International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

Afroj Jahan1, Ashish Kumar Srivastava2

1Assistant Professor, Department of Mechanical Engineering, GITM, Lucknow

2 Assistant Professor, Department of Mechanical Engineering, GITM, Lucknow ***

Abstract: With the new innovation in technology energy absorption performance is the most important mark in the vehicle safety. The front rail layout must be adjusted so that more strength is absorbed. In this paper different energy absorbing materials and different criterion that is non identical rib (inside) thickness are estimate using FEA in rectangular column (loaded beam) The four front load beam under goes the path of direct load which affects the deformable barrier of the offset and the whole front By design of rails the acceleration pulse exert influence on the passenger compartment Effective design helps in the reduction of injury to the occupants Whole model is simulated in LS-DYNA.

Key words: FEA, Impact analysis, Beam structure, Dynamic crushing, Thin-walled structure, LS- Dyna.

1. Introduction:

Increasingpopulationofworldcausesmoremanufacturingand usesofvehicles.Theremarkableincrementinnumberof vehiclescreatesthesignificantsafetyissueofpassengersanddriversinthetermsofpoorroadconditionandnegligenceof drivingrules.Therearesomanyvehicleaccidentshappeninonlythesecondsinalloverworld.

Among them, major percentage of accident cases is due to collision of cars at front sides i.e., Frontal vehicle collisions. Anterior vehicle crash declared as the crucial type of car accident in the whole world. Customers have become highly conscious of the seriousness of vehicle security. As a result, vehicle safety becomes the primary selling feature in automobileindustriesintoday’sworld. Vehiclecrash-resistantisexplainedastheestimationofinhabitantsecuritywhen vehicle is required in the RTA (road traffic accident) By the designers keep on to make the frontal of the vehicle so competenttosoakupmaximumpartofenergyforthereductionofamount accelerationoftheheadofoccupant,alsofor thereductionoftheimmersionoftheupperpartandlowerpartofthedash.Theleadpartofrailofautomobileplaysthe roleofthecomponentwhichabsorbsmaximumpartofenergy Thisstudywillhelptogetbetterutilizationofenergyofthe frontrails

The crash in the front is the most familiar accidents which is on the vehicles. The impact test on the front was fundamentallydraftedunderthecommitteewhichisunderEEVsafety Thistestwhichisdoneissimulatedandcomesout tobethemostcommontypeofroadcrashwhichisfettle.Itsbottlenecksaretheinabilityofcartoresistthesuddenhitin the section of traveller which causes the injuries which are deadly and serious. Since, it does not provide protection against the sudden frontal hit. In ECE regulations for Frontal crashes, the testing vehicle should pass the two basic tests, theOffsetdeformableBarrier40%offsettestandfullFrontal100%overlaptest.

Immersionofenergyandminimumchangeofenergytotheriderortravellersclassifiedintotwobasicdesignofstructures invehicleselements.Thedesignofstructureofvehiclecontainsthedesignofbodyandsupportingframeofstructure.

