International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Bhat1, Jaswant Singh2

1Mtech Student , CBS Group of Institution , Haryana, India.

2Assistant Professor , Department of Civil Engineering, CBS Group of Institutions , Haryana, India. ***

Abstract - The present study aims to see how different Polycarboxylic ether (PC) dosages affect the distinctive features of concrete with M-30 grade at 0.35 water-cement ratio. The results of testing concrete in its green and hardened states for M30 grade were compared to those of concrete in its normal condition. The period for which the slump value was kept and the strength at which concrete collapsed in compression, known as compressive strength, were among the parameters studied. The results of compressive strength of the concrete were analyzed after one week and then after twenty eight days, and the results were reported as 7 day strength and 28 day strength, respectively. The optimal quantity of PC based admixture is reported as the amount at which the compressive strength will be highest and the slump loss will be minimum. The entire study was studied in two phases. In the first phase of experiments, the effect of superplasticizer on concrete properties was studied while reducing the water at a variable rate and in the second phase; the effect of superplasticizer was studied by reducing the water content at constant rate. The experimental findings depicted a considerable effect of the superplasticizer dosage on concrete properties in fresh as well as hardened state. The results revealed that the effectiveness of polycarboxylic etherbased superplasticizer was maximum at a quantity of 0.8% and 0.9% by cement weight for compressive strength andslumplossrespectively.

Keywords: Compressive strength, Concrete, Polycarboxylic ether, Slump, Slump loss, Superplasticizer,Water-cementratio

In the structural construction industry, concrete is the widelyutilizedbuildingmaterial.Itiscomposedofcement, coarseandfineaggregates,water,andadmixtures.Cement and water combine in a concrete mix to generate a paste

that covers the surface of coarse and fine aggregates and holds them together, in addition to filling fine aggregate gaps (Duggal, 2008). Concrete buildings must perform the purposesforwhichtheyweredesigned,andtheirprimary requirements are strength and durability. Ready-mixed concrete has recently become popular in major constructions. The use of ready-mixed concrete can result inhigherstructuralquality,Basreadymixedconcreteisso widely used nowadays that it is critical to use admixtures to improve its qualities. Some admixtures contain chemistrythataffectsavarietyofconcretequalities,while others are simply added during the batching process. Admixtures are widely used because they offer significant economic and physical benefitsover the regularly usedconcrete (Alsadey, 2021). However, using additives will not enhance the quality of substandard concrete causedbyinsufficientmixproportion,poormixingskillsin concrete,orchallengesbyB-graderawmaterials(Alsadey, 2012; 2013). A superplasticizer, also known as a high range water reducer, is an additive that minimizes the amount of water needed to mix concrete. It was designed to boost the plasticity orfluidityof low-water concrete, making it easier to pump up to higher elevations without affecting strength or durability. (Wilson & Kosmatka, 2011). Superplasticizers can cut water use by up to 30%, allowing for the production of workable concrete with extremely high strength, which was previously difficult andexpensive.(Hassouna,2016).

Superplasticizers orHigh-range water reducers(HRWR) are chemically reactive admixtures that react with the

International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

concrete's constituents and are typically added in a concrete that must be transported from the place of manufacturetotheplacewhere itwill beusedtoimprove its properties in both the green and sett states. These Admixtures are also known super water reducers and superfluidifiers. The first HRWR was invented in Japan in the year 1964 by Kenichi Hattori. This HRWR was formaldehyde condensates of beta-naphthalene sulphonates. After this superplasticizer in the same year on other HRWR sulphonated melamine formaldehyde condensatebasedwasknownasMelmetwaspresentedin West Germany. HRWR have the property of reducing the waterrequirement byabout 30%ofthewaterusedin the concrete. By using HRWR we can produce the concrete of high strength, durable and high slump. Before HRWR we hadconventionalwaterreducerswhichcouldonlyreduce water by about 15%. We may limit the possibility of concrete segregation by adding water reducers, which lowerthequantityofwaterrequiredintheconcrete.Using HRWR in concrete results in significant savings in construction cost, quantity of cement, and number oflaborers,despitethefactthatHRWRcosts120perlitre. As in the modern world we can’t think of the concrete withoutusingadmixtures,soinordertohaveefficientuse of the admixtures known as superplasticizer, proper guidelinesforitsproficientusebecomesanecessity.Many difficultiesarisewhenutilizingadmixtures,astheusageof admixture in concrete is dependent on numerous parameters.Suchasthewatercementratiotobeused,the temperature at the site, the site condition, the quantity of additivetobeused,andtheperiodinwhichtheadmixture must be added. To overcome any issue and manufacture excellent concrete with strength and serviceability, suitable action must be taken. This researchtook into accounthow touse HRWR, itsmodeofaction,theamount

thatwould provide beneficial outcomes, and itsimpact on the qualities of concrete in theset (hardened) andgreen (fresh)phases. After studying the various factors governing the use of HRWR, it provides the proper information to be followed by the engineers while using this in the field, such as how to add the HRWR in the concreteandthedosageatwhichatefficientresultswillbe achieved. Properties of Concrete which were evaluated duringthegreenstatewereRheologicalpropertiessuchas slump test and in hardened state compressive strength testsweredone.

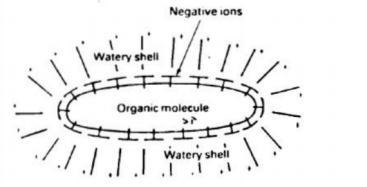

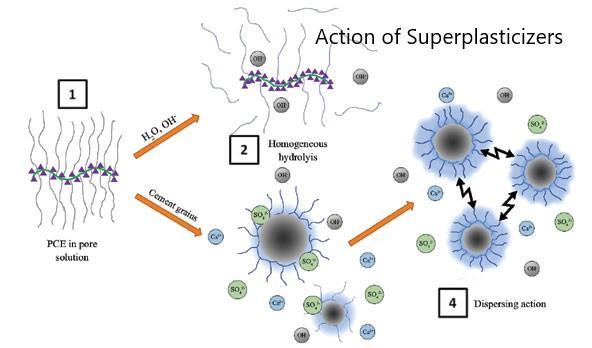

TostudyactionofHRWR,detailedstudyofmicrostructural behavior, pattern of adsorption and action of superplasticizer in hydration process is must. These superplasticizers enhance the rheological properties of cement significantly .During the action of HRWR with the cement particles , the molecules of superplasticizer align themselves around the periphery of the cement particles , due to which watery film as shown in the fig 2 is formed. Superplasticizer molecules are attracted to cement particles from one side and to water from the other, resulting in the formation of a lubricating film surface along the surface of cement particles, which improves the rheological characteristics of cement. Microscopic examination of cement particles with superplasticizer revealed that cement particles floating in water exhibit irregular and huge agglomerates cement particles are formed into tiny particles. Figure 2 depicts the formation of needle-shaped products as a result of hydration, which are not evident in regular concrete. At six months, the concrete containing the additive has a compacted and flawlessstructure.

International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

speed and amount of adsorption. Delaying the addition of the admixture will result in a enough quantity of admixture remaining in the solution to create silicate phase dispersal and, as a result, will aid in enhancing workability. Adsorption prior to 5 hours is mostly caused byC3Shydratesinthecement.

