International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

1M.Tech student, Structural Engineering, universal Engineering college, Thrissur, Kerala

2Associate professor, Civil Department, universal Engineering college, Thrissur ,Kerala ***

Abstract - In the present day, much research is being done globally to identify a viable cementitious material to take the role of cement. For the purpose of partially or completely substituting cement in concrete, many materials are tested in this order: fly ash, silica fume, GGBS, Metakaolin , Micro materials, Quartz powder, etc. In this paper, a novel ultrafine material named Alccofine and cement made with biobased materials might have lower CO2 emissions. Recently, it has been known as alccofine, is an efficient partial replacement for cement. Here, cement is partially replaced in selfcompacting concrete by substituting 10% of alccofine The optimum percentage of alccofine content is considered for the research. Fresh and hardened properties of SCC andselfcompactingconcrete (SCC) were investigated for the mix and control one. The results showed that all tested properties have similar results of conventional SCC for alccofine. %. Where, slump flow diameter (SFD), compressive strengths and split tensile strength for alccofine were 550 mm, 38.66MPa and 3.6 MPa respectively achieved at 35% ratio of WS. Flexural behaviour of reinforced concrete beam using this alccofine is studied and compared with conventional SCC beam. Hence obtained similar results of conventional SCC.

Key Words: Alccofine, mineral admixture, Flexural strength

Self-CompactingConcrete(SCC)isacutting-edgemethod that was developed to take the place of conventional vibrated concrete (CVC). In CVC, external vibration is necessary,andreinforcementsthatarecrowdedrequire extracare.Itcauseslapsedtimeandaninadequatesurface polish.Athoroughexaminationintothecauseandeffects of concrete degradation is necessary before placing concrete in different locations. Serious durability issues ariseinplaceslikethemarineenvironment,underground, etc.duetocarbonation,sulphate,acid,andchlorideattack. TheselimitationscanbeeliminatedwiththeuseofSCC, whichalsohasvariousbenefits,includingquickconcrete placement,homogeneity,removalofvibratingequipment, reduced noise, fewer air spaces, shortened time,

higherproductivity,andenhancedstrengthanddurability. The amount of powder content and the particle size are importantaspectsofSCC.Costsofproductionwouldriseif SCC contained more cement. Considering rapidly expanding industries, many researchers have proposed alternativesupplementalcementitiousmaterials(SCMs)or mineral admixtures to attain higher economic value. Alccofine1203 is a high range water reducer that helps concreteworkmoreeasilyandhavegreatercompressive strength.Biochariswidelyconsideredaseffectivewayof sequesteringcarbondioxide.Thepossibilityofusingitto enhancethemechanicalstrengthandreducepermeability ofcementmortarisexploredinthisstudy.

Alccofine-1203isaspecificallyprocessedproductwitha high glass content and high reactivity that was created through a carefully monitored granulation process. The principalcomponentoftherawmaterialsislowcalcium silicates.Particlesizedistributionismanagedasaresultof the processing with other carefully chosen substances (PSD). The calculated blain value using PSD is approximately 12000cm2/gm, which is absolutely extremelyfine.Duetoitsdistinctchemistryandultra-fine particlesize,ALCCOFINE-1203offerslowerwatercontent and, depending on the workability, even up to 70% replacementlevelforconcreteperformance.Additionally, ALCCOFINE1203maybeutilisedasasuperworkability aid to enhance flow or as a high range water reducer to enhancecompressivestrength.

Table -1: ChemicalCompositionandPhysicalproperties Chemical Analysis Range

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Table-4: PropertiesofCoarseAggregate

Use of Ordinary Portland Cement (OPC) of Grade 53 accordingtoISspecificationsismadeinthisinvestigation. Table2providescement'scharacteristics.

Table-2: PropertiesofOPC53gradecement

Properties Test results Technicalreference

Specificgravity 3.12 IS4031(PART11):1988 Consistency(%) 30 IS4031(PART4):1988 Finenessof cement(%) 4.7 IS4031(PART2):1996

Initialsetting time(minutes) 78 IS4031(PART5):1988

Forbuilding,manufacturedsand(M-Sand)isanalternative toriversand.M-sandisaproductmadefromhardgranite stonethathasbeencrushed.M-Sandislessthan4.75mm insize.Riversandisinshortsupply,henceartificialsand hasbeenemployedasanalternativeforconstruction.MSandisalsousedsinceitisreadilyavailableandcostsless to transport. Additionally, it is a dust-free material that pollutes very little. Table 3 lists the fine aggregate's characteristics.

Table-3

Properties Test results

Specificgravity 2.52

Finessmodulus 3.84

Freesurfacemoisture Nil

Aggregates with a particle size range of more than 4.75 mm,buttypicallybetween10and40mminsize.Concrete benefitsfromcoarseaggregate'sstrength,toughness,and hardnessqualitiesaswellasitsresistancetoabrasion.The experimentalstudy'scoarseaggregatewas12.5mminsize and conformed to IS 383:1970. Table 4 lists the characteristicsofcoarseaggregate.

Specific gravity 2.69 IS2386(PART3):Clause 2.4.2

Freesurface moisture Nil IS383(PART3):1970

Fineness modulus 4.25 IS383(PART 3): 1970 table2

Oneofthenewestmicro-finematerials,Alccofine1203,is produced in India and has a particle size that is smaller than that of cement, fly ash, silica fume, etc. Due to its efficient particle size distribution, Alccofine 1203 has specialcharacteristicsthatcanaffecttheperformanceof concreteinbothitsfreshandhardenedstates.Theearly strengthofconcretemadewithalccofine1203isfoundto besimilartoorgreaterthanthatofsilicafume.Because alccofine starts the initial chain of events when cement hydrates, this is the reason. Additionally, the alccofine 1203 eats the calcium hydroxide byproduct that is generatedduringthehydrationofcement,increasingthe concrete's late-age strength. As a result, it produces additional C-S-H gel that is comparable to that of other pozzolans.Alcofine'scalculatedparticlesizedistribution (PSD)isroughly12000cm2/g.Accordingtotheneed,it can be replaced with cement up to a 70% replacement level.Table5liststhealccofine1203'sproperties.

Fig- 1 : Alccofine1203

Table-5: PropertiesofAlccofine1203

Specificgravity 2.9 Bulkdensity(kg/m³) 700-900 Fineness(cm²/g) >1200

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

AdmixturesaredefinedinACI116Ras“amaterialother than water, aggregates, hydraulic cement, and fiber reinforcement,usedasaningredientofconcreteormortar, and added to the batch right away before or during its mixing”. Chemical admixtures are used to upgrade the qualityofconcreteduringmixing,transporting,placement andcuring.MASTERRHEOBUILD1126NDisanadmixture of a new generation based on modified naphthalene formaldehyde ether. The product has been primarily developedforapplicationsinhighperformanceconcrete wherethehighestdurabilityandperformanceisrequired.

MASTERRHEOBUILD 1126ND is free of chloride & low alkali. It is compatible with all types of cements. MASTERRHEOBUILD 1126ND has a different chemical structurefromthetraditionalsuperplasticisers.Itconsists of a naphthalene formaldehyde polymer with long side chains.Atthebeginningofthemixingprocess,itinitiatesthe sameelectrostaticdispersionmechanismasthetraditional super plasticisers, but the side chains linked to the polymerbackbone generates a steric hindrance which greatlystabilizesthecementparticles'abilitytoseparate anddisperse.Sterichindranceprovidesaphysicalbarrier (alongsidetheelectrostaticbarrier)betweenthecement grains.Withthis process,flowableconcrete withgreatly reducedwatercontentisobtained.

Aspect Darkbrownliquid

Relativedensity 1.24±002at25 c pH ≥6

Chlorideironcontent ˂0.2%

Beamofsize150mmx200mmx1250mmwasusedfor thestudy. A total of 2 specimen was casted. Mould of castingbeamspecimen.Thespecimenwastestedbythe optimumcontentofalccofinewithoptimumcontentof10 %inself-compactingconcrete.Thebeamsweredesignedas balancedsection,accordingtoIS456:2000andthedetails.

Therequiredquantitiesofcement,fineaggregate,coarse aggregate,superplasticisers,mineraladmixtureandwater were taken for control specimens, in addition to this, alccofineweremixedwiththeingredients.Concretewas

prepared by machine mixing. Initially cement and fine aggregateweremixedindrystateuntilitisofevencolour throughout and free from streaks followed and then measuredquantityofcoarseaggregatewasspreadout.The wholemasswasmixedbymachineinanangleof45%.Three quarterofthetotalquantityofwaterwas addedwhilethe materialswereturnedintowardsthecentrewithspades. Theremainingwaterwasaddedslowlywhen thewhole mixturewasturningoverandoveragainuntila uniform colour and consistency was obtained throughout.The mould was made ready by applying oil in all contact surfaces.Thecontrolspecimensofnormalconcretecover of25mmwerepreparedbyplacingthereinforcementsin themouldwithsuitablecoverblocks.Concretewasspread onthemouldanduniformlyspreadthemixonthemould. Theotherspecimenwascastbyaddingalccofine10%tothe concrete Proper surface finishing was provided. The specimenwasremovedfromthemouldafter24hoursand keptforcuring. After28daysofcuring,specimens were readyfortesting

Theexperimentalinvestigationofthisprojectincludessix (6)beams.Three(3)beamscastascontrolspecimenswith Fe415steelusingnormalM30mixandthree(3)beams cast asthe 35 percentages of walnut shell as volume of coarseaggregateinconcrete.Allbeamshaveatotallength of1250mm,widthof150mmanddepthof200mmeach. The longitudinal reinforcement was calculated using IS 456-2000toobtainflexuralfailureandwassameforall beams.Themainlowerreinforcementis2#8mmdiameter and8mmdiameterstirrups.

Thesteelcoverusedwas25mm.Allbeamswerecastusing M30concretemix.Thebeamswerecuredusingjutebags with room temperature for 28 days. The compressive strengthoftheconcretemixwasmeasuredafter28days usingstandardcubes.Themeancompressivestrengthfor themixwas30MPa.

Theflexuralstrengthofthespecimenswastestedusinga 30-ton loading frame. A dial gauge was attached at the bottom of the beam to determine the deflection at the centre of the beam. For testing of the specimen, the supportswereprovidedatadistanceof130mmfromthe edges of the beam. The effective span of the beam was takenas990mminthecaseof1250mmbeam.Aproving ring of 500 kN was connected at the top of the beam to determinetheloadapplied.

Theflexuralstrengthofthebeamwastestedasatwo-point loadingsystemusingahydraulicjackof30tonattachedto

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

the loading frame. The behaviour of beam was keenly observedfrombeginningto thefailure.Theloadingwas stoppedwhenthebeamwasjustonthevergeofcollapse. The first crack propagation and its development were observed carefully. The values of load applied and deflectionwerenoteddirectlyandfurthertheplotofload v/s deflection was performed which was taken as the output. The load in KN was applied with uniformly increasingthevalueoftheloadandthedeflectionunder thedifferentappliedloadswasnoted.The appliedloadwasincreaseduptothebreakingpointortill thefailureofthemate

Duetoincreaseintheload,thebeamstartstodeflect,upto certainleveltheloadv/sdeflectiongraphwillbelinearthat isloadwillbedirectlyproportionaltodeflection.Dueto further increase in the load, the load value will not be proportional to deflection, since the deflection values increases as the strength of the materials goes on increasingmaterialloseselasticityandundergoesplastic deformation.Thedeflectionandthecorrespondingload,of RCbeamsreinforcedwithwalnutshellascoarseaggregate werecomparedwithnormalRCbeamsofSCC.

The load values and corresponding deflection of control specimens and other specimens are given in table 7. Flexuralcracksandshearcrackswereformedinthemidspanandquarterspanrespectivelyofallthetestedbeams. Noshearfailureofthebeamwasobservedtillthefailure. Themaximumloadvaluesandmaximumverticaldeflection at midspan is given in table 7 and observed that the maximum load was carried by the scc beams with alccofine.

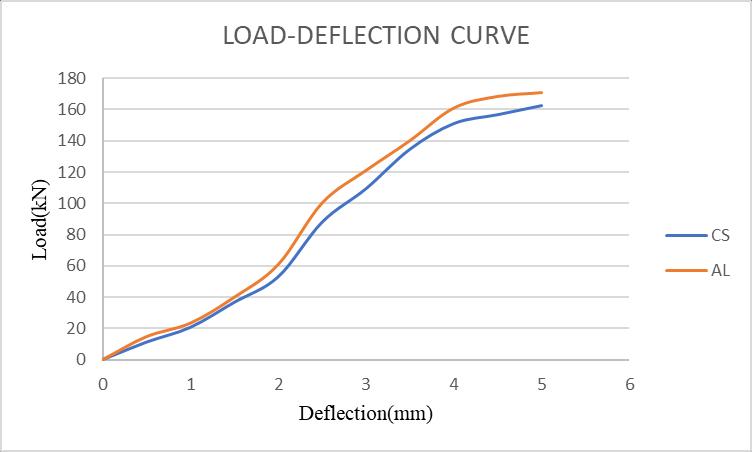

Figure6.1indicatestheload-deflectioncurvesofcontrol beamsandRCbeamsreinforcedwith alccofine. It can be observed that the alccofine beams and control beams shows similar inelastic behavior. The curves for all the beams showed similar response in the initial stage of loadingtilltheformationoffirstcrack.Butwiththeincrease inload,avariationwasobservedforalccofinemix.

Deflection (mm)

Controlspecimen Load(kN) Testspecimen Load(kN)

0 0 0

0.5 11.26 14.724 1 20.71 23.313 1.5 36.77 39.878 2 53.0333 60.73 2.5 88.0332 100.02 3 109.484 120.85 3.5 134.74 139.87 4 151.194 160.73 4.5 156.88 168.09 5 162.646 170.53

Fig6.1Load-DeflectionGraph

The main findings of this investigation are described below.

SCCbeamswith10%alccofinehadmore load carrying capacity compared toCS. Alsotheinitialcrackloadwasincreased foralccofine.

All the specimens showed a linear relationshipbetweenloadanddeflection untiltheformationofcracks

SCCbeamswith10%alccofinehadmore load carrying capacity compared to CS. Alsotheinitialcrackloadwasincreased foralccofine.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

All the specimens showed a linear relationshipbetweenloadanddeflection untiltheformationofcracks

SCCbeamswith10%alccofinehadmore load carrying capacity compared to CS. Alsotheinitialcrackloadwasincreased foralccofine

All the specimens showed a linear relationshipbetweenloadanddeflection untiltheformationofcracks

Thebeamfailuresflexurally

I wish to thank the Management, Principal and Head of Civil Engineering Department of Universal Engineering College, Thrissur, affiliated by Kerala Technological University for their support. This paper is based on the workcarriedoutbyme(SheethalSasikumar),aspartof myPGcourse,undertheguidanceofAnimap.(Associate professor,CivilDepartment,UniversalEngineeringCollege, Thrissur,Kerala).Iexpressmygratitudetowardsherfor valuableguidance

[1] Saloni, Abhishek singh, Vaibhav sandhu & Jatin, Parveen(2020),“EffectofAlccofineandcuringcondition onproperties of low calcium fly ash based geopolymer concrete”,Vol.32,Part4,Pp:620–625

[2] Yatin et al. (2013) “Study on durability of High Performance Concrete with Alccofine and Fly Ash” InternationalJournalofAdvancedEngineeringResearch andStudies.,2(3),154-157.BodeVenkataKavyatejaetal. “Effectiveness of alccofine and fly ash on mechanical properties of ternary blended self compacting concrete”Volume33,Part1,2020,Pages73-7.

[3] Sagar, B.; Sivakumar, M.V.N. An Experimental and Analytical Study on Alccofine Based High Strength Concrete.Int.J.Eng.2020,33,530–538

[4] B. Venkatasan, M. Venuga, P.R. Dhevasenna & V. Kannan(2020), “Experimental study on concrete using partialreplacementofcementbyalccofinefineaggregate asironpowder”Vol.37,Part2,Pp:2183–2188

Factor value:

[5] K.Ashwinietal.(2021)”Freezeandthawresistance of concrete using alcofine and nano-silica ”ELSEVIER, MaterialsToday,Vol32Pp:1-5.

[6] Parmar,A.,Patel,D.M.,Chaudhari,D.,andRaol,H. (2014) “Effect of Alccofine and fly Ash Addition on the Durability of High Performance Concrete.” International JournalofEngineeringResearch&Technology.,3(1), 1600-1605.

[7] Rithiviraj, C.; Saravanan, J. Characteristics of SelfCompacting Concrete with Different Size of Coarse AggregatesandAlcco-fine.TrendsSci.2022,19.