International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | August 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | August 2022 www.irjet.net p-ISSN: 2395-0072

1

, P. Dhanabal2

, P. Narendra Reddy3 and A. Anil1MM.Tech student, Annamacharya Institute of Technology and Science, Tirupati, Andhra Pradesh. 2-4Assistant Professor, Department of Civil Engineering, Annamacharya Institute of Technology and Science, Tirupati, Andhra Pradesh. ***

Abstract - An The main scope of this study is to find variouspropertiesofconcretewithreplacementofcement bypumicestonepowder.Nowadaysmanyofresearchare going to find the best possible alternate for cement in concrete. In this work pumicestone powder waspartially replacedascementintherange10%,20%,30%,40%.The fresh and hardened properties of concrete with pumice stoneis tobecomparedwithconventionalconcrete.Pumice powder,generated bythestoneprocessingindustry,isan inert by-product possessing excellent cementitious characteristics.Utilizationofpumicepowderinconcretecan reducethecostofconstructionandatthesametimeaddress the waste disposal problem. This study is focused on the strengthpropertiesofpumicepowderinpozzolanconcrete .Theresultsindicatethatthefreshandhardenedproperties ofthemodifiedmixwithpumicestonepowderasimproved considerably.Theuseofpumicepowderasasubstitutefor cement in the concrete mixture also has the ability to improvethecompressive,andtensilestrengthofconcrete.

Key Words: Freshproperties,hardenedproperties,pumice stonepowderandcementreplacement.

A naturally occurring light aggregate known as pumice stone,whichresemblesasponge,wascreatedwhenmolten lavaswiftlycooledandsolidified.Lightweightconcretehas been used by ACI for more than 2000 years (American concreteinstitute,2003).Constructionsmadeofstructural lightweightconcretearestillfairlywidespread,despitebeing used much less frequently than ordinary weight concrete today. In comparison to conventional cement, pumice powderhasbenefitssuchasincreasedthermalandacoustic insulation, fire resistance, abrasion resistance, decreased unitweight,hydrationheat,dryingshrinkage,andautoclave expansion. It also has advantages in terms of improved sulphate resistance, sea water resistance, acid resistance, electrical resistivity, and decreased alkali silica reaction expansionandporosity.

A naturally occurring lightweight aggregate known as pumice stone is created when molten volcanic material suddenly cools. Viscous magma that is primarily siliceous

andrichindissolvedvolatilecomponents,particularlywater vapour,eruptsfromvolcanoesduringeruptionstoproduce pumice.

Pumicecanbeutilisedasalightweightaggregatesinceitis bothlightandrobust.Whenmoltenlavaeruptedfromadeep locationbeneaththe earth's crust,gaswasableto escape, whichiswhytheyweresolight.Dueofitssmallweightand poroustexture,pumicecanfloatforalongtime sometimes years before it ultimately gets wet. The bulk density of pumice,alight-colored,froth-likevolcanicglass,rangesfrom 500to900kg/m3.

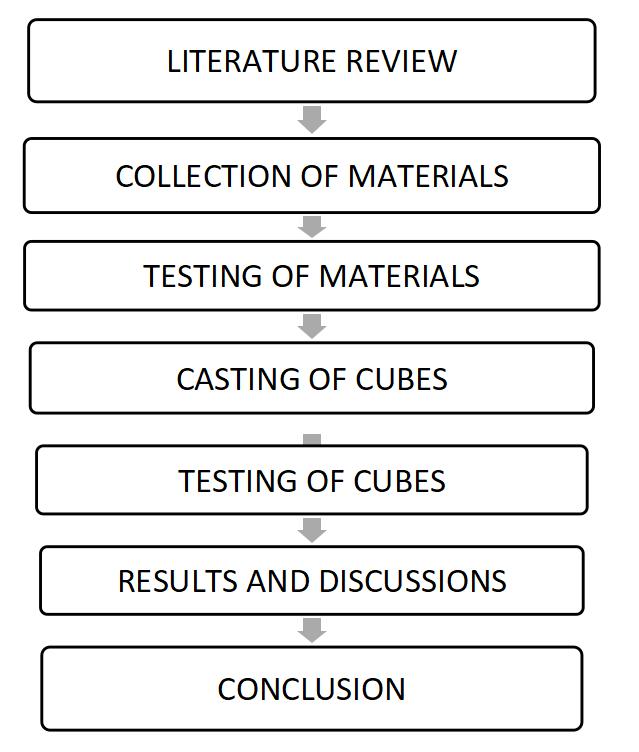

This study's primary goals are to compare concrete'sfreshandhardenedqualitieswhenpumicestone powderisusedinplaceofcement.

Figure1:Methodology

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | August 2022 www.irjet.net p-ISSN: 2395-0072

Thefollowingresearchpaperswerestudiedbeforestarting theprojectwork

A thorough analysis of the characteristics of sustainable concrete employing ash from volcanic pumice as an additionalcementitiousmaterial(2022)

AliS.AlqarniWithregardtotheuseofVPPAinconcreteanditseffectson properties such as workability, compressive strength, flexural strength, splitting tensile strength, and durability performance,thisarticleaimstoprovideathoroughreview oftheliteraturethathasalreadybeenpublishedinthisarea. Additionally, by using a scanning electron microscope to investigatethemicrostructureofconcrete,thisarticleseeks to determine how VPPA affects sustainability (SEM). The study's findings showed that using VPPA with partial substitution decreased workability and compressive strength,butenhancedperformanceinsplittensilestrength, flexuralstrength,anddurabilitycharacteristics.Thisessay alsoemphasisestheneedforadditionaldevelopmentsinthis areaofresearch.

2.Evaluationofthemechanical,thermal,andmorphological characteristics of polyester composites reinforced with modifiedcornhuskpumicepowder(2022).

NasmiHerlinaSarietal.

NasmiHerlinaSarietal.

The SBA/CHF composites' mechanical and thermal propertiesweregreatlyenhanced.ThestrongestSBA/CHF interfacebondsinthecompositeswereresponsibleforthe composite with 5:30 volume fraction (JPA) having the highest values of tensile strength (18.61 MPa), tensile modulus (3.23 GPa), flexural strength (36.12 MPa), and flexuralmodulus(3.39GPa)amongallthecompositesand the polymer matrix. While a significant number of CHF pullouts contributed to the composite specimens' lowest values being recorded. Similar to how JPA composites performedbetterintermsofthermalstabilitythantheother composites. According to the morphological investigation, CHFpulloutincreasedastheamountofCHFincreasedand decreased as the amount of SBA increased and became evenly distributed throughout the composite. The results showthattheCHF/SBAcompositeshadbettermechanical characteristicsthanthefiber-glasscomposites.

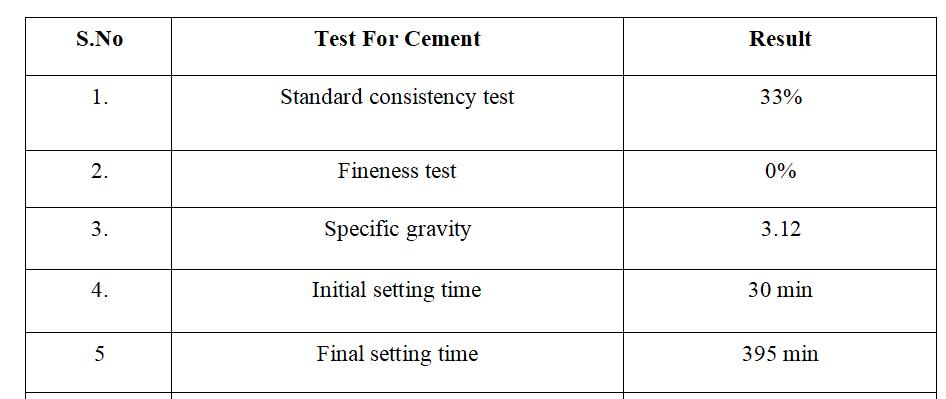

4.1 Cement

Table1:PropertiesofCement

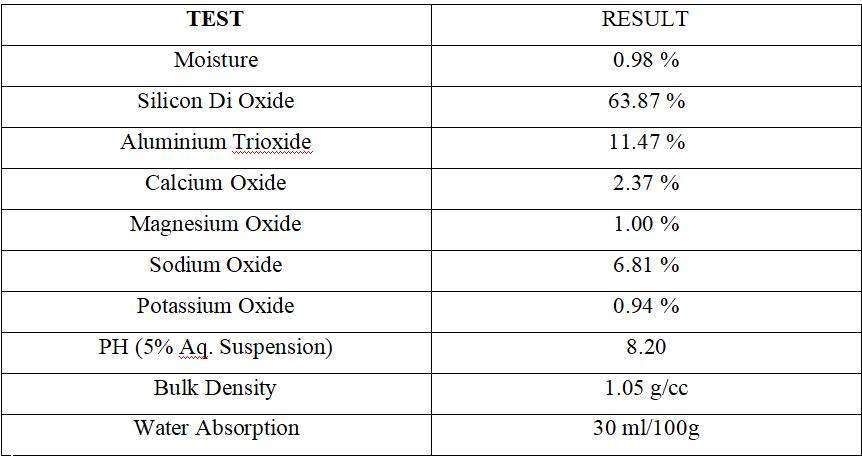

4.2 Pumice stone powder

Table2:pumicestonepowder

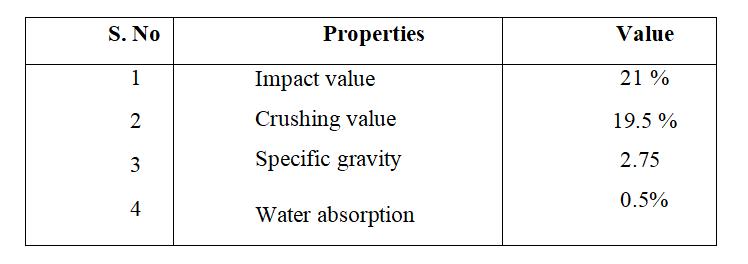

4.3 Coarse aggregate

Table3:Coarseaggregateproperties

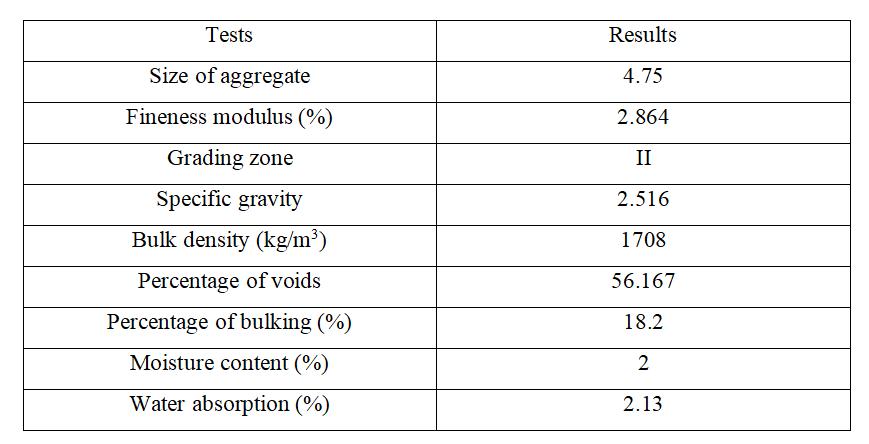

4.4 Fine aggregate

Table4:Fineaggregateproperties

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | August 2022 www.irjet.net p-ISSN: 2395-0072

Workability,compressivestrengths,permeabilityandwater tightness,durabilityandweathering,anddryingshrinkage potential for cracking are all controlled by the precise amountofwaterinconcrete.Itmakesthemixtureworkable andservesasalubricantforthefineandcoarsematerial.It joinscementchemicallytocreatethebindingpaste.Itisused todampentheaggregatesurfacetostopitfromabsorbing thewaterthatisessentialforchemicalaction.

5.1 Slump Test

Figure2:Slumpconetest

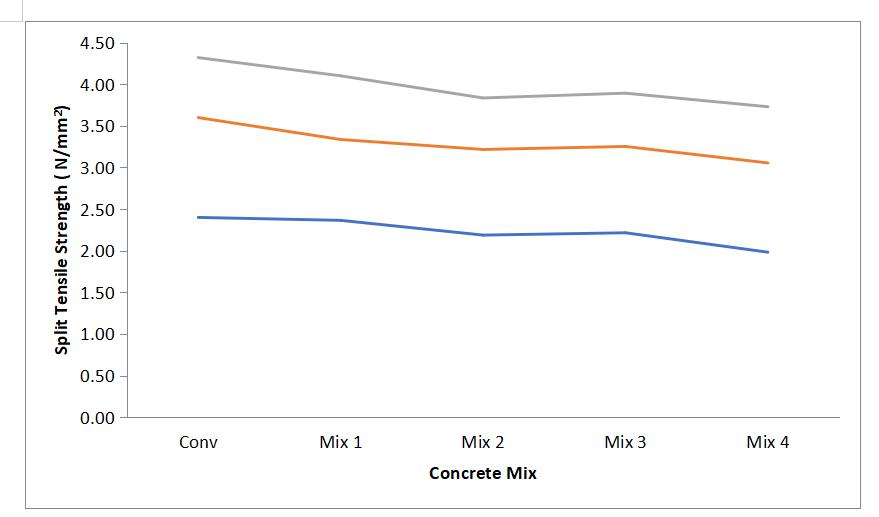

5.3 Split Tensile Strength

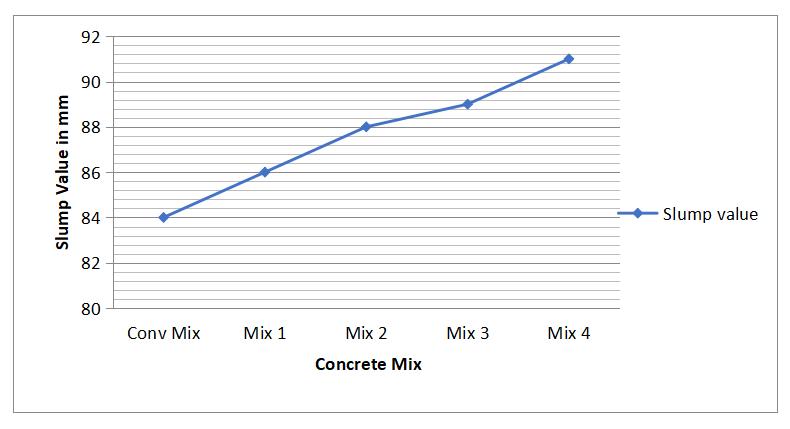

Figure3:Slumpconetestresult 5.2

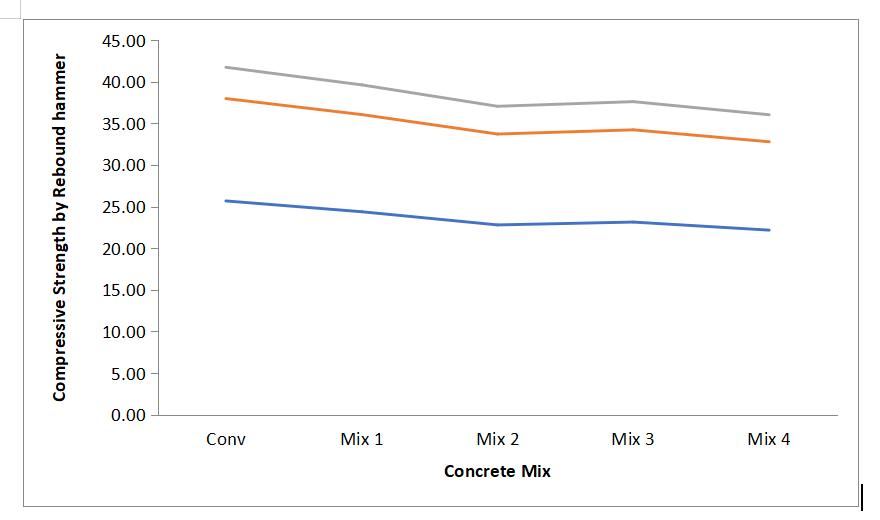

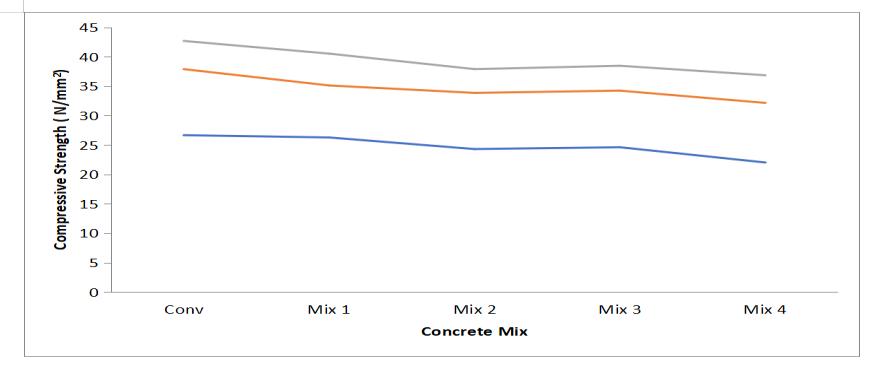

Figure4:CompressiveStrengthresults

Fromthisresearch,thefollowingconclusionswere made,Thefollowingconclusionsweredrawnfromthisstudy:

Concrete elements become less dense when mixed with pumicestonepowder.Theexperimentalresultsalsoindicate that the percentage of cement that is replaced by pumice stonewillenhancetheslumpvalue(Con-.84mm,C90:PS86mm, C 80: PS -88mm, C 70: PS -89mm, and C 60: PS91mm). When compared to other mixes, the compressive strength of concrete made with 30 percent pumice stone powderascementreachesitsoptimumat7days,14days, and28days.However,atallages(7days,14days,and28 days), the strength starts to decline when more cement is added.Comparingdifferentmixes,concretewith30percent pumice stone powder produces the strongest split tensile strength.Itdemonstratesthatcementmaybereplacedwith 30%pumicestonepowdertoprovidethedesiredstrength. Pumicestonepowdercanthereforebeusedasasubstitute

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | August 2022 www.irjet.net p-ISSN: 2395-0072

for cement to create concrete pieces that are lighter in weight.

[1] concrete mix proportioning standards according to IS 10262:2019.

[2] S. Mohanty, S. Verma, and S. K. Nayak Dynamic mechanical and thermal characteristics of jute/HDPE composites treated with MAPE. (2006) Compos Sci Technol66:538–547.

[3] [3]Lightweightconcreteandcementarebasedonthe propertiesofvolcanicpumicestonepowder.

[4] [4] S. Mohanty, S. Verma, and S. K. Nayak Dynamic mechanical and thermal characteristics of jute/HDPE composites treated with MAPE. (2006) Compos Sci Technol66:538–547.

[5] [5] Effect of ground pumice powder on the durability and mechanical characteristics of self-compacting mortars

[6] [6]IS: 2062- 2019, fourthversion, 1992, specification forsteelforgeneralstructuralreasons.

[7] [7] IS: 383-1970, specification for coarse and fine aggregatesfromnaturalsourcesforconcrete,(second revision),B.I.S.,1970.

[8] [8] Behavior of pumice cement concrete cubes with bamboo as a Partial Replacement for Cement by Syed FarazSiddique,PriyankaS,andNishanthL.580-587can be found in International Journal of Civil Engineering andTechnology,8(9),2017.

[9] [9] Behavior of pumice powder Concrete cubes with Opening,InternationalJournalofCivilEngineeringand Technology,8(7),2017,pp.581–593.Dr.LathaM.S.and NaveenKumarB.M.

[10] [10] Behavior of pumice Concrete cubes by Lalramnghaki Hauhnar, R. Rajkumar, and N. Umamaheswari303–309areincludedinInternational JournalofCivilEngineeringandTechnology's8(5),2017 edition.

[11] [11] Mechanical and thermal properties of pumice powderfilledPPScomposites,Sahin,AE,Yildiran,Y,and Avcu,E.2014;125:518–520inActaPhysPolymA.

[12] [12] Properties and durability of concrete including polymeric wastes (tyre rubber and polyethylene terephthalatebottles):anoverview.Pacheco-Torgal,F., Ding,Y.,andJalali,S.2012.ConstrBuildMater30:714–724.

[13] [13]Poly (2 chloroaniline) and poly (o-toluidine) compositeswithpumiceandtheiruseintheelimination ofchromium(VI)ionsfromaqueoussolutions.Gök,AU, Göde,F.2008;107:2295-2303inJApplPolymSci.

[14] [14] Sahin, A., Sinmazcelik, T., and Karsli, NG. Comparisonofthepumiceandcalciumcarbonatefilled poly (phenylene sulphide) composites' mechanical, thermomechanical, thermal, and morphological characteristics. 2016; 37(11): 3160-3166 for Polym Compos.

[15] [15] George, A., Jayakrishnan, P., and MT Ramesan Pumiceparticles'impactonthethermal,electrical,and mechanical characteristics of composites made of poly(vinylalcohol)andpoly(vinylpyrrolidone).2016; 126(2):511–519;ThermAnalCalorim.

[16] [16] Tetracycline removal from wastewater using pumicestone:equilibrium,kinetic,andthermodynamic studies.Guler,UA;Sarioglu,M.2014;12:79inJEnviron HealthSciEng.

[17] [17] A X-ray investigation of 2-phase and molecular orientation in nucleated and non-nucleated injection moulded polypropylene resins was conducted by Favaro, MM, Branciforti, MC, and Bretas. 2009; 12(4): 455-464inMatRes.

[18] [18] Dynamic mechanical investigation of randomly orientedcloselymixedshortbanana/sisalhybridfibre reinforcedpolyestercomposites.Idicula,M.,Malhotra, SK, Joseph, K. 2005; 65: 1077–1087 for Compos Sci Technol.

[19] [19]Comparisonofthemechanicalcharacteristicsand interfacialinteractionsbetweentalc,kaolin,andcalcium carbonate filled polypropylene composites, Leong, Y., Bakar,A.,andIshak,Z.2004;91(5):3315–3326;JAppl PolymSci.

[20] [20] S. Siriwardena, H. Ismail, and US Ishiaku. A comparisonofthewhitericehuskashandsilicafilled polypropylenecomposites' mechanical characteristics andwaterabsorption behaviour2003;22(18):1645–1666inJReinfPlastCompos.

[21] [21] Standard Practice for Choosing Proportions for Structural Lightweight Concrete (ACI 211.2-98). IS 516:1959-MethodsofConcreteStrengthTesting.

[22] [22]. IS 269:1989 Specification for ordinary Portland cement. IS 383:1970 Specification for coarse and fine aggregatesfromnaturalsourcesofconcrete

[23] [23]. IS 2386(PART V):1963 Methods of test for aggregates for concrete. A.M. NEVILLE, Properties of concrete-edition2013.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page301

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

[24] [24].M.S.SHETTY,Concretetechnology-Revisededition 2005. M.L. GAMBIR, Concrete technology theory and practice-fifthedition

[25] [25].A.M.NEVILLE, J.J.BROOKS, Concrete technology16th edition, SHAN SOMAYAJI, Civil engineering materials.

Volume: 09 Issue: 08 | August 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page302