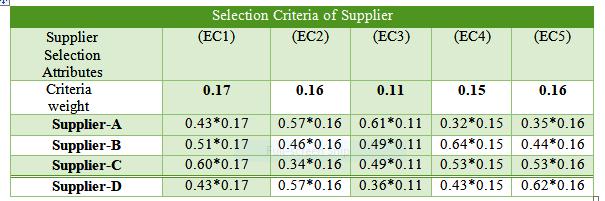

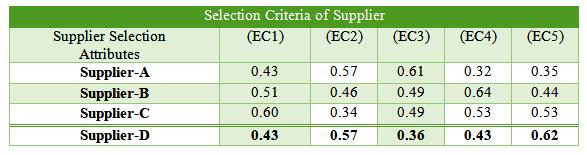

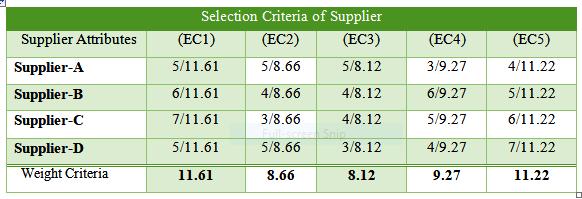

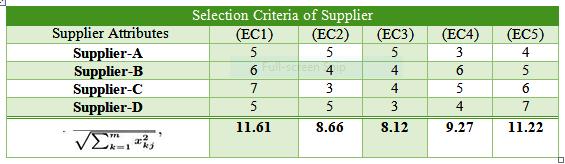

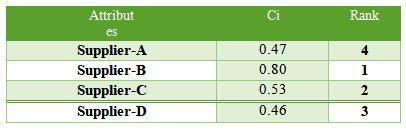

TOPSISisaMCDMstrategycreatedbyHwangandYoon, whichdependsontheguidelineof "relativeclosenessto an optimal arrangement”. All in all, the principal objective is to find an ideal arrangement from a few choices that ought to be as close as conceivable to the positiveidealarrangement(PIS),andbeyondwhatmany would consider possible from the negative ideal arrangement (NIS). In this strategy, in the wake of characterizing the loads for each alternative basis, the scores are determined, standardized, and afterward the mathematical distanceof every option in contrastto the PISandNISisprocessed.Thebestoptionisthenchosen through the closeness coefficient, which can be viewed as a composite characterization list, showing the choice with the best similitude to the best arrangement. In the exemplary TOPSIS approach, as referenced previously, theinfodatathatmakesthechoiceframeworkshouldbe numeric and obvious. Although being a simple comprehension technique, its application in disconnection is wasteful in addressing supplier determinationissuessinceitcan'tdealwithuncertainty. In any case, the TOPSIS technique can be adjusted to manage the dubiousness of the evaluation data through its reconciliation with fuzzy validation. TOPSIS joins customaryTOPSISwiththefuzzysethypothesis, Table 1: Decision Matrix

International Research Journal of Engineering and Technology (IRJET)

e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

Being one of the most vital dynamic occasions for the association,supplierselectionassumesasignificantpart to obtain serious advantages. To achieve this objective, theadministrationoughttoapplyasuccessfulmodeland selectsuitablerulesforthe choiceofsupplier.Linguistic variables assume a critical part in the choice-making process as these decide the presentation values which cannot be displayed in the mathematical qualities. Subsequently,withtheassistanceofthefuzzysettheory set hypothesis, DMs' inclinations and encounters are changed over into productive outcomes by applying linguistictermstoassesseverybasisforeachmultiplier. With regards to maintainable Suppliers, Selection was presented as one of the supportable practices that impact the whole functional exercises inside an organization. Choosing the best Supplier (s) who is/are fit for obtaining materials/parts with respect to foreordained reasonable models and hierarchical necessitiesisadifficultchoice.Inthisresearchwork,the SS issue was examined in the INTEGRA Engineering India Limited (IEIL) with the goal of proposing a reasonable methodology for the Supplier Selection dynamic cycle. An extensive literature survey was

directed to recognize the most essential measures and sub criteria. The last standards and sub-models were picked by the DM's total sentiments. By utilizing an intuitionistic TOPSIS approach, the most maintainable supplier was chosen. The determination of providers and assessments are uncertain and imprecise. First and foremost,itgivesthedataaboutdifferentdifficultiesthat

the firm faces while picking the best supplier in an assembling unit for delivering great quality items. Besides, it distinguishes the expected execution of exhibitions and gives a better comprehension of the determination of the supplier that goes under fuzzy circumstances. Moreover, this proposed model can be utilized in different MCDM issues, for example, area choice,projectorganization,advancementexercises,and new items improvement when available information is definite,precise,unsure,andunpleasantordinarily.

In the current global marketplace, firms need to expand their adaptability to remain serious and answer rapidly evolving markets. Subsequently, the viable demonstration of supplier selection is basic for the organizations keep up with seriousness by exhibiting greatoutcomesineachcyclebothinsideandbeyondthe firm. The motivation behind this research work are looked to find the bits of knowledge on supplier determination, especially on the idea of SMEs as suppliersintheIndianrailwayindustry,theobstructions theyexperiencetobeingsuppliers,themovestheymake toturnintothesupplierchoicewiththepurchasers,and difficulties they face in the supplier selection determinationprocess.

The reviewdemonstrated thatthere are barrierslooked at by supplier in the Indian railway industry. The purpose of this research work were discoveries that industry explicit human resources, industry guidelines, and assets are the most predominant sustainable to supplier improvement. With regards to economical SupplierchoiceinteractionwiththeassistanceofIntegra Engineering India Limited (IEIL) association was presentedasoneofthereasonablepracticesthatimpact the whole functional exercises inside an organization. Choosingthebestsupplier(s)whois/arefitforacquiring materials/parts regarding predetermined economical models and hierarchical requirements is a difficult choice. Thusly, offering exact decision-making help for DMs would be valuable for a useful organizational development towards executing the feasible obtaining activity. The supplier determination interaction will be characterized by exercises that will step-by-step follow as start with inquiries, assets activation, and gatherings covering legitimate conversations, business, and specialized. Recognized difficulties during the cycle exercises are the process of engagement taking more

time to go with contract understanding which will generallyemptyassetsoutofasmallsupplier.

Notwithstanding, any reasonable supplier selection models and technique to be utilized by the buyer relies

International Research Journal of Engineering and Technology (IRJET)

e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

upon the necessary capacity and their assumption. Accordingly, because of the buyer needs and worldwide market changes, there may be a requirement for new advanced techniques including both quantitative and subjective viewpoints for supplier choice and assessment, this is featuring the significance of additionalexaminationinfutureresearchinthisfield

1. Rouyendegh, B. and Saputro, T. (2014) ‘Supplier selectionusingintegratedfuzzyTOPSISandMCGP, A Case Study, Procedia - Social and Behavioral Sciences’,Volume116,pp.3957–3970.

2. Kannan, D., Beatriz, A., Sousa, L. De José, C. and Jabbour,C.(2014)'Selectinggreensuppliersbased on GSCM practices, ‘Using fuzzy TOPSIS applied to aBrazilianelectronicscompany’.EuropeanJournal ofOperationalResearch,Vol233,pp.432–447.

3. Mokhtari, M, Javanshir, H., Dolatabadi, Kamali, M (2013)‘SupplierSelectioninTextileIndustryUsing Fuzzy MADM’, Research Journal of Applied Sciences, Engineering and Technology 6(3). 400411.

4. Sunil Kumar, C. V., Routroy, Srikanta (2017). ‘ModelingSupplierDevelopmentbarriersinIndian manufacturing industry’, Asia Pacific Management Review,p1-16.

5. Biswas, Tapas Kumar, Chandra Das, M (2020). ‘Selection Of the Barriers of Supply Chain Management in Indian Manufacturing Sectors Due to Covid-19 Impacts’, Operational Research in Engineering Sciences, Theory and Applications, Vol.3,Issue3,2020,pp.1-12.

6. Kumar, A., Kumar, R, Garg, Garg, D. (2019) ‘Development of decision support system for esupplier selection in Indian mechanical manufacturing industry using distance-based approximation’, Decision Science Letters, Volume 8,Issue3,pp.295-308.

7. Kathirvel, P. Parthiban, P. (2019). ‘Supplier Management and Selection System considering Sustainability for a Thermal Power Heavy Industry’, IEEE International Conference on Advances in Computing and Communication Engineering(ICACCE)’,1–6.

8. Sureeyatanapas, P., Sriwattananusart, K., Niyamosothath, T., Setsomboon, W., Arunyanar, S (2018). ‘Supplier selection towards uncertain and

9. Kumar, A., Jain, V., & Kumar, S. (2014a). ‘A comprehensiveenvironmentfriendlyapproachfor supplierselection’,Omega,42(1),109-123.

10. Ageron, B., Gunasekaran, A. & Spalanzani, A. (2012). ‘Sustainable supply management: An empirical study’, International Journal of ProductionEconomics,140(1),168-182.

11. Hsu,C.W.,Kuo,T.C.,Chen,S.H.,&Hu,A.H.(2013). 'UsingDEMATELtodevelopacarbonmanagement model of supplier selection in green supply chain management’, Journal of Cleaner Production, 56, 164-172.

12. Brandenburg,M.,Govindan,K.,Sarkis,J.&Seuring, S. (2014). ‘Quantitative models for sustainable supply chain management: Developments and directions’, European Journal of Operational Research,233(2),299-312.

13. Azadi,M.,Jafarian,M.,Saen,R.F.,&Mirhedayatian, S. M. (2015). ‘A new fuzzy DEA model for evaluation of efficiency and effectiveness of suppliers insustainablesupplychainmanagement context’, Computers & Operations Research, 54, 274-285.

14. Schoenherr,T.,RaoTummala,V.M.,&Harrison,T.P. (2008). ‘Assessing supply chain risks with the analytic hierarchy processes, providing decision support for the offshoring decision by a US manufacturing company. European Journal of Purchasing & Supply Management. Volume 14, pp. 100-111.

15. W Thanaraksakul, B Phruksaphanrat (2009). ‘Supplierevaluationframeworkbasedonbalanced scorecard with integrated corporate social responsibility perspective’, Proceedings of the International Multiconference of Engineers and ComputerScientists,2.

16. A.Sarkar,P.K.J.Mohapatra.‘Evaluationofsupplier capability and performance’, A method for supply base reduction’, Journal of Purchasing and Supply Management.,12(3):p.148-163.

17. O. Ustun, E.A. Demirtas (2008). ‘Multi-period lotsizing with supplier selection using achievement

unavailable information: an extension of TOPSIS method’, Operations Research Perspectives, S2214-7160(17)30132-X. scalarizing functions’, Computers & Industrial Engineering,54(4):p.918-931.

International Research Journal of Engineering and Technology (IRJET)

e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

18. D.J. Watt, B. Kayis, K. Willey (2010). ‘The relative importance of tender evaluation and contractor selection criteria’, International Journal of Project Management,28(1):p.51-60.

19. W. Xia, Z. Wu (2007). ‘Supplier selection with multiple criteria in volume discount environments’, Omega the International Journal of ManagementScience,35(5):p.494-504.

20. H.J.Shyur,H.S.Shih(2006).‘AhybridMCDMmodel for strategic vendor selection Mathematical and ComputerModelling’,44(7-8):p.749-761.

21. S. Jharkharia, R. Shankar (2007). ‘Selection of logistics service provider’, An analytic network process (ANP) approach. Omega, 35(3): p. 274289.

22. O. Ustun, E.A. Demirtas (2008). ‘Multi-period lotsizing with supplier selection using achievement scalarizing functions’, Computers & Industrial Engineering,54(4):p.918-931.