International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Manthale S N1 , Pol C B2

1PG Student, Dept. of Civil Engineering, Walchand College of Engineering, Sangli, Maharashtra, India, 416415 2Professor, Walchand College of Engineering, Sangli, Maharashtra, India, 416415 ***

Abstract -Stiffened sandwich plates are mechanically resistant structural components and used in a lot of engineering applications ranging from bridges and buildings to planes and ships. In the shipping sector, a large number of these structures are required to withstand very high stresses caused by their own structure's weight or by sea conditions faced during navigation. These constructions must be exceptionally resistant to shearstressesandbendingmoments due to the high loadings. Adding more material to a structure can improve its strength, but it also increasesitsweight,which should be avoided when building projects for the offshore and naval industries. The use of mechanical stiffeners becomes necessary in this situation. These stiffeners are longstructural profiles that are fixed horizontally to the plates. The present report describes the results and insights developed for load analysis of an aluminium stiffened plate with varyingstiffener configurations as required for the loading criterion based on ANSYS 18.2. High-strength aluminium alloys have become more widely used in the design and building of high-speed boats over the last decade, as their sizehasincreasedandtheir operations have shifted into more harsher ocean-going conditions. As a result, in terms of strength or reliability analysis and fabrication quality control, the design and building procedure to assure the structural safety of aluminium high-speed vessels has become more complicated.

Key Words: Stiffener, Finite Element, Configuration, Stiffenedsandwichplateetc.

Structuralhealthmonitoringisanemergingtechnologythat hasseveraluses.Thebroadsubjectofsmartstructuresgave rise to SHM, which also includes fields like structural dynamics,materialsandstructures,nondestructivetesting, sensorsandactuators,anddatascience.signalprocessing, acquisition, and perhaps much more. Traditional NDT methods, include Thermography, radiography, and ultrasonicC-scanhaveallbeenusedsuccessfullytoinspect structural soundness. The use of these conventional methods,though,hasbeenrestrictedtotestingverysimple shapesorlookingattheareawherethetransducerchanges. Mostsomeofthesetechniquesmightnotbeappropriatefor monitoringverybigandcomplexsystemsonlineorinsitu structures.

Monitoringchangestothematerialandgeometricqualities ofengineeringstructures,suchasbridgesandbuildings,is knownasstructuralhealthmonitoring.Damagecanbeeasily foundbyevaluatingmeasuresthatareperiodicallysampled. Monitoringthehealthofstructuresiscrucialsincetheyare all susceptible to internal and external causes that could result in malfunctions or wear-related damage. Use of a damage identification system is crucial to detecting these flaws.Asystemlikethiswouldenablesuperfluouscheck-ups ormaintenancetobeavoidedandsubstitutedbyworkthat has been determined to be essential. Damage could be identified early on, before any significant damage has occurred.

Thestiffenedsandwichplatedstructuresareofcommon occurrenceinpresentdayengineering.Thecomponentsof ship, a traffic road bridge and a launching pedestal of a rocketareonlyafewexamplesofstiffenedplatedstructures. With such a wide range of application, it is obvious that stiffened plates are subjected to dynamic loads of varying magnitudeandcomplexity.Anaircraftstructurenecessitates analysisforflutter,jetnoise,etc.Thewingorthefuselageof anaircraftconsistsofaskinwithanarrayofstiffeningribs.A roadbridgeisdesignedtowithstandmovingvehicleloadas well as those due to possible earthquake. Stiffened plated structuresencounteroceanwavesandearthquakeswhich are random in nature. The narrow-banded spectra of sea wavesforsuchcasesrequiresthespectralanalysistodesign anoffshoreplatformorashiphull.Bothdeterministicand stochastic methods have been applied to solve these problems.Steelplatesarestructuralelementsthatcanbear mechanical stresses and are utilized in a variety of engineering areas, including bridge and building construction,aswellasaviationandshipconstruction.

Manyscholarshavedoneadiversesetofstudiesforthe resilient design of ships and offshore buildings, analyzing andforecastingthestructuralconditionofundamagedand damagedstructures.Thefiniteelementmethod(FEM),for example, is a well-known numerical method that may be used to solve problems in a variety of sectors, including engineering and medicine. Furthermore, as computer technology advances, numerical simulations based on computational fluid dynamic (CFDs) and fluid-structure interaction (FSIs) are becoming increasingly prevalent in structuraldesign.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

1. Formulation of problem statement and development of methodology using high quality researcharticle.

2. Simulationofaluminiumstiffenedsandwichplate subjected to transient load by using FEM based software.

3. Modellingofvariousstiffenerplacementtypesfor aluminiumstiffenedsandwichplate.

4. Analysisfordifferentconfigurationsofaluminium stiffened sandwich plate subjected to Transient load.

For the present study, an aluminium stiffened sandwich plate is considered. The dimensions of the plate are 1200×1200×3mm.Thesupportandboundaryconditionsfor theplateareassumedasfixed.Theconfigurationoftheplate isgiven below.Thealuminiumstiffenedsandwichplate is subjected to transient load and the corresponding deformation in each of the plate is calculated and by comparing the results, best configuration of stiffeners is determined.

Forthepresentstudy,differentconfigurationsofstiffeners are considered which are rectangular, hexagonal and triangular.Theanalysisiscarriedoutforeachconfiguration of stiffeners and optimum configuration of stiffeners is determined.

4.1 Stiffened sandwich plate having rectangular stiffeners

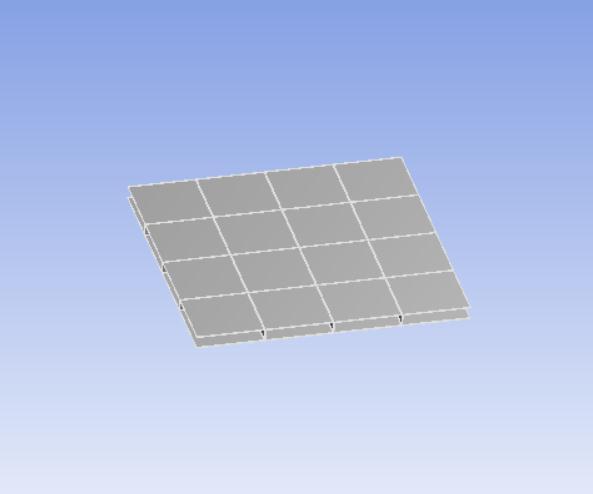

Figure-2 Stiffenedsandwichplatehavingrectangular stiffeners

Above figure shows aluminium stiffened sandwich plate havingrectangularconfigurationofstiffeners.Thespacingof stiffenersisconstantwhichis300mminboththedirections. Threestiffenersareprovidedbetweentwoaluminiumplates inboththedirections.

4.2 Stiffened sandwich plate having hexagonal stiffeners

• Platetype:stiffenedsandwichplate

• DimensionsofreferenceplatePlate:1200×1200×3mm

• Platematerial:Aluminium

• Heightofstiffener:50mm

• Thicknessofstiffener:5mm

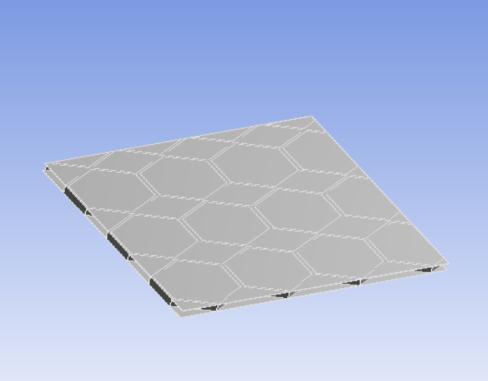

Figure-3 StiffenedSandwichplatehavinghexagonal stiffeners

Above figure shows aluminium stiffened sandwich plate having hexagonal configuration of stiffeners. The area of eachhexagonalstiffenerissameastherectangularstiffener.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

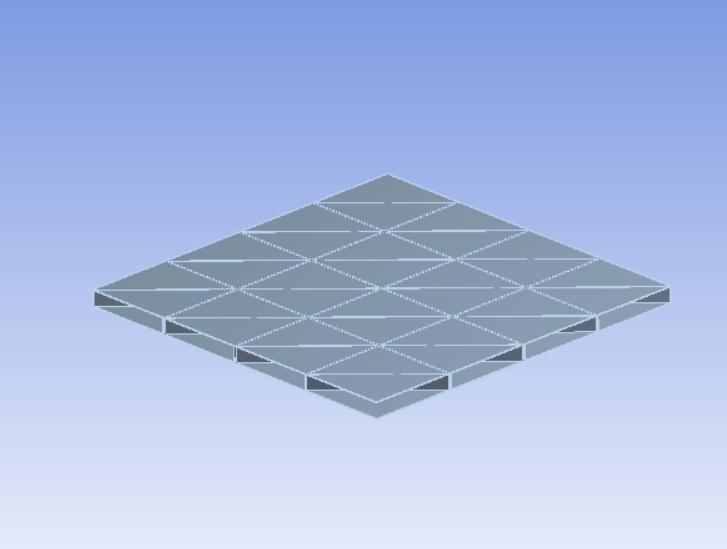

Fig- 4: Stiffenedsandwichplatehavingtriangular stiffeners

Above figure shows Aluminium stiffened sandwich plate havingtriangularconfigurationofstiffeners.

In this chapter, the results of deformation of aluminium stiffened sandwich plate having different configuration of stiffenersaredeterminedandbasedonthecomparisonof maximum deformation for each configuration of stiffener, optimumconfigurationofstiffenerisdetermined.

5.1 Analysis of aluminium stiffened sandwich plate having rectangular stiffeners

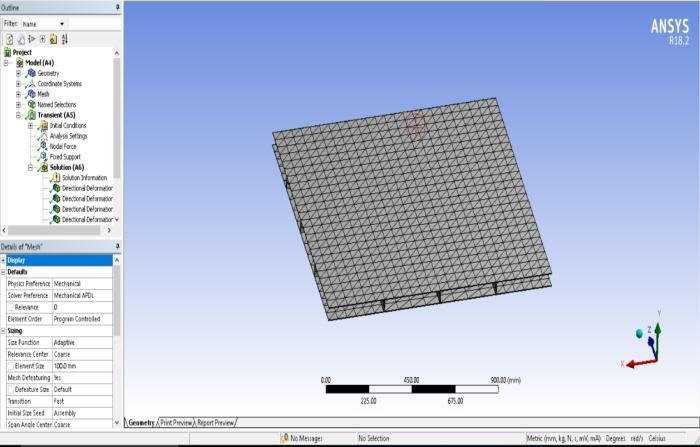

Fig- 6: Meshofaluminiumstiffenedsandwichplate

Figure shows meshing of aluminium stiffened sandwich plate.Forthismodel,quadrilateralmeshingisused.

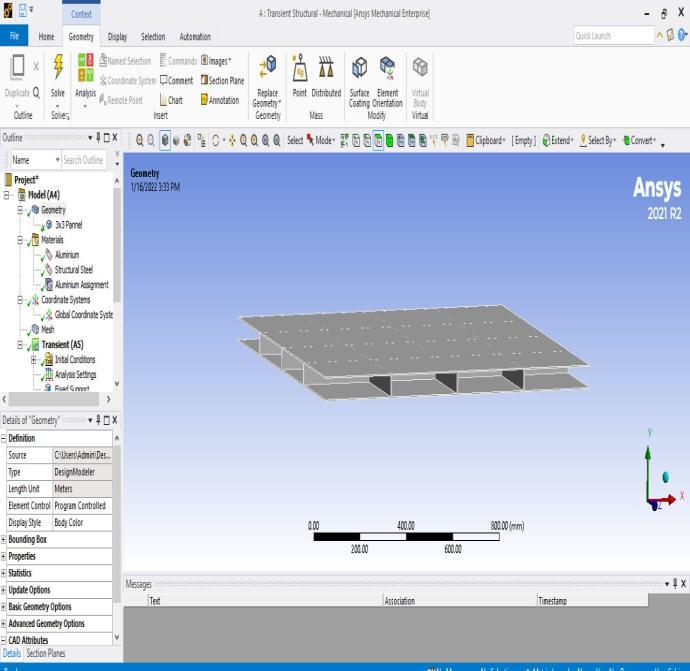

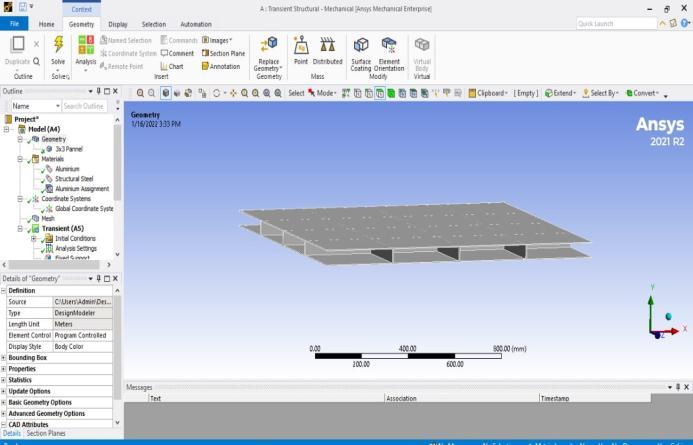

Fig- 5: Geometryofaluminiumstiffenedsandwichplate havingrectangular stiffeners

Above figure shows aluminium stiffened sandwich plate havingrectangularconfigurationofstiffeners.Thespacingof stiffenersisconstantwhichis300mminboththedirections. Threestiffenersareprovidedbetweentwoaluminiumplates inboththedirections.

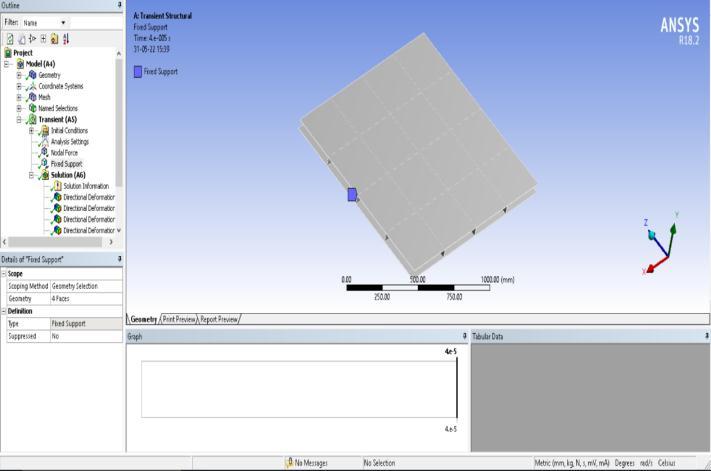

Fig- 7: FixedSupportConditions

Abovefigureshowssupportsconditionsoftheplate.Fixed supports are applied on all the four sides of plate and analysisiscarriedout.

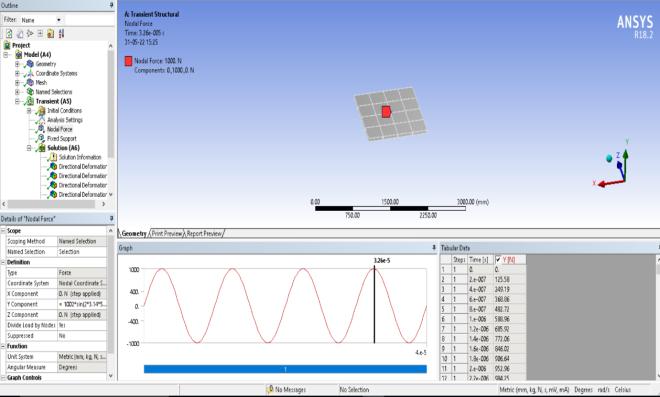

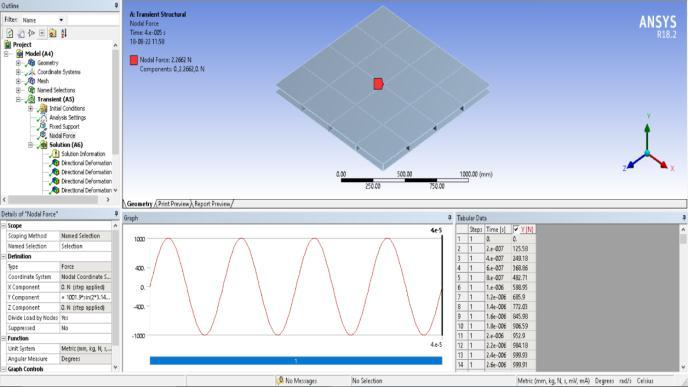

Fig- 8: NodalForceof1000Namplitudeand100KHz frequency

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Figureshowstheforceappliedonthealuminiumstiffened sandwich plate having rectangular configuration of stiffeners. Four cycles of sinusoidal load having 1000 N amplitudeand10microsecondscycletimeisconsideredfor thisanalysis.

5.2 Analysis of aluminium stiffened sandwich plate having hexagonal stiffeners

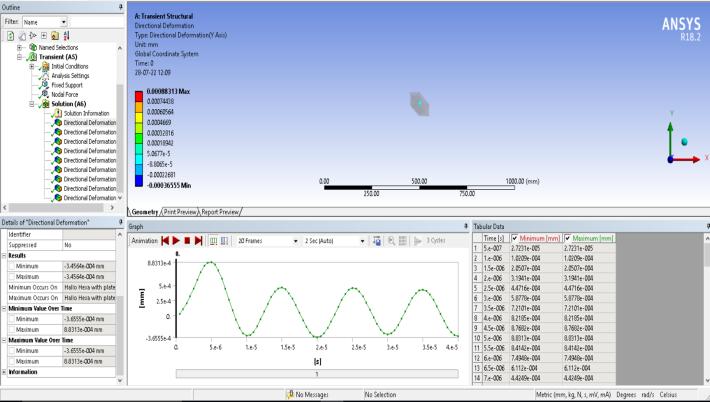

Figure- 9: Deformationresultsofaluminiumstiffened sandwichplatehavingrectangularstiffeners

Figureshowsdirectionaldeformationofplateatcentralnode foraluminiumstiffenedsandwichplatehavingrectangular stiffenersfor100KHzfrequency.

Table-1 Deflectionresultsforrectangularstiffened sandwichplate

SR No NodeNo Deflection(mm)

Maximum Minimum

1 Node1 6.0771e-004 -3.4871e-004 2 Node2 62289e-005 -7209e-005 3 Node3 4531e-005 -50762e-005 4 Node4 3.0499e-005 -3.5718e-005 5 Node5 75955e-005 -59597e-005 6 Node6 39882e-005 -4926e-005 7 Node7 4.6149e-005 -3.9814e-005 8 Node8 39882e-005 -4926e-005 9 Node9 46149e-005 -39814e-005

Above table shows results of directional deformation at differentnodes.Themaximumdeformationoccursatnode1 whichiscentralnode.

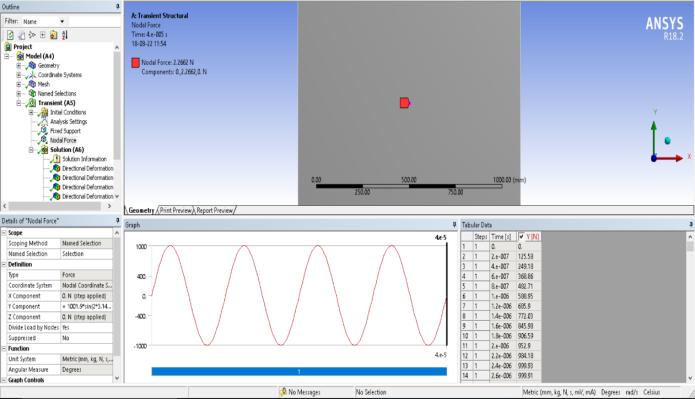

Figure-10 NodalForceof1000Namplitudeand100KHz frequency

Figureshowstheforceappliedonthealuminiumstiffened sandwich plate having hexagonal stiffeners. Four cycles of sinusoidal load having 1000 N amplitude and 10 microsecondscycletimeisconsideredforthisanalysis.

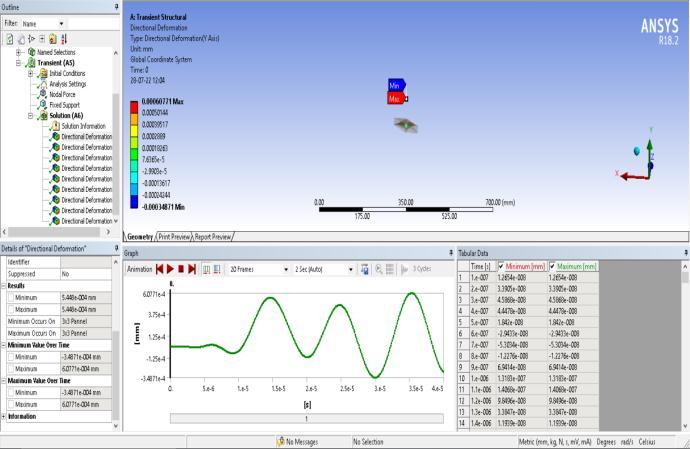

Figure-11 Deformationresultsofaluminiumstiffened sandwichplatehavinghexagonalstiffeners

Figureshowsdirectionaldeformationofplateatcentralnode for aluminium stiffened sandwich plate having hexagonal stiffenersfor100KHZfrequency.

Table-2 Deflectionresultsforhexagonalstiffened sandwichplate

SR.No NodeNo Deflection(mm)

Maximum Minimum

1 Node1 88313e-004 -36555e-004

2 Node2 28299e-005 -32472e-005

3 Node3 3.6238e-005 -4.0494e-005 4 Node4 1.9807e-005 -2.0466e-005

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

5 Node5 3.6013e-005 -4.0197e-005

6 Node6 24171e-005 -21605e-005

7 Node7 67401e-006 -17886e-005

8 Node8 76946e-006 -92976e-006

9 Node9 8.7114e-006 -1.2683e-005

Above table shows results of directional deformation at differentnodes.Themaximumdeformationoccursatnode1 whichiscentralnode.

5.3 Analysis of aluminium stiffened sandwich plate having triangular stiffeners

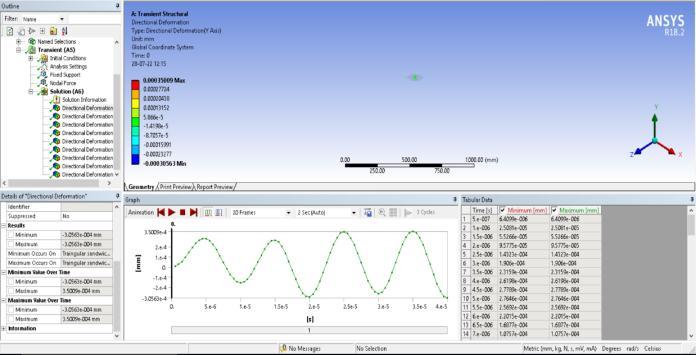

Table-3 DeflectionresultsfortriangularStiffened sandwichplatefor100KHZfrequency

SRNo NodeNo Deflection(mm)

Maximum Minimum

1 Node1 35009e-004 -30563e-004

2 Node2 40635e-006 -46643e-006

3 Node3 7.3532e-006 -8.878e-006

4 Node4 90477e-006 -98517e-006

5 Node5 13871e-005 -15951e-005

6 Node6 -19047e-006 -19047e-006

7 Node7 6.6951e-006 -8.5207e-006

8 Node8 2.7194e-006 6.6951e-006

9 Node9 -32162e-006 -32162e-006

Above table shows results of directional deformation at differentnodes.Themaximumdeformationoccursatnode1 whichiscentralnode.

Figure-12 NodalForceof1000Namplitudeand100KHz frequency

Figureshowstheforceappliedonthealuminiumstiffened sandwich plate having triangular stiffeners. Four cycles of sinusoidal load having 1000 N amplitude and 10 microsecondscycletimeisconsideredforthisanalysis.

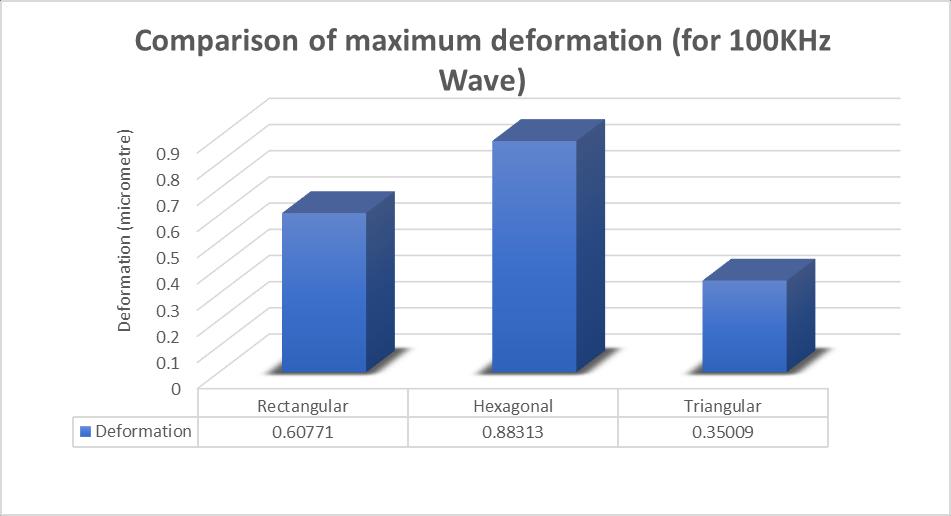

Figure-14 Comparisonofmaximumdeformationdueto fourcyclessinusoidalwaveof100KHzfrequencyfor differentconfigurationofstiffeners

Figure-13 Deformationresultsofaluminiumstiffened sandwichplatehavinghexagonalstiffeners

Figureshowsdirectionaldeformationofplateatcentralnode for aluminium stiffened sandwich plate having triangular stiffenersfor100KHzfrequency.

Factor value:

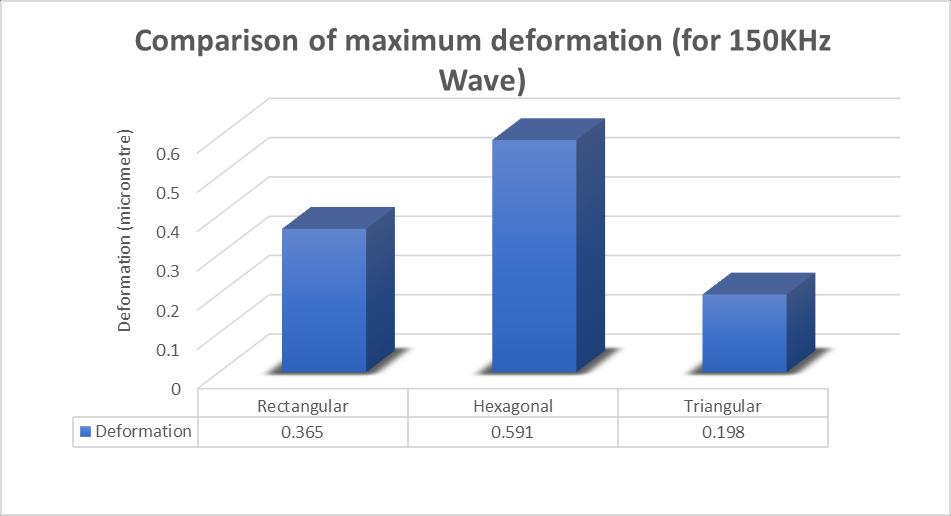

Figure-15 Comparisonofmaximumdeformationdueto fourcyclessinusoidalwaveof150KHzfrequencyfor differentconfigurationofstiffeners

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

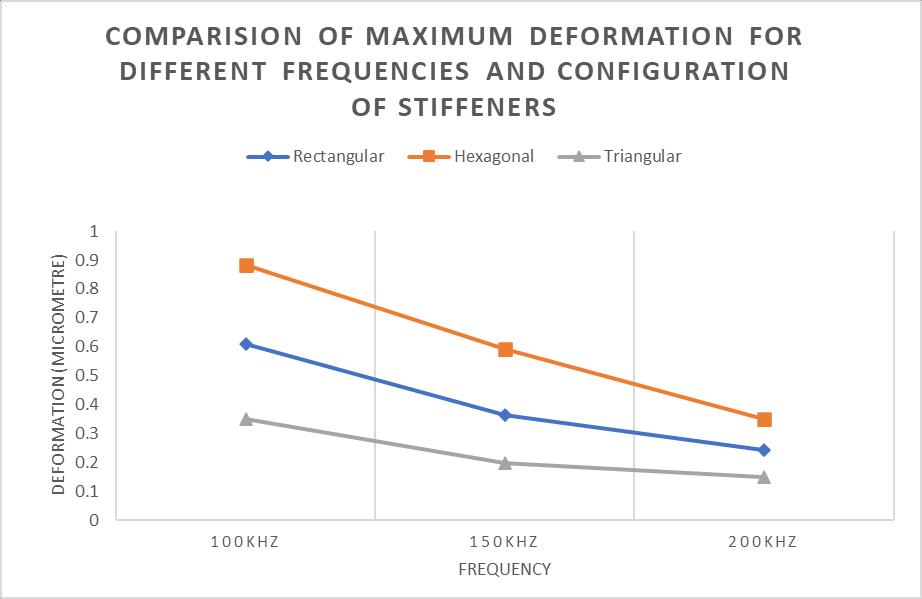

ii. Maximum deformation at central node in aluminium stiffened sandwich plate having triangular configuration of stiffeners is less as comparedtorectangularstiffenersandhexagonal stiffeners

iii. Hencetheoptimumconfigurationofstiffenerthat should be adopted for aluminium stiffened sandwich plate is triangular configuration of stiffeners.

iv. Thedeformationofaluminiumstiffenedsandwich plateislessascomparedtoconventionalaluminium plate.

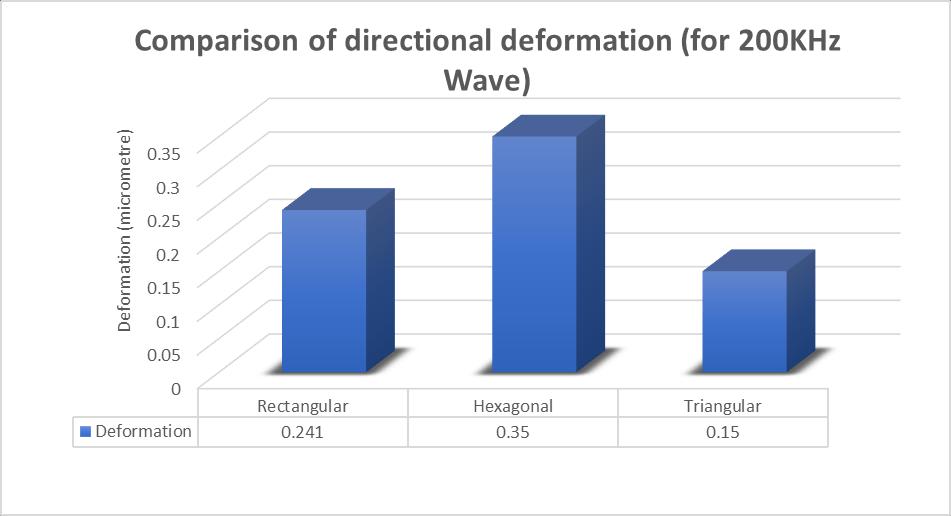

Figure-16 Comparisonofmaximumdeformationdueto fourcyclessinusoidalwaveof200KHzfrequencyfor differentconfigurationofstiffeners

Table-4 maximumdeformationfordifferentfrequencies andconfigurationofstiffenersinmicrometer

Shape of stiffener Maximumdeformation(micrometer) 100KHz 150KHz 200KHz

Rectangular 0.60771 0.365 0.241 Hexagonal 0.88313 0.591 0.35 Triangular 0.35009 0.198 0.15

Figure-17 Comparisonofmaximumdeformationfor differentfrequenciesandconfigurationofstiffeners

i. For same number of sinusoidal cycles, if the frequency of sinusoidal wave is increased, total cycle time decreases and hence maximum deformationinaluminiumstiffenedsandwichplate decreases.

1) A.YousefiandM.Safarabadi(2020),“Damage identification of the rice husk sandwich structure for ship deck structure,” International conference on marine technology. S. Popovics, Concrete Materials: Properties,Specifications,andTesting,2nded. ParkRidge,NJ:Noyes,1992.

2) AbdiIsmail(2020),“vibrationbaseddamage identification for ship sandwich plate using finite element method,” Article in Open Engineering.

3) Aparna Aradhye and Dhanashri Joglekar (2021)“Adiabeticguidedwavepropogation through a honeycomb composite sandwich structure,”Internationaljournalofsolidsand structures.

4) B.Janarthan(2016)“Bucklingofbars,plates andshells,”McGraw-HillCompany.Bambang Piscesa, Rizky Chandra Ariesta, and Tuswan (2020)“Vibrationbaseddamageidentification for ship sandwich plate using finite element method,” computational and applied mechanics.

5) C. Droza, O. Bareillea, J.-P. Lain´ea, M. N. Ichchoua (2020) “Wave-based SHM of sandwich structures using cross-sectional waves”

6) Chen, J, Su, Z and Cheng, L, (2010) “Identification of corrosion damage in submergedstructuresusingfundamentalantisymmetricLambwaves”,SmartMaterialsand structures,Vol.19,015004

7) DeepakkumarsinghandS.K.duggal(2015), “Analysis of stiffened plates using FEM,”

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

International journal of engineering and technology.

8) DoKyunKim(2018),“DesignwithConstructal Theory,”1stInternationalWorkshoponshape andthermodynamics.

9) JoaopedroandQueiroz(2002),“Analysisof stiffenedplatesunderlateral

10) Konstantinos N. Anyfantis (2020) “Ultimate strengthofstiffenedpanelssubjectedtonon uniformthrust,”Internationaljournalofnaval architectureandoceanengineering.

11) Mirco Muttilo and Vincezo Stornelli (2020) “Structuralhealthmonitoring:anIOTsensor system for structural damage indicator evaluation,” department of industrial and informationengineeringandeconomics.

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2080