International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

1 B.E Student, Department of Civil Engineering, Late G.N.Sapkal College of Engineering, Nashik, Mahatashtra, India.

2 Assistant Professor, Department of Civil Engineering, Late G.N.Sapkal College of Engineering, Nashik, Mahatashtra, India ***

Abstract :TheCracksformintheconcretearenotavoidable,anditisnaturaloccurringprocessiftheloadisgreaterorthe mortarwouldnotinaproperproportionthentherewouldbe weaknessinthe concrete. Throughthesecrackswater,salts andotherschemicalcomponents canseepintotheconcretestructure.Itistheinitialcorrosionprocesswhich furtherreduced thelifeoftheconcretestructure.Thereforetopreventfromthecorrosionwhichsimultaneouslyhelptonottodecreesthelife spanoftheconcretestructureThereforeiswasnecessarytodevelopanaself-repairingtechnologyfromwhichwherewould bepreventionfrom thecracks Bio-concreteisonekindof material whichcan strongly preventfromcracksinconcrete structure.Thistechnologyisveryfascinatingasaresultoftheactofcrackremedyitisalsoan eco-friendlyandnaturally occurringsubstance.DuetothecrackontheconcretestructuresTherearesomeadverseeffectonthecompressivestrength, water absorption etc of cement concrete It was found in the study that with the use of Bacillus Megaterium substance improvesthecompressivestrengthandstiffnessofconcretestructureandalso reductioninwaterabsorptionand water permeabilitywhenitiscomparedtogeneral concretestructure Thebacteriathatgoestobeintroducedinconcrete,shouldto have the property of alkali-resistance and it jointly should be kind spore, so it will stand up to the stresses produced in concreteintheprocessofmixing,transportationofconcretelikeRMCandwhileplacingtheconcrete.

Key Words: Concrete , Self Healing , Cracks , Bacillus , DurabilityConcrete,itisthemostwidelyusedforconstructionmaterial.Concreteisweakintensionandstrongin compressionand cracks are unavoidable in concrete. Once cracks form in concrete Structure it star reducing the lifespan of the concrete structures.TheMicro-cracksandporesinconcreteareexcessivelybecausetheycreateawayforthewaterandthesubstances whichleadstothecorrosionofreinforcementprovidedintheconcretestructureanditalsoreducesthestrengthdurabilityetc ofconcrete.Therearemanyrepairtechniqueswhichareavailabletorepairthecrackspresentintheconcretestructure,but theyareveyexpensiveandtimeconsumingprocess.Therearesomemoderatetechniquestorepairthecracksintheconcrete structurebyitself iscalledas“Self-HealingConcrete”.Thisbacterialrestorationtechniquearebetterthanothertechniques presentinthecurrentscenarioasitisabio-based,environmentfriendly,economicalanddurable.Concreteisaveryalkaline material,thebacteriawhichis addediscapableofpreventive alkalienvironment.Bacteriawithcalciumnutrientsourceare addedintotheconcreteatthetimeofmixingtheconcrete.Ifanywouldbeanykindofcrackswillbeformedinconcretethe bacteriaprematurelycalciumcarbonatethenitwillsealthecrackspresentontheconcretestructure.TheCrackwhichare morethan0.8mmisverydifficultfortherepairedpurposewiththeuseofbacteriacrackcanrepairedwiththehelpofcalcium carbonateprecipitation.

Thiseco-friendlymethodwasfirstlyadoptedfortheusedof repairofcracksontheconcretestructuretopreventleachingin channels,withthehelp ofthebacteria Bacillus megaterium,Bacillus pasteurii, Bacillus ,Bacillussubtilis,Bacillusaerius, Sporosarcinapasteurii,ShewanellaSpeciesand Bacillusflexusetc.BacteriausedinthiskindofworkisBacillusmegaterium Bacteria of one hundred and five cells/ml of water. These bacterium based mostly self-healing agent is believed to stay hibernatedatintervalstheconcreteforuptotwohundredyears.Thebacterialsporesbeginmicrobicactivitiesoncetheyare availableindirectcontactwithwaterandoxygenduetowhichthedevelopmentofcracksinconcrete.Recently,theselfhealing approachesareexhibitingpromisingleadstoremediatingthecrackswithintheearlierstagesofformationofcracks.