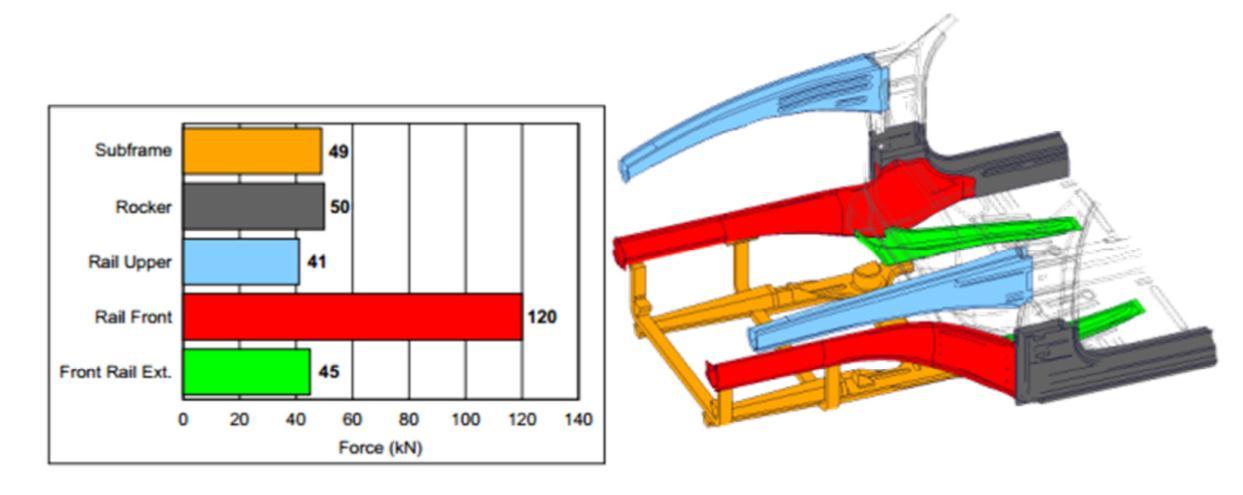

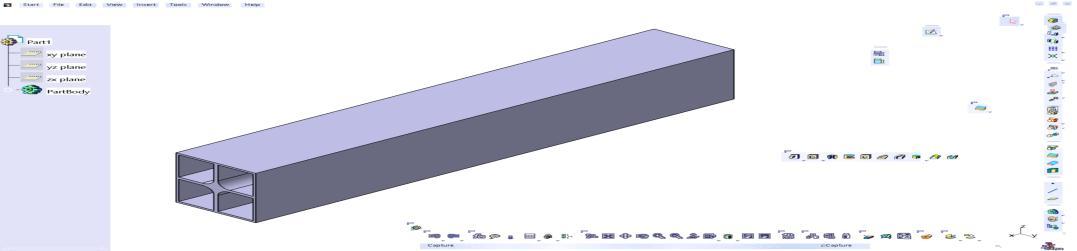

Figure.1.showsthatthe120kNforceistakenbythefrontrail,around40%oftheforce,takenbytheotheruniquepartof the assembly which also designed in such a way that it assembled with different parts of units of the manufacturer’s vehicle

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

Figure1.

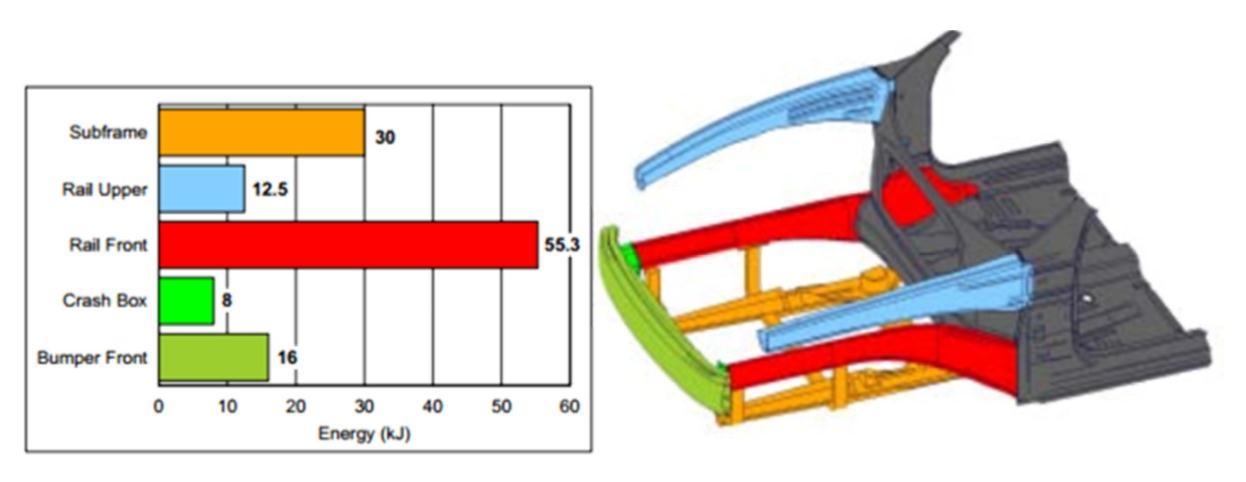

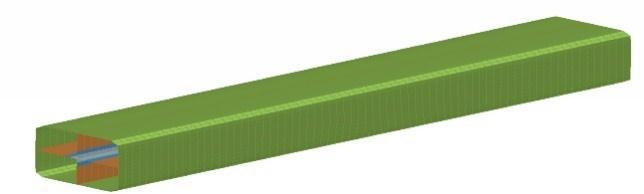

Front rail absorbs around 45% of the other by the other unique part of the assembly which also designed in such a way thatitassembledwithdifferentpartsofunitsofthemanufacturer’svehicleshowninfigure.2

Figure2.

Energy absorption and peak force on the material depends upon the tensile strength. Advanced steel materials are developed which have the properties from low strength to high strength are of the range from low carbon steel to martensitic.Thestrengthvariesfrom200MPato1800MPa.

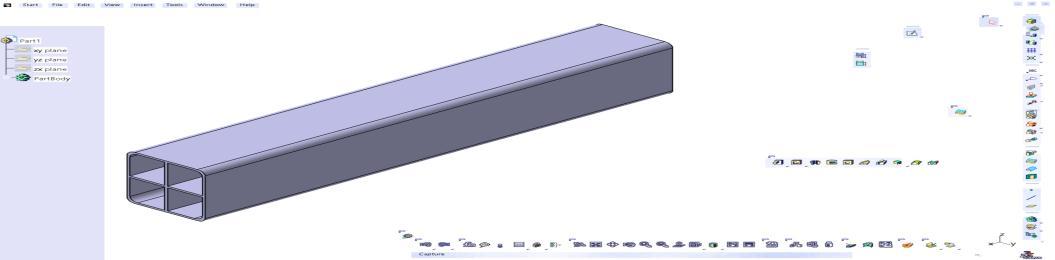

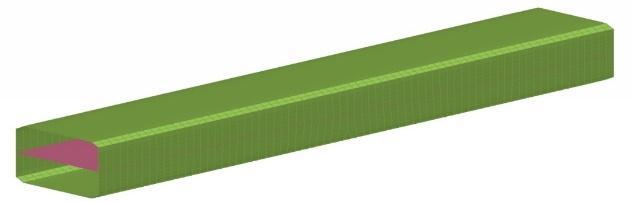

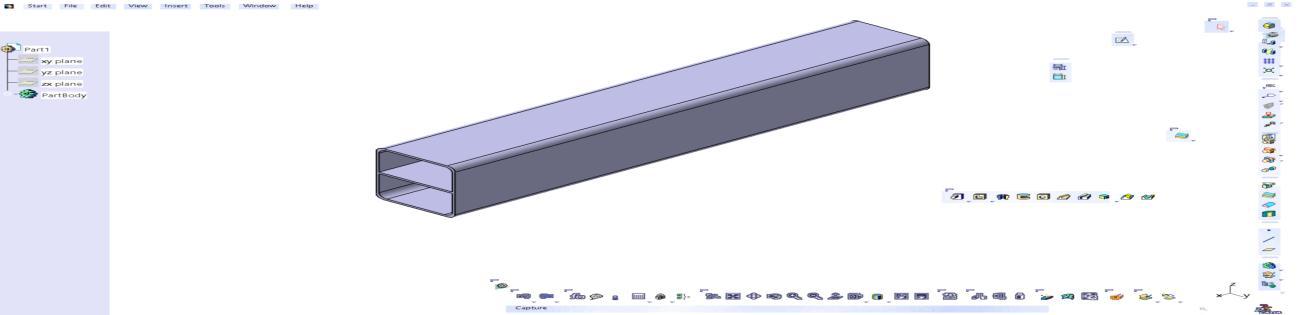

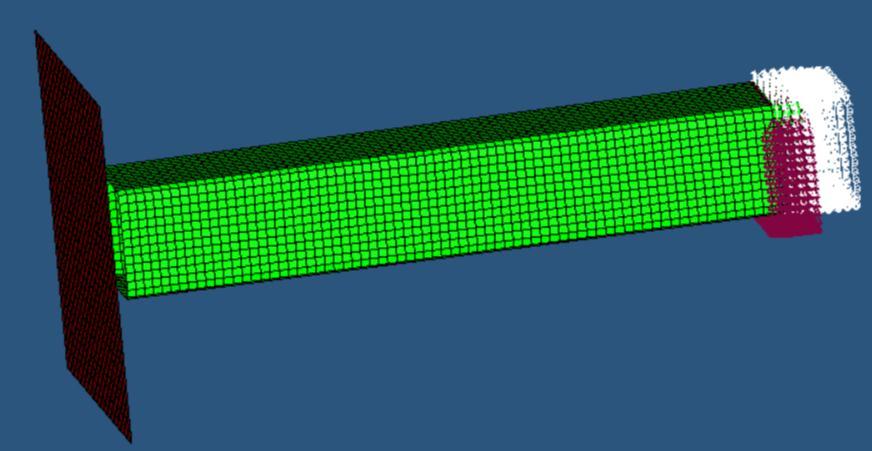

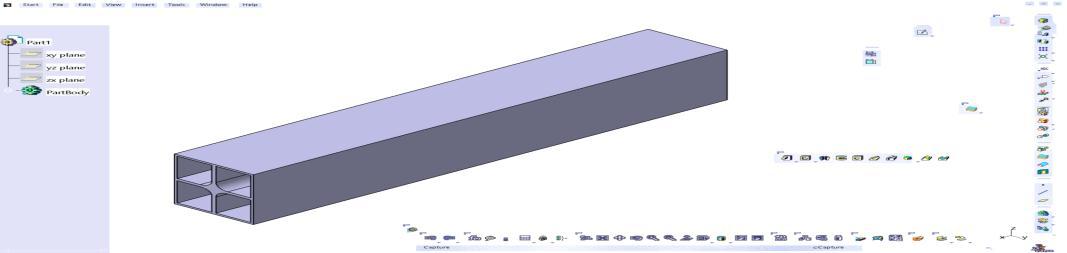

Average mesh size of 4mm is used for the model. The minimum size of the element is 2 mm and maximum is 5mm.A rectangular section of 60*50*1.8 mm thick is used with a length of 300mm. The component is fixed in all degrees of freedomatoneatasshowninFigure,6

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

ShellElementwarpageinDegrees <15,Degrees

MinimumElementsizeforshellElements 2mm

MaximumElementsizeforshellElements 5mm

ShellElementquadangle >45,<135,Degrees

ShellElementTrias >20,<120,Degrees

AspectRatiooftheShellElement <=5

JacobianoftheShellElement >0.6,=1

SkewnessofShellElement <45,Degrees

PercentageofTrias <=7%

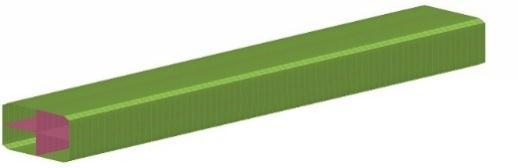

Figure 6. Section -Cross Mid Ribs (1.8 mm thick)

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

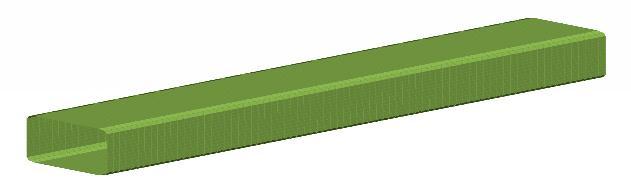

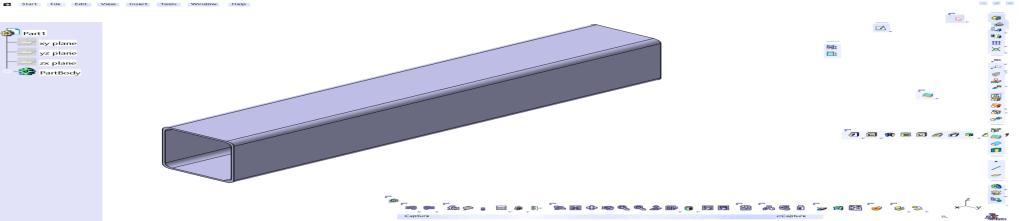

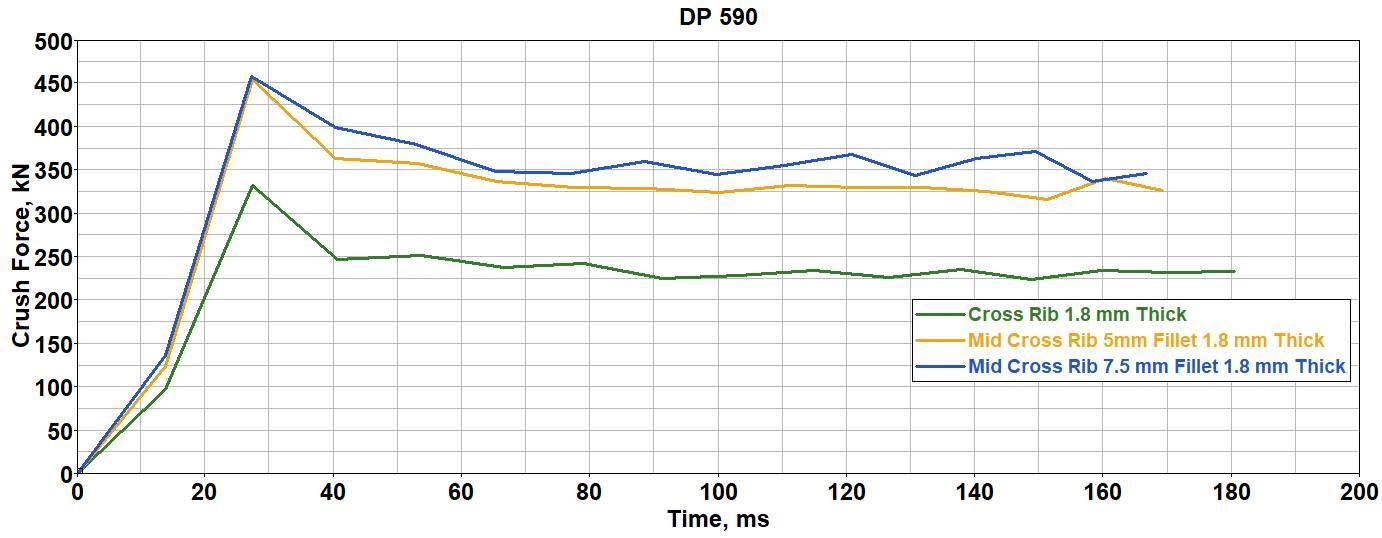

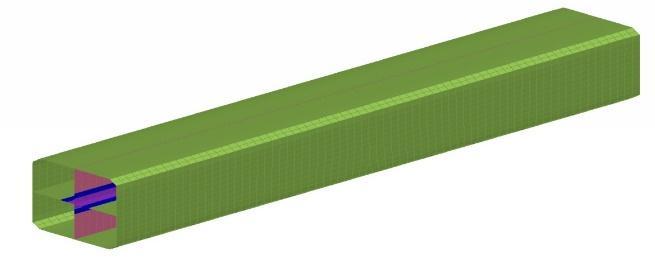

Figure 7 Section - Cross Mid Rib (5 mm fillet radius)

Figure 8. Section - Cross Mid Rib (7.5 mm fillet radius)

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

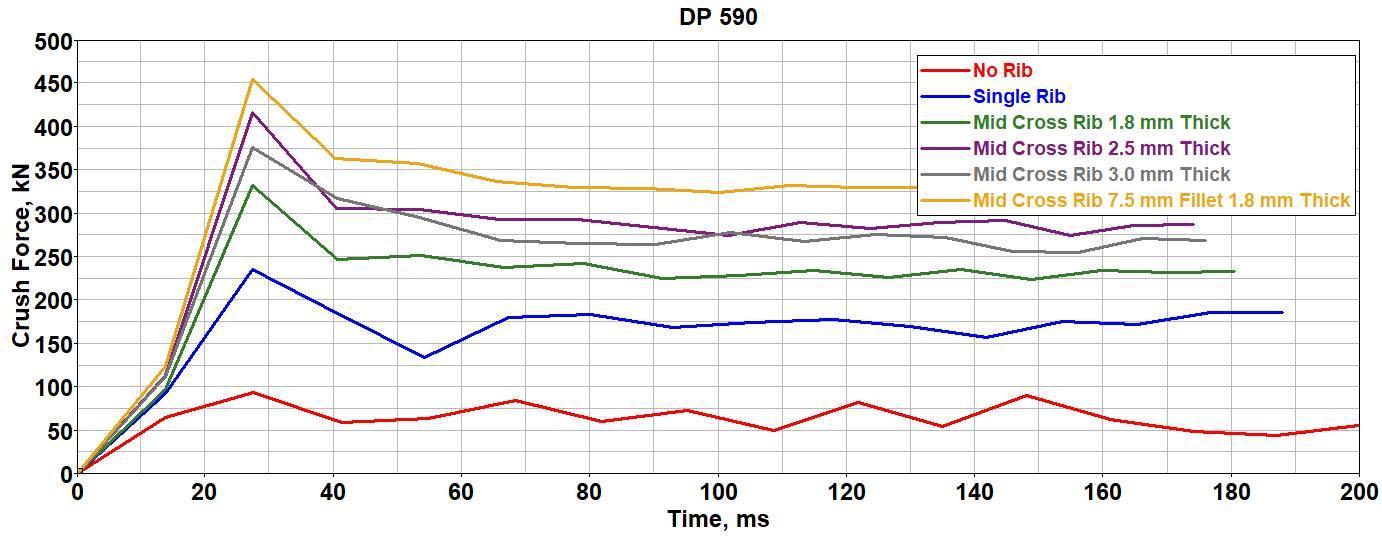

Theresultsshowthatthestrengthandenergyabsorptionabilityoflongrectangularcolumnincreaseswithadditionofribs and fillet radius of the cross ribs. The incident of frontal collision, the front region at the front rail section is made up of rectangular long column. There is considerable quantity of absorption of energy if only using 3mm rib thickness as a alternativeofenlargethefullfrontrailthickness.Dualphasesteelmaterialshashigherstrength.Thisstudycanbefurther extendedandmoresectionoptionscanbeusedtoabsorbmoreenergy.

[1] Muhammad Emin Erdin, Cengiz Baykasoglua, “ MerveTunay Cetin, “Quasi-static Axial Crushing Behavior of Thinwalled Circular Aluminum Tubes with Functionally Graded Thickness”, International Conference on Manufacturing EngineeringandMaterials,ICMEM2016,6-10June2016.

[2] N.Baaskaran, K.Ponappa, S.Shankar,“Quasi-StaticCrushingandEnergyAbsorptionCharacteristicsof Thin-Walled Cylinders with Geometric Discontinuitiesof Various Aspect Ratios”, Lattin American Journal of Solids and Structures, http://dx.doi.org/10.1590/1679-78253866.Received24.03.2017Availableonline10.07.2017

[3] Chein-Hsun Wu, “ Improvement Design of Vehicle’s Front Rail for Dynamic Impact”, 5th European LS-DYNA Users Confrence.

[4] Elmarakbi, Ahmed, Long, YandMacIntyre, John(2013)“CrashAnalysisandEnergyAbsorptionCharacteristicsofSshaped Longitudinal Members”. Thin- Walled Structures, 68. pp. 65-74. ISSN 0263-8231, http://sure.sunderland.ac.uk/3594/, Volume50Issue1January2012.

[5] J. Han &K. Yamazaki, “ A study on the crashworthiness of S-shape square tubes”, Transactions on the Built Environmentvol52,

[6] RameshKoora, RamavathSuman, SyedAzamPashaQuadri,“DesignOptimizationofCrushBeamsofSUVChassisfor Crashworthiness”, InternationalJournalofScienceandResearch(IJSR)ISSN(Online):2319-7064IndexCopernicusValue (2013)

[7] R.Fragoudakis and A. Saigal , “EFFECT OF ALUMINUM FOAM AND FOAM DENSITY ON THE ENERGY ABSORPTION CAPACITY OF 3D “S” SPACE FRAMES”, Department of Mechanical Engineering Tufts University, Medford, MA 02155 UnitedStatesofAmerica

[8] Neil Sharpe, Robert Vendrig, Kees Houtzager, “ IMPROVED DESIGN FOR FRONTAL PROTECTION”, Alcoa – Reynolds AluminiumHollandB.VTheNetherlandsPaperNo.329

[9] SABER VATANISAHLAN, K. VIJAYA KUMAR REDDY, “QUASI-STATIC CRUSH BEHAVIOUR OF ALUMINUM AND STEEL CIRCULAR TUBES WITH THROUGH-HOLE DISCONTINUITIES”, International Journal of Mechanical and Production Engineering,ISSN:2320-2092,Volume-1,Issue-1,July-2013