International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

Students, Mechanical Engineering, Sandip Institue of Technology and research center, Nashik, Maharashtra, India ***

Abstract - Inelectricalvehicles,batteriesarethefirstsupplyofpower.Thebatterywetendtouseinelectricvehiclesaren't thateconomicalandneedschargingwhenfewmiles.Thus,hereisthattheideaoflatestbatterymanagementsystem.This studypresentsacomprehensivesummaryofthiscomparativelyrevolutionaryandgratifyingresolutionforbatterydifficulties inelectricalvehicles,additionallyasassociatein-depthinvestigationofit.Duringthisnewbatterymanagementsystem,The Battery Management System of this Vehicle is essential in determinative the overall operate of ATV. This Report tries to spotlighttheobjectivesofthisreplacementandapplicationofBMSonATV.AnATVisfuntodrive,versatile,safe,sturdyand superiorcross-countryvehicle.Thisvehicleshouldbecapableofnegotiatingtheforemostextremetractconfidentlyandease. Theseobjectivesweremetbydividingthevehicleintoitsmajorelementsubsystems.Andoneamongstitsmajorsubsystemsis thattheBatteryManagementSystem.TheBatteryManagementSystem’sapplicationonATVfocusestowardsexplainingthe procedureandmethodologyusedforpoweringthecross-countryvehicle.ThiscanbeatryandapplytheBatteryManagement System and is additionally value effective at identical time. Each single system has been centered upon to enhance the performanceofeveryelement.Thevehiclewillnavigatethroughmosttractthatultimatelyisthattheobjective behindthe creating of any all-terrain vehicles. The task of application of BMS began by conducting intensive analysis of every main elementofthevehicle.Therewasnowouldliketodesignboundareasliketheframe,aswetendtowerevictimizationthe prevailing ATV engineered for competition and so build the remainder to suit thus, every element was designed to be significant,andtherebyputtingintheBatterymanagementsystemonvehicleasanentiretryingtooptimizeeveryelement whereasperpetuallyconsideringhoweverdifferentpartswouldbeaffected.ThisforcedNorthAmericannationtoassume outsidethebox,analysisalotoftotally,andredesigningtheabilitytrainmountingonthemannersoastopossessaflourishing installation.Themostpurposeoftheprojectisobtainingaccustomedthedynamictechnologies.

KeyWords: AllTerrainVehicle,Batterymanagementsystem,Subsystem,Terrain.

Nowadays withthe risingtechnologies,EV’sutilizeless energy totravel a certain distance.Thevaluepermilefor Fuel is considerablycheaper.AsweareconvertingtheAll-TerrainVehiclethatwasantecedentlypoweredbyassociateICEngineto theelectricalVehicle.Forthis,a‘BatteryManagementSystem’isrequired.Thesloganbehindcreatingthesemajorshiftsfrom associate‘ICEnginetoanelectricalVehicleistobeatthebreakdownassociatedproblemscausedthankstoanICEnginewithin theAll-TerrainVehicle.Transportsectordependenttotallyonoilandfuelthattheircostsareaunitunstableandtheirreserves areaunitseverelydepleted.Moreover,theutilizationofthosestylesofenergypollutestheatmosphereandcausestheemission ofgreenhouse.Abundantanalysishasbeeninquisitiveabouttheeconomicpotencyofthemixingofelectricalvehicles.Theygift asummaryoftheimpactoftheincreasing penetrationoftheelectronvoltintovehiclemarket.Focusingoftheelectricity systemandthereforetheemergenceofautotogridtechnologies,batteriesandelectronvoltrechargeinfrastructureconclude therequirementforstandardizationtofacilitatesafetransitionwitheconomicallyeconomicalandenvironmentallypermanent .Andestimatepricesofplug-inelectricalvehiclesandtheirworkshowsthebenefitsofsensibleelectricalvehiclescomparedto thedumbelectricalvehiclesthatthatseemmostintemporalarrangementofcharginganddischargingofEVs.Toimprove vehicleperformancenumerousresearches,managetheoptimizationofenergymanagementforthenewgenerationofauto BatteryisoneineveryoftheenergystoragemanagementsystemsinHEVorelectronvolt.Thebatteryofferpoweroncevehicle acceleratingandabsorbpoweroncevehiclebraking.So,thejarvaryandaccelerateperformancedependuponthebattery. Accordingtopreviousanalysiseighteenofthesuspendedparticulates,27%ofthevolatileorganiccompounds,28%ofPb, thirtysecondofchemicalelementoxides,andsixtytwooftheCOofair-bornepollutioninAmericaareaunitcreatedbyvehicles withcombustionengines.Additionally,twentyfifthofenergy-relatedcarbondioxide(theprincipalcauseforthegreenhouse effect)ofallthecarbondioxidewithintheatmosphereareaunitdischargedfromancientVehicles.Asassociateincreasing rangeofindividualusepublicandprivatetransportation,theamountofpollutionwillincreaseeachsingleday.Consequently, electricalvehicleshavebecomeadditionalandadditionalcommon.Anelectricalvehicletypicallycontainsthesubsequent majorcomponents:anelectricalmotor,amotorcontroller,atractionbattery,batterymanagementsystem,aplug-incharger thatcanbeoperatedonanindividualbasisfromthevehicle,awiringsystem,aregenerativebrakingsystem,avehiclebodyand

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

aframe.Thebatterymanagementsystemisoneoftheforemostnecessaryelements,particularlyoncemistreatmentlithiumionbatteries.

Currently,threekindsoftractionbatteriesareaunitavailable:thelead-acid,nickel-metalhydrideandlithium-ionbatteries. Lithium-ionbatterieshavevarietyofbenefitsovertheopposite2kindsofbatteries,andthattheyperformwellifthey're operatedmistreatmentaneffectivebatterymanagementsystem

TheresquaremeasuredifferingtypesofBMSsthatsquaremeasureaccustomedavoidbatteryfailures.Themostcommonkind maybeabatteryobservationsystemthatrecordsthekeyoperationalparameterslikevoltage,currentandalsotheinternal temperatureofthebatteryonwiththeclosetemperaturethroughoutcharginganddischarging.Thesystemprovidesinputsto theprotectiondevicessotheobservationcircuitsmaygeneratealarmsand evendisconnectthe battery fromtheloador chargerifanyoftheparametersexceedthevaluessetbythesecurityzone.Thebatteryisthatthesolelypowersupplyinpure electricvehicles.Therefore,theBMSduringthisstyleofapplicationoughttoembracebatteryobservationandprotection systems,asystemthatkeepsthebatteryabletodeliverfullpoweroncenecessaryandasystemthatmayextendthelifetimeof the battery. The BMS ought to embrace systems that management the charging regime and people that manage thermal problems. In an exceedingly vehicle, the BMS is a component of a fancy and fast-acting power management system. Additionally,itshouldinterfacewithalternativeon-boardsystemssuchasthemotorcontroller,theclimatecontroller,the communicationsbus,thesafetysystemandalsothevehiclecontroller.

WhilethedefinitionofaBMSmaydisagreecountingontheapplying,thebasictaskoftheBMSmaywellbeoutlinedwithinthe followingmanner.

•Itoughttomakesurethattheenergyofthebatteryisoptimizedtopowerthemerchandise.

•Itoughttomakesurethatthechanceofdamagingthebatteryistokenism.

•ItoughttoMonitorandmanagementthecharginganddischargingmethodofthebattery.

Asthepowertrainisanimportantfactoroftheelectricvehicle,itmainlyconsistsveryessentialdeviceswhicharediscussedin subsequentpoints.

1) The48v120AHLIBatteryisconnectedtothemotoraswellasinputtotheDcconvertor.

2) Moreover,DctoDcconvertorisconnectedtotheaccessories.

3) TheaccessoriesareHVcontactor,brakeswitch,tractionsystemlight(TSL),potentiometer,instrumentcluster,FNRswitch.

4) Nowthemotorcontrollerisanimportantsystemwhichgivesinputfromtheaccessories.

5) Themotorcontrollersendsignaltothemotor,accordingtotheoutputfromtheaccessories.

6) Themotorisconnectedtogearbox(singlespeed)throughpositivedrive(chaindrive)asthereisnoslipoccur.

7) Furthermore,thegearboxisconnectedtothedriveshaftwhicharesubsequentlyconnectedtothewheel.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

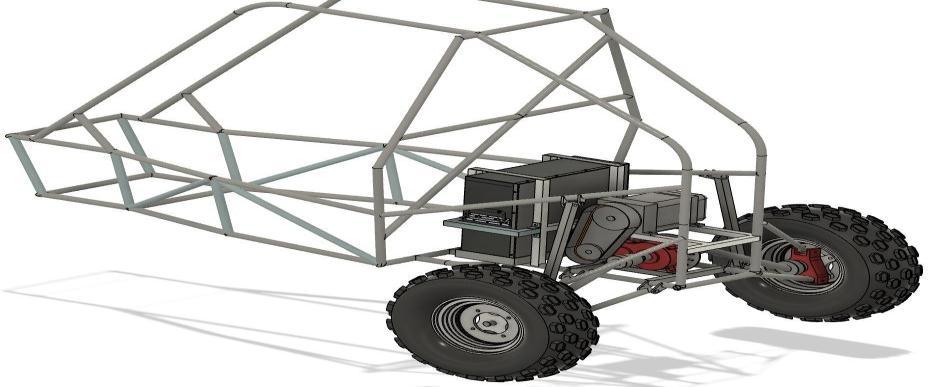

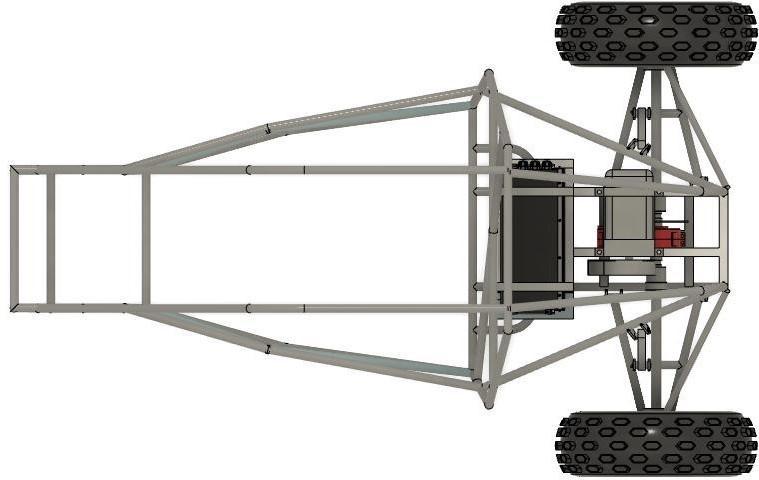

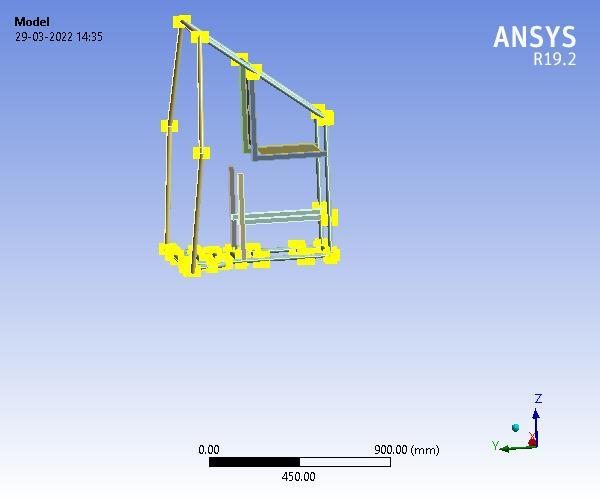

Fig 2: TopView

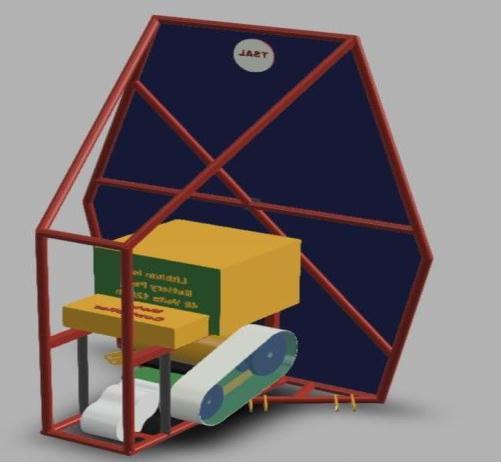

Fig 3: RearSection

Fig 4: SideView

PowerTrainworkingtherearefourmajorcomponentsofpowertrainare:

TheBattery

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Motor MotorController Gearbox.

1) First,AC440Vcurrentsuppliedistothebatteryforinitialchargingpurposeofbattery.

2) Thestep-downtransformerreducevoltageto48vwhichisrequired.

3) Now,thebatteryisconnectedtothemotoraswellasdctodcconverter.

4) Thenthedc-to-dcconverterisconnectedwithbrakeswitch,FNRswitch(forforward,neutral,reversemotion),TSL(for theindicationofsystemisworking),accelerationpedal(potentiometer),instrumentcluster,HVcontactor(useaskill switch).

5) Astheoutputofsomeaccessoriesisconnectedtothemotorcontroller.

6) Then the motor controller is connected with the motor and send signal which are received from accessories as per requiredcondition.

7) Now,themotorisconnectedwiththegearboxthroughpositivedrive(chaindrive)andtransmitpower.

8) Thenlastlygearboxtransmittingthepowertothewheelsthroughdriveshafts

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

1) Maintainsbatteryinanexceedinglystatewithinwhichitwillfulfillitspurposefulstylenecessities.

2) Protectstheprotectionofthebattery-operateddeviceanddetectsunsafeoperativeconditionsandresponds.

3) Protectscellsofbatteryfromharminabuse/failureCases.

4) Prolongslifetimeofbattery(normaloperativecases).

5) BMSistostaytrackofthestateofcharge(SOC)oftheBattery.

6) EasyinCoulombenumeration.

7) EasyandsimpletopredictcapabilityfadeandinternalResistanceincrement.

1) AdvancedinACimminentness.

2) Additionalcomputationallydearly-wonthannon-feedbackstrategiesandhighlyrelyonmodelaccuracy.

3) Sensitivetothequantityandqualityofcoachingknowledge.

4) Openloopsensitivetothevoltagesensingelementexactitude,Unsuitableforcellwithflatcurves.

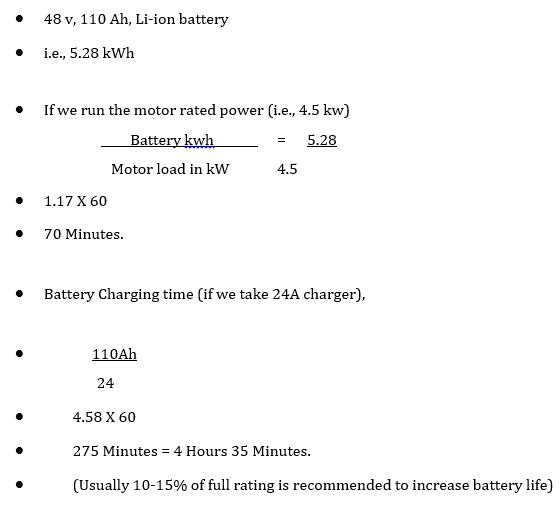

Actualspeed-60-80km/hr(Approx.*)

Batterydrainage-3%forevery10mininhalfthrottle&4%forevery10mininfullthrottle. i.e.,100/4=25

25*10=250minutes

250minutes*=4Hours10minutes(Approx.)

•Considering the nature of the track and some other factors the Battery’s Run timemightgetaffected.

•TheruntimewegotwhiletheTestingwasaround4Hoursand10mminutes*withfullyCharged Battery.

1) OmkarChitnis,aReviewonBatteryManagementSystemforElectricVehicle,2019.IJSERVol10.

2) ATextbookofAutomobileEngineeringbyKripalSingh.

3) OlivierTremblay,Louis-A.Dessaint,ExperimentalValidationofaBatteryDynamic

4) FundamentalsOfVehicleDynamicsbyThomasD.Gillespie,PublishedBytheSocietyOfAutomotiveEngineersInc.400 CommonwealthDriveWarrendalePA,15096_0003

5) AProjectreportonDesignonAllTerrainVehiclebyAkshaySalveandShantanuBihani.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

6) RuiHu,BatteryManagementSystemforElectricVehicleApplications,UniversityofWindsor,2011

7) SandeepDhameja,ElectricVehicleBatterySystems,2002,ISBN0-7506-9916-7

8) H.J.Bergveld,BatteryManagementSystemsDesignbyModelling,2001,ISBN90-74445-51-9

9) Shepherd,C.M.,DesignofPrimaryandSecondaryCells-Part2.Anequation

10) Describingbatterydischarge,JournalofElectrochemicalSociety,Volume112,July1965,pp657-664.

11) ModelforEVApplications,WorldElectricVehicleJournalVol.3-ISSN2032-6653

12) D.Fisher,A.Lohner,andP.Mauracher,“Batterymanagement:IncreaseintheReliabilityofUPS,”ETZ,vol.117,pp.18–22,1996.

13) Z. Noworolski and J. M. Noworolski, “A microcomputer-based UPS battery Management system,” in Proc. IEEE APEC’91,1991,pp.475–479.

14) K.Shimitzu,N.Shirai,andM.Nihei,“On-boardbatterymanagementsystemwithSOCindicator,”inProc.Int.Electric VehicleSymp.,vol.2,1996,pp.99–104.

15) 4.V.BBhandari,DesignofMachineElements,McGraw-HillEducation,2012.

16) PSGDesignData-Book,PSGCollege,KalaikathirAchchaagam.

17) J.LaeminieandJ.Lowry,ElectricVehicleTechnologyExplained,UK:JohnWiley&Sons,2003.

18) A.F.burke,“Batteriesandultracapacitorsforelectric,hybridandfuelcellvehicles.”ProceedingsoftheIEEE,vol.95, pp806-820,April2007.

19) C.C.Chan,Y.S.Wong,“Electricvehicleschargeforward,”IEEEPowerandEnergyMagazine,vol.2,iss.6,pp.24-33, Nov-Dec.2004.

20) C.C.Chan,“Thestateoftheartofelectricvehiclestechnology,”ProceedingsoftheIEEE,vol.90,pp247-275,Feb2002.

Mr.ShreyasRajendraKshirsagarisa Mechanical Engineering student from Sandip Institute of technology and research center, Nashik, Maharashtra, India and servedasaBAJAteamcaptain

Mr. Atharva Sandeep Kavare is a Mechanical Engineering Student from Sandip Institute of technology and research center, Nashik, Maharashtra, India and servingasacurrentteamcaptain.

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

Mr. Tejas Kailas Rautray is a Mechanical Engineering Student from Sandip Institute of technology and research center, Nashik, Maharashtra, India and servingasacurrentteammanager.

Mr. Tejas Subhash Pawar is a Mechanical Engineering Student from Sandip Institute of technology and research center, Nashik, Maharashtra, India and servingasacurrentSteeringHead.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |