International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

1M.Techstudent, Structural Engineering, universal Engineering college, Thrissur, Kerala

2Head of department, Civil Department, universal Engineering college, Thrissur, Kerala

2Associate professor, Civil Department, universal Engineering college, Thrissur, Kerala ***

Abstract - Thisresearchlookedintothebehaviourofan SCCreinforcedconcrete(RC)beamwithapoly-vinylmeshas an extra reinforcement. The use of PVC in concrete gave syntheticsawholenewmeaninginstructuralengineering. ThepurposeofexaminingthebehaviourofPVCinstructural membersgivesopportunitytoobservebenefitandfeasibility ofusingPVCforwrappingreinforcement.Inthisresearchfly ashisusedasmineraladmixtureforconstructingSCC.The optimumpercentageofflyashcontentisconsideredforthis research.thefreshandhardenedpropertiesofSCC where testedandsatisfied.ARCbeamofconventionalSCCiscasted and compared with beam which is provided by double spaced reinforcement and PVC is wrapped on alternate phasesofreinforcement.ThemixdesignofSCCdoneAsper IS.10262:2019andEFNARCspecifications.Thetestresults for acceptance characteristics of self-compacting concrete suchasslumpflow,T50cmslumpflowtest,V-funnelandLBox are presented. The shear behaviour of RC beam is studiedandcomparedwithconventionalSCCbeam.Hence obtainedsimilarresultsofconventionalSCC.

Key Words: SCC (Self compacting Concrete), PVC (Poly Vinyl Chloride)

Concrete is the most common and widely used structural material in the construction area. It is more versatile but moderndayengineeringstructuresrequiremorestandard concreteowingtothehugeappliedloadonsmallerareaand increasing adverse environmental aspects. This research lookedintothebehaviourofanSCCreinforcedconcrete(RC) beamwithapoly-vinylmeshasanextrareinforcement.The useofPVCinconcretegavesyntheticsawholenewmeaning in structural engineering. The purpose of examining the behaviourofPVCinstructuralmembersgivesopportunityto observe benefit and feasibility of using PVC for wrapping reinforcement

The properties of PVC are less rigid; has high impact strength; is easier to extrude or mould; has lower temperatureresistancealsolessresistanttochemicals,and usually has lower ultimate tensile strength Poly vinyl

chloride mesh is used here to wrap the reinforcement for check the shear capacity that can be taken. Property enhancementbymolecularorientationisknownandsome industrial examples have been produced for over thirty years.Inmorerecenttimes,ithasbeenappliedtoconsumer products such as films, high strength garbage bags, some carbonatedbottlesetc.

Self-compacting concrete (SCC) has many benefits in of productionandplacementcomparedtotraditionalconcrete, elimination of external or internal vibration for compaction,flowability,workabilityandpumpability,aswell as increased bonding with congested reinforcement. The placementofSCCiseasyandspeedandrequireslesslabour. Theappearance,mechanicalperformanceanddurabilityof SCCcanbeconsiderablybetterthantraditionalconcrete

OrdinaryPortlandCement(53grade)–SHARJAHCEMENTS confirmingtoIS12269-1987wasusedfortheexperimental programme.TestswereconductedasperIS:1489(PartI). The properties of the cement are tabulated in Table.The varioustestsconductedoncementarefinenessofcement, standardconsistencytest,specificgravity,initialandfinal settingtimeandcompressiontestonmortarcube.

Table-1:PropertiesofOPC53gradecement

Properties Testresults Technicalreference

Specificgravity 3.12 IS4031(PART11):1988 Consistency(%) 30 IS4031(PART4):1988 Fineness ofcement(%) 4.7 IS4031(PART2):1996

Initialsetting time(minutes) 78 IS4031(PART5):1988

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1766

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

M–Sandwasusedasfineaggregate.Laboratorytestwere conducted on fine aggregate to determine the different physicalpropertiesasperIS2386(Part–III)–1963andIS: 383- 1970.The properties of fine aggregate are given in Table3.2.Testconductedonfineaggregateweregrainsieve analysis,specificgravity,bulkdensity

Table-3:PropertiesofFineAggregate

Properties Test results

Specificgravity 2.52 Finesmodulus 3.84

Freesurfacemoisture Nil

Aggregatepassingthrough20mmISsieveandretainedon 4.75mmISsieveisconsideredascoarseaggregate.Various testsoncoarseaggregatewereconductedbasedonIS:2386 (PartIandPartIII)–1963andIS:383–1970.Theproperties ofcoarseaggregatedeterminedasgiveninTable3.3.Tests conducted on coarse aggregate were grain sieve analysis, specificgravity,andbulkdensity.

Table-4:PropertiesofCoarseAggregate

Properties Test results Technical reference

Specific gravity 2.69 IS2386(PART3):Clause 2.4.2

Freesurface moisture Nil IS383(PART3):1970

Finenessm odulus 4.25 IS383(PART3):1970 table2

Waterisrequiredtowetthesurfaceofaggregatetodevelop adhesive quality as the cement paste binds quickly and satisfactorilytothewetsurfaceoftheaggregatesthandry surface. It is commonly accepted view that any portable water is suitable to be used in concrete making. It should haveinorganicsolidlessthan1000ppmandshouldbefree frominjuriousquantitiesofalkalies,acids,oils,salts,sugars, organicmaterials,vegetablegrowthorothersubstancethat maybeharmful tobricks,stones,concreteorsteel.

Admixtures are defined as a material other than water, hydrauliccement,aggregatesandfiberreinforcement,used as an ingredient of concrete or mortar, and added immediately before or during its mixing.Chemical admixtures are used to increase the quality of concrete duringtheirentireprocess

Theyfallintothefollowingcategories.

Airentrainers

Waterreducers

Setretarders

Setaccelerators

Superplasticizers

MASTER RHEOBUILD 1126ND is an admixture of a new generation based on modified poly carboxylic ether. The producthasbeendevelopedforutilizeinhighperformance concrete where the highest durability and performance is required.MasterRheobuild1126NDisfreeofchloride&low alkali. It is compatible with all types of cements. Master Rheobuild1126NDhasadifferentchemicalstructurefrom the other superplasticisers.At the beginning of the mixing process it initiates the same electrostatic dispersion mechanismstheothersuperplasticisers,butthesidechains linked to the polymer back bone generate which greatly stabilizes the cement particles' ability to separate and disperse.Richindranceprovidephysicalbarrier(alongside theelectrostaticbarrier)betweenthecementgrains.With thisprocess,flowableconcretewithreducedwatercontent isobtained

Vinyl mesh fabric is an open weave, durable and flexible fabric. Use coated mesh in a variety of applications from tennis court screens, garden tarps, barrier fabric and muchmore .Vinyl coated polyester open mesh fabrics,or PVC-PES Mesh, are strong and durable fabrics, a popular choiceintensilefabricandmembranearchitecture.Thebase materialcomprisesofawovenhightenacitypolyesterbase fabric grid and a flexible plasticised PVC coating which protects the grid from all sides. It is possible to apply coatings or lacquers, for example, dirt repellent surface lacquers,toenhancetheperformanceofthesemeshfabrics. Therearecertainmeshopeningsavailable.PVCCoatedMesh

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1767

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

(PCS) consists of two components: liquid vinyl (PVC) compoundandknitpolyesterscrim.PVCisappliedtomesh and is heat cured. Like our laminate products, the PCS products contain anti-bacterial heat stabilizers agents, mildewinhibitors,UVandheatstabilizersheatstabilizers

Table5PropertiesofPVC

SL.

NO. ChemicalComposition Result 1 Silica(SiO2) 18.59 2 IronOxide(Fe2O3) 3.04

Table7ChemicalCompositionofclassFFlyash

SL.NO. ChemicalComposition Result 1

Silica(SiO2) 62.5

IronOxide(Fe2O3) 3.5

Alumina(Al2O3) 23.4

CalciumOxide(CaO) 1.8

Flyash is a fine powder that is a byproduct of burning pulverizedcoalinelectricgenerationpowerplants.Flyashis apozzolanicmaterial,asubstancecontainingaluminousand siliceous material that forms cement in the presence of water. When mixed with lime and water, flyash will be change in the similar form of Portland cement. As per IS 3812:2003,thegenericnameofthewasteproductdueto burning of coal or lignitein the boiler of a thermal power plantispulverizedfuelash.Pulverizedfuelashcanbeflyash, bottomash,pondashormoundash.Flyashisthepulverized fuelashextractedfromthefuelgasesbyanysuitableprocess likecycloneseparationorelectrostaticprecipitation.

AccordingtoIS3812-1981,therearetwoclassification of FlyAsh

GradeIflyash,whicharederivedfrombituminous coal havingfractions SiO2+ Al2O3+Fe2O3greater than70%.

GradeIIFlyashwhicharederivedfromlignitecoal havingfractionsSiO2+Al2O3+Fe2O3greaterthan 50%

Table6PhysicalPropertiesofClassFFlyash

Magnesiumoxide(MgO) 0.34 6 Totalsulphur(SO3) 1.2 7

Potassiumoxide(K2O) 0.95

Beamofsize150mmx200mmx1250mmwasusedforthe experiment.

Table8ReinforcementDetails

MainReinforcement Anchor Bars Shear reinforcement

2#8mm 2#6mm 8mmdia @180mmc/c

Twopointbendingtestprovidesvaluesforthemodulusof elasticityinbendingEf,flexuralstressσf,flexuralstrainεf andtheflexuralstress–strainresponseofthematerial.This testisverysimilartothreepointsbendingflexuraltest.The major difference being that with the addition of fourth bearingpointsisputundermaximumstressasopposedto onlythematerialrightunderthecentralbearinginthecase ofthreepointbending.

Thisdifferenceisofprimeimportancewhenstudyingbrittle materials,whenthenumberandseverityofflawsexposedto the maximum stress is directly related to the flexural strengthandcrackinitiation.Comparedtothethreepoint bendingflexuraltest,therearenoshearforcesinthefour point bending flexural test in the area between the two loading pins. The four point bending test is therefore particularly suitable for brittle materials that cannot withstand shear stress very well. It is commonly used apparatus to characterize fatigue and flexural stiffness of asphaltmixtures.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1768

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

lower reinforcement is 2-6 mm in diameter and 8 mm diameterstirrups.Thesteelcoverusedis25mm.Allbeams using Self Compacting Concrete. Normally curing can be doneusingjutebagswithroomtemperaturefor28days.The compressive strength of the concrete mix was measured after28daysusingstandardcubes.Themeancompressive strength(cube)forthemixwas37.25MPa

Theshearstrengthofthespecimenswastestedusinga30 tonloadingframe.Adialgaugewasattachedatthebottomof the beam to determine the deflection at the centre of the beam. For the testing of the specimen the supports are provided at a distance of 130 mm from the edges of the beam.Theeffectivespanofthebeamistakenas990mmin the case of 1250 mm beam. A proving ring of 500 kN is connected at the top of the beam to determine the load applied.

The shear strength of the beam is tested as a three point loading system using a hydraulic jack connected to the loadingframe.Thebehaviourofbeamiscarefullyobserved frombeginningtothefailure.Theloadingwasstoppedwhen the beam was just on the end of collapse. The first crack propagationanditsdevelopmentareobservedkeenly.The values of load verses deflection are noted directly and furthertheplotofloadvs.deflectionisperformedwhichis takenastheresult.TheloadinkNisappliedwithuniformly increasingthevalueoftheloadandthedeflectionunderthe differentloadsisnoted.Theappliedloadisincreasedupto thebreakingpointortillthefailureofthematerial.

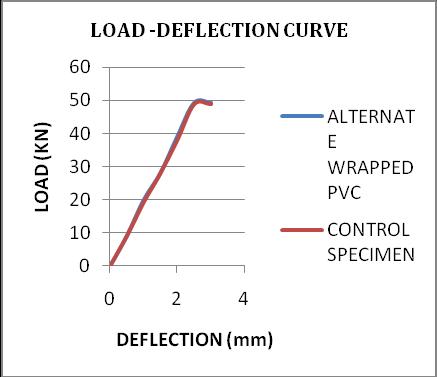

Duetoincreaseintheload,deflectionofthebeamsemerge, up to certain level the load v/s. Deflection graph will be linearwhereloadwillbedirectlyproportionaltodeflection. Duetofurtherincreaseintheload,theload valuewillnot proportional to deflection, when the deflection values increasesasthestrengthofthematerialsgoesonincreasing materialloseselasticityandundergoesplasticdeformation. Thedeflectionandthecorrespondingload,ofSCCbeamwith alternate placing of PVC mesh reinforcement is compared with SCC beams with conventional reinforcement arrangement.

Table

1.5 28.01 28.22 2 38.02 39.22

2.5 48.77 49.33 3 48.77 49.33

Fig.1LoadDeflectionCurve

TheultimateloadcarryingcapacityofPVCmeshbeamswere foundtoincreaseasthetheplacementofmeshchangeslike full phase is more better, because of contribution by PVC Mesh in load carrying capacity. As compared with conventional SCC beam the PVC Mesh beam has same strengthorsomeslightvariation.WhenPVCmeshbeamis placed in full phase doubly reinforced, the ultimate load carryingcapacityofbeamisslightlyhigher.Aspecialtypeof loadvs.deflectionbehaviorisobservedbecauseofusingPVC Meshasreinforcingmaterial.Fromtheresultitwasfound thatthePVCreinforcedbeamwithfullphasedwithdoubly reinforced exhibit as same load or slightly greater than carryingcapacityofcontrolSCCbeam.

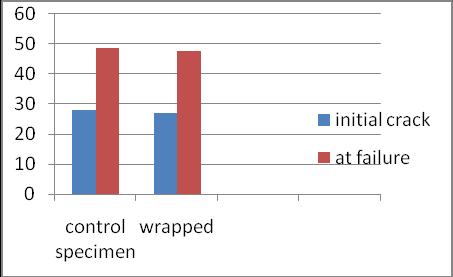

Thefirstshearcrackswereformedatbottomsurfaceinthe maximum moment region at the mid span of the beams whentheappliedloadwasapproximatelyincreased.Asthe applied load increased, the cracks began to spread out throughthelengthofthebeamsandbecameperpendicular towardstheneutral axisbeams. Thesevaluesvaryamong different beams depending on transverse reinforcement ratios(ρt)andspacingofthestirrupsforeachgroup.Inthe under reinforced section beam, the member approaches failureduetogradualreductionofcompressionzone,which showscracksdeveloped atthesoffitandprogresstowards thecompressionface.Itcanbeobservedthatthecracksin

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

the control specimen are mainly shear and the specimens withPVCinfullyandalternatewrappedalsomainlyshear.

An experimental study looked into the behaviour of selfcompactingreinforcedconcretebeamswithPVCMeshes.One conventionalbeamandthreePVCbeamsarecasted.These beamsweretestedusingtwo-pointloading.

When PVC s are kept in the tension zone of reinforcedconcretebeams,theyalsocarrytensile pressures.

WhilecomparingwithconventionalSCCbeamsthe wrappedoneshowsgreaterstrength

Fig2initialcrackloadandfinalloadofspecimen

The ratio between the deflection at ultimate load and the deflectionatyieldingloadoftheRCbeamswasdefinedas ductility index .The rate of increase in the ductility index from beam without PVC Mesh reinforcement to that with alternatephaseofmeshwashigher.Moreover,asignificant increaseorsameintheductilityindexwasobservedwhen usingof PVC meshcomparedtothat ofcontrol beam.The load deflection curves show that the ductility of the specimenincreaseswithchangingtheplacementlikefully wrapped.

Thefirstflexuralcrackswereformedatbottomsurfacein themaximummomentregionatthemidspanofthebeams whentheappliedloadwasapproximatelyincreased.Inthe under reinforced section beam, the member approaches failure due to gradual reduction of compression zone, exhibiting and cracks, develop at the soffit and progress towardsthecompressionface.

Themodesoffailureofbeamsareasfollows

AllReinforcedconcretebeamsfailedinshearzone

After the first crack load, the reinforcement started yieldingandmorenumberofcrackshaveformedinthe shearzoneandextendedtowardsthepointloadswith incrementinloads.

PVCisalsoutilisedasasupplementaryreinforcing materialinRCbeamswhenincreasedstrengthand reduceddeflectionandcrackingarerequired.

A. Sharaky et. al, (2020), “Flexural Behaviour of Rubberised Concrete Beams Strengthened in Shear Using Welded Wire Mesh”, Science direct, Vol.247,pp:1-40

Ibrahim S. Shaaban et. al, (2018), “Flexural Characteristics of Light Weight Ferrocement BeamswithVariousTypesofCoreMaterialsand MeshReinforcement”, Science Direct,Vol.171,pp: 802–816

K. J. H. Zhou and Ho and Su (2011), “Flexural StrengthandDeformabilityDesignofReinforced Concrete Beams”, Science Direct, Vol. 14 , pp: 1399–1407