International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

1 T.Y. Student, Department of Mechanical Engineering, Vishwakarma Institute of Technology, Bibwewadi, Pune ***

Abstract - Thefollowingstudy isthe heattransferanalysis of conventional compact brazed plate heat exchanger consisting of 10 plates wherein a bird feather pattern is designed using biomimetic approach at certain heights on the surface of the plate to improve heat transfer and pressure drop ofthe PHE.Theinspirationbehindthisisthat birds can maintain suitable body temperatures even in most adverse environments. Heat transfer in birds takes place through conduction, convection and radiation. The structure of bird feathers plays a major role in thermoregulatory mechanismofbirdsandhasbeenknown to offer excellent heat transfer rates. With the help of additive manufacturingtechniques,PHEswithanycomplex pattern can be designed and manufactured. In this study, different heat exchangers have been modelled with an attempt to mimic the pattern of bird feathers in order to increase heat transfer area and turbulence. CFD simulations were then performed using SolidWorks Flow Simulationtool forthe same operatingconditionswithhotwaterandcold-water inlettemperaturesequalto900 Cand 250 C respectively, and a mass flow rate of 0.05 kg/s to compare the heat transfer rate, pressure drop and effectivenessoftheconventionalPHEandtheonesdesigned by biomimetic approach. The simulation results were validated by numerical and experimental results of an existing PHE with Chevron pattern. However, it has been observed that the Chevron-type PHE offers better heat transfer rates compared to the biomimetic ones due to effective use of patterned area.

Key Words: plateheatexchanger, featherpattern,heat transferrate,turbulence,CFD

Heatexchangersfindtheirapplicationsinalmostallkinds of industries due to their compactness and high heat transferareaasthefluidisspreadoutovertheplates.The haveanalternatingflowofhotandcoldfluidbetweenthe metalplatesandareusuallyavailablein2configurations, viz.gasketedandbrazed.Thegasketedversionsareused for large-sized PHEs whereas smaller units tend to be brazedwhereintheplatesarealignedsidebysideusing vacuum soldering process. This creates a joint at each point of contact between the plate and the brazing materialprovidingabettersealingandallowingtheheat exchanger to withstand high pressures. The inlet and

value:

outlet ports provideseparate flow paths or thehot and coldfluid.

TheperformanceofPHEslargelydependsuponthetype ofpatternusedontheplates.TheChevronpatternisthe most commonly used pattern in conventional heat exchangers. Geometric factors such as Chevron angle, corrugation pitch, depth of printing, dimensions of the plates as well as the flow type (viz. laminar, transition, turbulent)highlyaffectthethermohydraulicperformance of PHEs. The patterns on the plates offer better heat transfer rates by increasing the heat transfer area. However,theymightalsoleadtoconsiderablepressure drop due to friction resulting in high pumping power requirements.Thus,heattransferrateandpressuredrop shouldbethemaincriteriafordecidingthetypeofplate patternduringoptimizationprocess.

Biomimeticapproachhelpsinsolving reallifeproblems byanalyzingandmimickingthepatternsandbehaviorsin nature. Severalresearchershave provedthattheuse of fractal structure in heat transfer devices lead to an improvement in heat transfer rate and decrease in pressuredrop.Afractalisapatterninnaturethatrepeats itselfatsmallerandsmallerscales.Examplesforthesame are tree branches, leaf veins, bird feathers, etc. The following study is inspired by the effective thermoregulationinbirdswhichisbroughtaboutbythe patternoftheirfeathers.Heattransferinbirdstakesplace via3modesviz.conductionandconvectionthroughair, conductionthroughsolidelementsofthefeatheraswell as radiation. However, 95% of the heat transfer occurs throughconductionandconvectionaloneandthiscanbe beneficial from the point of view of heat exchanger design.Thus,effectivethermohydraulicsolutionscanbe deduced from the strategies in nature. In this study, differentplateheatexchangersweremodelledwithbird feather-likepatternandCFDsimulationswereperformed usingSolidWorksFlowSimulationtool.Inthesimulations, operatingconditionsataflowrateof0.05kg/sandhot/cold inlet temperatures of 900 C and 250 C are used for single phase parallel flow. The model was validated using numericalandexperimentalresultsforastate-of-the-art Chevron-typeplateheatexchanger.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Baris Gurel et. al. [1] have investigated the flow and thermohydraulicperformanceofacompactbrazedplate heat exchanger with lung pattern using biomimetic approach.Thestudyisbasedonthefactthathumanlungs areoneofthebestheatexchangersknowntilldateand have a very high compactness which is the ratio of effectiveheattransferareaandtotalvolumeofthePHE. SimulationswereperformedusingANSYSFluentonthe lung patterned heat exchanger and the results thus obtainedwerecomparedwiththeconventionalChevrontype PHE. The use of lung pattern resulted in 71.3% increase in heat transfer rate and 67.8% decrease in pressure drop along with 6.66% reduction in total volume. Huang et. al. [2] investigated the thermal and hydraulic performance of fractal heat exchangers with major focus on fractal channels. A fractal structure is a patternthatnaturerepeatsonsmallerscales.According totheresearch,theuseoffractalgeometriesasfoundin bloodvessels,leafveins,humanlungs,treebranches,etc. inheattransferdevicesoffershigherheattransferrates while minimizing flow resistance and the resulting pressuredrop.Oneofthemajorfindingsoftheresearch wasthedirectrelationshipbetweennumberofbranching andheattransfercapabilitiesofthedevice.GangWang, YuGuet.al.[3]conductedanexperimentalandnumerical investigation of a fractal tree-like heat exchanger manufacturedby3Dprinting.TheperformanceoftheHE was evaluated from both thermal and hydraulic perspectives. Their findings reveal that a fractal-tree-like heat exchanger can improve hydrodynamic performance, reduce pressure drops and has great heat transfer ability andcoefficientofperformance. Theresultswereobtained for a fractal H-type and Y-type heat exchanger and a 23% improvement in heat transfer rate was achieved in comparisonwithconventional spiral tubeheat exchanger. Pingnan Huang, Guanping Dong et. al. [4] performed numericalinvestigationofthefluidflowandheattransfer characteristicsof a tree-shaped microchannel heat sink withvariablecross-section.Theanalysiswasperformed onthreedifferentheatsinkgeometrieswithribs,cavities andasmoothstructurerespectivelyusingANSYSFluent software. The tree-shaped heat sink with cavities was foundtohavehighestcomprehensiveperformanceasthe cavities increase branching effects. Blair O. Wolf and GlennE.Walsberg[5]studiedtheroleoftheplumagein thermoregulatory mechanism of birds. Their findings suggest that dry heat transfer through bird plumage occurs via 3 avenues, viz. conduction and convection through air, conduction through solid elements of the featherandradiation.However,around95%oftheheat transferoccursthroughconductionandconvectionalone. Thestructureofbirdfeathersconsistsofaquill,anumber of barbs andtheirfurther branches known as barbules. Theintersectingbarbulesincreasethesurfaceareaofthe feather,thusincreasingheattransferthroughconvection.

This principle was the driving motivation behind the biomimetic approach in designing and analyzing plate heatexchangerswithbirdfeatherspatternedonthem.

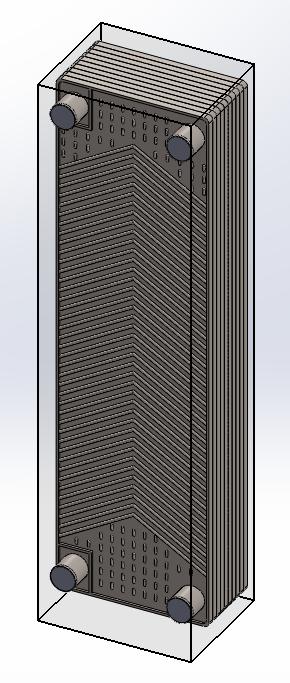

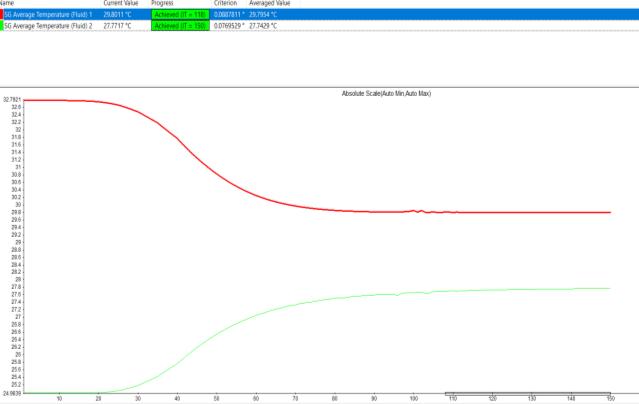

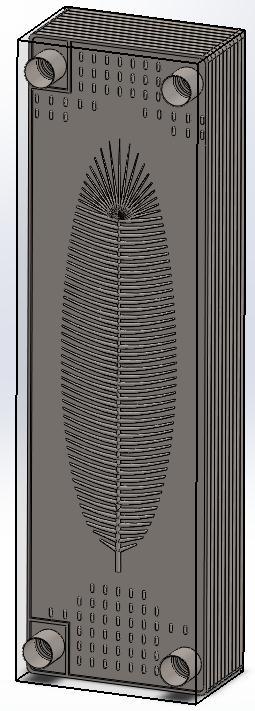

InordertovalidatetheresultsoftheCFDsimulations,the numericalresultswerecomparedwiththeexperimental results obtained from [1] for a conventional compact brazed Chevron-type plate heat exchanger. The same Chevronangle(300),massflowrate(0.167kg/s)andinlet temperatures of hot and cold fluid as 32.80C and 250C respectively have been used for geometry creation and boundaryconditions.Themodelconsistsof10plateswith thesamematerial(AISI316StainlessSteel).Thelength, width and thickness of the plate was kept as 431 mm, 125.5 mm and 2 mm respectively. The value of specific heatcapacityofwaterwastakentobeconstantandequal to 4182 J/KgK and thus, the ambient temperature was consideredtobe200Cbyreferringthepropertytablefor water.

Theoutlettemperatureofthehotfluidattheendofthe numerical analysis was obtained as 29.800 C with a deviation of 0.33% from the experimental outlet temperaturewhichwasequalto29.90C.Accordingtothe experimentalresults,theactualheattransferrateofthe referenced PHE was 2167W whereas the value of the sameobtainedfrom CFD analysiswas2094.41W. Thus, theexperimentaldataandnumericalresultsareingood agreement with a deviation of 3.35%. Hence, the same method can be used for heat transfer analysis of plate heatexchangerdesignedbybiomimeticapproach.

Fig -1:CADgeometryreferencedPHE

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

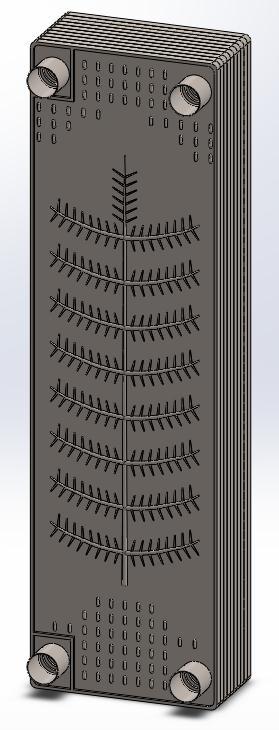

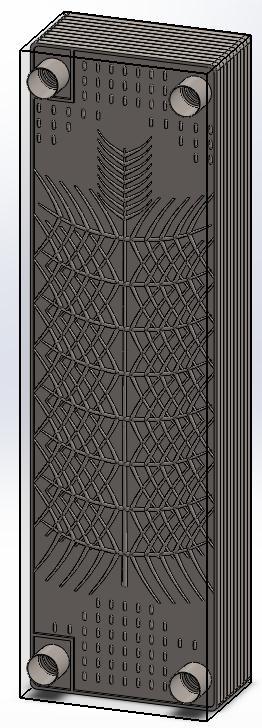

Inthisstudy,CFDsimulationsforheattransferanalysis wereperformedon5differentcompactbrazedplateheat exchangers with different geometries of bird feathers patternedonthem.Thedesignmethodforthesamehas been validated through numerical and experimental results of a pre-existing study. In the simulations, mass flowrateof0.05kg/sandhot/coldinlettemperaturesof 900C and 250C have been used for single phase parallel flowandtheresultsobtainedwereusedtocomparethe conventionalChevron-typePHEwithbiomimeticmodels. ThebasicdimensionsforallthePHEshavebeenkeptthe same as that for the referenced model. The value of specificheatcapacityofwateristakenas4178J/KgKfor thenormaloperatingconditions.

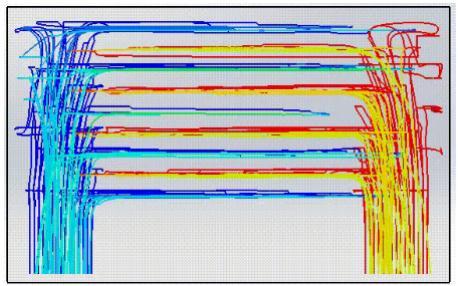

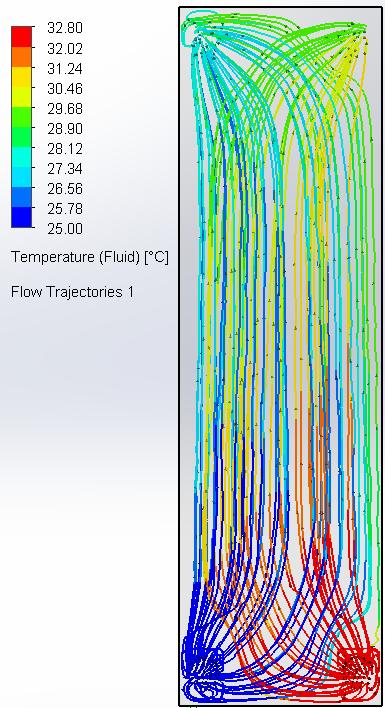

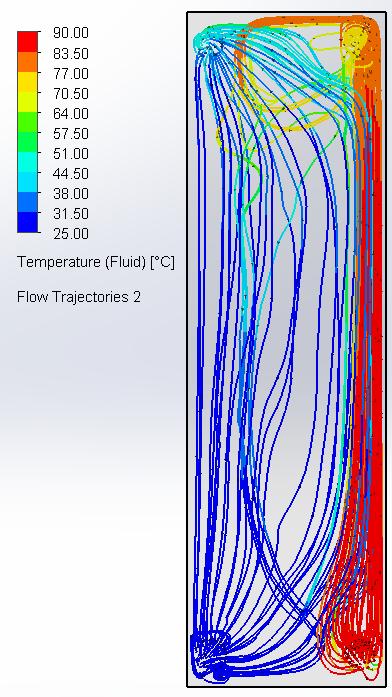

Fig -2:FlowtrajectoriesforreferencedPHE

Fig -3:Flowtrajectoriesshowingalternatinghot/cold fluidforreferencedPHE

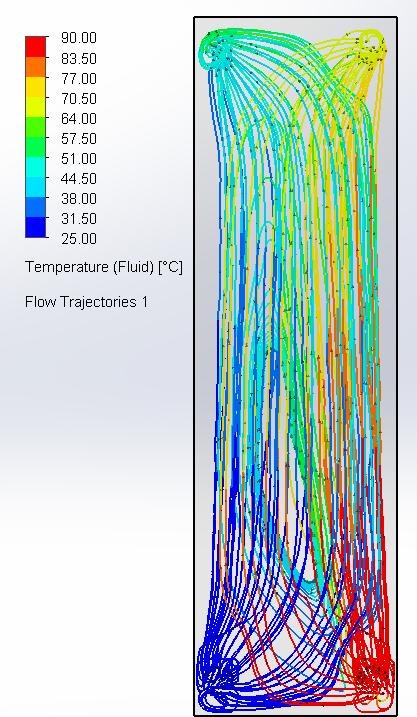

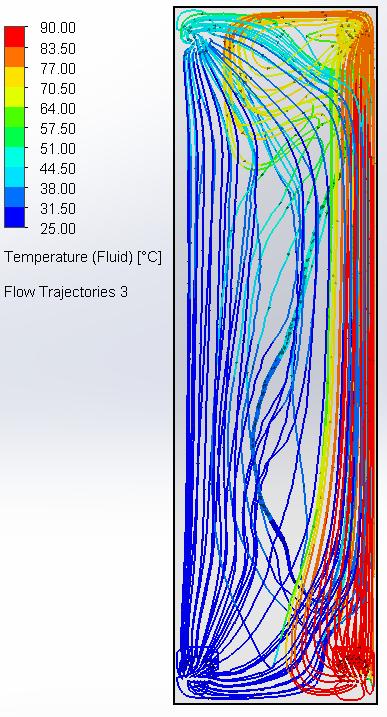

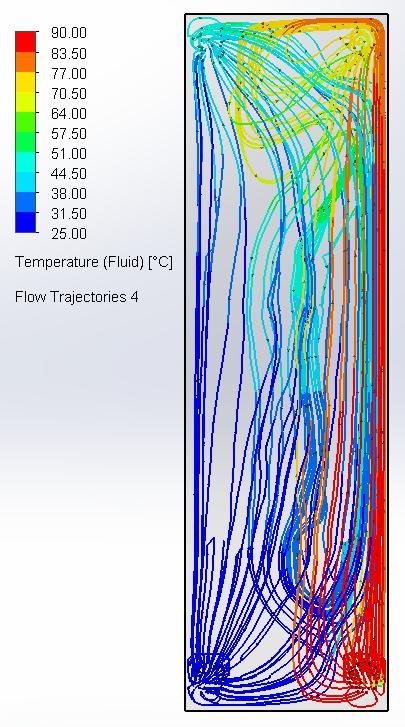

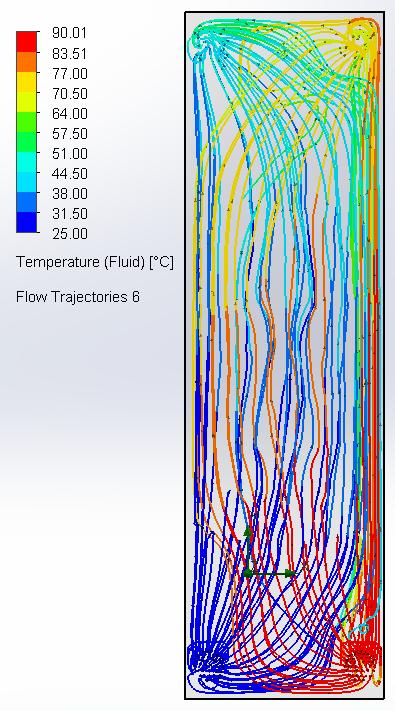

Fig -5:FlowtrajectoriesforChevronPHE

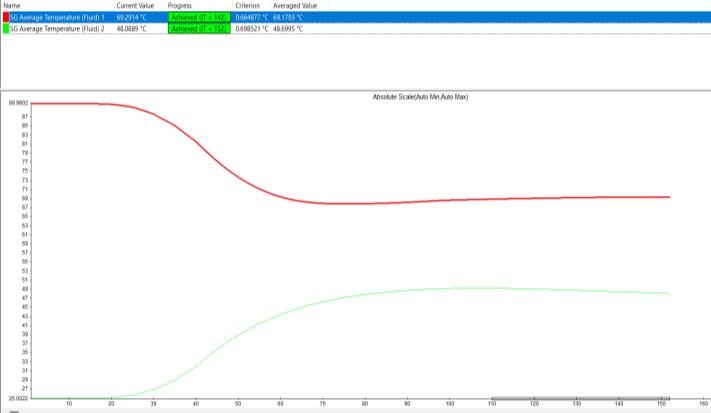

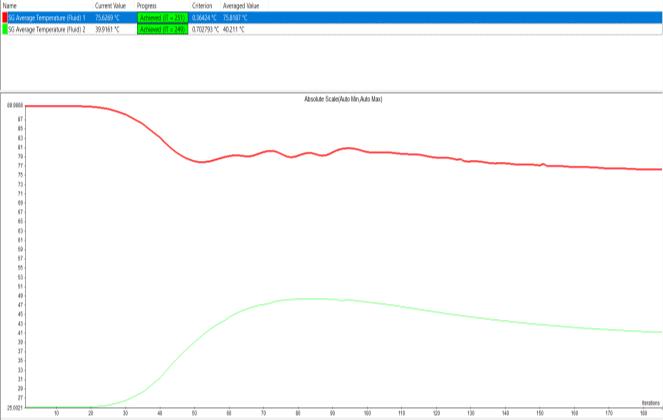

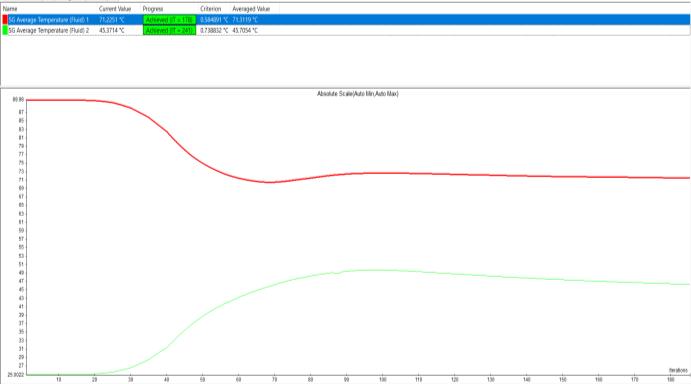

Fig -4:Temperaturedistributioncurvesfor referencedPHE

Fig -6:TemperaturedistributioncurvesforChevron PHE

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

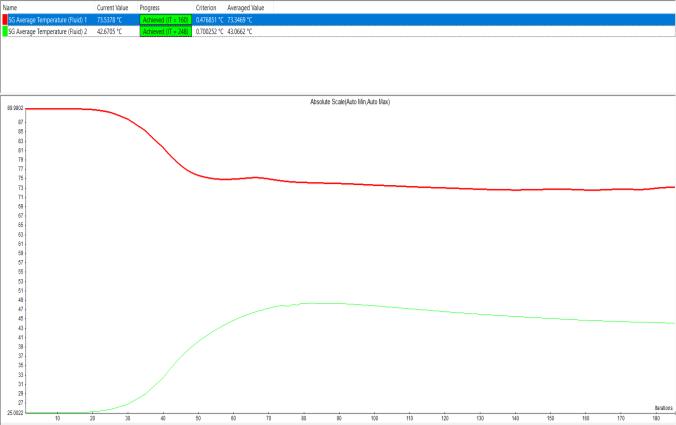

The flow trajectories for the Chevron PHE have been showninfig.5.Itcanbeseenfromthesamethatthehot andcoldfluidsflowoveramajorportionoftheplatearea andthus,thereisaneffectiveutilizationofheattransfer area and the corrugated patterns. With the onset of turbulence due to the corrugations, the temperature of the hot fluid goes on decreasing rapidly indicating an increase in heat transfer rate. Fig. 6 shows the temperature distribution curves for hot and cold fluid throughouttheflow.Thehotwateroutlettemperatureis obtained as 69.290C whereas the temperature of cold waterattheoutletis48.080C.Theheattransferratethus calculatedisequalto4326.32W.

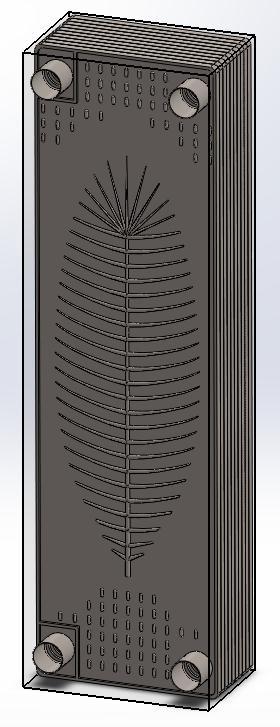

Fig. 7 shows the geometry and flow trajectories for biomimetic PHE model with sparse barbs without any barbulespresent.Itcanbeseenfromthefigurethatmost of the hot and cold fluid travels along the edges of the plate.Thisleadstoapoorutilizationoftheheattransfer area and hence, the effect of the plate pattern on heat transferrateisnegligible.Therequiredturbulenceisnot initiatedinthismodelsincethefluidpassesovertheflat portionsoftheplate.Thetemperaturedistributioncurves forthemodelareshowninfig.8andthehot/coldoutlet temperatures are obtained as 75.620C and 39.920C respectively.Theheattransferratesoachievedis3003.98 WwhichisconsiderablylowerthanthatfortheChevron PHE.

An almost similar condition occurs in the case of the biomimeticPHEmodelwithdensebarbsascanbeseen fromfig. 9. The temperaturedistributioncurves for the modelareshowninfig.10andthetemperatureofhotand coldfluidisobtainedas74.870Cand39.870Crespectively from the CFD analysis. The heat transfer rate again is lower than that for Chevron PHE and is found to be 3160.66W.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

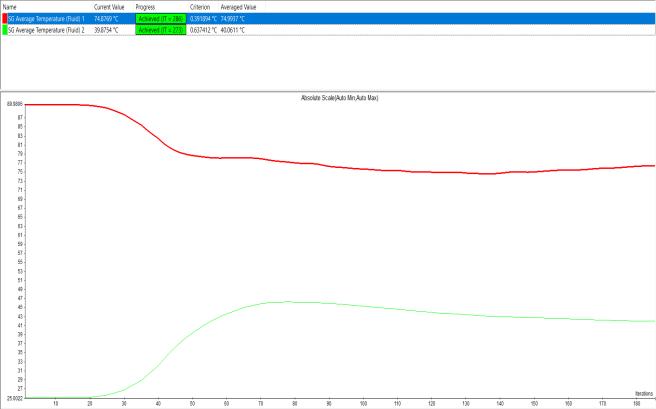

Thegeometryandflowtrajectoriesfor biomimeticPHE modelwithshortbarbsandnon-intersectingbarbuleshas beenshowninfig.11.Thehotwaterflowlinesindicate that mostofthe fluidis passing closetothe edge of the plate and the corrugations or patterns are not being utilized to their full potential. The added benefit of turbulencethatcomeswithplatepatternsisnotachieved inthiscaseaswell.Thetemperaturedistributioncurves forthesameas shownin fig.12show thehot andcoldwater outlet temperature as 73.540C and 42.670C resultinginaheattransferrateof3440.58Wforthegiven valuesofmassflowrateandspecificheatcapacityofthe fluid.

Fig -10:Temperaturedistributioncurvesfor biomimeticmodelwithdensebarbs

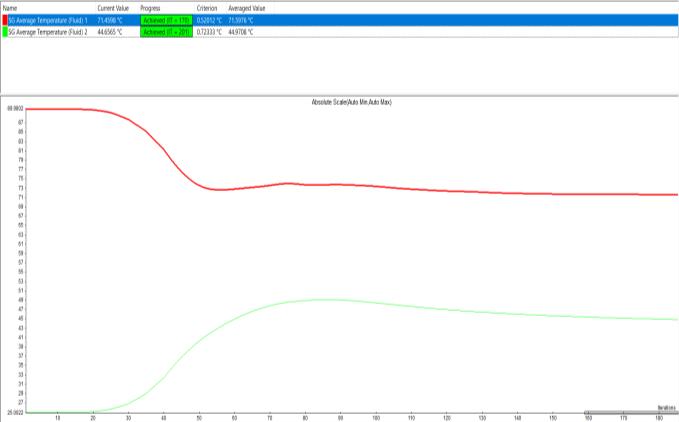

In the biomimetic model with long barbs and nonintersecting barbules, as shown in fig. 13, a better utilizationoftheplateareaforheattransfertakesplace. Theflowlinesseemtobemorespreadoutovertheplates andagreaterdropintemperatureofthehotfluidcanbe seen.Thetemperaturedistributioncurvesofthehotand coldfluidareshowninfig.14andtheoutlettemperature of the hot and cold side is 71.460C and 44.660C respectively. The turbulence caused by effective utilizationofthepatternedareaontheplateresultsina betterheattransferratewhichisequalto3875.09W.

Fig -11:Geometryandflowtrajectoriesforbiomimetic modelwithshortbarbsandnon-intersectingbarbules

Fig -12:Temperaturedistributioncurvesfor biomimeticmodelwithshortbarbsandnonintersectingbarbules

Fig -13:Geometryandflowtrajectoriesforbiomimetic modelwithlongbarbsandnon-intersectingbarbules

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Fig -14:Temperaturedistributioncurvesfor biomimeticmodelwithlongbarbsandnon-intersecting barbules

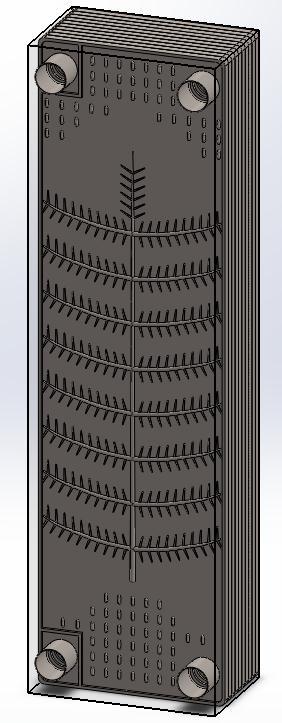

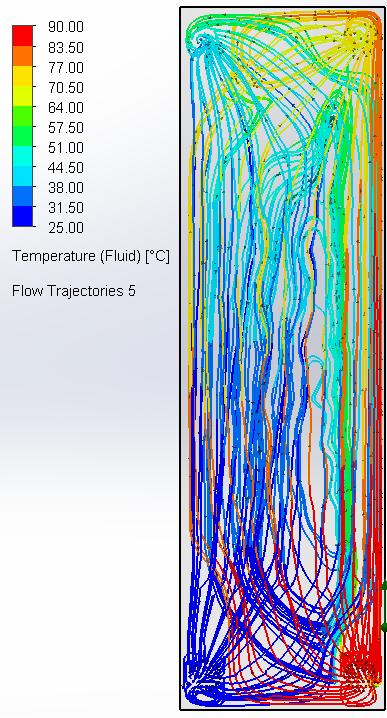

Fig.15 shows the geometry and flow trajectories for biomimeticPHEmodelwithlongbarbulesthatintersect witheachotherandincreasetheeffectivesurfacearea.A quitesimilarstructurecanbeseenincaseofbirdsatthe microscalewhereanumberofbarbulescometogetherto form a mesh-like fractal geometry. However, due to manufacturing considerations, the relative size of the barbulesiskeptprettylargeincaseoftheproposedPHE model. It can be seen from fig. 15 that a much better utilization of plate area takes place in this model as comparedtootherbiomimeticmodelsmentionedabove. Theoutlettemperatureforhotandcoldfluidis71.230C and 45.370C respectively as can be seen from the temperaturedistributioncurvesgiveninfig.16.Theheat transferratethusobtainedisequalto3923.14Wwhichis much better than other biomimetic models but not as good as that for conventional Chevron-type PHE. The effective utilization of plate area and formation of turbulent boundary layer is quite better in case of Chevron-type heat exchanger leading to higher heat transferrate.

Fig -15:Geometryandflowtrajectoriesforbiomimetic modelwithlongandintersectingbarbules

The Chevron-type heat exchanger was found to have a better heat transfer rate as compared to the ones designed by biomimetic approach. This is due to the effective utilization of heat transfer area offered by the corrugated plates as well as formation of turbulent boundarylayer.However,theprojectdoesnottakeinto considerationtheeffectofplatepatternonthepressure dropwhichisamajorcriterionwhiledesigninganyheat exchanger.Also,theresultsfordifferentPHEmodelshave been obtained for single phase parallel flow. However, significantvariationintheresultsmightbeobtainedfor counterflowwhereintheboththehotandcoldfluidsflow in opposite directions. The flow simulations can be carriedoutfordifferentorientationsoftheplatepatterns whichmightleadtoconsiderablevariationsinresultse.g. by increasing the number of feathers per plate, the numberofbarbsperfeather,thenumberofbarbulesper barb as well as the length and width of the feathered pattern. The brazing material used in actual practice is differentfromtheplatematerialandthus,hasadifferent valueofthermalconductivity.Thisneedstobeconsidered for obtaining more accurate results. Even though the effect of radiation in thermoregulatory mechanism of birdsisnegligible,itcanhighlyaffecttheresultsobtained for PHEs in terms of temperature difference and heat transferrates.Theprojectdoesnotconsidertheeffectsof radiation which might lead to a large deviation in the resultsobtainedthroughexperimentationandnumerical analysis.

Fig -16:Temperaturedistributioncurvesfor biomimeticmodelwithlongandintersectingbarbules

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Theauthorgratefullyacknowledgesthesupportprovided by the authorities of Vishwakarma Institute of Technology,Puneregardingtheproject.Theauthoralso expresses his sincere gratitude towards Prof. (Dr.) Mangesh Chaudhari for his guidance during the completion of the project and providing appropriate referenceswheneverrequired.

[1]Investigationof Flow and Heat Transfer of Compact Brazed Plate Heat Exchanger with Lung Pattern, Baris Gurel,VolkanRamazanAkkayaet.al.

[2] Review of Fractal Heat Exchangers, Zhiwei Huang, YunhoHwang,VikrantAute,ReinhardRadermacher

[3]Experimentalandnumericalinvestigation offractaltree-like heat exchanger manufactured by 3D printing GangWang,YuGu,LuhaiboZhao,JinXuan,GaofengZeng, ZhiyongTang,YuhanSun

[4] Numerical investigation of the fluid flow and heat transfercharacteristicsoftreeshapedmicrochannelheat sink with variable cross-section, Pingnan Huang, GuanpingDong,XinengZhong,MinqiangPan

[5]TheRoleofthePlumageinHeatTransferProcessesof Birds,BlairO.WolfandGlennE.Walsberg

[6]Nature-InspiredStructuresAppliedinHeatTransfer EnhancementandDragReduction,ZhangyuZhu,JuanLi, HaoPengandDongrenLiu

[7]Anexperimentalinvestigationontheheattransferand frictioncoefficientsofasmallplateheatexchangerwith chevronangle,SaeedMohebbi&FarzadVeysi

[8]Energy,RadiationandTemperatureRegulationinPlants, HamlynGJonesandEyalRotenberg

[9] Investigation of Brazed Plate Heat Exchangers with VariableChevronAngles,S.Muthuraman

[10]ModelingandDesignofPlateHeatExchanger,Fábio A.S.Mota,E.P.CarvalhoandMauroA.S.S.Ravagnani

[11]Fundamentalsofheatandmasstransfer,TheodoreL. Bergman,AdrienneS.Lavine

[12]Heattransfer–Apracticalapproach,YunusCengel

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page430