Fig – 1: Watery

around cement particle (Source: Courtesy of William Wilson)

The type of cement used has the greatest influence on adsorption. Type III cement was discovered to have the highestdegreeofadsorption,followedbyTypeIandType II cement. Figure 3 depicts the aqueous adsorption properties of a melamine-based superplasticizer (SMF) on cement, C3A, and C3S. Superplasticizer adsorption on C3A occurs instantly. Due to the development of complexes between the SMF and the hydrating C3A, hexagonal aluminates adsorbs a substantial quantity of superplasticizer and is not instantly transformed to the cubic form in the system C3A-H2O-SMF. The process is analogous to C3A hydration in the presence of calcium lignosulphonate. During the first hour, however, there is insufficient adsorption on the surface of C3S. The adsorption process is insignificant up to around 4 to 5 hours and then rapidly rises. SMF is adsorbed by C3A + gypsum in cement. This adsorption takes only a few minutes. It is recommended to add the admixture 5 to 30 minutes after the start of hydration to help reduce the

The concentration of superplasticizer supplied increasesadsorption.Particlesgeneratechargesasaresult of ion adsorption. The repulsion between particles with the same charge prevents agglomeration or precipitation and diminishes the system's uniformity. The enormous negative potentials created by the application of superplasticizer were shown to reduce over time while remaining high even after 1200 minutes. Just following initialpointofcontactbetweencementand water,cement particles re-aggregate and grow bigger in size, causing fluidity to rapidly diminish. The hydration products formed on the surface of the cement particles are separated by continuous mixing of the concrete. The combination of higher temperature and peeling action significantly increases both the pace and amount of hydration product created, resulting in a significant reduction in fluidity. The superplasticizer should work on both the cement particles and the hydration products to restore fluidity. As a result, if the time of addition is extended, a higher dosage of superplasticizer is needed. Superplasticizersbasedon melamineandnaphthalene are responsible for interfering with the hydration of C3S and C3A. Opinions differ on the impact of these admixtures on therateofhydrationofC3A+gypsummixes.

In the present study, the effect of superplasticizer on concreteinfreshandhardenedstatesisdetermined.Inthe fresh state, the superplasticizer has a great influence on workability, while in the hardened state; it affects its

International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

compressive strength. The workability of concrete is affected by the type and quantity of cement,the time of superplasticizer addition, the nature and dosage of superplasticizer,the initial slump,the temperature, relative humidity, the mixing situation which includes mixer type, total mixing time, and mixer speed), and the presenceofotheradmixtures.Mixtureshavingalowinitial slumpneedahighersuperplasticizerdosage.Theimpactof initial slump on the rate of slump loss following superplasticizeradditioniscontroversial.Ingeneral,mixes with a bigger starting slump lost droop more gradually. The cement type and quantity in the mix also affect workability. It was observed that a larger superplasticizer dosage is required for Type I cement to obtain the same workability as Type V cement. To obtain a particular slump,mixeswithahighercementpercentagerequireless superplasticizer. This is to be expected given that high cementconcentrationcombinationsareknowntobemore fluid, even when no additive is used. Furthermore, mixes with a higher cement percentage lose slump at a slower pace. The type and brand of superplasticizers differ. Melamine-based superplasticizers lose their effect (with timeconsistencyoffreshconcretewilldecrease)atafaster pace than other forms of superplasticizers. The rate of slump loss decreases when the superplasticizer dose is increased.Excesssuperplasticizerinthemixtureenhances workabilityevenfurther,leadinginaveryhighslump,but itcanalsocauseexcessivebleedingandsegregation. Themomentatwhichthesuperplasticizersareintroduced is another factor that influences workability. Superplasticizers' ability to increase workability deteriorates with time. It is better to wait until some C3A hasbeen hydrated andso then removed fromthe mixture before adding it. Slump loss is greatly reduced as a result of this. Low temperatures generate less workability loss

and thus increase the dosage required to get the desired slump, particularly below 20°C. Superplasticizers can be used frequently to restore workability. In general, repeated dosing does not affect the concrete in any way, however it may allow entrapped air to escape, increasing theplasticunitweight.Regardlessoftheslumpthatoccurs aftertheinitial dose,repeateddosesenhancesworkability foranadditional25to45minutes.Asthenumberofdoses is increased, the efficiency of superplasticizers in enhancing workability declines,andthe rateofslumploss riseswitheachdose.

Concrete is affected by superplasticizers with extraordinarily high utility and better strength, as the superplasticizer work by integrating the particles of cementwithasubstantialnegativecharge,causingthemto oppose one another because ofthe same charge (electrostatic charge). More water is supplied toconcrete mixing by deflocculating the particles of cement (Neville, 2005). The use of superplasticizer is becoming more common as it provides benefits in both the fresh and hardened stages (Yamakawa et al., 1990). In case of hardened cement concrete, the superplasticizer improves compaction efficiency to produce denser concrete with highercompressivestrengthbyloweringthewatercement ratio (Alsadey, 2021). The concrete strength after superplasticizeradditionwasobservedtobemorethanor equal to the strength of comparable concrete prepared without head mixture. Because superplasticizers enhance workability and compatibility while reducing the watercement ratio, they boost concrete strength and so contribute to the overall progress in hardened concrete properties.Infact,usingthese superplasticizers is a viable step toward enhancing the overall properties of hardened concrete. Superplasticizers

International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

have become an integral part in today's high performance concrete. Different superplasticizers have varying impacts on the characteristics and working of concrete. Borsai (1994) analyzed the influence of 2 categories of superplasticizers on concrete having a high quantity of fly ash: acrylic polymer (AP) and sulphonated naphthalene (SN). Followingcarefulanalysis,itwasconcludedthatAP-based superplasticizer surpasses SN-based superplasticizer. In theformercase,itprovidesagreaterwaterreduction,less slump loss, and higher slump level. Additionally, concrete containing a superplasticizer based on AP has improved durability and compressive strength (Fukuda et al., 1990; Borsai,1994).

ULTRATECH 43 grade cement was used, which is commerciallyavailable.ThiscementsatisfiestheIS:81122013 criteria for OPC 43 grade. The following are its properties:

In this study, two varieties of coarse aggregates having nominal diameters of 10 mm and 20 mm were employed. Course Aggregate's specific gravity was calculated to be 2.71. Crushed boulder was used as coarse aggregate.The analysis of aggregates using sieves (sieve analysis) is a method used to check the different particle sizes ofaggregates in a sample, often termed as gradation. Concrete aggregates are commonly 150 micron, 300 micron, 600 micron, 2.36mm, 4.75mm, 10mm, 20mm, 40mm, and80mm in size. The fineaggregate fraction is4.75 mm to 150 micronin size, while the coarseaggregate fraction is 80mm to4.75 mmin size. Sifting a sample of Course aggregateor Fine

Aggregatethrough complete sieves positioned one on another respective of their size, with the smallest sieve at thebottom,gradesit.Theaggregatecoarserthanthesieve under consideration and finer than the sieve on top is described by the material remaining on each sieve after shaking. Sieving can be carried out either mechanically or by hand. During the manual operation (shaking with hands),thesieveisquiveredineverydirectionpossibleto allow all particles to pass through. The procedure should be repeated until not even a single particle is going through. The particle size distribution of an aggregate sample is determined through sieve analysis. The particle sizedistributionisdescribedbythefinenessmodulus.F.M is a thorough indicator of a substance's coarseness or fineness. It's calculated by summing together the percentage of aggregates remaining on each of the standard sieves ranging from 80mm to 150 micron and dividingthetotalby100.Thefinerthematerial,thehigher thefigure.Thefollowingarethesieveanalysisresults:

Table – 2: Sieve analysis results of coarse aggregate (20mm)

AVERAGE INDIVIDUAL GRADATION OF 20mm COARSE AGGREGATE

AsperIS:2386(Part-1) TypeofMaterial:20mm Source:LASSIPORA ProposedUse:Concrete Sieve sizes (mm)

SampleNo-01,02and03 Average Percentageof Passing Sample01 Sample02 Sample-03 40 100.00 100.00 100.00 100.00 20 93.60 95.20 93.20 94.00 10 8.90 9.40 8.70 9.00 4.75 - - - -

Table – 3: Sieve analysis results of coarse aggregate (10mm)

AVERAGE INDIVIDUAL GRADATION OF 10mm COARSE AGGREGATE

AsperIS:2386(Part-1)

TypeofMaterial:10mmCA

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page411

International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Source:LASSIPORAAWANTIPORA

ProposedUse: Concrete

Sievesizes (mm) SampleNo-1,2&3 Average Percentage OfPassing Sample1 Sample-2 Sample3

12.5 100.00 100.00 100.00 100.00 10 87.88 87.48 88.60 87.99 4.75 13.88 11.56 13.48 12.97 2.36 2.16 1.76 1.96 1.96

Fine aggregates used consist of sand obtained from Baramulla River.Aspertheanalysisgivenbelow,the sandusedwasZone-IItype.

Tests on fine aggregates

Sieve Analysis

Water

Water is the most significant component of concrete because it aids in the chemical interaction betweencement and itself. While water assists to give the strengthofthecementgel,itsamount/volumeandquality mustbecarefullyregulated.

The superplasticizer used was AURAMIX 400, a well developed low viscosity high performance polycarboxylicethersuperplasticizer.

01)

100 100 100

2.36 86 8.6 15.4 84.6 6095 75 –100 85–100 1.18 195 19.5 34.9 65.1 3070 5590 75–100 0.60 0 168 16.8 51.7 48.3 1534 3559 60–79 0.30 0 371 37.1 88.8 11.2 520 830 12–40 0.15 0 78 7.8 96.6 3.4 010 010 0–10 Fineness Modulus: 2.94 Zon e-II

Table -6: Results of Sieve analysis of fine aggregate (Sample 03)

Total weight of sample = 1000gm IS Size of Sieve (mm)

Mate rial Retai ned [gra ms]

Percen tage Retain ed on Sieve

Percent age Retaine d cumula tive

Percen tage Passin g throug h Sieve

Specification Limits As IS383 Table No04 Zo ne -I Zon e –II Zone–III 10 0 0 0 100 10 0 100 100 4.75 59 5.9 5.9 94.1 9010 0

90100 90–100 2.36 98 9.8 15.7 84.3 6095 75100 85–100 1.18 161 16.1 31.8 68.2 3070 5590 75–100 0.600 180 18 49.8 50.2 1534 3559 60–79 0.300 394 39.4 89.2 10.8 5208-3012–40

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

0.150 89 8.9 98.1 1.9 0100-10 0–10 Fineness Modulus 2.91 Zon e–II

Table – 7: Average sieve analysis results of the three samples

Total wt. of Sample = 1000gms

IS Size of Sieve (mm)

Percent age Passing (Sample -01)

Percen tage Passin g (Sampl e-02)

Perce ntage Passi ng (Sam ple03)

Aver age perce ntage of Passi ng

SpecificationLimi tsAsIS383 Table No-04 Zon e -I Zone - II ZoneIII

10 100 100 100 100.0100 100 100

4.75 93.1 93.2 94.1 93.5 90100 90100 90-100

2.36 84.9 84.6 84.3 84.6 6095 75100 85-100

1.18 64.2 65.1 68.2 65.8 3070 55-9075-100

0.600 49.9 48.3 50.2 49.5 1534 35-59 60-79

0.300 12.1 11.2 10.8 11.4 520 8-30 12-40

0.150 2.7 3.4 1.9 2.7 010 0-10 0-10 Average Fineness Modulus: 2.93 Zone –II

Initially, approximately half of the coarse material is placed on the skip, followed by approximately half of the fine aggregate. The entire amount of cement, i.e. one bag, is then dumpedontop,followedbytheremainingofthe coarse and fine aggregate. This keeps cement from spilling when filling the drum and keeps cement from flying away in high winds. Before

releasing the full skip to the drum, approximately25%ofthetotalquantityofwater required for mixing is pumped into the mixer drumtowetitandpreventcementfromsticking to the blades or the bottom of the drum. The remaining water, except one litre, is put to the drum immediately after the dry material is discharged. The phase begins when all of the material, notably the entire amount of water, is placed into the drum. Following approximately oneminuteofmixing,thedeterminedamountof superplasticizer is blended with that one litre of water and added to the mixer drum. It is desirable to mix the concrete for a little longer (half a minute longer) to ensure that the plasticizing action is fully realized through properdispersion.

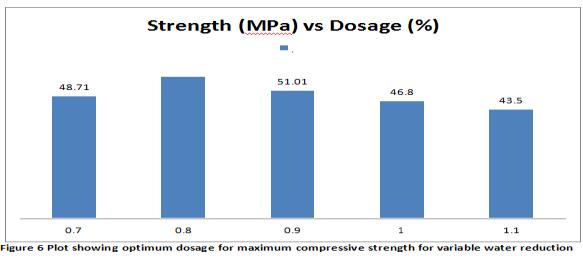

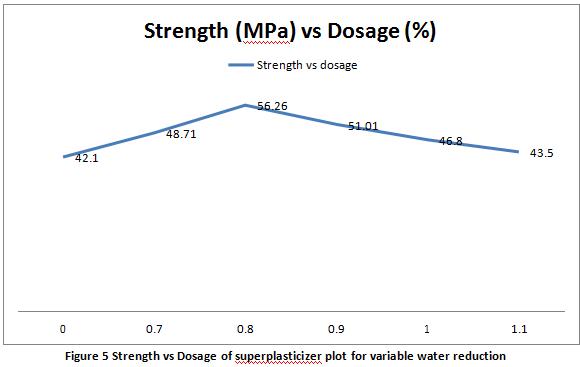

Table 1 28-day compressive strength of different Trial mixes for variable water reduction

S.No Dosage (%)

28 day compressive strength(MPa)

Trial1 Nil 41.07

Trial2 Nil 42.10

Trial3 0.7 48.71

Trial4 0.8 56.26

Trial5 0.9 51.01

Trial6 1.0 46.8

Trial7 1.1 43.5

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page413

International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

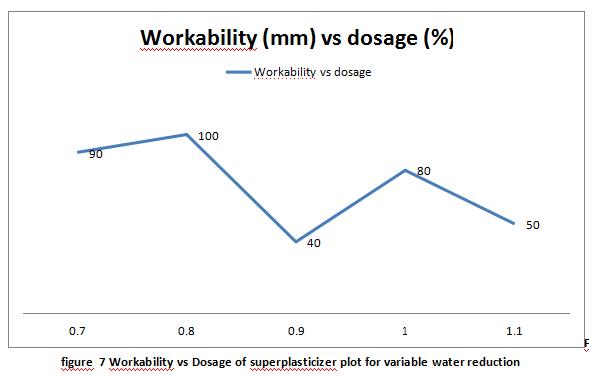

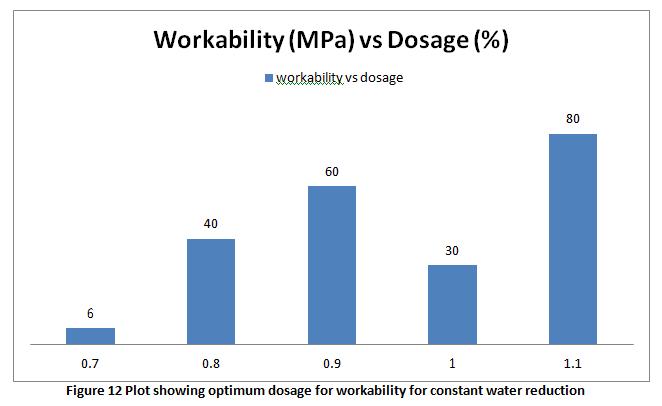

S.No. Dosage (%) Slumploss(mm)

0min 30min 60min

Trial1 0.7 6 0 0 Trial2 0.8 40 0 0

Trial3 0.9 100 60 40 Trial4 1.0 120 105 90 Trial5 1.1 140 115 60

Table 2 Slump loss of different Trial mixes for variable water reduction

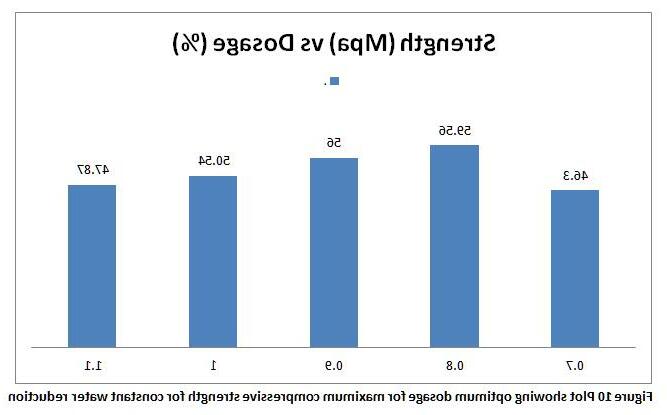

S.No. Dosage(%) 28 daycompressive strength

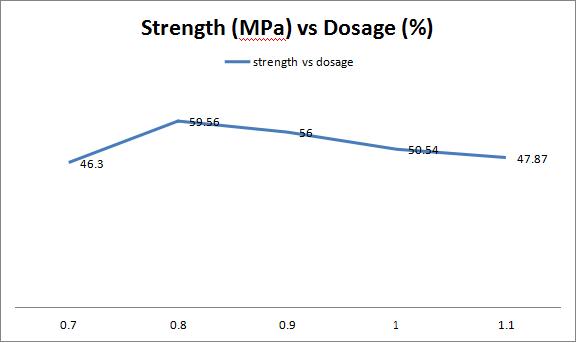

Trial1 0.7 46.3 Trial2 0.8 59.56 Trial3 0.9 56.00 Trial4 1.0 50.54 Trial5 1.1 47.87

Table 3 28-day compressive strength of different Trial mixes for constant water reduction

Figure 9 Strength vs. dosage of superplasti cizer plot for constant water reduction.

Fromtheabove,itcanbereferredthat forstrength criteriatobebesttheoptimaldosageofHRWR is 0.8%.

International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Basedontheabove,theoptimalsuperplasticizer dose based on workability requirements is 1.0 percent.

Themainobjectiveofthisresearchwastoassess the impact of superplasticizer on the characteristics of freshly and hardened cured concrete (M30 at 0.35 water/cementratio) with variable water reduction in the first trials and constant water reduction in the second trials owing to superplasticizer. The qualities of concrete that were tested were slump retention and compressive strength. Within the scope of the laboratory testing, the following conclusions canbereached:

For Trials in which water reduction was taken variable,theoptimalquantityofSuperplasticizer for which strength was found maximum was 0.8 percent by weight of cement (22 percent water reduction), with a strength of 56.26 MPa obtained, and the optimal quantity for highest slump retention was observed to be 0.9 percent by weight of cement used when reduction for watertakenas24percent.

For Trials with constant water reductions of 30%, the optimal quantity for which compressive strength was maximum was found to be 0.8 percent by weight of cement, with strength of 59.56MPa obtained, while the best dosageforminimumslumplosswasfoundtobe 0.9percentbyweightofcement.

The inclusion of superplasticizer increases the workability of concrete; nevertheless, excessively large dosages of HRWR tend to compromise cohesiveness characteristic of concrete.

Superplasticizerimprovesstrength; however, its final strength is greater than the intended characteristicstrength.

• The optimum dose for maximal compressive strength in all scenarios, whether constant or variablewaterreductionhasbeendeterminedto be0.8percentofthecombinationquantity.

• For all conditions, the optimal dose for minimum slump values or highest retention was determined to be 0.9 percent of the quantity of HRWR.

This study includes a method for the proper use of superplasticizing admixtures, also named as HRWRadmixtures,intheproductionofconcrete with high quality with the regular and steady constancy. The technique discussed here is designed to assist employees at field in

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page415

International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

formulating a easy plan of work for the proper application of superplasticizers in concrete to achieve properties which are required for the particular type of concrete. After a thorough analysis of technical and construction problems for each individual application, a choice on how to employ superplasticizers should be taken. If properly utilized, this sort of additive may be a beneficial ingredient of the mixture, producing concrete of better rheology, good strength, and ease with which it can be worked. In contrast, if not handled appropriately, these admixtures might cause extra problems that exceed their advantages. Because the efficiency of superplasticizers is affected by a variety of elements such as field conditions, equipments required at the construction site, resources, surroundings and the plan of work must be tailored accordingly. Furthermore, field experimentsmustbecarriedoutunderidentical conditions to those predicted during construction. Superplasticizer is fairly expensive, costing aroundhundredtwentyperlitrewhichresultsin rise in cost of project, however regardless of capital, the admixture can achieve significant reductions in human labor and manufacturing expenses. Furthermore, the use of superplasticizer minimizes the quantity of cement that must be added to the concrete

mixture, lowering the cost even further. As a result, superplasticizers supply us with both economicalandhigh-qualityconcrete. Thefollowingarea fewsuggestions that may be implementedtoimprovethevalueofthecurrent research:

• UHSP (Ultra high strength concrete) may be produced by integrating superplasticizers at the optimal quantity together with various mineral additivessuchassilicafume,flyash,andsoon.

•Furthermore, thecurrentstudy maybeexpanded by employing other types of admixtures to determine their optimal dose and then increasing the strength of the same by addition ofthosemineraladditivesoradmixtures.

• Different admixtures can be compared to find which one works best under various exposure scenarios.

• By reducing the difference between two successive dosages, a more accurate optimal dosagemaybedetermined.

• As we selected Zone-II sand and boulder crushed coarse aggregate, investigations with different types of fine and coarse aggregates may be conductedandcomparisonsmade.

Alsadey S (2012) Effects of Superplasticizing and Retarding Admixtures on Properties of Concrete. Paper presented at International Conference on Transport, Environment and

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Civil Engineering (ICTECE-1012). Kuala Lumpur(Malaysia),August25-26,2012.

AlsadeyS(2013)EffectsofSuperplasticizingand Retarding Admixtures on Properties of Concrete. International Conference on Innovations in Engineering and Technology (ICIET),Bangkok(Thailand).

Alsadey S (2015) Effect of Superplasticizer on Fresh and Hardened Properties of Concrete. Journal of Agricultural Science and Engineering,1(2):70-74.

Borsai A (1994) Effect of superplasticizer type on the performance of high-volume fly ash concrete.

Duggal SK (2008) Building Materials. 3rd Ed. India:NewAgeInternationalPublishers.

Fukuda M, Mizunuma T, Iumi T and Iizuka M (1990) Slump control and properties of concrete with a new superplasticizer. ChapmanandHall.

Hassouna FMA (2016) Effects of Superplasticizers on Fresh and Hardened Portland Cement Concrete Characteristics. International Journal of Applied Science and Technology,5(2):32-36.

Neville AM (2005) Properties of concrete. Pearson,PrenticeHall,255-262.

Wilson ML and Kosmatka SH (2011) Design and ControlofConcreteMixtures. 15thEd. United StatesofAmerica:PortlandCementAssn.

YamakawaC,KishitaniK,FukushiIandKurohaK

(1990) Slump control and properties of concrete with a new uperplasticizer. II: High strengthin-situconcreteworkatHikariga-oka HousingProject,ChapmanandHall,94.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page417