International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | August 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | August 2022 www.irjet.net p-ISSN: 2395-0072

1

, D.Nirosha2

, Dr J.Guru jawahar3, A.ANIL41P.G student, Department of Civil, Annamacharya institute of technology & sciences, Tirupati, India

2Assistant Professor, Department of civil, Annamacharya institute of technology & sciences, Tirupati, India 3 Professor, Department of civil, Annamacharya institute of technology & sciences, Tirupati, India

4Assistant Professor, Department of civil,Annamacharya institute of technology & sciences, Tirupati, India ***

Abstract - Concrete is one of the foremost wide used constructionmaterials,andit'ssometimesassociatedwith cementbecauseofthemainelementforcreatingconcrete. Theuseof(HSC)construction,particularlyformulti-story buildings,hasbecomequitecommoninindustrializedand developingcountries.ThemandatoryingredientofHSClike agroundgranulatedblastfurnace(GGBS).Superplasticizer is getting used in these concretes to realize the specified workability.Thisinvestigationprincipallycenteredonthe strengthpropertiesofGGBSbasedHSC.Duringthisstudythe mix was designed with a powder content range of 230 Kg/m3 to700Kg/m3. GGBSisusedatdifferentreplacement levels from 30% to 60% production of HSC. During this study,freshpropertiesofconcreteandtheslumpflowvalues are studied to find the workability of fresh concrete, the compressivestrengthofHSCwasdeterminedonce3,7,and 28daysofcuring.AscertainedthattheGGBS-basedmostly concrete earned the specified high strength based mostly HSC earn additional strength properties when put next to thoseofGGBS-basedmostlyHSC.

Key Words: Highstrengthconcrete,GGBS,Slumpflow test,compressivestrengthtest.

Concreteisthemostcommonlyusedandpreferredmaterial forconstructionpurposesthroughouttheworldtheconcrete isdurableandeasytomakefortheconstructionofhigh-rise buildingsattheconstructionsite.Itiseasytotransportand it can place where the concrete need, The high-strength concretecan beeasilymoldedintoany desiredshapeand size by using different molds and casting specimens like woodmoldsandsteelmoldstheconcreteiscannotexpand inanyconditionsremainsconstant.Themainingredientof theconcreteiseasilyavailableinmostplaceswhichmakes concrete evenmorepopular accordingtothe IS456:2000 andIS10262-2019.Theplaintothereinforcedconcreteand code practice and mix design code practice for ordinary concreteand,StandardconcreteandHighstrengthconcrete. (HSC)

High-strength concrete is much of the time considered a material, its improvement has been slow over numerous years. In the USA, during the 1950s concrete with a compressive strength of 34 MPa was viewed as high strength, during the 1960s, concrete with 41 to 52mpa compressivestrengthwasutilizedeconomically.insidethe mid-1970',62mpacementwasbeingmadeinsidetheworld situationless,insidethemostrecentfifteenyears,cementof highstrengthenteredtheareaofdevelopment,thespecific requirementofelevatedstructuresandlong-rangespans.in accordance with code IS 456-2000 compressive strength over 110 MPa has been pondered for applications in cast setupstructuresandprestressedsubstantialindividuals.

Asexpressedintheintroduction,oneinall objectivesofthis analysis was to supply knowledge from a scientific investigation and therefore on contribute to the event of High-strength specifications for HSC. though the latter wasn'tapartofthisanalysis,ithadbeenthoughtabouttobe essential toliving eachphysical propertiesandsturdiness characteristics of HSC containing each binary and ternary blends of Portland cement and supplementary building materialmaterials.thefactorsforassessingthestandardof hardened HSC area unit captivated with their supposed functions.

Thedevelopmentofhigh-strengthconcreteispredicatedon thewater-cement(water-binder)quantitativerelation.For the high-strength concrete, the w/c quantitative relation ought to be unbroken low. The utilization of low watercement quantitative relation and different building materials create the utilization of polycarboxylate etherbased on Super plasticizers oughtto be wont to winmost waterreduction, though plasticizersarealsoadequatefor lower strength. Increasing the cement content might not continuouslyturnouthigherstrength.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | August 2022 www.irjet.net p-ISSN: 2395-0072

Theseincludeadecreaseinmembersize. Decrease in the self-weight and superimposed dead load with the accompanying saving due to smaller foundations. decreaseinformworkareaandcost.

Longerspansandfewerbeamsforthesame magnitudeofloading.

Decreaseaxialshorteningofcompressionmembers

HighriseBuildingsandstructures

Prestressedconcretemembers Highwaypayments

Hydropowerstructures

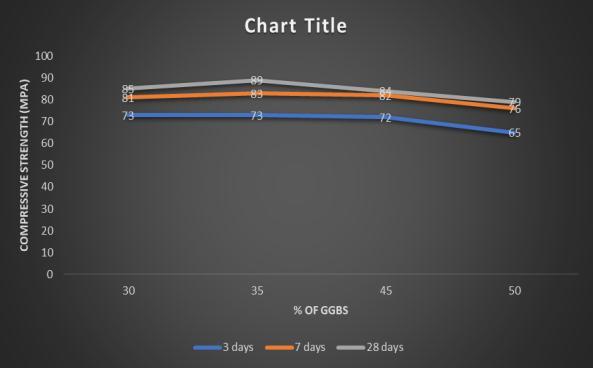

Thisinvestigationismainlyfocusedonthedevelopmentof high-strengthconcrete(HSC)usingmixdesign,especiallyfor HSC by varying the replacement levels of GGBS is varied from30%to50%.Basedonthebackgroundofthisproject, theresearch thefollowingstages.

Tostudythefreshpropertiesofslumpflowtestby workability of concrete different GGBS replacementlevels

TostudytheCompressivestrengthofGGBS-based HSCafter3,7,and28daysofcuring.

(1) Dr. Arun Kumar (2009) Studied The GGBS As limited displacement Of OPC In Cement Concrete And ExperimentalStudythemainaimofthestudyistoobtainthe suitabilityofGGBSasadisplacementofOPCinconcrete.It maybeobservedfromtheplotsthatthepropertiesofcanbe maintainedwithGGBSasalimiteddisplacementofcement upto20%.Theincreasein%ofGGBSresultsinadecreasein the strength of concrete. The reduction in the cost of concrete at the current market rate is 14%, in the case of GGBSasdisplacementofOPCby20%.

(2) Reshma Rughooputh And Jaylina Rana (2010) The limited displacement of OPC with GGBS improves the workabilitybutcausesadecreaseinsidetheplasticdensity of the concrete. The compressive and tensile ripping strengths, flexure, and modulus of property increase with increasingGGBScontent.Thedryingshrinkageshowsalittle increment with GGBS. GGBS fails the initial surface absorption check confirming that the surfaces of their concretemixeswereabundantlyrubberized.supportedthe

results,theoptimummixistheonewith5hundredthsOPC 0%GGBS.

(3) Sonali K. Gadpalliwar, R. S. Deotale, Abhijeet R. Narde (2012) itisfoundthatbyincreasingthe GGBSworkability canincreasebutstrengthdecreases.theutmost28-daysplit permanencewasobtainedwiththeunitoftime GGBSwas replaced with cement. sensible compressive strength is obtained once 2.5% GGBS + 5% is replaced with cement andnaturalsandisreplacedbytimeunitquarrysand.

(4) Sonali K. Gadpalliwar, R. S. Deotale, Abhijeet R. Narde (2012)ThePartialdisplacementOfCementByGGBS&And NaturalSandByQuarrySandInConcreteitisfoundthatby increasingthe GGBSworkabilitycanincreasebutstrength decreases.theutmost28-daysplitpermanencewasobtained with a unit of time GGBS replaced with cement. sensible compressivestrengthisobtainedonce 2.5%GGBS+5% is replacedwithcementandnaturalsandisreplacedbytime unitquarrysand.

In this project, the first stage includes raw materials and their properties no of trails and mixes In this present investigationconcretemixdesignM70toM90wasdesigned IS10262-2019Inthisstudy,Thedisplacementoflevelsof GGBSvariedfrom30%to50%.Lowwatertocementitious ratiowasmaintainedforallHighstrengthconcretemixes. Superplasticizer(SP)dosageat0.8%forallHighstrength concrete mixes. The coarse aggregate and fine aggregate proportions were 63% and 37% respectively this code provides generally a method for selecting mixture proportion for high strength concrete and optimizing the mixproportiononthebasisoftrialbatches,Themethodis limited to high strength concrete production using conventionalmaterials

weusedBirlaA1OPCgradecement.TheOrdinaryPortland cementof53gradeconformingtoIS:12269-2013.Testswe are conducted on cement are specific gravity, setting test, compressivestrengthtestN/mm2

In the present investigation, GGBS was brought from Ultra Tech RMC plant Tirupati. Ground Granulated Blast Furnace slag is one of the mineral admixtures and it is obtained from the quenching of iron slag a by-product of ironandsteel.ConformingtotheIS12089-:1981andGGBS specificgravityis2.9.ConcretemadewithGGBScementsets more slowly than concrete made with ordinary portland cement, depending on the amount of GGBS added to the cementitious material but also continues to gain strength

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page260

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

over a longer period in production conditions. This outcomes in a lower intensity of hydration and a lower temperatureclimbandmakekeepingawayfromcoldjoints morestraightforward.butmayalsoaffecttheconstruction schedule where a quick setting is required. ground granulated blast furnace slag is one of the mineral admixturesanditisobtainedfromthequenchingofironslag aby-productofironandsteelmadefromashootheaterin waterorsteam,todeliverashiny,granularitemthatisdried andgroundintoafinepowderpropertiesisshowninTable 1

compoundadmixturesforconcreteutilizedinthedecrease of water to solidify quantitative connection while not moving functionality and to stay away from molecule accumulationinsidethesubstantialcombination.Theseare calledhighchangewaterreducers(HRWR)andtheirspecific gravityis1.08

Inthisproject,Iusecastingandcuringofspecimenswere doneusingportablewater.itshouldbegoodqualityandfree from chemical impurities harm full greasy and oil substances.

Fig: 1 GGBS

Table:1 PropertiesofGGBS

PROPERTIES

GGBS

Colour Off-white Specificgravity 2.9 Bulkdensity 1200Kg/m3 Fineness 350m2/kg

Inthisproject,Iusenaturalaggregatesofcrushedgranite stoneofsize10mmwasusedascoarseaggregate.Thebulk specificgravityinovendryconditionsandwaterabsorption ofthecoarseaggregate10mmasperIS2386(PartIII)were 2.6 and 0.3% respectively. The gradation of the coarse aggregate was determined by sieve analysis as per IS 383 (2016).

Inthisproject,Iusednaturalriversandwasusedasfine sand. the bulk gravity in oven dry condition and water absorptionofthesandasper2386(part3)zone Ⅱ were2.6 and1%respectively. radiationofthesandwasdetermined bysieveAnalysisasperIS383-2006.

In this study, Conplast 430 used a polycarboxylate etherbased superplasticizer (SP). It is brought from Astra chemicals, Chennai. Superplasticizers are standard

In this present investigation concrete mix design M70 to M90 was designed IS 10262-2019 In this study, The replacementoflevelsofGGBSvariedfrom30%to50%.Low water to cementitious ratio was maintained for all High strength concrete mixes. Super plasticizer (SP) dosage at 0.8% for all High strength concrete mixes. The coarse aggregate and fine aggregate proportions were 63% and 37%respectivelythiscodeprovidesgenerallyamethodfor selectingmixtureproportionforhighstrengthconcreteand optimizingthemixproportiononthebasisoftrialbatches, Themethodislimitedtohighstrengthconcreteproduction usingconventionalmaterialsandproductiontechniques.Mix proportionsdetailsaregivenbelowintable2

Table :2 GGBSblendedHSCmixproportions

Mix Cementitious Kg/m3 Cement Kg/m3 GGBS Kg/m3 C400GGBS230 630 400 230 C770GGBS330 1100 770 330 C770GGBS440 1210 770 440 C770GGBS630 1400 770 630 C770GGBS770 1540 770 770 C900GGBS90 1290 900 390 C900GGBS510 1490 900 510

Table: 3 GGBSblendedHSCmixproportions

Water Litre/m3 W/cm 10mm Kg/m3 Sand Kg/m3 Sp %

190.4 0.33 978.54 574.69 0.8 190.4 0.19 723.89 425.20 0.8 190.4 0.17 660.11 387.7 0.8 190.4 0.15 550.37 323.23 0.8 190.4 0.14 468.47 275.13 0.8 190.4 0.16 620.8 364.68 0.8 1904 0.15 550.36 323.23 0.8

Volume: 09 Issue: 08 | August 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page261

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | August 2022 www.irjet.net p-ISSN: 2395-0072

Table:4 ParametersofGGBSmixproportions

Mix Cementitious Cement Kg/m3

GGBS Kg/m3

C400GGBS230 630 400 230

C400GGBS230 1100 770 330

C400GGBS230 1210 770 440

C400GGBS230 1400 770 630

C400GGBS230 1540 770 770

C400GGBS230 1290 900 390

C400GGBS230 1410 900 510

InthisprojectweuseApanmixermachine(40kgcapacity) isusedtomixHSC.weaddcement,GroundGranulatedBlast furnaceSlag,areplacedinthemixer,andmixingisdonefor 3minutes.(120rpm)foroneminuteanditisaddedtothe mix. ThenGGBSisadded andmixed for 3minutes. water alongwithhalfofSPisaddedandmixedfor2minutes.When proper blending of ingredients is observed, remaining SP and water are added and mixed for 3 minutes. When consistency is observed, are added slowly then mixing is continuedfor2minutes.

Table:5 GGBSblendedmixproportions

W/CM GGBS/Cement %GGBS

0.35 0.6 35 0.19 0.4 30 0.17 0.6 35 0.15 0.8 45 0.14 1 50 0.16 0.4 30 0.15 0.6 35

For each mix 6 cubes are cast. Size of cube is 100mmx 100mmx100mm.curingofcubesisdoneinnormalwaterfor curing.

Cubesweretestedforcompressivestrengthand3days,7 days, and 28 days respectively. They are tested under Compression Testing Machine (CTM) for compressive strength

Inthistest,Icancalculatetheworkabilityoffreshconcrete the concrete should spread on the surface in the circular areawhenwelifttheconeverticallyupwards.Thistestwas conducted for all mixes with various mix proportions by using GGBS in the replacement of 30% to 60%. It is observedthattheincreaseofGGBSreplacementdecreased the slump values of high strength concrete mixes we can calculatetheslumpSlumpflowtestofconcreteisthetestof measuringtheworkabilityofconcretewhichisextensively usedinconstructionsite-workallovertheworld.Theslump conehasfilledtheconcreteandthemoldisthenremoved from the concrete immediately by raising it slowly and carefully in a vertical direction. The slump flow spread is measured by determining the diameter of the concrete spreadinthesurface

Table:6 SlumpflowvaluesforggbsmixforHSC

Mix

Cementiti ous Kg/m3

%GGBS SLUMP FLOW MM

C400GGBS230 630 35 551

C770GGBS330 1100 30 590

C770GGBS440 1210 35 628

C770GGBS630 1400 45 619 C770GGBS770 1540 50 572 C900GGBS390 1290 30 662 C900GGBS510 1410 35 648

It is observed that the increase in GGBS replacement decreasedtheslumpflowofHSCmixes

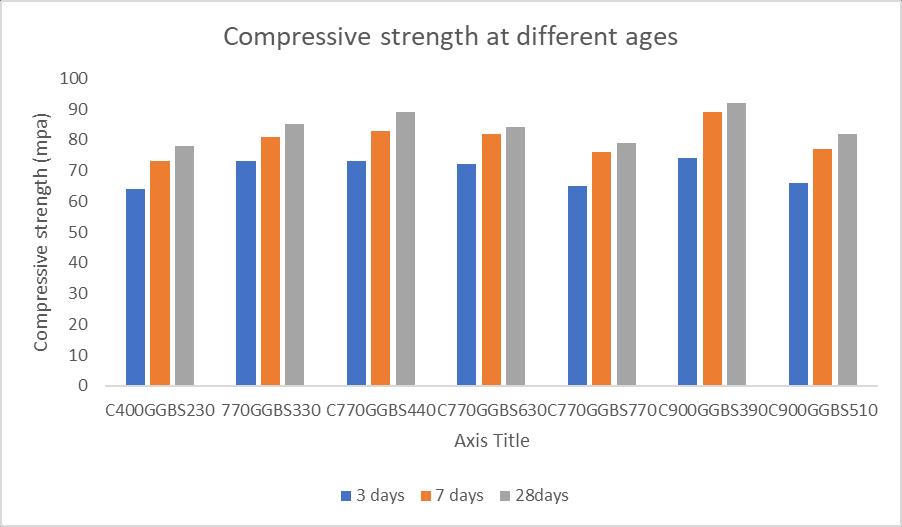

Table:7 CompressivestrengthforGGBSblend

Mix

Compressive strength (MPa) Grade

3 days 7 days 28 days

C400GGBS230 64 73 78 M70

C770GGBS330 73 81 85 M80

C770GGBS440 73 83 89 M80

C770GGBS630 72 82 84 M70

C770GGBS770 65 76 79 M70

C900GGBS390 74 89 92 M80 C900GGBS510 66 77 82 M70

value:

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | August 2022 www.irjet.net p-ISSN: 2395-0072

CompressivestrengthofM70toM80wasdeterminedduring the3days,7days,and28daysofcuring,andtheirresults From the above results, it is observed that HSC mixes achieved M70 andM80 grade of concrete after 28 days of curing. Among the mixes C770GGBS330,C770GGBS440,C770GGBS630 and C770GGBS770,the two mixes C770GGBS330 and C770GGBS440attainedM80gradestrength.Theothertwo mixesC770GGBS630andC770GGBS770attainedM70grade strength. The mixes C400GGBS230, C770GGBS630, C770GGBS770 and C900GGBS510 attained M70 grade strength. The mixes C770GGBS330, C770GGBS440 and C900GGBS390attainedM80gradestrength.

1. ItisobservedthattheincreaseofGGBSreplacement decreased the slump flow values of High strength concretemixes.

2. The mix C900GGBS390 the replacement of GGBS in 30% increased the maximum slump value to be attained.

3. CompressivestrengthofmixC400GGBS230with35% GGBS achieved the M70 grade concrete 28 days of curing.

4. CompressivestrengthofmixC770GGBS630with45% GGBS achieved the M70 grade concrete 28 days of curing.

5. CompressivestrengthofmixC770GGBS330with30% GGBS achieved the M80 grade concrete 28 days of curing.

6. CompressivestrengthofmixC900GGBS390with30% GGBS achieved the M80 grade concrete 28 days of curing.

FIG 2: Compressivestrengthatdifferentages

7. CompressivestrengthofmixC770GGBS440with35% GGBS achieved the M80 grade concrete 28 days of curing.

1. Dr. Arun Kumar Studied The GGBS As limited displacementOfOPCInCementConcreteAndExperimental Study2009IJMTS.

2. Reshma Rughooputh And Jaylina Rana GGBS As limited displacementOfOPCInCementConcreteAndExperimental Study”,IJMTS2010.

3.SonaliK.Gadpalliwar,R.S.Deotale,AbhijeetR.Nardeitis foundthatbyincreasingthe GGBSworkabilitycanincrease butstrengthdecreasesIjmts2012.

4.A.H.Shekari,M.S.Razzaghi,Influenceofnanoparticleson durability and mechanical properties of high strength concrete,ProcediaEng.14(2011)3036–3041.

5.B.Cather,Concreteandfireexposure,Advance.Concrete. Technology.: Concrete Properties 2(2003)1.Of Cement By GGBS&AndNaturalSandByQuarrySandInConcrete.

6.ZhouFP,BarrBIG,LydonFD.Fracturepropertiesofhigh strength concrete with varying silica fume conteMuller H. Constitutive modeling of high strength/high strength concrete–stateoftheartreport.CEBFIPBull2008:42.Not andaggregates.CemConcrRes1995;25(3):543–52.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | August 2022 www.irjet.net p-ISSN: 2395-0072

7.ZhangXX,YuRC,RuizG,TarifaM,CamaraMA.Effectof loading rate on crack velocities in HSC. Int J Impact Eng 2010;37(4):359–70.

8.ZimbelmannR.Acontributiontotheproblemofcement aggregatebond.CemConcrRes1985;15(5):801–8.

9. Scrivener KL, Pratt PL. The characterization and quantificationofcementandconcretemicrostructures.In: First international conference from material science to constructionmaterialsengineering,vol.1;1997.p.61–8.

10. Peng GF, Huang ZS. Change in the microstructure of hardenedcementpastesubjectedtoelevated.

11. Malhotra HL. The effects of temperature on the compressive strength of concrete. Mag Concr Res 1956;8(3):85–94

12. Ali F. Is high strength concrete more susceptible to explosive spalling than normal-strength concrete in fire? Jalal,M.,Mansouri,E.,2012.

13. Testing aggregates: “Methods of determination of density”,BS:812(Part2),1995,BritishStandardsinstitute.

14. ”Methods of test for the strength of concrete”, IS 516:1959,BureauofIndianStandards,NewDelhi,2002.

15.D.Nirosha,C.Sasidhar,k.Narasimhulu,Investigationon HighStrengthConcreteUsingGGBSandsilicafumeVolume 16;issue6,2022.

16.IS10262:2019Recommendedguidelinesformix designforHighstrengthconcrete.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal