International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

1Master of Technology, Electrical Engineering (Power System), KNIT Sultanpur, UP, India 2Professor, Department of Electrical Engineering, KNIT Sultanpur, UP, India 3 Professor, Department of Electrical Engineering, KNIT Sultanpur, UP, India ***

Abstract -Hybridelectricvehicles,sometimesabbreviated asHEVs,areaproductoftheautomotiveindustry'sreaction tothegrowingenvironmentalchallengesitfaces.Thesecars combinetheadvantagesofgasandelectricpowertrains.The benefitsthatelectriccarsandconventionalvehiclespowered by internal combustion engines provide are brought together in hybrid electric vehicles, or HEVs. They accomplish this by combining a traditional internal combustionenginewithanelectricalsystemthatconsistsof abatteryandanelectricmotor.Thisallowsthemtoachieve higher fuel efficiency and reduced emissions while still retaining an appropriate driving range. Plug-in hybrid electricvehicles,alsoknownasPHEVs,havelargerbattery storagesystemsthanconventionalhybridelectricvehicles (HEVs).Becauseofthis,plug-inhybridelectricvehiclesare able to receive a full charge by connecting to an external electricpowersource,suchastheelectricalgrid.Oneofthe threefundamentalideasforPHEVsiscalledthepower-split architecture.Ithasatendencytoprovidehigherefficiency thantheparallelarchitectureandtheseriesarchitecture,but it also has more sophisticated dynamics than those two types of architecture. In light of this, the objective of this researchprojectwastoexaminetheproblemofoptimizing thecomponentsizesofapower-splitPHEVinanattemptto makethemostoftheedibilityofthispowertrainsystemand furtherincreasethevehicle'sfuelefficiency.Forthepurpose of this experiment, a Toyota Prius with a plug-in hybrid system was employed as the baseline car. In order to developamodelofthevehicle,theAutonomiessoftwarewas used. This model was then used as the basis for the formulationofanoptimizationproblem.Themajorobjective ofthismatteristolessenthequantityofgasolinethatisused upduringthetypicaldrivingroutines.Severalfactorsofthe design were taken into account, including the maximum power of the engine, the number of battery cells, and the maximum power of the electric motor. The issue of optimizationforthevariousdrivingcycleswasresolvedby making use of the genetic algorithm technique, and an adequate reduction in fuel consumption was achieved by making use of the sizing procedure. Both of these accomplishmentswerepossiblethankstotheapplicationof thegeneticalgorithmtechnique.Inordertoensurethatthe modelwasaccurate,aMapleSimmodelwasused.

Key Words: Dynamicmodeling,HybridPower,Electrical, vehicle,Hybridelectricvehicle.

Electriccars,alsoknownasEVs,areapracticalalternativeto conventionalautomobilespoweredbyinternalcombustion engines(ICE),whicharenotoriousfortheexcessiveamount ofnoisetheyproduceandtheamountofgasolinetheyuse. Electriccars,alsoknownasEVs,areaviablealternativeto conventionalautomobilespoweredbyinternalcombustion engines(ICE).Becausetheonlysourceofpowerthatelectric cars need is the electrical energy that is stored in their battery systems, there is no longer any need to directly consume fossil fuels while operating electric vehicles becausethisrequirementiseliminatedentirely.Inaddition, theexhaustthatexitstheirtailpipesdoesnotgenerateany noise or particles that contribute to air pollution. Nevertheless,despitethesebenefits,electriccarshavenot hadasubstantialeffectontheglobalvehiclemarkets,which arestilldominatedbytraditionalinternalcombustionengine (ICE)vehicles.Thisisbecauseelectricautomobilesaremore expensivethanconventionalICEvehicles.Thisisduetothe factthatelectriccarshaveahigherpurchasepricecompared tootherkindsofvehicles.Thekeyreasonsforthistendency are the expensive price tag of electric cars as well as the restricted driving range that can be achieved due to the limitations of their battery packs. As a result of these challenges, manufacturers have been compelled to design platformsthatarecapableofsuccessfullybridgingthegap betweencarspoweredbyinternalcombustionengines(ICE) and vehicles that produce no emissions as part of their efforts to overcome these deficiencies. These efforts are being made as part of the manufacturers' efforts to overcometheseshortcomings.Theseplatformswillfillthe roleoftransitionaltechnologiesuntilelectriccarsareableto morefullypenetratetheconsumermarket.Asadirectand immediateconsequenceoftheseefforts,hybridelectriccars and,morerecently,plug-inhybridelectricvehiclesarenow available to purchase on the market (HEVs and PHEVs, respectively).

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

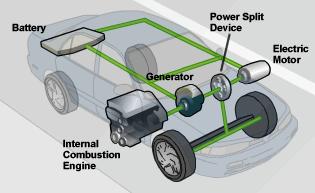

Previously,itwasmentionedthatthehybridelectricvehicle (HEV) was presented as a short-term solution that makes useoftechnologiesfromboththeelectricvehicle(EV)and the internal combustion engine (ICE) platforms. This was donesobecausetheHEVisabletotakeadvantageofboth setsofplatforms'respectivestrengths.Thisapproachmakes useofthetechnologythatisspecifictobothelectricvehicle and internal combustion engine platforms. Combining the internal combustion engines that are found in traditional automobiles with the electric motors that are found in electricvehiclesisonewaythatthismaybeaccomplished (EVs). This makes it possible to have access to a different source of energy, which opens up the possibility of incorporatingitintothefunctioningofpropulsionsystems for vehicles. Hybrid electric automobiles are clearly more fuelefficientthantheirconventionallypoweredequivalents. Thisisduetothefactthattheelectricsystemsupportsthe engineinmaintainingwithinitsmosteconomicaloperating range.Asaresultofthis,theengineisabletoeithertotally shut off while it is idling or charge the batteries with the extra power that it generates while it is running. Conventional motor vehicles are not equipped to provide propulsionthroughelectricpropulsion.Becauseofthis,itis especially beneficial to operate a vehicle in an urban environment using the electric propulsion system, as it is possibletodosoalmostentirely.Asadirectconsequenceof this,thisisparticularlyusefulinurbansettings.Thisresults inadecreaseinfuelconsumptionandmakesitfeasiblefor the vehicle to have a smaller engine, both of which are desirablefeaturestohaveinareaswitha highpopulation densitysincetheymakeitpossibletoutilisevehicleswith smaller engines. In addition, the kinetic energy that is generallylostasheatasthevehicleisdeceleratingmaybe reclaimed and put to use to charge the batteries, which is somethingthatisnotnormallyfeasibleforavehicleofthis kind. Each of these benefits contributes to the overall reduction in the amount of gasoline that may be saved, makingthetotalamountoffuelsavingsamorereasonable quantity. Nevertheless, hybrid electric vehicles (HEVs), despitethefactthattheycannotrunontheelectricsystem aloneand,asaresult,mustconsumeatleastasmallamount of fuel, can be regarded as a workable solution for the intermediatetermuntilfullyfunctionalelectricvehiclesthat have zero fuel consumption and zero emissions are produced.ThisisbecauseHEVsareabletorunonboththe electricsystemandthefuel systemsimultaneously,which allows them to run on the electric system alone when the fuelsystemisnotinuse.Thisisasaresultofthefactthat HEVs are able to operate on the electric system in combination with the electric system. The figure of the hybridelectricvehicleisgivenbelow:

Afterstudiedresearchpaperrelatedtothehybridelectric vehicle, the summary of all paper is given below with the authorname:

[1] David: modellingandsimulationofhigh-energyvehicles, withthemajorfocusbeingonmodellingthatisparticularly focusedonphysics.Inthisessay,wewilltakeabrieflookata few alternative tactics that may be employed in dynamic digital simulations in order to suppress numerical oscillations.Thesestrategieshavethepotentialtobeapplied in a variety of different ways. When modelling and simulatingHEVs,itispossibletoattainagreaterdegreeof freedombymakinguseofadditionalsimulationapproaches, such as bond graph modelling. This may be done by modelling and simulating HEVs. Because powerful computing,thedevelopmentofcomputationalmethods,and advancementsinsoftware-in-the-loop(SIL)andhardwarein-the-loop (HIL) modelling and simulations are now available,itisnowpossibletostudynumerousiterationsof different designs with the combinations of different componentsanddifferenttopologyconfigurations.Thiswas notpossibleinthepast.Intimespast,doingsowouldhave beenimpossible.Myfirstattemptwasacompleteandutter failure. For the goals of quick prototyping and the developmentofcontrolsystemsfornewvehiclessuchasXby-Wire [46], HIL is becoming an increasingly crucial component.HEVwillattractgrowingattentionfromboththe automotive industry and the consumer as constraints imposedonenergysuppliesbecomeevermorerigorousand asenvironmentalconcernsbecomemorewidespread.Thisis because HEVs provide a number of advantages that conventionalvehiclesdonot.Thisisduetothefactthatitis anticipatedthatthelimitationsplacedonavailableenergy supplieswouldgetmorerestrictiveastimegoeson.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Even though their current market share is still relatively modest, it is reasonable to anticipate that HEVs will graduallyacquireappeal in themarketasa resultoftheir improvedfuelefficiencyandincreasedvehicleperformance. ThiscanbeattributedtothefactthatHEVshaveimproved fuel efficiency and increased vehicle performance. This is duetothefactthatHEVshavesuperiorvehicleperformance whencomparedtoconventionalautomobiles.Whenitcomes tothedesignanddevelopmentofHEVs,theuseofmodelling and simulation will be an extremely important factor in decidingtheamountofsuccessthatwillbeachieved.

[2] Grunditz, Jansson: After the vehicle was constructed and modelled racing circumstances were simulated, the performance of an electric go-kart was simulated as it competedinamodelledrace.However,tothisday,ago-kart ofthiskindhasnotbeenbuiltintherealworld,norhaveany tests or measurements been carried out on the go-kart or any of its parts in order to validate the correctness of the model. This is despite the fact that the model has been in existenceforquitesometime.Thisisbyfarthemostserious problemwiththeworkthathasbeendoneuptothispoint. Inaddition,somemechanicalandelectricallosses,including thosethatoccurinelectricalmotors,gears,andwheels,in additiontotheelectricallossesthatoccurincables,arenot takenintoconsideration.Ithasbeenmadetoseemasifthis isthecase,despitethefactthatthevaluesoftheelectrical parameters of the induction machine are not, in fact, predetermined in any way. For example, an increase in temperatureandanincreaseinthefrequencyofthecurrent both lead to an increase in the rotor's resistance. Additionally, the magnetization of the motor iron may approachitslimit,whichwillhaveanimpactnotonlyonthe capacitancesbutalsoontheinductances.Thiswillhavean effect not only on the capacitances but also on the inductances.Whenitisdesiredtoanalysearealgo-kartby using this simulation tool, there are a few essential parameters,inadditiontotheparametersforthedriveline, that need to be validated and possibly altered in order to obtain a valid result. These parameters include: the wheelbase,thetyrediameter,thetyrepressure,andthetyre width. These criteria include things like: These elements make up the total mass of the go-kart, which takes into accounttheweightofthedriverinadditiontothego-crosssectionalkart'sarea,thevehicle'srollingcoefficient,andthe amount of air resistance. In light of the specific circumstances, these figures should at best be considered mereestimates.

[3] Chehresaz: kind of hybrid electric vehicle (HEV) that utilisestheframeworkestablishedbytheToyotaPrius.The computer simulation application Autonomies was used at variousstagesduringtheprocessoffabricatingthemodelof the vehicle in order to give help. Before beginning the processofoptimization,themodelofthecarwasanalysedin order to determine the effect that size would have on the amountofgasolinethatwouldbeconsumedaswellasthe

overallperformanceofthevehicle.Thiswasdoneinorderto determinewhetherornotthevehiclecouldbeoptimised.As a direct consequence of doing this study, we were in a position to validate the precision of the optimization outcomeseven beforeputtingthem intopractise.Because wewantedtobesuccessfulinaccomplishingourmaintarget of reducing the amount of fuel that we used, we came up withanoptimizationproblemutilisingthismodel.Thiswas donebecausewewantedtoreducetheamountofgasoline thatweused.Weweresuccessfulindeterminingtheoptimal dimensionsfortheautomobile'smostimportantparts,such astheinternal combustion engine,theelectricmotor,and the batteries. Our efforts in this direction were met with great success. As a direct consequence of this, the highest possible combined output of the engine and motor, in additiontothetotalnumberofbatterycells,wasoneofour keyconcernsduringthewholedesignprocess.Throughthe use of the Genetic Tool (GA) approach as an optimization algorithm, the issue was resolved across a wide range of different trip cycles. This was carried out. These driving cyclescomprisedcommutingoncitystreets,highways,anda mixof thetwotypes ofroads,inaddition tobothtypes of roadsindividually.

When compared with rates calculated from the baseline model and in other driving cycles,suchasurban (FTP) or highway(HWFET)oramixofurbanandhighwaycycles,this efforttosizethecomponentsledtoasignificantreductionin fuelconsumption.Thiswasthecasebothintheurban(FTP) andhighway(HWFET)drivingcyclesaswell.Thisdecrease wasaccomplishedwhencomparedwithratesderivedfrom thebaselinemodelaswellasinotherdrivingcycles(EPA). Whilesomeofouroptimizationfindingsthatwereidentified without taking limits into account showed dramatically lowerfuelusage,thevehicleplatformthatwasproducedasa consequence was unable to fulfil needed performance parametersandwas,asaresult,unattractive.Someof our optimizationfindingswereidentifiedwithouttakinglimits intoaccount.Thishappenedbecausewefailedtotakeinto considerationanyrestrictionsthatcouldbepresent.

[4] Abdelrahman: Theparametersofthecarmodelwere adjustedsothatitwouldbeconsistentwithaprototypeofan electric vehicle that is now being manufactured by the industrialpartnersthatareapartoftheMotiveorganization. TheUnitedStatesofAmerica aretheonesresponsiblefor this new breakthrough. This included the transmission systemoftheautomobile,whichwascapableofoperatingat two different speeds. Both single-speed and two-speed gearboxes were put through their paces in a series of performance tests and simulated driving cycles so that researchers could compare and contrast the advantages offeredbybothtypesoftransmissions.Thepurposeofthese studieswastoinvestigateandcontrastthevariousbenefits offeredbythevariousgearboxes.Accordingtothefindings ofthestudy,thetwo-speedgivessubstantialbenefitsover the single-speed in terms of both performance and the

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2042

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

amountofenergyitconsumes.Acyclistridingabicyclewith asinglespeedhasjustonegearratiotoselectfrom.Boththe effects of using a single transmission and those of using a transmissionthatcanswitchbetweentwospeedshavebeen analyzed and compared, respectively. According to the findings of the study, the research shows that the performanceofthevehiclethathasagearboxthatonlyhas two speeds is superior in terms of both its economic and dynamic performance. A gearbox that has two speeds, as opposedtoatransmissionthatonlyhasonespeed,notonly makes the motor more efficient, but it also extends the distance that it is capable of travelling in comparison to a transmission that only has one speed. According to the findings,switchingtoatransmissionthatcanoperateattwo speedsresultsinanimprovementof2.2percentagepoints withregardtothetotaltransmissionefficiency.

[5] Hong et.al: thedynamicmodelofapassivehybridpower system that is based on the idea of an ultra capacitor in conjunctionwithaveninbattery.Accordingtotheresultsof the simulation, optimising the performance of the power system by combining high-energy-density batteries and high-power-density ultra capacitors for use in electric vehiclescantakeadvantageofthebenefitsofferedbybothof these components and improve the system's overall functionality. This combination is intended to be used in order to maximise the performance of the power system. When employing a hybrid power system, it is feasible to avoid the impact that a high current would have on the battery pack. This is made possible because of the hybrid natureofthepowersystem.Becauseitschargingcurrentis significantlylowerthanthatofthepowersystemthatrelies solely on the battery, it will be of great assistance in increasing the cycle life of the battery in order to provide smootherworkingconditions.Thisisbecauseitscharging currentissignificantlylowerthanthatofthepowersystem thatreliesonlyonthebattery.Theenergyconsumptionof thebatterypackinahybridpowersystemisloweredby2 percent when compared to that of a power system that depends only on batteries, while the system as a whole is abletoaccomplisha7.78percentdecreaseinthequantityof electricitythatisutilised.Itisessentialtoestablishasuitable matchingofthefeaturesofthepassivehybridpowersystem inordertogeta higherlevel ofperformance.Thismaybe accomplishedby:Ithasbeendeterminedthatthemaximum voltageoftheultracapacitorpackshouldbeidenticaltothe open-circuit voltage of the battery pack when the state of chargeisequaltoninetypercent.

[6] Rahul et.al: Thisdecisionwasbasedonthebenefitsand convenience of integrating signal-based solutions into the design control process rather than Matlab/toolbox Simulink's(SimPowerSystemandSimDriveline).SimPower System and SimDriveline were developed using a signalbasedmethodowingtotheirdependencyonphysicalmodel modelling. With Matlab/toolboxes, SimDriveline and the SimPowerSystem,wewereabletosimulatethebehaviourof

electricautomobiles.Asignal-basedstrategywasdiscovered tobecompatiblewithMatlab/Simulinkanditstoolbox.To test a broad range of controller simulation models on the samecomputer,theEVmodelisveryflexible.Becauseofthe design, this is a viable alternative. This is now possible because to the framework's scalability. Electrical systems operatedynamically,andyoumustunderstandthisinorder toevaluatealternativevehiclecontrollerdesigns.Asaresult, you may put your trust in the designs you get. In this research,MatlabandSimulinkareusedtoassessandanalyse many aspects of electric vehicle design, such as efficiency andemissions.Softwareusersmayrapidlyseetheeffectsof architectural and parameter changes made using visual programming methodologies. A lot of features of the software are implemented using visual programming techniques.Dataiscompletelywithinthecontroloftheuser. Inadditiontothelargerelectricmotorsandbatterypacks, therearesmallerversionsofboth.Variousstandardsmaybe defined by using data. The finished product may be comparedtotheoriginalspecsafterithasbeencompleted. Futureelectricvehicleswillbenefitfromimprovedvehicle anddrivingsystemdesign.Thedevelopmentofelectriccars thataremoreefficientisongoing.Wewanttoimprovethe quality of electric cars via the implementation of this programme.Anelectricvehiclethatcanfulfilfuturedemand mustfirstbedemographicallystudied.Theycanmeettheir performance standards in the actual world, according to substantial evidence. According to computer simulations, usingthisstrategyhasa significantimpactonbatteryand controllerdesign.Withoutsimulations,thisjobwouldhave takensignificantlylongerandbeenfarmoredifficult.These claims need to be supported by a computer simulation. Virtualbatteryarchitectureshavebeenconstructedaspart of our study. This approach will be used to assess battery packsinelectricvehicles.Acloserexaminationofthisissue is forthcoming. This method resulted in a simple and modular description of the components of an electric automobile(EV).Toprovideamorecompletepictureofthe vehicle's performance, these models may be merged. It's possible to examine this option after the prototypes have been completed. You may easily examine the design and controlsystemsofthecarwiththisrealisticmodel.Amore efficientandcost-effectivecreativeprocesswillresult.Ifthis strategy works, it might benefit any other electric vehicle design.Accordingto[Insertreference],isthisaccurate?"It's verypossiblethatthesimulationmayrevealnewdomainsin themodel.Datacollectiononthechargingprocessmaybe enhanced by applying regenerative braking to improve batterydynamics.Themodel'smeticulousattentiontodetail and careful analysis may be to fault for the issue. A wide rangeofparameterswereexaminedinordertofine-tunethe model.

[7] Kyung: Themodelling,analysis,andcontrollerdesignfor afuelcellpowersystemthatcombinesafuelcellsystem,a DC/DC converter, and a battery in a number of different electriccombinationsinordertoprovideavarietyofvarious

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

electric outputs. We create controllers by making use of linearquadraticoptimizationmethodologies,andtherange offuelcelloperationsthatwecoverincludesloadfollowing as well as load levelling. Because of this, we are able to compute the required size of the fuel cell-battery combination (the degree of hybridization), as well as the subsequenttrendsinthesystem'sefficiency.Thecontroller thatwasdevelopediscapableofhandlingtheflowofairand electronsinthefuelcellstackinanidealmanner.Asaresult, thecontrollerwasabletoachieveabalanceinthesluggish powerresponseofthestackwithouteitheroverestimating or underestimating the stack's capacity to respond to transientevents.Ouroptimalcontrolmethodconsumesthe absoluteminimumamountofbatterypowerfeasible,hence establishingtheabsoluteminimumamountofhybridization thatisrequiredinFCautonomouspowersystems.Thiswork is being done with the end goal of making a significant contributiontothefieldoffuelcelltechnology,notablyinthe fields of control and coordination, and in particular for hybrid power applications that make use of a variety of power sources. A lot of attention is now being paid to the ideaofincreasingthenumberofFCsthatarealreadypresent in the power system. The control strategy as well as the dynamicloadcapacitiesarebothsusceptibletochangebased on the connection (whether it be parallel, series, or somethingelse).Thisworkwillalsomakeacontributionto the research that is currently being done in the field of powermanagementoffuelcells.Thisresearchisbeingdone inordertomaximisefueleconomyinapplicationsthatare relevanttothetransportationindustry.Theresultsofthis researchwillcontributetothecoresystemtechnologythat will be used for the design assessment of other potential futureenergysystems.Becauseoftheemphasisplacedon coordination issues and the incorporation of multidisciplinaryelements,itisanticipatedthatthiseffort willhaveasubstantialinfluence.Longterm,theworkthat we have been doing on multivariable dynamic energy systems will be able to be expanded to address reliable distributed energy by defining requirements on the minimumcommunicationamongtheembeddedcontrollers indistributedpowersourcesandtherequirementforenergy storage.Thiswillallowtheworkthatwehavebeendoingon multivariable dynamic energy systems to address reliable distributedenergy.Becauseofthis,wewillbeabletosolve theproblemofconsistentenergydistribution.

[8] Yuliang: ADVISOR and Dymola are both examples of software programmes that may be used in the process of modelling cars. In order to better assist in the design and development of future generations of HEV, these programmeswereutilisedtoconductresearchandsimulate threedistinctvehicularsystems.Thefirstprototypeisofa hybridpowerbackupsystemthatisbasedonfuelcells.Itis intended to be used in an elevator that is positioned in a high-rise building. It was initially based on a model of an electric automobile that was created in ADVISOR before beingchanged.Theresultsofthesimulationindicatedthatit

would be possible, both technically and monetarily, to employ a fuel cell power system in order to supply continuous energy to the elevator system. The building of the second model, which was a Class 7 commercial truck, madeadvantageofanexistingtwo-modevehiclemodelthat hadbeenbuiltonADVISOR.Thefindingsofthesimulation showedthatthetwo-modehybridpowertrainhasadequate powerandaconsiderableimprovementinitsefficiencyin termsoftheamountoffuelituses.Thefinalvehiclemodelof aparallelhybridelectricautomobilehasbeenfinishedusing theDymolaplatform.Itwasagreedthatcomputermodelsof importantcomponentsofavehicle'spowertrain,suchasthe engine, transmission, and chassis, would be constructed. Utilizing the test data provided by the automobile manufacturerisonemethodthatmaybeusedtovalidatethe reliabilityoftheresultsacquiredfromthesimulation.Ithas not yet been determined whether or not the integrated systemmodelorthevehiclesimulationwillbesuccessful.

[9] Ramachandra: Oneoptionforimprovingtheairquality in urban areas is to replace conventional internal combustion engine (IC) cars with hybrid electric vehicles (HEVs),whicharepoweredbyrechargeablebatteriesrather thantraditionalgasoline-poweredautomobiles.Batteriesare acrucialcomponentofthehybridelectriccarsthatarenow inthedesignstage.Inthisregard,simulationtoolsarevery important since they make it feasible to construct and improve battery technology. Vehicle simulators have the capacitytodealwithabroadrangeofchargeanddischarge routines, which is one of the features of these simulators. PSATisanexcellentsimulationtoolthatmaybeusedinthe testingandassessmentofvehicles.Theresultsofthemodel's simulation and the PSAT for a high voltage NiMH battery packwerecomparedandcontrastedwithoneanother.The two models were able to reach a mutually agreeable consensuswithoneanotherintermsoftheshapethatthe profile should take. The size, on the other hand, was not consistent from one instance to the next because of the existence of a number of other aspects, all of which were takenintoconsiderationinthemodelthatwasdevelopedfor thisthesis.Inordertostudythepotentialoutcomesofthe oxygen reactions that were taking on inside the batteries, simulations were carried out. However, the important characteristicslikechargeefficiencyandpressurehavenot beentestedwithanyoftheothermodels.Thisisaproblem. Thisisduetothefactthatmanyofthetraditionalmodelling toolsignoretheseconcerns,andasthisisarelativelynew areaofdifficultyandstudyinthedesignofbatteries,itisalso a very new area of focus for researchers. As a direct consequenceofthis,noneofthealternativemodelshasbeen successfulinvalidatingtheseparameters.

Afterstudiedaboveresearchpaperintheliteraturesurvey section,thereisconclusionfoundthatgiventhat,Thetotal efficiencyofthevehicleisimprovedwhenitisequippedwith

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

a hybrid-electric power train. This is accomplished by ensuringthattheenginefunctionsinthemostefficientway possibleandbymakingthemosteffectiveuseofthepower that is available. Research on the many different hybridelectric drive-trains that are now available on the market was the first thing that needed to be done in order to get started on this project. The terms "series," "parallel," and "power-splitgearbased"drivetrainsareusedtorefertothe threebasickindsofhybriddrivetrainsthatarenowinuse. Everypossiblechoiceforthedrivetraincomeswithitsown specific set of advantages as well as disadvantages. After consideringtheadvantagesanddisadvantagesofeachofthe prospective drive trains, the researchers came to the conclusionthatthepower-splitgearbaseddrivetrainwould bethebestcandidateforfurtherinvestigation.Thiswasdue to the great performance of this drive-train as well as the factthatthisdrive-trainisusedin a significantnumber of hybrid electric vehicles that are now for sale on the market.Bothofthesefactorscontributedtothisresult.

[1]S.Golbu_,Designoptimizationofaplug-inhybridelectric vehicle,"SAETechnicalPapers,042007.

[2] J. Zeman and I. Papadimitriou, \Modeling and optimizationofplug-Inhybridelectricvehiclefueleconomy," SAETechnicalPapers,2012.

[3] T.-S. Dao, A. Seaman, J. McPhee, and K. Shigematsu, \Developmentofahighdeityseries-hybridelectricvehicle model using a mathematics-based approach," SAE International,no.9,2012.

[4] F. Mapelli, M. Mauri, and D. Tarsitano, \Plug-in hybrid electrical commercial vehicle: modeling and prototype realization,"pp.1{8,Mar.2012.

[5] F. Cheli, F. L. Mapelli, R. Manigrasso, and D. Tarsitano, \Fullenergeticmodelofaplug-inhybridelectricalvehicle," in SPEEDAM - International Symposium on Power Electronics, Electrical Drives, Automation and Motion, pp. 733{738,Ieee,June2008.

[6]Z.Fu,G.Hou,andA.Gao,\Modelingandsimulationfor parallel hybridelectricve- hiclepowertrain,"inAdvanced Mechatronic Systems (ICAMechS), 2011 International Conferenceon,pp.114{117,2011.

[7] M. Cipek, D. Pavkovi, and J. Petri, \A control-oriented simulationmodelofapower-splithybridelectricvehicle," AppliedEnergy,vol.101,pp.121{133,2013.

[8] J. Ahn, K. Jung, D. Kim, H. Jin, H. Kim, and S. Hwang, \Analysis of a regenerative braking system for hybrid electric vehicles using an electro-mechanical brake," InternationalJournalofAutomotiveTechnology,vol.10,no. 2,pp.229{234,2009.

[9] Y. Ye, Y. Shi, N. Cai, J. Lee, and X. He, \Electro-thermal modeling and experimental validation for lithium ion battery,"JournalofPowerSources,vol.199,pp.227{238, 2012.

[10] S. Williamson, A. Emadi, and K. Rajashekara, \Comprehensive efficiency modeling of electric traction motor drives for hybrid electric vehicle propulsion applications,"IEEETransactionsonVehicularTechnology, vol.56,no.4,pp.1561{1572,2007.

[11] P. C. Manning, E. White, R. J. Alley, J. King, and D. J. Nelson,\Vehiclesystemdesignprocessforaseries-parallel plug-inhybridelectricvehicle,"SAEInternationalJournalof AlternativePowertrains,vol.1,no.2,pp.503{524,2012.

[12] D. W. Gao, C. Mi, and A. Emadi, \Modeling and simulationofelectricandhybridvehicles,"Proceedingsof theIEEE,vol.95,pp.729{745,Apr.2007.

[13] Y. Ma, H. Teng, and M. Thelliez, \Electro-thermal modelingofalithium-ionbatterysystem,"SAEInternational JournalofEngines,vol.3,no.2,pp.306{317,2010.

[14] X. Hu, S. Lin, S. Stanton, and W. Lian, \A state space thermal model for HEV/EV battery modeling," SAE paper, 2011.

[15] E. C. De Oliveira and D. C. Donha, \Modeling and SimulationofSmallHybrid,"SAETechnicalPapers,2006.

[16] K. Butler, M. Ehsani, and P. Kamath, \A Matlab-based modeling and simulation package for electric and hybrid electric vehicle design," IEEE Transactions on Vehicular Technology,vol.48,no.6,pp.1770{1778,1999.

[17] X. He, \Battery Modeling for HEV Simulation Model Development,"SAEpaper,no.724,2001.

[18] H. Zhang and M. . Chow, \Comprehensive dynamic batterymodelingforphevapplications,"inIEEEPowerand EnergySocietyGeneralMeeting,pp.1{6,IEEE,2010.

[19] X. He and J. Hodgson, \Modeling and simulation for hybridelectricvehicles.i.modeling,"IEEETransactionson IntelligentTransportationSystems,vol.3,no.4,pp.235{243, 2002.

[20] W. Gao and S. Porandla, \Design optimization of a parallel hybrid electric power train," Vehicle Power and PropulsionConference,VPPC,pp.530{535,2005.

[21]J.Deur,M.Cipek,andJ.Petri_c,\Bondgraphmodelingof series-parallelhybridelectricvehiclepowertraindynamics," in Proceedings of the 2010 Spring Simulation Multiconference, SpringSim '10,pp. 218:1{218:10, Society forComputerSimulationInternational,2010.

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2045

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

[22] E. Tara, S. Shahidinejad, S. Filizadeh, and E. Bibeau, \Batterystoragesizinginaretro_ttedplug-inhybridelectric vehicle,"IEEETransactionsonVehicularTechnology,vol.59, no.6,pp.2786{2794,2010.

[23]C.Musardo,G.Rizzoni,Y.Guezennec,andB.Staccia,\AECMS: An adaptive algorithm for hybrid electric vehicle energymanagement,"EuropeanJournalofControl,vol.11, pp.509{524,Oct.2005.

[24]S.HamidifarandN.Kar,\Energybasedgraphicaluser interfacemodelingforPHEVenergymanagementsystem," ElectricalPower&EnergyConference(EPEC),pp.1{6,2009.

[25]J.Che,P.Tsou,L.Rose,andM.Jennings,\Modelingand simulation of the dual drive hybrid electric propulsion system,"SAETechnicalPapers,2009.

[26]J.BattehandM.Tiller,\Implementationofanextended vehicle model architecture in modelica for hybrid vehicle modeling:developmentandapplications,"Proceedings7th ModelicaConference,pp.823{832,Oct.2009.

[27] A. H. Niasar, H. Moghbelli, and A. Vahedi, \Design methodology of drive train for a series-parallel hybrid electricvehicle(sp-hev)anditspowerowcontrolstrategy," inInternationalConferenceonElectricMachinesandDrives, pp.1549{1554,IEEE,2005.

[28] S. Overington, S. Rajakaruna, and S. Member, \A modi_edmethodforthesizingoftheplug-inhybridelectric vehiclepropulsiondevices,"UniversitiesPowerEngineering Conference(AUPEC),pp.1{7,2011.

[29] V. Galdi, L. Ippolito, a. Piccolo, and a. Vaccaro, \A genetic-based methodology for hybrid electric vehicles sizing,"SoftComputing,vol.5,pp.451{457,Dec.2001.

[30]A.Hasanzadeh,B.Asaei,andA.Emadi,\Optimumdesign ofserieshybridelectricbusesbygeneticalgorithm,"Energy, pp.1465{1470,2005.

[31] X. Wu, B. Cao, J. Wen, and Z. Wang, \Application of particleswarmoptimizationforcomponentsizesinparallel hybrid electric vehicles," in Congress on Evolutionary Computation,CEC,pp.2874{2878,IEEE,2008.

[32] C. Desai, F. Berthold, and S. S. Williamson, \Optimal drivetrain component sizing for a plug-in hybrid electric transitbususingmulti-objectivegeneticalgorithm,"inEPECElectrical Power and Energy Conference: "Sustainable EnergyforanIntelligentGrid",pp.1{5,IEEE,2010.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |