International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

1Associate Professor, Dept. Of Mechanical Engineering, N.K. Orchid college of engineering and Technology, Solapur, Maharashtra, India. 2,3,4,5,6 U.G Student, Dept. Of Mechanical Engineering, N.K. Orchid college of engineering and Technology, Solapur, Maharashtra, India ***

Abstract - Food preservation over a longer period is a technique that dates back centuries and applies to a wide rangeoffoodsincludingfruitsveggiesaswellasothermeals tosafelypreservefoodthereareseveraldifferentmethods moistureseemstobethekeyreasonwhyfooddecomposes or odors after a certain amount of time which is also dangerousandunhealthythecapacityoffoodtokeepfresh is strongly affected by water or moisture products can become spoiled as a result of excessive moisture pickup water is necessary for bacteria to dissolve the food they consume food is used for energy and growth in bacterial yeastandmoldcellsthankstowaternobodydesirestohave decayedfoodforeveryrightreasonsoforpreventingfood foralongerperiodremovingmoisturewhichmainlyaffects thefoodonalargerscaleisthebestchoiceacceptingwecan havethosetastyandfullofnutrientsvariousflavorstypesof foodfora longertimewith no worriesthe drying process removesenoughmoisturefromfoodtosignificantlyreduce the humidity levels likelihood of these adverse outcomes differenttypesoffoodhaveadifferentrangeofmoisturein themaftercalculatingwhichtypesoffoodsubstanceshave whichrangeofmoisturecontentwecaneasilyeliminatethis unwantedmoistureweanalyzedthesituationthoroughlyto create a model that can easily complete this process in a certain time which is expected to be helpful for a longer periodinlesstimeitalsousesnaturalresourcestocomplete itsprocessieusingthesunsolar-operateddryerscancome totherescueinthiskindofsituationandthereisnodoubt aboutit.

Words: Portable,Food,Domestic,Humidity.

Theessentialfunctionofasolardryer isusingsunrays to remove the extra water content from the food substances insidethedryingchamber.

DomesticandAgricultureeatableproductsrequiredryingof vegetables,fruitsindifferentseasons.Dryingtheseeatables isanoldtechniqueintropicalcountries.Dryinginsunlightis asimple,quick,andlow-costmethodwhichdonotreduces thefoodvalueandmaintainshygiene.

Nowadays,dryingisusedtoincreaseutility,improvethelife span, and provide lead time between various processes. Dryingisanexcellentwaytopreservefoodandsolarfood dryers are appropriate food preservation technology for sustainabledevelopment.Dryingwasprobablythefirstever foodpreservingmethodusedbyman,evenbeforecooking.It involvestheremovalofmoisturefromagriculturalproduce toprovideaproductthatcanbesafelystoredforalonger time.“Sundrying" istheconventional techniqueofdrying fresh produce known to man, and it generally involves ploppingagriculturalcommoditiesinthetropicsonsheets, roofs,orevaporationcarpeting.Becausethefarmproduceis laidoutintheopenair,thereisagreaterriskofspoilagedue toadverseclimaticcircumstancessuchasrain,wind,mist, anddust,andlossofproducetobirds,insects,androdents (pests);dependentongoodweatherandveryslowdrying rate with the danger of mold growth thereby causing deteriorationanddecompositionoftheproduce.Theprocess alsorequiresalargeareaofland,takestime,andishighly labor intensive. With the advancement of culture and industry, artificial mechanical drying became a reality; however, this process is both energy intensive and costly, raising the overall cost of the product. Efforts to improve "sundrying"haverecentlyresultedin"solardrying."Solar dryersarecustomizeddevicesthatregulatethedryingtime andsafeguardagriculturalgoodsfrominsectpests,dust,and rain damage. Solar dryers produce higher temperatures, lower relative humidity, lower product moisture content, andlessspoilageduringthedryingprocessthannatural"sun drying."Inaddition,ittakesuplessspace,takeslesstime, and is relatively inexpensive compared to the artificial mechanicaldryingmethod.

Solar draying equipment and their designs are available readilyinthemarket.Inthisasolardryerdesignsuitablefor asinglehomeisconsidered.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

The Portability and compactness of the design were the major objectives of design, so that the machine thus designedcouldbestationedeasilyatanyhouseholdplace.

Alsotheproducthadtobesimpleindesignandconstruction such that it could aid easy maintenance.

SummersinSolapurareridiculouslyhot,withhighsranging from30to45°C(86to113°F).Temperaturesof40°C(104 °F)orhigherarecommoninSolapur.InThemay1988,the maximumtemperatureeverrecordedwas46.0°C(114.8°F). Asaresult,Solapurexplicitlyreceivesasignificantamountof solar energy, Without a reason to suspect. Among all the otherplacesinMaharashtra,Solapurisoneofveryfewwith extended amounts of time as well as plenty of sunshine. Solapur's latitude angle is 17oN and its longitude angle is 75oE,withanaveragesolarradiationof670W/m2.

Thereisrequirementofportabledryeratdomesticlevel.The portable domestic solar dryer can be made at small level. ThissolardryerwillabsorbSolarenergy availableatwhich will be utilized to remove moisture from our domestic product ie- Onion, Potato, Chilly, Coriander, Currey tree, Spinach,etc.Thecirculationofthehotaircanbedonewith thehelpsmallSolarFan.Thesolarenergycanbeabstracted withthehelpoftoughenedglass.

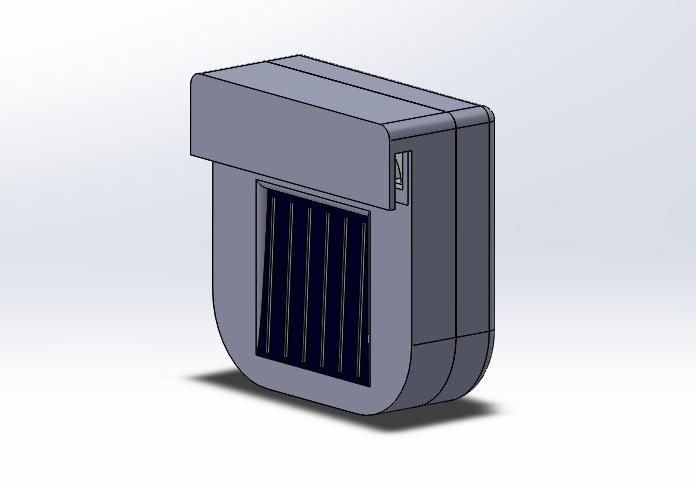

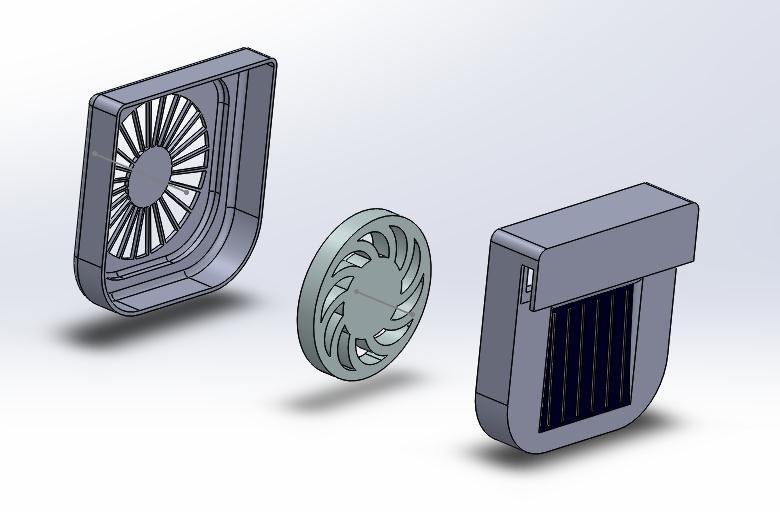

Figure1 showsthesystem modellingdone in Solidworks platform, this is a front view of model in this figure some parts like collector, solar panels, transparent glass, roller wheel,exhaustholeisindicated

Chart -1: Solid Works of Design And Development of Domestic Solar Dryer

This Design and Development of Domestic Solar Dryer consistsfollowingparts:

SolarFan,StorageChamber,Trays,ToughenedGlass,Roller Wheels,Door.

All above parts are modelled in Solid Works platform accordingtoitsspecificationobtainedfromcalculation.

Thesolarfanareusedtocirculatethehotairintheproduct. Itisof16*9*12.5cm anditisof300gramsinweightandit isblackincolor.ThematerialisABSplastic.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

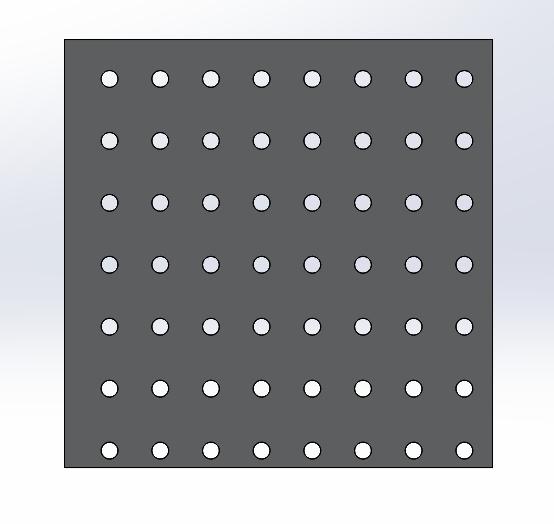

Thetraysareusedforkeepingthefoodproductsonthisand this tray loaded into dehydration system. There are total Four trays are used which are of size 40cm by 40cm in width and length. The trays are manufactured by using stainlesssteelandsmallholesareprovidedbecausetoflow the air and the holes is of 7mm diameter. Figure shows imageofonetraywhichisusedforkeepingfoodsampleon this,likewiseFourtraysareused.

It is toughened glass used on the top of solar Fan. This is goodwearresistantthanordinaryglass.Thedimensionsof this toughened glass is 80cn x 40cm (L x W) thickness of 3mm.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Fig:- 4.4 Toughened Glass

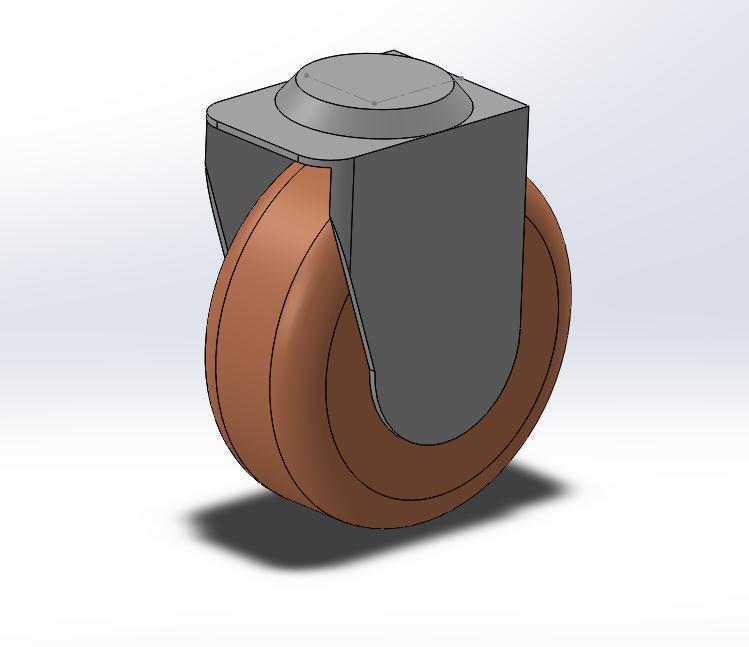

RollerWheelsareusedtocarrysystemtoanyplace.Thisisa casterroller wheelsthiscancarryupto100kgofweight. Thiswheelismadefromhighqualitypolyurethaneplasticis veryhardandcancorrosionresistantandquiteinoperation.

The proposed experimental set-up consists of different componentssuchas, i. SolarFan ii. Trays iii. ToughenedGlass iv. RollerWheel v. Handle

Photograph5.1showstheexperimentalset-up.Itconsistsof theSolarFanthedimensionofsolarfanis16*9*12.5cm,itis of300granditmadeup ofABSPlasticthefunctionofthatis tocirculatetheairintheproductandtheToughenedglassis usedtoPassthesunradiationandalsoProtectedfromthe dustitsthicknessis6mmanditisof40*80cm.Theproduct is made of Stainless Steel. The Roller Wheels are Used to movehereandtherewherewewantbecauseweareusingin thehouse.TreysaremadeupofStainlesssteelitisusedto keep foods on that and it thickness of 2mm and it is of 40*40cm.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

spaceavailable.Thesunraysaretakeninsidethroughaclear glasswhichtransferheattotheeatablesfordrying.Thetrays aredesignedtoaccumulateheat.Asmallsolarpoweredfan is mounted to circulate hot air inside the dryer. The time required to dry the vegetables vary according to initial conditions.Aglassshieldisinclinedat35-40°togroundwith hingedpanel.Threeslidingdrawersareverticallymounted tokeepthevegetables.Asmallchimneyisprovidedonthe side top to remove hot air. The inlet air passage is at the bottomwithascreentoavoidinsectsenteringin.Thespace iscalculatedaspertheheatgeneratedinbetween9:30AM to4:30PMtime.

Theperformanceofexistingsolarfooddehydrationsystem can still be improved upon especially in the aspect of reducingthedehydrationtime,andprobablystorageofheat energy within the system by increasing the size of the dehydration system. They are some future scopes on this projectthoseareasfollows,

This project has achieved the objective of using conventional/Naturalresourcesforthecompletionofthe requiredprocedurewithoutelectricityorharmingnaturein anyindirectform.

Photograph5.2dehydrationsystemthefoodproductsare keptfordehydration,thefoodproductsarekeptontrays. ThedehydrationsystemismadebyusingStainlesssteelof 2mmthicknessand40*40cm.

Theproductishighlyuserfriendly. Surelythereisscopeforfuturedevelopmentasrequired.

TheDesignandDevelopmentofDomesticSolarDryerisa unique,compactandportable.

Solar drying has proven to be both technically and economicallybeneficialforavarietyofcrops.Howeveritis, necessary to develop large-scale dryers that may be used throughout the year for different products to make them attractivetothefarmers.

Toenhanceproductquality,UVradiation,dust,insects,fungi, and other sources of contamination must be protected, as well as temperature and relative humidity control. Analogously, if a long shelf-life is permitted, the storage conditionsofsolar-driedproductsshouldbetailoredtothe cropandthepackagingfinetuned.

Thedesignofsolardryerconsistsofacupboardanddrawer typeconstructionsuitablewithsmalltraysforhandling.The traysareperforatedtocirculateheatedairuniformlyinthe

Hencewehavecometoendoftheprojectonthistopicwe wouldliketosharetheexperienceourteamwhiledoingthis projectaverythankstoOurearnestGuide&OurdearHOD. Soforsettingsuchtargetforusweenjoyedeverybitofwork weputintothisprojectwedohopethatourprovideswillbe interestingandknowledgeablethankyou

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Our project can surely help to build new society with less amount of Food Waste around. This can surely help our naturetogrowandbreathewithoutWastageoffood.

[1]LokeshR.Dhumne, VipinH.Bipte,Prof. Y.M. Jibhkate, 2015, “Solar Dehydration system for dehydration Agriculturalproducts”InternationalJournalofEngineering Research-OnlineISSN:2321-7758

[2] Amedorme, S. K., Apodi, J., and Agbezudor, K., 2013, “DesignandConstructionofForcedConvectionindirectsolar dehydration system for dehydration moringa leaves”, Scholar’sjournalofengineeringandtechnology,1(3),pp.9197.

[3] Jyoti Singh Fabrication of Hybrid Solar Dryer,International Journal of Scientific and Research Publications,Volume5,Issue6,June2015

[4]AtulPatel ReviewonSolarDryerforGrains,Vegetables and Fruits. Atul H Patel1, Prof. S A Shah2, Prof. Hitesh Bhargav3 1.P.G.Student(Machine Design) 2.Associate Professor 3.Assistant Professor Birla Vishvakarma Mahavidhyalaya Engineering College, Vallabh Vidyanagar388120.

[5]Pardhi,C.B.,andBagoria,J.L.,2013“Developmentand performance evaluation of mixed mode solar dryer with forced convection”, International Journal of Energy and EnvironmentalEngineering.

[6]Abdullahi,Y.,Momoh,M.,GarbaM.,and Musa,M.,2013 “DesignandConstructionofanAdjustableandCollapsible Natural Convection Solar Dryer”, International Journal of ComputationalEngineeringResearch,3(6).

[7]Mohanraj,M.,andChandrasekhar,P.,2009“Performance ofaforcedconvectionsolardryerintegratedwithgravelas heat storage material for chilly drying”, Journal of EngineeringScienceandTechnology,4(3),pp.305–314.

[8]Purohit,P.,Kumar,A.,andKandpal,T.,2006“Solardrying vs.opensundrying:Aframeworkforfinancialevaluation”, Solarenergy,Elsevier,80,pp.1568-1579.

[9] Panghavane, D. R., and Sawhney, 2002, “Review of researchanddevelopmentonsolardryerforgrapedrying”, EnergyConservationandManagement,43,pp.45-91.

[10] Folayan, C. O., Pam, G. Y., and Lawrence, D., 2013, “Design, Construction and Performance Evaluation of A Mixed- Mode Solar Dryer”, International Journal of EngineeringandScience,2(8),pp.08-16.

[11]Mustafa,B.G.,Babagana,G.,andSilas,K.,2012,“Design and Construction of Forced/Natural Convection Solar Vegetable Dryer with Heat Storage”, ARPN Journal of EngineeringandAppliedSciences,7(10),pp.1213-1217.

[12]Farid,M.M.,Khudhair,M.A.,Razack,S.K.,andHallaj,S. A., 2004 “A review on phase change energy storage: materials and applications”, Energy Conversion and Management,45,pp.1597–1615.

[13]Patel,A.H.,Shaikh,S.A.,andBhargav,H.,2013“Solar dryerforgrains,vegetablesandfruits”,2(1).

Associate Professor Anandrao Kashid, Dept. of Mechanical engineering,N.K.Orchidcollegeof Engineering and Technology, Solapur,Maharashtra,India.

Swapnil Bharale, Undergraduate student, Dept. of Mechanical engineering,N.K.Orchidcollegeof Engineering and Technology, Solapur,Maharashtra,India.

Muskan Shaikh, Undergraduate student, Dept. of Mechanical engineering,N.K.Orchidcollegeof Engineering and Technology, Solapur,Maharashtra,India.

BhavanaYanganul,Undergraduate student, Dept. of Mechanical engineering,N.K.Orchidcollegeof Engineering and Technology, Solapur,Maharashtra,India.

Ishwar Konda, Undergraduate student, Dept. of Mechanical engineering,N.K.Orchidcollegeof Engineering and Technology, Solapur,Maharashtra,India.