International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | August 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | August 2022 www.irjet.net p-ISSN: 2395-0072

R N1, Pol C B2

1PG Student, Dept. of Civil Engineering, Walchand College of Engineering, Sangli, Maharashtra, India, 416415 2Professor, Walchand College of Engineering, Sangli, Maharashtra, India, 416415 ***

Abstract - This paper consists of an investigation carried out in the field of Nano-Technology more specifically NanoMaterials. This investigation involves the smart use of Nano Materials particularly in conventional concrete forms new nano-concrete which is defined as Ultra High Strength NanoConcrete. Basic ingredients for this nano-concrete are Graphene, Nano silica, cement, sand, aggregates, and water. Nano technology is an enabling technology that opens new possibilities in construction sustainability. A concrete Produced by replacing a certain percentage of cement with nano material is called the nano concrete. This paper deals with the study of mechanical properties like compressive strength, tensile strength and bond strength of the nano concrete in comparison with conventional concrete. This studysummarizestheinfluenceofnano-silicaonstrength anddurabilityofdifferentgradesofconcretewiththeused ofnano-silicaasareplacementofcement

Key Words: Nano concrete, Conventional concrete, Nano silica, Compressive strength, flexural strength.

Nano technology is a new emerging area in field of engineering.Developmentofnanotechnologyinthefieldof materialscienceandevolutionofadvancedinstrumentation have paved way for application of nanotechnology in the constructionfield.Incorporationofnanosizedparticlesin cementcompositesmakesasignificantchangeinstructural andnonstructural propertiesofcementpaste,mortarand concrete.Nanoparticleshavemorespecificsurfaceareaand thisincreaseinsurfacearealeadstochangesinmorphology, increase in chemical reactivity, structural modification of cement hydrates and enhancement of the properties of concrete. Theuseof nanomaterialsinconcrete, results in stronger and more durable concrete with desired stressstrainbehaviour.

Concrete is the most common material used in the construction.Itiscomposingmaterialcomposedofcoarse aggregate,finelypowderedcement,fineaggregateandwater withinherentphysical,chemical,andmechanicalproperties. The use of nano-silica will create a new concrete mixture that will result in long lasting concrete structure in the future.Onlyasmallpercentageofcementcanbereplacedto achieve the desired results. These nanomaterials improve thestrengthandpermeabilityofconcretebyfillingupthe minute voids and pores in the microstructure. The use of

nano-silicainconcretemixhasshownresultsofincreasein thecompressive, tensile andflexural strength ofconcrete. Nano-silicamixedcementcangeneratenano-crystalsofC-SHgelafterhydration.Thesenano-crystalsaccommodatein themicroporesofthecementconcrete,henceimprovingthe permeabilityandstrengthofconcrete.

1. Parametric study of limit state design philosophy forconventionalconcrete.

2. Modelling various parameters of Ultra High StrengthNanoConcreteinaccordancewiththelaid conventionaldesignphilosophy.

3. Design of Ultra High Strength Nano Concrete structuralcomponentsbydevelopedmethodology.

4. Comparisonofthedesignsofconventionalandultra highstrengthnanoconcretestructuralcomponents.

Accordingtothisinvention,thereisprovidedaUltra-HighStrengthNano-ConcreteMaterialforenhancingCompressive Strength, Tensile Strength and Young’s Modulus, the said materialcomprises:

Carbonisbrittlematerialwithhighmodulusofelasticity,so using carbon-parent material -Graphen in concrete mix designimprovestheTensileStrengthofConcreteandoverall modulusofelasticity.AlsothesilicateintheformofNanosilica gives the improved chemical reaction between cementetious materials and enhances the compressive strengthofconcretemixproportion.

OrdinaryPortlandCementofanydesiredgradesconforming toIS:12269-1987isusedforpreparingconcretespecimens. ThepropertiesofcementusedaregivenintheTable1.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | August 2022 www.irjet.net p-ISSN: 2395-0072

Table-1: Propertiesofcement

Sr. No. Characteristics Value

1 Specificgravity 3.15 2 NormalConsistency 30% 3 SettingTime a. InitialSettingTime b. FinalSettingTime 35min 180n

Thefineaggregatewasusedintheexperimentationwas confirmingtoIS:383-1970specificationsfineaggregate isthemaincomponentgradingzone-IIofIS:383-1978 wasused.

Table-2: Propertiesoffineaggregate

Sr. No. Characteristics value

1 Finenessmodulus 3.88 2 Specificgravity 2.75 3 Waterabsorption 1%

Thecoarseaggregateusedinconcreteis12mmsize aggregateandtestedasperIS:383-1970specification

Table-3: PropertiesofCoarseaggregate

Sr. No. Characteristics value

1 Finenessmodulus 8.21 2 Specificgravity 2.82 3 Waterabsorption 0.8%

D. Nano-SiO2 has been found to improve concrete workabilityandstrength,toincreaseresistanceto waterpenetration,andtohelpcontroltheleaching ofcalcium,whichiscloselyassociatedwithvarious typesofconcretedegradation.

Table-4: PropertiesofNano-silica

Sr. No. Characteristics Value

1 Physicalstate Powder 2 Particlesize 5 3 Specificgravity 1.3-1.32

The water, which is used for making concrete, should be clean and free from harmful impurities suchasoil,alkali,acid,etc.Locallyavailablepotable tapwaterisusedforcuring.

Experimental work was done to compare compressive strength, tensile strength and modulus of elasticity of concreteofdifferentgradesandwithreplacementofordinary Portland cement with optimum nano-silica concrete. The comparativestudyofmechanicalpropertiesofconventional andnano-concretewerestudiedwithoptimumnano-silica concrete.

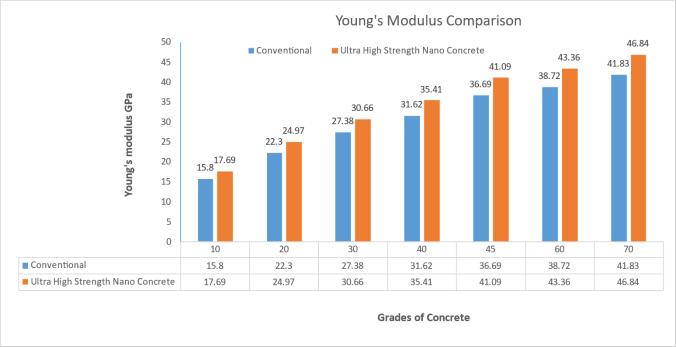

The compressive strength of concrete is determined after curing of 3, 7 and 28 days cubes and test results were obtainedfordifferentgradesofconventionalconcreteand nano-silica.

Table-6: GradesvsStrength

Grades Conventional UltraHighstrengthNano concrete 10 14.2 18.46 20 28.41 37.39 30 32.7 42.51 40 47.2 60.03 45 55.38 74.5 60 69.58 88.15 70 76.3 94.83

Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

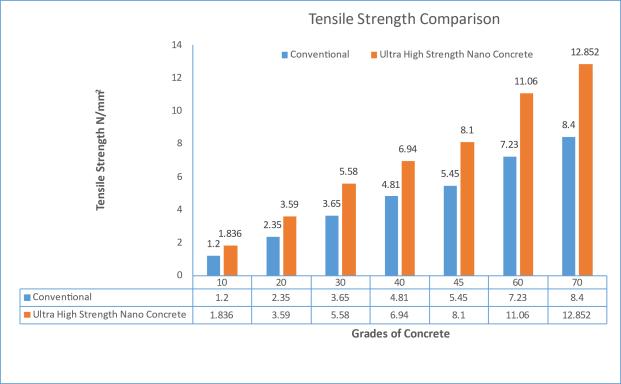

tensileorcompressivestiffnessofasolidmaterialwhenforce isappliedlengthwise.

Table-8: Young’sModulusComparison

Fig-1: CompressiveStrengthComparison

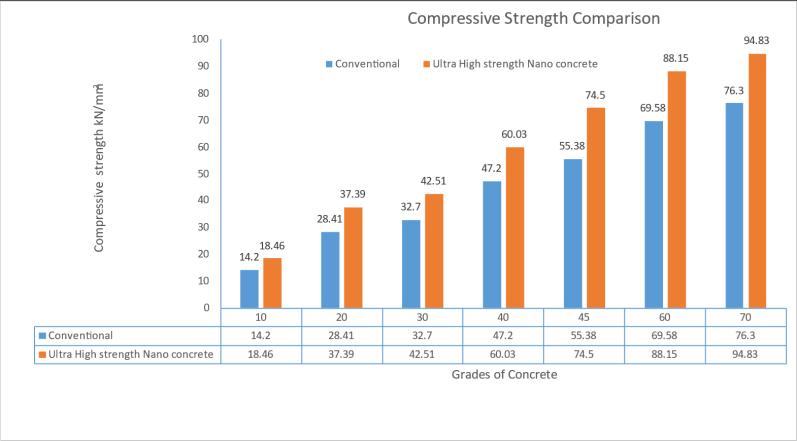

b)Tensilestrength

Determinationoftensilestrengthofconcreteisnecessary to determine the load at which the concrete member may crack.Testsareconductedoncastedcylinderattheageof3, 7&28days

Table-7: TensileStrength

Grades Conventional UltraHighStrength NanoConcrete 10 1.2 1.836 20 2.35 3.59 30 3.65 5.58 40 4.81 6.94 45 5.45 8.1 60 7.23 11.06 70 8.4 12.852

Grades Conventional UltraHigh StrengthNano Concrete 10 15.8 17.69 20 223 2497 30 2738 3066 40 3162 3541 45 3669 4109 60 3872 4336 70 4183 4684

Fig-2: TensileStrengthComparison

c)Young’smodulus

Young modulus, or modulus of elasticity in tension or compression, is a mechanical property that measures the

Fig-3: Young’sModulusComparison

UseofUltraHighStrengthNano-concreteforconstruction will

i. Attains highest tensile strength (50% more as comparedwithconventionalconcrete)

ii. Attainshighestcompressivestrength(30%moreas comparedwithconventionalconcrete)

iii. Attainshighestyoung’smodulusandhenceductility (20% more as compared with conventional concrete)

iv. Attains highest bonding capacity between intermoleculararrangementschangedbythenanosilica.

v. Attainshighestwatertightness

vi. Attainshighestcorrosionresistance

vii. Attainshighestdurability. viii. Attainshighesttoughness

ix. Attainshighestductility.

Volume: 09 Issue: 08 | August 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1960

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | August 2022 www.irjet.net p-ISSN: 2395-0072

x. Attainshighestworkability.

[1]Zou,Z.H.,Wu,J.,Wang,Z.,Wang,Z.(2016).“Relationship BetweenHalf-CellPotentialandCorrosionLevelofRebarin Concrete,CorrosionEngineering.”ScienceandTechnology, Vol.51,Issue8,pp.588-595.

[2] Hassan, A. A. A., Hossain, K. M. A., Lachemi, M. (2009). “CorrosionResistanceofSelf-ConsolidatingConcreteinFullScaleReinforcedBeams.”CementandConcreteComposites, Vol.31,Issue1,pp.29-38.

[3]Aveldaño,R.R.,Ortega,N.F.(2011).“Characterizationof concrete cracking due to corrosion of reinforcements in different environments.” Construction and Building Materials,Vol.25,Issue2,pp.630-637.

[4] Malumbela, G. (2010). “Measurable Parameters for Performance of Corroded and Repaired RC Beams Under Load.” PHD thesis, Department of Civil Engineering, UniversityofCapeTown,SouthAfrica.

[5]Supit,S.,Shaikh,F.U.A.(2015).“DurabilityPropertiesof High Volume Fly Ash Concrete Containing Nano Silica.” MaterialsandStructures,Vol.48,Issue8,pp.2431-2445.

[6]Shaikh,F.U.A.,Supit,S.W.M.(2015).“ChlorideInduced Corrosion Durability of High Volume Fly Ash Concretes Containing Nano Particles.” Construction and Building Materials,Vol.99,pp.208-225.

[7]Ranjbar,M.M.,Madandoust,R.,Mousavi,S.Y.,Yosefi,S. (2013). “Effects of Natural Zeolite on the Fresh and Hardened Properties of Self-Compacted Concrete.” ConstructionandBuildingMaterials,Vol.47,pp.806-813.

[8]Torkaman,J.,Ashori,A.,SadrMomtazi,A.(2014).“Using WoodFiberWaste,RiceHuskAsh,andLimestonePowder Waste as Cement Replacement Materials for Lightweight ConcreteBlocks.”ConstructionandBuildingMaterials,Vol. 50,pp.432-436.

[9] Kalla, P., Misra, A., Gupta, R. C., Csetenyi, L., Gahlot, V. (2013). “Mechanical and Durability Studies on Concrete ContainingWollastonite–FlyashCombination.”Construction andBuildingMaterials,Vol.40,pp.1142-1150.

[10]Sujjavanich,S.,Suwanvitaya,P.,Chaysuwan,D.,Heness, G.(2017).“SynergisticEffectofMetakaolinandFlyashon PropertiesofConcrete.”ConstructionandBuildingMaterials, Vol.155,pp.830–837.

[11]AlMenhosh,A.,Wang,Y.,Wang,Y.,Augusthus-Nelson,L. (2018). “Long Term Durability Properties of Concrete

Modified with Metakaolin and Polymer Admixture.” ConstructionandBuildingMaterials,Vol.172,pp.41–51

[12] Miri, M., Beheshti Nezhad, H., Jafari, M. (2014). “Experimental Investigation on Mechanical Properties of ConcreteContainingNanoWollastoniteandModellingwith GMDH- Type Neural Networks.” (in Persian), Amirkabir Journal of Science & Research (Civil & Environmental Engineering),Vol.46,Issue2,pp.49-51.

[13] Ni, T., Zhang, L., Yuan, B. (2011). “Influence of WollastoniteorPlantFiberonPerformanceofAutoclaved CementConcrete.”AppliedMechanicsandMaterials,Vol.99100,pp.692-695.

[14] Kalla, P., Rana, A., Chad, Y. B., Misra, A., Csetenyi, L. (2015). “Durability Studies on Concrete Containing Wollastonite.” Journal of Cleaner Production, Vol. 87, pp. 726-734.

[15]Soliman,A.M.,Nehdi,M.L.(2014).“EffectsofShrinkage ReducingAdmixtureandWollastoniteMicrofiberonEarlyAgeBehaviorofUltra-HighPerformanceConcrete.”Cement andConcreteComposites,Vol.46,pp.81-89.

[16]Zhang,L.C.(2013).“DurabilityofConcreteContaining WollastoniteandFlyAsh.”AdvancedMaterialsResearch,Vol. 800,pp.361-364.

[17] Wu, F., Gong, J. h., Zhang, Z. (2014). “Calculation of Corrosion Rate for Reinforced Concrete Beams Based on Corrosive Crack Width.” Journal of Zhejiang University SCIENCEA,Vol.15,Issue3,pp.197-207.

[18]Cao,Ch.,Cheung,M.M.S.,Chan,B.Y.B.(2013).“Modelling ofInteractionBetweenCorrosion-InducedConcreteCover CrackandSteelCorrosionRate.”CorrosionScience,Vol.69, pp.97–109

[19] Rodriguez, J., Ortega, L.M., Casal, J., Diez, J.M. (1996). “Corrosion of Reinforcement and Service Life of Concrete Structures.” Durability of Building Materials and Components,Vol.7,Issue1,pp.117–126.

[20]Vidal,T.,Castel,A.,François,R.(2004).“AnalyzingCrack WidthtoPredictCorrosioninReinforcedConcrete.”Cement andConcreteResearch,Vol.34,pp.165–174.

[21]Zhang,R.,Castel,A.,François,R.(2010).“ConcreteCover CrackingwithReinforcementCorrosionofRCbeamDuring Chloride-InducedCorrosionProcess.”CementandConcrete Research,Vol.40,pp.415–425.

[22] Khan, I., François, R., Castel, A. (2014). “Prediction of Reinforcement Corrosion Using Corrosion Induced Cracks WidthinCorrodedReinforcedConcreteBeams.”Cementand ConcreteResearch,Vol.56,pp.84–96

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1961

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 08 | August 2022 www.irjet.net p-ISSN: 2395-0072

[23] Li, H., Li, B., Jin, R., Li, Sh., Yu, J-G. (2018). “Effects of Sustained Loading and Corrosion on the Performance of Reinforced Concrete Beams.” Construction and Building Materials,Vol.169,pp.179–187.

[24] Ye, H., Fu, Ch., Jin, N., Jin, X. (2018). “Performance of Reinforced Concrete Beams Corroded under Sustained Service Loads: A Comparative Study of Two Accelerated CorrosionTechniques.”ConstructionandBuildingMaterials, Vol.162,pp.286–297.

[25] Malumbela, G., Moyo, P., Alexander, M. (2012). “LongitudinalStrainsandStiffnessofRCBeamsunderLoad as Measures of Corrosion Levels.” Engineering Structures, Vol.35,pp.215-227.

[26] Kim, Y. Y., Kim, J. M., Bang, J.-W.,Kwon, S.-J. (2014). “EffectofCoverDepth,W/CRatio,andCrackWidthonHalf CellPotentialinCrackedConcreteExposedtoSaltSprayed Condition.”ConstructionandBuildingMaterials,Vol.54,pp. 636-645.

[27] ASTM C 876. (2015). “Standard Test Method for Half Cell Potential of Reinforcing Steel in Concrete.” West Conshohocken,PA:ASTMInternational.

[28]Nygaard,P.V.(2008).“Non-DestructiveElectrochemical Monitoring of Reinforcement Corrosion.” Phd thesis, Department of Civil Engineering, Technical University of Denmark.

[29] Madandoust, R., Bungey, J. H., Ghavidel, R. (2012). “PredictionoftheConcreteCompressiveStrengthbyMeans of Core Testing Using GMDH-Type Neural Network and ANFISModels.”ComputationalMaterialsScience,Vol.51,pp. 261–272.

[30]Du,Y.,Cullen,M.,Li,C.(2013).“StructuralPerformance of RC Beams under Simultaneous Loading and Reinforcement Corrosion.” Construction and Building Materials,Vol.38,pp.472–481.

[31]ElMaaddawy,T.,Soudki,Kh.,Topper,T.(2005).“LongTerm Performance of Corrosion-Damaged Reinforced ConcreteBeams.”ACIStructuralJournal,Vol.102,Issue 5, pp.649-656.

[32] ASTM C150. (2009). “Standard Specification for Portland Cement.” West Conshohocken, PA: ASTM International.

[33] Balaguru, P., Chong, K. (2008). “Nanotechnology and Concrete: Research Opportunities.” In Nanotechnology of concrete: Recent Developments and Future Perspectives (ACISP-254),Detroit,MI:AmericanConcreteInstitute.

[34] Sanchez, F., Sobolev, K. (2010). “Nanotechnology in Concrete–aReview.”ConstructionandBuildingMaterials, Vol.24,pp.2060–2071.

[35]ASTMC618.(2015).“StandardSpecificationforCoal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete.”WestConshohocken,PA:ASTMInternational.

[36]ASTMC33.(2016).“StandardSpecificationforConcrete Aggregates.”WestConshohocken,PA:ASTMInternational.

[37]ASTMC494/C494M-10.(2010).“StandardSpecification forChemicalAdmixturesforConcrete.”WestConshohocken, PA:ASTMInternational.

[38]ASTMC143.(2001).“StandardTestMethodforSlump of Hydraulic-Cement Concrete.” West Conshohocken, PA: ASTMInternational.

[39]BS1881:Part116.(1983).“TestingConcrete:Method for Determination of Compressive Strength of Concrete Cubes.”BritishStandardInstitution(BSI).

[40]ElMaaddawy,T.,Soudki,Kh.(2003).“Effectivenessof ImpressedCurrentTechniquetoSimulateCorrosionofSteel Reinforcement in Concrete.” Journal of Material in Civil Engineering,Vol.15,Issue1,pp.41-47.

[41]Malumbela,G.,Moyo,P.,Alexander,M.(2012).“AStep Towards Standardising Accelerated Corrosion Tests on LaboratoryReinforcedConcreteSpecimens.”Journalofthe SouthAfricaninstitutionofcivilengineering,Vol.54,Issue2, pp.78–85.

[42] Rinaldi, Z., Imperatore, S., Valente, C. (2010). “Experimental Evaluation of the Flexural Behavior of CorrodedP/CBeams.”ConstructionandBuildingMaterials, Vol.24,pp.2267–2278.

[43] ASTM G1. (2003). “Standard Practice for Preparing, Cleaning,andEvaluatingCorrosionTestSpecimens.”West Conshohocken,PA:ASTMInternational.

[44] DuraCrete-Final Technical Report. (2000). “The European Union-Brite EuRam III Research Project: Probabilistic Performance Based Durability Design of Concrete Structures.” Document BE95-1347/R17, CUR, Gauda.

[45]Zhang,R.,Castel,A.,Francois,R.(2009).“Serviceability LimitStateCriteriaBasedonSteel–ConcreteBondLossfor Corroded Reinforced Concrete in Chloride Environment.” MaterialsandStructures,Vol.42,pp.1407–1421.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1962