International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Patil A. B.1 , Tande S.N.2

1P.G. Student, Walchand College of Engineering, Sangli. 2H.O.D. , Civil Engineering Department, Walchand College of Engineering, Sangli. ***

Abstract - Viscosity-modifying admixtures change SCC cohesion without changing fluidity (VMA). These admixtures areaddedtotheSCCtomakeitlesssensitivetotinyvariations in quantities and circumstances. This is done by decreasing fluctuations in sand moisture, particles, and grain size distribution.Theyshouldn'tbeusedtoavoidasolidmixdesign and careful selection of other SCC ingredients. Both prerequisites aren't met.

Key Words: ViscosityModifyingAdmixture,Rheology,Vfunnel,L-box

As megastructures are built across the world, selfcompactingconcrete(SCC)isbecomingmorepopular.It's oneofthelatesthigh-performanceconcreteinnovationsin ourindustry.Reinforcementcongestionaffectsmanyplaces. Cyclonicstormsandmassivepillarcapacityadditions.SCCis the sole alternative for tough site settings. The genuine qualityoftheconcreteinthefinalbuildinganditslongevity should be enhanced by developing a concrete mix that minimises the impact of site-specific craftsmanship on puttingandcompaction.ThisdroveSCC'sgrowth.

SCCisaninnovationinconcretetechnologybecause toits improved performance and more pleasant working environment. It's employed for thin components and big, robust constructions. SCC is considered the most major technological innovation in concrete technology in recent history.SCCwilllikelyreplaceordinaryconcretedueofits many features. SCC, sometimes called Rheodynamic concrete, does not require vibration for placement and compaction.Evenwithcrowdedreinforcement,itmayflow underitsownweight,fillingformworkandcompactingfully. Thehardenedconcreteisthick,uniform,andasdurableas typical vibrated concrete. SCC's theory is that aggregate settlementisproportionaltonewconcreteviscosity.

SCCmaybemadewithtypicalconcreteingredients.Tighter tolerances are needed to regulate workability. SCC is proportioned more scientifically than ordinary concrete mixes.SCCmixmusthaveahighpowdercontent,butless coarseaggregate,high-rangesuperplasticizer,andVMA.SCC is workable by balancing fluidity, deformability, filling ability,andsegregationresistance.

Okamura in Japan developed it, and it's shown to be inexpensiveanddurable.It'satypeofconcretethatdoesn't requirevibrationorcompactionduringplacementsinceit canflowthroughreinforcingandformworkcorners.SCCis fluid, resists segregation, and self-compacts without vibrationduringplacement.

Viscosity-modifyingadmixtureschangeSCCcohesionwithout changingfluidity(VMA).Theseadmixturesareaddedtothe SCCtomakeitlesssensitivetotinyvariationsinquantities andcircumstances.Thisisdonebydecreasingfluctuationsin sand moisture, particles, and grain size distribution. They shouldn't be used to avoid a solid mix design and careful selectionofotherSCCingredients.Bothprerequisitesaren't met.

A VMA modifies cement paste rheology. Yield point is the forcerequiredtomoveconcrete.Theslumptestcanbeused to determine the yield point of concrete. Plastic viscosity defines a concrete's reluctance to flow. Friction causes viscosity.Plasticviscosityaffectsconcrete'sflowrate.

Gettingtherightconcreterheologyrequiresbalancingthe yield point and plastic viscosity. VMAs modify the rheologicalcharacteristicsofconcretebyraisingtheplastic viscosityandyieldpoint.PlasticizersareusedwithaVMAto reducetheyieldpoint.

So,VMAsareadmixturesforspecialiseduses.Theyreduce segregation in highly flowable concrete, washout in underwater concrete, friction and pressure in pumped concrete,compensateforpooraggregategrading,notablya lackofparticlesinthesand,reduceconcretebleeding,and improvesemi-dryconcretegreenstrength.

This chapter describes the process in depth. As the effort involves improving the qualities of concrete, several trials havebeenconducted.Theworkperformedinrelationtoa flowchartthatwascreatedexpresslyforthisproject.They arediscussedinfurtherdetail.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Thescienceofthedeformationandflowofmatter,rheology is concerned with the interactions between stress, strain, strain rate, and time. Rheology is the study of materials whoseflowcharacteristicsaremorecomplexthanthoseof idealliquids,whicharegovernedbyNewton'sruleofviscous flow,namely.Liquidswhoseshearstressisproportionalto the rate of shear strain are referred to as Newtonian. The flow characteristics of new concrete do not comply. For concrete, the ratio of shear stress to shear rate is not constant.Thefactthatconcretecanstandinapile(asina slump test) indicates that a certain minimum tension is requiredforflowtotakeplace..Theminimumstressiscalled asyieldstressanddesignatedbysymbolτ0.Thusforfresh concrete the flow equation is expressed by Bingham equationwhichcanbewrittenas

Where τ=yieldvalueindicatingcohesionofmaterial. μ=Plasticviscosity ﻻ' =Rateofshear.

Bingham'sequationdescribestheconnectionbetween shear stress and material cohesion, plastic viscosity, and shearload

FlexuralStrength

Investigationofpropertiesinfreshstate(Rheological).This investigationincludesfollowingtests:

SlumpFlowTest

V-funnelTest L-BoxTest

J-RingTest

Theslumpflowisusedtoassessthehorizontalfreeflowof SCCintheabsenceofobstructions.Itwasfirstdevelopedin Japanforuseinassessmentofunderwaterconcrete.Thetest method is based on the test method for determining the slump.Thediameteroftheconcretecircleisameasurefor thefillingabilityoftheconcrete.

Theinvestigationofpropertiesofself-compactingconcrete hasbeen dividedintotwomainpartsbasedonitsphysical forms.

Investigationofpropertiesinhardenedstatewhichincludes threeproperties

CompressiveStrength

This is a simple, speedy test process; however, two individualsarerequiredtomeasuretheT500orT500mm time.Itmaybeutilisedonsite,howeverthesizeofthebase plate makes it fairly cumbersome and flat ground is required.Itisthemostpopulartestandprovidesanaccurate evaluationoffillingability.Itdoesnotindicatetheconcrete's capacity to move through reinforcement without obstruction,butitmayindicateresistancetosegregation.It mightbeclaimedthattheentirelyfreeflow,unrestrictedby boundaries,isnotreflectiveofconcretebuildinginactuality, but the test can be used advantageously to evaluate the consistency of delivery of ready-mixed concrete to a site fromloadtoload..

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

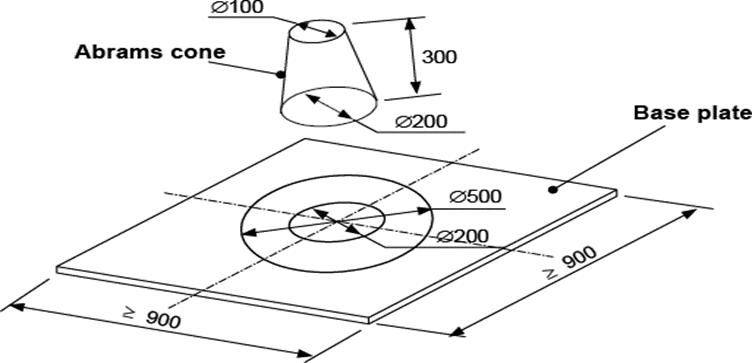

Theapparatusisshowninfigure.

Mould in the shape of a truncated cone with the internal dimensions200mmdiameteratthebase,100mmdiameter atthetopandaheightof300mm.

Baseplateofastiffnonabsorbingmaterial,atleast900mm square,markedwithacirclemarkingthecentrallocationfor the slump cone, and a further concentric circle of 500mm diameter

Trowel Scoop Ruler

Stopwatch(optional)

Thetestrequiresapproximately6litresofconcrete,sampled routinely.Wetthebaseplateandtheinterioroftheslump cone, Place the base plate on sturdy, level ground and the droop cone in the centre of the base plate, pressing down hard.Usethescooptofillthecone.Donottamptheconcrete; instead,usethetrowel tolevel itwiththetopofthecone. Removeanyexcessconcretefromaroundthecone'sbase. Raisetheconeverticallyandpermittheconcretetofreely flowout.Startthestopwatchsimultaneouslyandrecordthe timerequiredfortheconcretetoreachthe500mm(50cm) spreadcircle.(ThisisthetimefortheT500)Determinethe concrete's ultimate diameter in two perpendicular directions. Determine the mean of the two diameter measurements.Thisistheslumpflowinmillimetres.Note anymortarorcementpastewithoutcoarseaggregateatthe edgeoftheconcretepool.

The bigger the slump flow (SF) value, the greater the capacity of the material to fill a formwork under its own weight. A minimum value of 650mm is necessary for SCC. There is no widely acknowledged guidance for acceptable tolerances around a particular value, however 50mm, as withtheassociatedflowtabletest,maybeacceptable.

TheT500timeisasupplementaryflowindicator.Thelesser the time, the higher the flowability. According to the research conducted by Brite Eu Ram, a time range of 3-7 seconds is appropriate for civil engineering applications, whereas2-5secondsisgoodforhousingapplications.

Intheeventofextremesegregation,themajorityofcoarse aggregate will remain in the centre of the concrete pool, whilemortarandcementpastewillremainontheconcrete's perimeter. In the event of mild segregation, a border of mortar devoid of coarse aggregate may form around the perimeter of the concrete pool. There is no promise that

segregationwillnotoccurifnoneoftheseoccurrencesoccur, as this is a time-dependent factor that can arise after a longerduration.

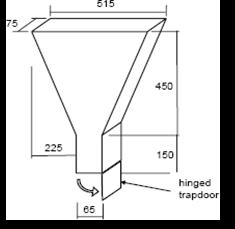

ThetestwascreatedinJapan,andOzawaetal.utilisedit.As seen in Figure 8, the equipment comprises of a V-shaped funnel.InJapan,theOfunnel,avariantoftheV-funnelwitha circularpart,isalsoutilised.ThestatedV-funneltestisused tomeasurethefillingability(flowability)of20mmaggregate concrete.Thetimeittakesforaround12litresofconcreteto flowthroughtheequipmentismeasuredoncethefunnelis filled with concrete. The funnel may then be refilled with concrete and given five minutes to settle. If the concrete exhibitssegregation,theflowtimewillbegreatlyincreased.

Althoughthetestisintendedtodetermineflowability,the outcome is impacted by other concrete qualities. The invertedconeformwillreflectanytendencyoftheconcrete tosetif,forinstance,thereisanexcessiveamountofcoarse aggregate. High flow time is also related with limited deformabilityasaresultofasignificantpasteviscosityand highinter-particlefriction.

Althoughtheequipmentisstraightforward,theinfluenceof thefunnel'sangleandthewalleffectontheflowofconcrete isunclear.

V-funnel bucket(±12liter) trowel scoop stopwatch

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

followingtestswereconductedtoassesswhetherornotthe concretesatisfiedthesecriteria.

Duringthisstageofthetesting,wewillbeutilisingM35and M25concrete,bothofwhicharedifferentgrades.

In order to evaluate the material's ability to withstand compression,wemadeasetof12cubesoutofitafterithad beencuredfor7,14,and28days,respectively.

Beforecasting12cylinders,wecuredthematerialforseven days,fourteendays,andtwenty-eightdaysrespectivelyin ordertogetanaccuratereadingofthetensilestrengthofthe materia During this round of the testing, we will use M35 andM25concrete,whichareofdistinctgrades.

Toexaminethematerial'scapacitytoendurecompression, wecreatedasetof12cubesfromitafter7,14,and28days ofcuring,respectively.

Beforecasting12cylinders,thematerialwascuredforseven days,fourteendays,andtwenty-eightdaysinordertoobtain anaccurateassessmentofthematerial'stensilestrength.

Afterthematerialhadbeencuredfor7,14,and28days,a totalof12beamswerecasttoassessitsflexuralstrengthat eachoftheseintervals.

In order to complete the process of acquiring the appropriaterheologicalqualities,severaltypesoftestingare alsoconducted.

Afterthematerialwascuredfor7,14,and28days,wecasta total of 12 beams so that we could evaluate its flexural strengthateachofthosetimeintervals.

Inaddition,differentkindsoftestsarecarriedoutinorderto complete the process of achieving the desired rheological properties.

Table -2: TestResultSummaryofhardenedconcrete

Grade Of Concrete Type Of Concrete

M35

M25

Compres sive Strength

Splitting Tensile Strength Flexural Strength

Normal 36.60 3.84 3.95

Scc 33.31 3.87 4.05

Normal 27.60 3.51 3.32

Scc 27.05 3.47 3.36

Above results are summary of tests done after 28 days of curing.Theseresultsaremeanof12cubeseach.

Table -3: TestResultSummaryoffreshconcrete

Grade Of Concrete Slump Flow V funnel time L- box ratio J-Ring

M35

M25

620 7.0 0.91 7.5 625 7.5 0.89 7.0

615 8.0 0.85 6.8

675 8.0 0.85 6.8 680 10.0 0.95 7.4 695 9.5 0.82 7.8

Fromaboveresultsfollowingmathematical modellinghas beenestablishedforcompressivestrength,tensilestrength andflexuralstrength.

Mathematicalmodellingforcompressivestrength σcus=0.028(0.04E-0.5x4-0.0036x3+0.0924x2-0.444x+ 36.089)

Where σ cus = Compressive strength of self-compacting concrete

Mathematicalmodellingfortensilestrength σts=0.23(0.002E-1.95x4–4.01x3+0.995x2-0.4x+5.289)

Whereσts=Tensilestrengthofself-compactingconcrete

Mathematicalmodellingforflexurestrength σ ts = 0.23(0.00195E-1.95x4 – 4.01x3 + 0.995x2 - 0.4x + 5.289)

Whereσfs=Flexuralstrengthofself-compactingconcrete

Inaboveequations,xisvariableandisdefinedastheratioof slumpvalueinmbyweightofVMA/cum.

And E is the modulus of elasticity of self-compacting concrete

All of the samples, when they were fresh, exhibited selfcompactingpropertiesthatweresatisfactory.Followingare someobservationsthatweremadebasedonthefindingsof thehardenedstateconcrete:

ThecompressivestrengthofSelfcompactingconcreteis found to be 33.31 Mpa on average, whereas the

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

compressivestrengthofnormalcementconcreteisfound tobe36.6Mpa.

The flexural and tensile strengths did not experience majorchanges.

AddingVMAtoSCCwasfoundtobeaneffectivesolution for preventing the segregation by making the concrete morecohesive.

SCCwithVMAisveryeffectiveinincreasingpump-ability ofconcrete.

[1]A.Belaidi,L.Azzouz,E.Marco,A.Garrido,E.Martinez,J. Canoves,(2012),“ConstructionandBuildingMaterials”28, 122-128.

[2]A. Dinesh, S. Harini, J.P. Jasmine, J. Shagufta, (2017), “Experimental study on self-compacting concrete”, InternationalJournalofEngineeringSciencesandResearch Technology,vol.6.

[3]B. Felekoglu, S. Turkel, B. Baradan, (2007), “Effect of water/cementratioonthefreshandhardenedpropertiesof self-compactingconcrete”,BuildingandEnvironment,vol.42.

[4]B. Persson, (2001) “A comparison between mechanical properties of self-compacting concrete and the correspondingpropertiesofnormalconcrete”,Cementand ConcreteResearch,vol.31.

[5]C. Ferraris, L. Brower, C. Ozyilidrim, J. Daczko, (2000) “Workabilityofself-compactingconcrete”,PCI/FWHA/FIB InternationalSymposiumonHighPerformanceConcrete

[6]DhiyaneshwaranS.,RamanathanP.,VenkatasubramaniR. , (2014) “Study on durability characteristics of selfcompacting concrete with fly ash”, Jordan Journal of Civil EngineeringandTechnology.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page565