Thecapsuleswhichcointainsbacteriaandcalciumlactateareinsertedintheconcrete,thereasontouseitwithinthecapsule kindistoavoidinteractionbetweenthem.Thecapsulesusedarepassiveandmaylastuptoacentury Theconcretestructures ismeanttoownsmallcracksbythephysicalreactionsthatdecreasedurabilityoftheconcretestructure.Thecapsulesneed

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

waterforhisnutritiontogrowitsselfthatgetsleakedintothecracksaftertheyexposedtoatmosphere.oncereactionwith water,saltformssedimentaryrockthathealsthecracks.Itspreadsthroughoutthecracksresultinginthehealingofthecracks.

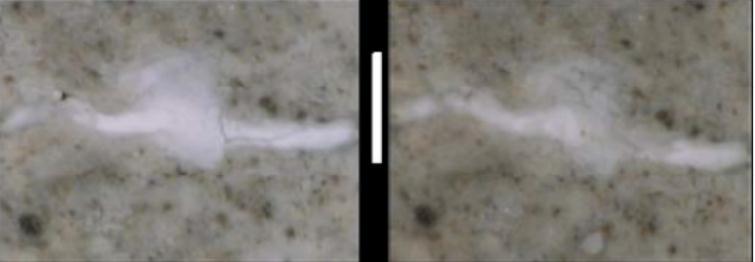

After formation of the salt forms sedimentary rock, the chances of the water leakage inside the concrete structure is not possible.bythisit increaseinthesustainabilityoftheconcretestructure.basicallytheyareaddedassporessothattheycan betheinactivehavingveryhighsurvivalrateandoncetheextantconditionsareagainsttheoddthentheactivebacteriaonce againformsspores 3Days Fig - 01 7Days

The different varieties of healing agents have already been tested on their potency to be used in self-healing concrete. Generally,Inthebusinesshealingagentsisbeing usedwhereastheirpropertiesareadjustedforthemanualcrackrepairand not for autonomous crack healing. Consequently, the amount of regain in properties because of self-healing of cracks is restrictedintheconcretestructure.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Oncetherequiredpropertieswereobtained,thehealingagentwasencapsulatedandscreenedforitsself-healingpotency, they'recapabletoscalebackthewaterporosityhoweverregainalotofstrength.methylradicalmethacrylate,aself-healing agent which might restore high strength more than the desired once healing of cracks. methyl radical methacrylate encapsulated in an exceedingly microcapsules will be side with the concrete structure . once the crack reaches the microcapsule,thecapsulebreaksandalsothechemicalcompoundbleedsintothecrack,whereveritwillpolymerizeandmend the crack. These microcapsules were crammed with a liquid chemical compound (methyl methacrylate). If a small crack happensduringthisconcrete,themicrocapsulecanruptureandalsothechemicalcompoundcanfillthecrack.Afterwardsit'll polymerizeandautogenouslyhealthecracksoftheConcretestructure

TheSteelwastematerials arethewastematerialswhicharecollectedfromthedifferentworkshopsandothersteelindustries ataveryminimumcostitisalsocalledasSteelscrap.Theyarelooklikethesteelfiberbuttheydidnothaveadefineshapeor size . The dimension may accordingly with the nature of source which depends upon the type of industries. Scraps are recyclablematerialsandistheunwantedpartsofthe vehicles,buildingmaterialsetcAccordingtoanalysisconductedbythe UnitedStatesofAmerica,EnvironmentalProtectionAgency,utilizationscrapmetalsmaybequitehelpfultothe atmosphere dailyaround eighttotenkilogramis generatedbyeveryshapingmachineindustriesanddroppedwithinthesoilthereby contaminatingthesoilandwellwater,thatcreatesANenvironmentalissue. thereforebyadoptingcorrectmanagementby utilizationtheshapingmachinescrapwithconcreteistakenintoaccounttobeoneinallthesimplestsolutions.Thetestwere conductedasper the Indian standard procedure forits mechanical propertieslike flexural,tensile strength,compressive strengthetcandcomparedwithordinaryPCC.AtTheseventhdaysstrengthoftheshapingmachinescrapconcreteshowsarise initscompressivestrengthincomparisonwithordinaryPCCconcrete.

FineaggregateorsandisAssociateinNursingaccumulationofgrainsofmineralmatterderivedfromthedisintegrationof rocks.it'sdistinguishedfromgravelsolelybythedimensionsofthegrainsorparticles,howeverisdistinctfromclaysthat containorganicmaterials.Sandsthataresortedoutandseparatedfromtheorganicmaterialbytheactionofwaterorbywinds acrossaridlandsareusuallyquiteuniforminsizeofgrains.Sandisusedforcreatingmortarandconcreteforsprucingand sandblasting.Thefinemixturewaspassingthrough4.75mmsieveandhadaselectedgravityof2.68.Thegradingzoneofthe mixturewaszonethreeasperIndiancommonplacespecifications

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Fig – 05 Sand

CoarseAggregateareaunitwhichisthecrushedstoneisusedforcreatingconcrete. crushedandhierarchal.alotofofthe crushedstoneusedisgranite,rockandenticerock.hierarchalcrushedstonetypicallyaccommodatesjustonequiterockandis brokenwithsharpedged.Thesizesareaunitfrom0.25to2.5inches (0.64to6.35cm)thoughlargersizescouldalsobeused forlargeconcretemixture.MachinecrushedgranitebrokenstoneangularinformwasusedascoarseAggregate.thehighest sizeofcoarsemixturewas20mmandrelativeitsspecificgravityisof2.78.

TheWaterwhichissuitablefordrinkingismostlysuitableforthecreatingofconcreteaspertheISCode456-2000thephvalue shouldbeinbetween6-7. Watershouldtobefreefromimpuritieslikeacidimpurities,oilsimpurities,alkalisimpurities, vegetablesoralternativeorganicimpurities. Theimpure watermadeconcretestructureweaker.Waterhastwofunctionina concretestructure mix.Firstly,itreactsinachemicallywiththecementtoformacementmortarinwhichtheinertaggregates areheldinsuspensionuntilthecementmortarhashardened.Secondly,itactasabondingagentbetween fineaggregateand cement

Cementisaconstructionmaterialwhichisforconstructionpurposeitisgenerallyintheformof powderformthatitcanbe madeintoacementmortarbytheaddingofwaterand,whenwroughtorpoured,cansetintoasolidmass.variedorganic

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

compoundsusedforadhering,orfasteningmaterials,areknownascements,howevertheseareclassifiedasadhesives,and alsoitisthetermascementalonesuggeststhataconstructionmaterial.theforemostwideusedofthedevelopmentcementsis Portlandcement.it'sabluish-gray powderobtainedbyfinelygrindingtheclinkercreatedbypowerfullyheatingassociate intimatemixtureofcarbonateandclayeyminerals.Thechiefrawmaterialscouldbeamixtureofhigh-calciumsedimentary rock,calledcementrock,andclayorsedimentaryrock.Blast-furnacescoriacanalsobeemployedinsomecementsandalsothe cementisnamedPortlandscoriacement(PSC).thecolourofthecementisdueprimarilytoironchemicalcompound.within theabsenceofimpurities,thecolourwouldbewhite,howeverneitherthecolournortheprecisegravitycouldbeacheckof quality.

Hydroxyethylpolyosecouldbeanon-ionicsolublechemicalcompoundderivedfrompolyose.Itcanbereadytodissolves promptlyincoldorquandary.it'sexcellentflowpropertiesthatmodifythefiberstomeettheworldofconcrete.Itisaviscous agent.it'sadditionallyusedasabinder,stabilizerinconcretetopushhigherbondingbetweencementpasteandaggregates.It additionallyisprotectingmixturethroughoutchemicalactionofalkylmethacrylate.

Silicafume,additionallycalledsmallsiliconoxide|oxide},isAssociateinNursingamorphous(non-crystalline)organismof silicondioxide,silica.it'sAssociateinNursingultrafinepowdercollectedasaby-productoftheSilicaandferrosiliconalloys productionanditisalsoconsistsofthesphericalparticleswithamedianparticle.themostofthefieldofapplicationisas pozzolanicmaterialforthetopperformanceconcrete.silicondioxidefumeisintercalarytoPortlandcementconcretetoboost itsproperties,specificallyitscompressivestrength,bondstrength,andabrasionresistance.Additionofsilicondioxidefume additionally reduces the porousness of concrete to chloride ions, which protects the reinforcing steel of concrete from corrosion.silicondioxidefumeadditionallyblockstheporeswithintherecentconcretethuswateratintervalstheconcrete isn'tallowedtocomebacktothesurfaceandreducesharm.

It had shown that Portland cement-basedconcretes containing silicon dioxide fumes had terribly high strengths and low porosities.Sincethentheanalysisanddevelopmentofsilicondioxidefumecreateditoneineveryofoneineveryofmost respectedandversatileadmixturesforconcreteandcementationsproduct.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Fig– 08 Silica Fume

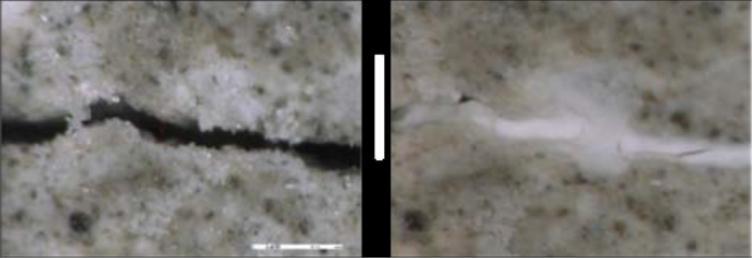

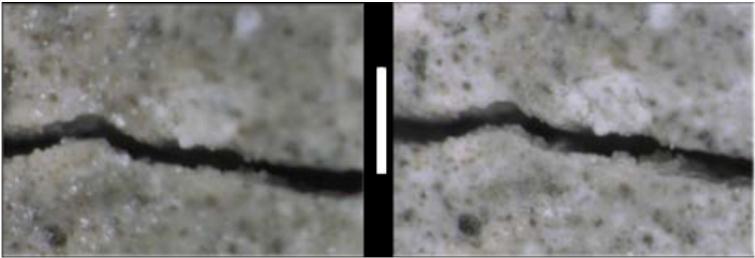

Autogenous self healing relies on the composition of concrete and is accomplished by hydration reaction of cementitous productswithinthematrix,orbyreactionofpolymericsubstancesinthematrix.Autogenousselfhealinghasbeenwidely studied .One of the weaknesses of this approach is the limitation posed by crack width. Autogenous healing is primarily effectiveforverynarrowcracks;differentresearchersstudiedtheeffectivenessofthistechniqueinsealingcracksofdifferent widths,of5–10μm,200μm,and300μm.Ithasbeenacknowledgedthatwidercracksthataredeterimentaltodurabilityof concretestructurescannotbeeffectivelyhealedbyautogenoushealing.Furthermore,aconstantsupplyofwatermustbe presenttosupportthehydrationprocesssothatcrackscanbecompletelysealed.

Therefore,thedevelopment ofself-producedhealingis alsoadditional distinguishedincontemporaryoryoung concrete, whereascarbonateprecipitationisalsothepronouncedmechanismatlaterstage.Severalresearcherstriedatmistreatment supplementarycementitousmaterials,likeashandfurnaceslag,tostimulateself-producedhealing.Materialslikeashandslag hydrateatslowerratethancementandso,unhydratedparticlesofsuchmineralspromoteself-producedhealingatlaterstage ofconcrete.

ThevascularviewoftheselfhealingConcreteiscloselyshowsthevascularnetworkpresentinthesystemofthehumanbody. Thenetworkofthevasculartubescanbeplacedintheconcretetobringahealingagenttothecrackedordamagedsites.Inthis waytheselfhealingagentsarecompactinhollowtubesornetworkofhollowtubesandsuppliedbyothersource.Thereare twomeansofachievingself-healingbyvascularapproach:single-channelandmultiple-channelsystems.oncesolelyasinglecomponentofself healingagentisemployed,thesingle-channelvascular-shapedstructureapproachisusedwhenitinvolves healingbythereactionof twohealingagents,multiplechannelssquaremeasureused.thoughexternalprovideofhealingagent iseffective,technicallyit'snotself-healinginandofitself,sinceitneedsexternalintervention.Moreover,thoughpossibleat laboratory scale, it's tough to forged concrete with a network of pipes vascular self-healing on self-healing on actual constructionsites.

Theserviceabilitylimitofconcretestructurebycrackingcouldbeovercomeby thecrackmanagementmethodologiesthe improvedservicelifetimeofconcretestructureswouldcutbackthedemandforcrackmaintenanceandrepair.specially,the useofselfhealingtechnologieshashighpotentialasareplacementrepairmethodologyforcrackedconcreteThistrendshows thatit'snecessaryforeachthecommercialandanalysisfieldstodevelopconcreteaswellasselfhealingcrack.Therefore,the aim of this study is to develop a building material composite at traditional or high water/cement ratios, the self-healing properties of concrete incorporating geo-materials as a partial cement replacement were investigated in terms of

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1687

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

recrystallizations.Thisstudycenteredon2primaryissues:(1)experimentalandanalyticalstyleofbuildingmaterialmaterials withself-healingcapabilities,(2)developmentof a self-healingconcrete victimisation new building material materialsat traditionalwater/bindermagnituderelation[overW/B=0.45].

In this study the potential of microorganism to act as a self healing in concrete is investigated. the thought of use of microorganismandintegratethemwithintheconcretematrixmightappearsoddinitially,itisnotamicrobiologicalread purpose.microorganismnaturallyoccureachwhereveronearthnotsolelyonsurfacehoweveradditionallydeepatintervals. Tothedatethemostconclusionofthiscurrentresearchesaretheexperimenttiredthisstudyshowthealkaliphilicspore formingmicroorganismintergratedinconcretematrixwillactivelyprecipitatecarbonateminerals.Water,requiredforthe activationofendosporeswillentertheconcrtestructurethroughfreshlyshapedcracks.

Research resultingin microbiccarbonate precipitation andits ability toheal cracksofconstruction materialshasleadto severalapplicationslikecrackcorrectionofconcrete,sandconsolidation,restorationofhistoricalmonumentsandalternative suchapplications.thusitwillbeoutlineas“Themethodwilloccurwithinoroutsidethemicrobiccellormaybeawaysawayat intervalstheconcrete.typicallymicroorganismactivitiesmerelytriggeraamendmentinanswerchemistrythatendsupinover saturationandmineralprecipitation.UseofthoseBiogeologyideasinconcreteendsupinpotentialinventionoflatestmaterial referredtoasreferredtoasConcrete”.Selfhealingconcretecouldbeaproductthatmaybiologicallyturnoutstonetoheal cracksthatseemonthesurfaceofconcretestructures.Speciallyhand-pickedkindsofthegenusBacillus,besideacalciumbasednutrientreferredtoassalt,andchemicalelementandphosphorus,areaunitextratotheingredientsoftheconcreteonce it'sbeingmixed.Theseselfhealingagentswillliedormantatintervalstheconcreteforuptotwohundredyears.

SelfHealingConcreteIsANewTechnologyDevelopedInDelftUniversity,Netherlands.ThisConcreteHasBacteriaIn TheFormOfCapsulesWhichRemainDormantTill100YearsUnlessItReceivesWaterWhichIsItsNutrientToBecome ActiveAndMultiplicate.CapsulesReceiveWaterOnlyWhenExposedToTheEnvironmentWhichIsPossibleWhen CracksAppearInTheStructures.

TheBacteriaHealTheCracksOrGapWithinThreeToFourWeeksByProducingLimestoneAsItsByProduct.

StructuresCanBeImprovedExponentiallyAndHenceIncurSavingsInTheCostOfMaintenance.

WeCanPrepareBricksUsingSelfHealingConcreteWhichAreEnvironmentalFriendlyAsTheyAreNotProducedIn KilnsAndAreMoreDurableThanConventionalBricks.

TheStudyHasAlsoShowedThatThereIsEnhancementOfCompressiveStrengthOfConcrete.

ItAlsoShowedThatUseOfSuchBacteriaHasPositiveEffectOnWaterAbsorption,SportivityAndWaterPermeabilityIn Concrete.

The Present Study Represent That Using Self Healing Concrete Can Be A Competent Alternative And High Quality ConcreteSealantWhichIsEcofriendly,Cost-EffectiveAndAlsoResultsIn ImprovementInTheDurabilityOfBuilding Materials.

AdditionOfSteelScrapInThePercentagesOf5%And10%ToTheSelf-HealingConcreteLeadsToAConsiderable IncreaseInTheTensileStrengthOfConcrete,BecauseItHasThePropertySimilarToTheSteelFiber.

ThisResearchPaperWouldNotHaveBeenPossibleWithoutTheSupportOfProfKiranMDeoreSirIAmWithWholeHearted ThankingHim ForHisMostValuableAdviceAndGuidance,

IWouldLikeToThanksProf.(Dr.)S.B.BagalSir,Prof.RahulM.JadhavSirAndAlsoOtherProfessorStaffMembers,Technical StaffMembers,OfCivilEngineeringDepartment,LastButNotLeast MyFatherAndMotherThankingAll.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

[1] Dong,B.,Wang,Y.,Fang,G.,Han,N.,Xing,F.,AndLu,Y.(2015).“SmartReleasingBehaviorOfAChemicalSelf-HealingMicro CapsuleInTheStimulatedConcretePoreSolution.

[2] GuptaSouradeepAndHarnWeiKua(2016)."EncapsulationTechnologyAndTechniquesInSelf-HealingConcrete".

[3] Mayur Shantilal Vekariya, Prof. Jayeshkumar Pitroda. Bacterial Concrete: New Era For Construction Industry. InternationalJournalOfEngineeringTrendsAndTechnology

[4] Neville,A.(2002).“AutogenousHealing:AConcreteMiracle?”Concrete

[5] Wang,J.,DeBelie,N.,AndVerstraete,W.(2012a).“DiatomaceousEarthAsAProtectiveVehicleForBacteriaAppliedFor Self-HealingConcrete.”

[6] Daisuke Homma, Hirozo Mihashi And Tomoya Mishiwlaki, “Self-Healing CapabilityOfFiberReinforcedCementationsComposites”-JournalOfAdvancedConcreteTechnologyVolume7.

[7] C.Edvardsen,“WaterPermeabilityAndAutogenouslyHealingOfCracksInConcrete”-ACIMaterialsJournal.

[8] P.S. Mangat, K. Gurusamy, “Permissible Crack Widths In Steel Fiber Reinforced MarineConcrete”-JournalOfMaterialsAndStructures

[9] Krishnapriya,D.L.VenketeshBabu,PrinceArulraj,IsolationAndIdentificationOfBacteriaToImproveTheStrengthOf Concrete,MicrobiologicalResearch

[10] NafiseHosseiniBalam,DavoodMostofinejad,MohamadrezaEftekar,EffectOfBacterialRemediationOnCompressive Strength,WaterAbsorption,AndChloridePermeabilityOfLightweightAggregateConcrete,ConstructionAndBuilding Material.

[11] KunamineniVijay,MeenaMurmu,ShrishV.Deo,BacteriaBasedSelfHealingConcrete,ConstructionAndBuilding Materials.

[12] MianLuo,Chuan-XiangQian,Rui-YangLi,FactorsAffectingCrackRepairingCapacityOfBacteria-BasedSelf-Healing Concrete,SConstructionAndBuildingMaterials.

BE Student, Department of Civil Engineering, Late G.N.Sapkal College of Engineering, Nashik, Mahatashtra,India.

AssistantProfessor,Departmentof CivilEngineering, LateG.N.Sapkal CollegeofEngineering,Nashik, Mahatashtra,India.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |