International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

1 P.G Scholar, M.E Structural Engineering Department of civil Engineering , Anna University Regional Campus Madurai, Tamilnadu-625019

2 Assistant Professor, Department of Civil Engineering, University College of Engineering Dindigul, Dindigul, Tamilnadu.-624622

3 Assistant Professor, Department of Civil Engineering, University College of Engineering Ramanathapuram, Ramanathapuram Tamilnadu-623513

*Corresponding author. ***

Abstract - The application of waste materials is getting more popular in the concrete industries, as it can reduce the associated costs and environmental impacts. In this paper Low Density Polyethylene (LDPE) granules and Alccofine are used as partial replacement for coarse aggregate and cement for producing concrete cubes and cylinders has been investigated and reported. Concrete cubes and cylinders are cast manually and the strength of concrete in terms of compression and split tension are experimentally evaluated. It is found that the strength of plastic replaced concrete in terms of compression, split tension and flexural strength can be comparable with the conventional concrete. The present study is aimed at concrete mix with partial replacement of coarse aggregate and cement by LDPE granules (0%, 2%, 4% & 6%) that will provide an advantage in reducing the dead weight of structure. Alccofine is used to improve the workability and strength of the concrete. This mix in the form of cubes, cylinders and beam were subjected to compression, split tension, flexural strength to ascertain the strength parameter. Hence the replacement of Coarse Aggregate and Cement in concrete making is not only beneficial but also eco-friendly.

Key Words: LowDensityPolyethylenegranules,Alccofine, Fine Aggregate, Coarse Aggregate M 50, Compressive Strength,SplitTensileStrength,FlexuralStrength.

Concrete and plastic are the most widely used man made materialinworld.Astheworldpopulationincreasesrapidly, various types of waste are generated. It is estimated that everyyear4.8to12.7millionmetrictonsofplasticenterthe oceaneachyear.Only9%ofplasticwasteeverproducedhas been recycled. The remaining 79 percent has collected in landfills, dumps, or the environment, with just around 12 percentbeingburned.LeoBaekeland,whopopularizedthe word "plastics," created Bakelite in 1907, the first totally

syntheticplasticintheworld.Disposingplastichasbecomea majorproblem;itcanbereusedinmanyways.

Manyresearchandstudyhasbeencarriedoutinorder to reusetheplasticinconstructionfield,whichiseconomical. In the plastic waste stream, High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE) form the largest fraction, followed by Polyethylene Terephthalate (PET), Polypropylene (PP) and Polystyrene (PS). Reusing plasticinconcreteisseentobethemostpracticalsolution fordealingwiththedisposalofvastamountsofplasticwaste andtofulfilthegrowingdemandforaggregates.Sinceplastic is built of polymers, which are composed of long string molecules comprised of carbon atoms coupled with other elementssuchashydrogen,nitrogen,oxygen,andfluorine,it cannot be crushed as readily as natural coarse aggregate (NCA).

The goal of this experiment is to determine if it would be possibletopartiallyreplacethecoarseaggregateinconcrete withplastic-granulatedwastematerialswhilemaintaining thestrengthoftheconcrete.

Athermoplasticpolymerwithavaryingcrystallinestructure ispolyethylene.Tensmillionstonnesofplasticareproduced globallyeachyear,makingitoneofthemostfrequentlyused polymers.Itsapproximatemeltingpointis110°C(230°F). Theyareutilizedinsqueezebottles,toys,householdgoods, agriculturalmulch,garbageandgrocerybags,wireandcable insulation,andpackagingfilm.

Anewcategoryofmicro-finematerialscalledalccofinehave much smaller particle sizes than conventional hydraulic materials like cement, fly ash, silica, etc. Alccofine is a supplemental cementitious material made from ultrafine

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

groundgranulatedblastfurnaceslag.Itsuniqueproperty,an optimum particle size distribution, is produced during manufacturing under carefully regulated settings using specializedequipment.Whenmakinghigh-strengthconcrete (HSC) and high-performance concrete, the material Alccofine-1203, which has a low calcium silicate concentration, is used as an SCM to replace silica fume (HPC).Alccofineisalsosimpletouseandcanbemixedright inwithcement.Abetter,smoothersurfacefinishisproduced byAlccofine'sultrafineparticles.

The project's primary objective is to i)Replace naturally occurringmaterialsinordertoreducepressureonthem.ii) Studying concrete's characteristics using LDPE and Alccofine. iii) To compare the compressive strength, split tensile strength, and flexural strength of conventional concretewithconcretethathasbeenpartiallyreplaced.iv) Using concrete of the M50 grade. V) To investigate how freshlypouredandhardenedconcretebehave.

The main aim of the paper is to compare the mechanical propertiesofconcretewithregularplasticwaste(RPW)and (IPW) as replacement of FA and OPC. The replacement of fineaggregateorcementbyIPWmayregainitsstrengthdue to improved microstructure. For 5% replacement of OPC with IPW 1.07% increases in compressive strength and 13.7% increases in split tensile strength. 7% replacement reduces59.69kg/m3ofsand(3).Inthispaperthecrumb tyre is used as the partial replacement of fine aggregateandalccofineis mixedintheratioof 5%, 10%and15%attheoptimumpercentageofcrumb rubber.Theidealreplacementrateforcrumbtyresis determinedtobe10%.Theconcreteismoreaffected bysulphuricacidcuringascomparedtohydrochloric acidcuring.So the sulphuric acid is more dangerous forconcrete(4-6) Usingrecycledplasticinreplacementof naturalaggregatesinconcrete,eithercompletelyorpartially. ThebondstrengthisdecreasedwhenincreasewithRPA.As the amount of RPA increased, the bond strength, elastic modulus,andcompressiveandflexuralstrengthallreduced. The thermal conductivity of concrete decreased with an increaseinthequantityofRPA.Thethermalconductivityof RPAwas35–65%lessthanthatofthecontrolconcrete(79)Thecementisreplacedby10%byalccofineandfine aggregate is replaced by 5%, 10%, 15%, 20% Iron powder. The addition of alccofine and iron powder increases its Compressive strength, Tensile strength and Flexural strength of concrete when compared to conventional concrete. The result of the test showed that concrete containing iron powder has good resistancetosulphateattack,acidattack.(10-12).

Cementactsasabindingmaterialinconcrete.Thisproject makes use of OPC 53 grade cement. The main reason for usingOPC53gradeisithelpsinhydrationprocessandalso itincreasesthestrengthofconcrete.Thespecificgravityof cement is 3.12. The physical properties of the cement is testedandresultedbelow.

Table

Specificgravity 3.1-3.2

Compressivestrengthat28days 53N/mm2(Minimum)

InitialsettingTime 30min(minimum) FinalSettingTime 600min(maximum)

FineAggregateusedhereisMsand,whichismanufactured sand made by crushing stones. The size of manufactured sand(M-sand)islessthan4.75mm.Specificgravityoffine aggregate is 2.62. The fundamental material tests for fine aggregatehavebeenresultedbelow.

Table -2: Physical Properties of Fine Aggregate

PHYSICAL PROPERTIES VALUES

Specificgravity 2.68 Finenessmodulus 2.998 Surfacetexture Smooth

Coarse is usually found naturally and can be obtained by blastingquarriesorcrushingitbyhandorwithcrushers.A coarseaggregatewithanominalsizeof20mmischosen,and thephysicalparametersaredeterminedaccordingtoIS383 –1970.Theaggregatewhichretainedon4.75mmsievewhen sieved.Thespecificgravityofcoarseaggregateis2.70.The physicalpropertiesofCoarseaggregateistabulatedbelow

Table -3: Physical properties of Coarse Aggregate PHYSICAL PROPERTIES VALUES

Specificgravity 2.70

Finenessmodulus 7.364 WaterAbsorption 0.512% ImpactValue 38.43%

ParticleSize Angular

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Lowdensitypolyethylene,orLDPE,isasupple,adaptable, andlight-weightplastic.LDPEissimpletoproduce,easyto form,andhasstrongchemicalandimpactresistance. Low tensilestrengthbuthighflexibilitycharacteriseLDPE.Plastic bagsarethelow-densitypolyethyleneproductthatisused the most frequently. Squeezable bottles, lids, and toys are someLDPE examples.LDPE'sspecific gravity rangesfrom 0.91to0.925.

Waterplaysanimportantcomponentofconstruction.Salts andsolidparticlesmustnotbepresentinthewaterusedfor building or curing. Water's pH shouldn't be less than 6. Throughoutthetrial,portablewaterthatmetIS456:2000 requirementswasused.

GradeofConcreteM50

TypeofCementOPC-53grade

NominalMaximumsizeofAggregate-20mm ExposureCondition-Sever

MaximumCementContent-450Kg/mm3

Maximumw/cratio-0.45 MineralAdmixture-Alccofine

Table-4: Mix Ratio

Cement Fine Aggregate Coarse Aggregate Water

Alccofine, a mineral admixture employed here, has been showntoboostconcrete'scompressivestrengthovertime. Due to its ideal particle size distribution, alccofine offers uniquequalitiesthatimprovetheperformanceofconcretein both fresh and hardened states. Alccofine comes in two varieties:Alccofine1101(whichhasahighcalciumsilicate content)andAlccofine1203.(withlowcalciumsilicate).The specificgravityis2.7.

1 1.12 1.66 0.34

Table-5: Percentage of materials replaced

Mix Ratio % of Coarse Aggregate

% of LDPE Granules

% of Cement % of Alccofine MSand

CC 100% 0% 100% 0% 100%

MR1 98% 2% 90% 10% 100%

MR2 96% 4% 90% 10% 100%

MR3 94% 6% 90% 10% 100%

To determine the concrete is workability, the Slump Cone test is performed. The distance between the top of the slumpedconcreteandthelevelofthetopoftheslumpcone isusedtocalculatetheconcrete'sslump.Theresultofthe Slumpconetestismentionedbelowandtheslumpissaidto beTrueorHighSlump.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Table-6: Slump cone test result

Replacement of PEG 4000(%)

Trial No Slump value (mm)

Average slump value (mm)

Type of Slump

NormalSlump 1 102 101 True or High Slump

2 100 MR1 1 105 104 2 103 MR2 1 106 107 2 118 MR3 1 105 `106 2 107

The concrete is said to be hardened only when it is fully cured.TheHardenedconcretetestareCompressivestrength, SplitTensileTest,andFlexuralstrengthtest.

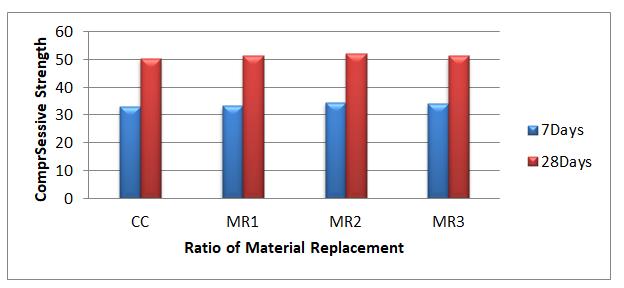

Theabilityofamaterialorstructuretoresistpushforces thatareappliedaxiallyisknownascompressionstrength.A cubeofstandarddimensionsof150x150x150mmisusedfor thecompressivestrengthtest.Theconcreteiscuredfor7and 28-daybeforeaconcretetestisconducted.TheCompressive Strength of 4% replacement of CA with LDPE granules increased when combared to conventional concrete. The resultsofthe compressivestrength istabulated below(1316)

Table-7: Compressive strength of concrete

% of Replacemen t

Average Compressive Strength (N/mm 2 ) at 7 days

Average Compressive Strength (N/mm 2 ) at 28 days

CC 33.21 50.34

MR1 33.38 51.14 MR2 34.52 52.11 MR3 34.20 51.28

8.2.2

Fig-3: CompressiveTestonCube

Chart-1: CompressiveStrengthofConcrete

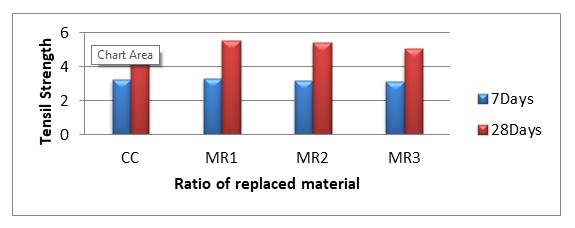

Thetensilestrengthofconcretecanbetestedindirectlyusing thistechnique.Thistesttakesplaceonacylindricalspecimen with dimensions of 300mm in length and 150mm in diameter. The concrete is cured for 7and 28-day before a concretetestisconducted.TheSplitTensileStrengthof 2% replacement of CA with LDPE granules increased when combaredtoconventionalconcrete.Theresultsofthesplit tensilestrengthistabulatedbelow(17-20).

Table-8: Split tensile strength of concrete

% of Replaceme nt

Average Split Tensile Strength (N/mm 2 ) at 7 days

Average Split Tensile Strength (N/mm 2 ) at 28 days

CC 3.26 4.85

MR1 3.31 5.52

MR2 3.18 5.38 MR3 3.13 5.04

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Fig-5: SplitTensiletestonCylinder

Chart-2: SplitTensileofConcrete

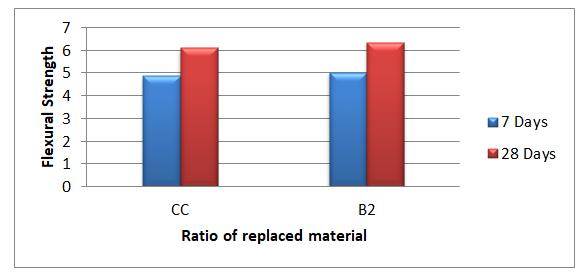

Flexuralstrengthistestedusingabeamwithaspecimensize of200mmx200mmx750mm.Theidealpercentagebased on compressive strength is MR2, or 4 percent LDPE granule replacement and 10 percent Alccofine. Fromthe optimumpercentagethebeamiscastedandaftercuring,the flexural test of a conventional concrete beam and a beam that has been replaced with materials is conducted, The Strengthis increased at 4% replacementwhencomparedto conventional concrete and the results are tabulated below(21-26).

Table-9: Flexural Strength of concrete

% of Replacement Average Compressive Strength (N/mm 2 ) at 7 days

Average Compressive Strength (N/mm 2 ) at 28 days

CC 4.87 6.11 MR2 5.02 6.35

Theworkabilityoftheconcreteisgraduallyincreasingwith replacement of plastic and mineral admixture when comparedtonormalslump.At28daysofcuringtheconcrete attainitsmaximumstrengthandthetestsarecarriedout. TheCompressivestrengthofReplacedconcretehighat MR2 (52.11 N/mm2) whencomparedtoconventionalconcrete. TheSplitTensiletestofreplacedconcreteishighat MR1 ( 5.52N/mm2) whencomparetoconventionalconcreteat28 days.TheFlexuralStrengthofconcretebeamisincreasingat B2 ( 6.35N/mm2) with 4% replacement of CA by LDPE granulesand10%ofCementbyAlccofine.Sincetheweight oftheconcreteisregucedbyusingplasticmaterialitcanbe used as light weight material also. By introducing waste recycledplasticintotheconcreteiswhichisenvironmental friendly

[1]AlirezaMohammadinia,Yatchoywong,ArulArulrajah& SuksunHorpibulsuk(2019),“StrengthEvaluationofutilizing recycledplasticwasteandrecycledcrusedglassinconcrete footpath”Elsevier,Constructionandbuildingmaterials,Vol 197,Pp:489-496.

[2] Ankit (2020), “Use of Low Density Polyethynene in Flexible pavements”, IJAST, Vol 29, Part 10S, Pp: 5063 –5075.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

[3] Arivalagan.S (2016), “Experimental investigation on partialreplacementofwasteplasticinconcrete”,Vol5,part 11.Pp:443-449.

[4]B.V.Bahoriaa,D.K.Parabata&P.B.Nagarnaik(2018),“XRD AnalysisofNaturalsand,QuarryDust,WastePlastic(LDPE) to be used as a Fine Aggregate in Concrete,” Elsevier, MateialsToday:Proceddings,Vol5,Pp:1432-1438.

[5] N.M.Mery Treasa Shinu & S.Nedhidasan (2017), “An experimental study of replaceing conventional coarse aggregatewithE-WasteplasticforM40gradeconcreteusing riverSand”, Vol.22,Part3,Pp:633–638.

[6] O luwarotini olofinnade, Sarath Chandra & Paromita Chakraborty(2020),“Recyclingofhighimpactpolystyrene andlowdensitypolyethyleneplasticwasteinlightweight basedonconcreteforsustainableconstruction”,Vol.38,Part 5,Pp2151–2156.

[7] Patil Hitesh Kumar, Bavisakar, Shirnkant R, Dr Ahirro SarjeraoP&DrAmolBsaner(2017),“PolymerConcreteby usingwasteplasticGranules”,Vol6,Pp:2319-8753

[8] Sachin Tiwari & Preeti Gangwar (2021), “Evaluate the effectofacidattackonrubberisedconcreteusingcrumbtyre rubber and replacement of cementby alccofine”, Elsevier, MaterialsToday,Vol.47,Part13,Pp:3778–3782.

[9]Saloni,Abhisheksingh,Vaibhavsandhu&Jatin,Parveen (2020), “Effect of Alccofine and curing condition on properties of low calcium fly ash based geopolymer concrete”,Vol.32,Part4,Pp:620–625.

[10] Z.C.Steyn, A.J.Babaf Emi, H. Fataar & R. Combricnk (2020), “Concrete containing waste recycled glass, plastic andrubberassandreplacement”,Elsevier,Constructionand BuildingsMaterials,Vol.269,Pp:0950-0618

[11] Tanveer Asif Zerdi, Mohammed Firasat Wasseem, MohammedMinhajuddin,MdYusuf&MehreenNaazZerdi (2016), “Experimental study on concrete containing RecycledPlastics(LDPE)”,Vol.5,Issue5,Pp:2277-8160

[12]TaoLiu,AfnanNafees,Sherbazkhan,Muhammedfaisal Jave,FahidAslam, HishamAlabjuljabbar,Jian–JunXiong,M Ijaz Khan & M.Y. Malik (2021), “Comparative Study of mechanical properties between irradiated and regular plasticwasteasareplacementofcementandfineaggregate for manufacturing of green concrete”, Vol. 13, Issue 2, Pp: 101563

[13]ComparativeStudyofmechanicalpropertiesbetween irradiated and regular plastic waste as a replacement of cement and fine aggregate for manufacturing of green concrete

[14] J. Thorneycroft, J.Orr, P.Savoikar & R.J.Ball (2018), “Performance of structural concrete with recycled plastic waste as a partial replacement of sand”, Elsevier, ConstructionandBuildingsMaterials,Vol.161,Pp:63-69.

[15]UAbdulkarIsmailAl-HadithiNahlaNajiHilal,(2016), “The possibility of Enhancing some properties of selfcompactingconcretebyaddingwasteplasticFibers”,Journal ofbuildingengineering.Vol.8,Pp:20-28.

[16] U Maher Al-Tayeb Mustafaa, Ismail Hanafib, Rade Mahmoudb & B.A. Taye (2019), “Effect of partial replacementofsandbyplasticwasteonimpactresitanceof concrete:ExperimentalandSimulation”Vol.20,Pp:519-526.

[17] U Shaik Inayath Basah, M.R.Ali, S.U.Al-Dulaijan &M.Meslehuddin (2020), “ Mechanical and thermal properties of lightweight recycled plastic aggregate concrete”, Elsevier, Construction and Buildings Materials, Vol.32,Pp:101710.

[18] U Sina Safina & Amani Alkalbani, (2016), “Use of recycledplasticwaterbottlesinconcreteblocks”Elsevier, ProcediaEngineering,Vol.164.Pp.214-221

[19]B.Venkatasan,M.Venuga,P.R.Dhevasenna&V.Kannan (2020), “Experimental study on concrete using partial replacement of cement by alccofine fine aggregate as iron powder”Vol.37,Part2,Pp:2183–2188.

[20] Zeeshan Ullah, Muhammad Irshad Qureshi, Afnan Ahmad, Sibghat Ullah Khan & Muhammad Farrukh Javaid (2021), “An experimental study on the mechanical and durability properties assessment of E – Waste concrete”. Elsevier, Journal of Building Engineering, Vol.35,Pp: 102177.

[21]V.Kavishankari,J.Thivya&J.Vijayaraghavan(2019),“ Experimental study of steel fibre and foamed reinforced concrete beam”, International Research Journal of EngineeringandTechnology,Vol6(5),pp935-939.

[22] J.Thivya, R.Monica & J.Vijayaraghavan, (2019), “Analysisofprecastposttensionedsegmentalbridgecolumn usingansys”,InternationalResearchJournalofEngineering andTechnology,Vol6(4),pp3727-3732.

[23] J.Thivya, R. Roopavathi & J.Vijayaraghavan, (2018), “ Experimental study on Behaviour of concrete by using Domestic plastic waste as a fiber content”, International JournalofInnovativeResearchinScience,Engineeringand Technology,Vol7(5),pp477-479.

[24]J.Thivya,M.Saranya,J.Vijayaraghavan(2018)“AStudy of Manufacturing and Experimental Behaviour of Cellular LightweightConcrete(CLC)Bricks”inInnovativeResearch

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

in Science, Engineering and Technology, Vol 7, Special Issue(5),pp:469-476.

[25] J. Vijayaraghavan, A. Belin Jude & J. Thivya (2017), “Effect of copper slag, iron slag and recycled concrete aggregate on the mechanical properties of concrete”, ResourcesPolicy,Vol.53,pp-219-225.

[26]S. Bensila, J.Thivya, J. Vijayaraghavan (2022) “An Expermentalinvestigationoneffectofmechanicalproperties ofM50GradeConcreteWithPartial Replacement of sandwithCopperSlag”, InternationalResearchJournalof Engineeringand Technology,Vol9(8),pp102-108