International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Gururaj Kumbar1 , Shriram Patil2 , Sourabh Patil3 , Bhagawan Patil4 , Dattatraya Patil5 , Nikhil Kupekar6 .

1Head of Department, Mechanical Engineering, Dr.A.D. Shinde College of Engineering, Gadhinglaj, Maharashtra, IN 2,3,4,5,6UG Scholar, Mechanical Engineering, Dr.A.D.Shinde College of Engineering, Gadhinglaj, Maharashtra, India. ***

Abstract - In current year’s big development has been made each in gaining a fundamental perception of the giant parameters of put on and in making use of a substances methodology to mitigate the troubles of wear. While this mission work will solely tackle strong particle erosion, it is properly to hold in thought that different put onprocesses, e.g., abrasive put on and oxidative wear, containmanycomparable traits and possibly mechanisms. Progress in grasp any one of these techniques can also be relevant to others, and to the improvement of greater put on resistant substances and systems. Testing on ferrous and non-ferrous substances has been broadly carried out to find out about their erosion resistance. Venkataraman & Sundararajan [1] carried out a learn about about the stable particle erosion of copper at a vary of low have an effect on velocities. In this unique case, the eroded floor used to be absolutely blanketed with the erosion particles in the structure of flakes or platelets. These flakes regarded to be definitely separatedor fracturedfromthe cloth floor and have been flattened via subsequent impacts. For this reason, it used to be concluded that at low affect velocities the erosion harm was once characterized on the whole via lip or platelet fracture whereas it used to be distinctive with lip formation (rather than its subsequent fracture) at greater affect velocities. In this undertaking erosion conduct of the stainless metal is evaluatedvia exposingthe metalsubstrate to erodent at predefined pace and pressure. Effect of have an effect on perspective and erodent speed on erosion resistance of the metal substrate is studied with the assist of strong particle erosion setup.

Key Words: Erosion,Stainlesssteel,SS,Steel,MaterialStudiesontheerosionbehaviourofAISI4140metalbeneath more than a few warmth remedy stipulations used to be investigated by way of Ambrosini & Bahadur [2]. In this work,theinvestigationwasoncecentredontheimpactofa number of microstructures and mechanical homes on the erosion resistance. A regular speed of 50 m/s used to be usedforalltheerosiontests.Thegoalusedtobeimpactedat anperspectiveof30ºtothespecimensurface,theparticle feed charge used to be 20 g/min, SiC particles, a hundred twentyfiveμminsize,hadbeenusedastheabrasive.From the results, it was once concluded that erosion fee will

increasewithgrowinghardnessandfinalstrength,however decreaseswithgrowingductility.Inthisspecificwork,the warmness cure with the greatest aggregate of erosion resistanceandmechanicalhomesusedtobeoilquenching accompaniedbywayoftemperinginthetemperaturevary 480-595ºCfortwoh.Inaddition,SEMresearchintroduced extremeplasticdeformationintheerodedzonescollectively with abrasion marks, indicating that cloth subjected to erosioninthebeginningundergoesplasticdeformationand islatereliminatedbywayofabrasion.Harsha&Bhaskar[3] carriedoutlookuptolearnabouttheerosionbehaviourof ferrousandnon-ferroussubstancesandadditionallytotake alookattheerosionmannequindevelopedforeverydayand indirect affect angles via Hutchings [4]. The substances examined had been aluminium, brass, copper, slight steel, stainlessmetalandsolidiron.TheydecidedfromtheSEM researchthatthewornsurfaceshadprintedquiteanumber putonmechanismssuchasmicroploughing,lipformation, platelet,smallcratersofindentationandmicrocracking.In additiontothesestudies,Morrison&Scattergood[5]carried outerosionexamson304stainlesssteel.Inthiswork,itwas onceconcludedfromtheSEMobservationsthatcomparable morphologiesforlowandexcessiveinfluenceanglesought to be determined in ductile metals when they had been subjected to the affect of sharp particles. The surfaces displayed a peak-andvalley topology collectively with connected platelet mechanisms. In addition, the bodily foundation for a single-mechanism to erosion in ductile metals was once viewed to be associated to shear deformations that manage cloth displacement inside a technique region for a everyday set of influence activities producingatallhaveaneffectonangles.

Wearreasonsanwidespreadannualexpenditureby means of enterprise and consumers. For some industries suchasagriculture,asmanyas40%oftheelementschanged onequipmentshavefailedbyusingwear.Estimatesofdirect valueofputontoindustrialinternationallocationsfluctuate from1%tofourpercentofGNPanditisestimatedthat10% ofallelectricitygeneratedbymeansofmanisdissipatedina range of friction processes. Thus the magnitude of losses prompted to mankind (which can be expressed in proportionfactorsofGDP)makesitreallyindispensableto learn about approaches to decrease it. Thus minimizing

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

wear, impacts the economics of manufacturing in a main way.

Previously put on was once described as broken to a surface.Themostfrequentstructureofthatinjuryislossor displacementofclothandquantitycanbeusedasameasure of wear volume of fabric eliminated or extent of fabric displaced.Forscientificfunctionsthisisoftenthemeasure usedtoquantifywear.Inmanystudies,inparticularfabric investigations,masslossisregularlythemeasureusedasan alternativeofvolume.Thisisexecutedduetothefactofthe relative ease of performing a weight loss measurement. However there are some troubles in the use of mass as importantmeasureofwear.

1. Directcontrastofsubstancescansolelybefinished iftheirdensitiesaresame.Forbulkfabricthisisno longerafundamentalobstacle,consideringthatthe density is both recognized or without difficulty determined. In the case of coatings however, this can be a main problem. The different issues are greaterintrinsicones.

2. A mass dimension does no longer measure displacedmaterials.Inadditionitistouchytoput onparticlesandtransferredfabricthatwillbecome connectedtothefloorandcan'tbe removed.This fabric does now not always have to be from the equalsurface;itcanfromthecounterfaceaswell.

From the above it can be viewed that quantity is the integralmeasureforputonwhenputoniscalculatedwith loss or displacement of material. However, in engineering applications, is normally with the loss of a dimension, the extend in clearance or alternate in contour now not the extentloss,Volume,masslossandadimensionarenolonger thesolelymeasuresforputonthatareusedinengineering. Life, vibration level, roughness, appearance, friction level, and diploma of floor crack or crazing are some of the operationalmeasuresthatareencountered.

Intheexistinginvestigationaself-madeerosionequipment ofthesandblastkindwasonceused.Itwasoncedesigned andfabricatedinourlaboratory.

Theerosiontryingoutdesktophasmanyparameterswhich canbevaried.Ithassomeawesomeparts.

Nozzle: Thenozzleisrelatedwiththesteeltubethruwhich compelled air entersthe nozzlemouth.As pressurized air entersthenozzlealongsidewiththesandsothesandflows with excessive speed and consequently with excessive momentum,Thuserodingwhatevercomingonitsway.

Reciprocating Air Compressor: High compelled air is furnished from the reciprocating air compressor, current besidetheerosiontryingoutmachine.Itasatwocylinder compressor,thelargercylindercarriesairoflowstressand excessivevolume.Thesmallercylinderconsistsofexcessive forced air. The desktop sucks air from the ecosystem and firstshopsinthelargecylinderwithexcessivepressure,and thenitstrikestothesmallercylinderwithpipes.

Fixture Arrangement: Thefixtureassociationissuppliedto maintain the sample or specimen at specific angles to the nozzle.Thefixtureassociationhasonemetallicplatewhich strikesoveraprogressivelymarkedarrangement.

Thefixturecanbeorganizedatuniqueanglesanditcanalso be moved linearly to come across the specimen precisely beneaththenozzle

N.B.:- Angle is measured with recognize to the nozzle and nownotthebaseline.

Funnel Arrangement: Funnel related with a pipe to the nozzle is furnished at the top. The funnel is used to pour sandinit.

Angle: Theattitudecanbeassortedbywayoftheuseofthe fixturearrangement.Differentangleswhichcanbeusedare 30º,60º,90º.

Pressure: Differentvaluesofstresswhichcanbeusedare 4Kgf/mm2,5Kgf/mm2and6Kgf/mm2.

Stand off distance: Itisthedistancebetweenthenozzletip andthespecimenofthesurface.Thestandoffdistancecan bediversethroughadjustingnozzletoptheuseofthescrew arrangement.Theexclusivevaluesofstandoffdistanceused havebeen100mmand200mm.

Erodent size: Sandparticlesofspecificmeasurementcanbe carriedoutviasieving.Meshdimensionusedwasoncefour hundredmicrons.

1. Beforeconductingthetakealookatthespecimen floorusedtobecleanedproperly.

2. Thepatternisclampedatthefixture.Therequired attitudeandstandoffdistanceusedtobeadjusted.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

3. The air at required strain is blended with the erosiveparticleandisdirectedtotheaspecimenfor specifictimeduration.

4. Thepreliminarymassandthemassofthespecimen aftererosionhadbeenobservedouttheuseofthe weighingmachine.

5. The above steps are repeated for exclusive parametersmentioned.

3.1 Results:

Mild Steel

SOD=10mm, PRESSURE= 1Mpa

Time 300 600 900 0 27.770 27.750 27.740 2 27.760 27.740 27.740 4 27.750 27.740 27.730 6 27.750 27.740 27.730

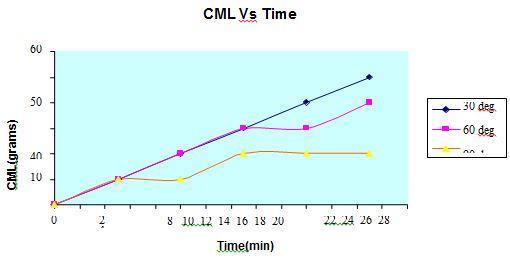

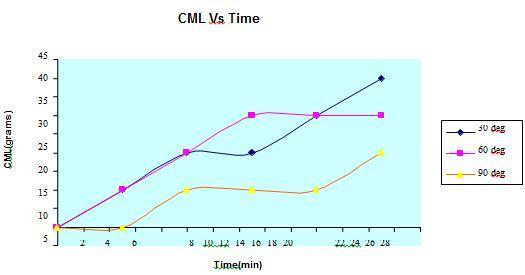

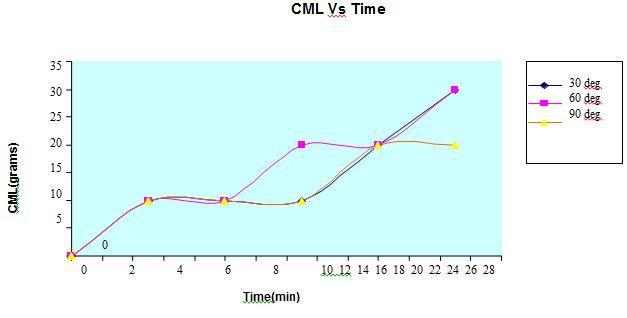

Figure3.2

SOD=10mm PRESSURE=3Mpa

Time 300 600 900 0 28.530 28.510 28.490 2 28.520 28.500 28.490 4 28.510 28.500 28.480 6 28.510 28.490 28.480 Table3.1

Table3.3

Figure3.1

SOD=10mm PRESSURE=2Mpa

Time 300 600 900 0 28.540 28.560 28.580 2 28.540 28.550 28.570 4 28 530 28 550 28 570 6 28.530 28.540 28.560

Table3.2

Figure3.3

3.2

Theusualincrementalerosioncurveisintroduced in preceding page. The erodent particles strike the lined samples at a variety of perspective of impact. It is viewed that at first the cumulative mass loss will increase unexpectedlyandlateronwillbecomenearlystagnant.This styleislocatedincaseoferosioncarriedoutatalldifferent influence angles i.e. 600 and 900. In all these cases, a transientregimeintheerosionsystemappearstoexist,for the duration of which the mass loss will increase monotonicallyandtendstoreapasteadyregularkingdom value. This consistent price is referred to as the constant nationerosionrate.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

The cumulative increment in cloth loss due to erosion put on with publicity time (or erodent dose) has been mentioned previously by means of Levy [7]. He has proven that, the incremental erosion fee curves of substancesbeginwithaexcessivefeeatthefirstmeasurable quantity of erosion and then decreases to a an awful lot decreaseregularkingdomfee[8].

Intheexistingworkalso,thisstyleisdeterminedin caseofallthreemetalssubjectedtoerosioncheckatarange of have an effect on angles. This can be attributed to the realitythattheexceptionalprotrusionsonthefloorofmetals are tremendously unfastened and can be eliminated with muchlesspowerthanwhatwouldbequintessentialtotake away a comparable phase from the bulk of the metal. Consequently, the preliminary put on fee is high. With growingpublicitytimethepriceofputonstartsoffevolved loweringandinthetransienterosionregime,asharpdropin the put on charge is obtained. As the coating floor progressivelyreceivessmoothened,thefeeoferosiontends togrowtobesteady.

Figure a (previous page) illustrates the impact of haveaneffectonattitude(α)ontheerosionpriceofmetals subjectedtostrongparticleerosion.Theerosionoutcomes for metals (MILD STEEL, STAINLESS STEEL AND ALUMUNIUM) at have an effect on angles of 30, 60 and ninetylevelsareshown.Theerosionmasslossisgreaterat smaller perspective of have an effect on and the most erosiontakesvicinityatα=300.

This is ordinary of all ductile materials. The outcomes bought in the current work exhibit that for 300 influenceattitudethemetalslosemostmassascomparedto thatofα=600andα=300ataregularSODandpressure. This variant of erosion put on loss confirms that the perspective at which the circulation of strong particles impingesthemetallicfloorinfluencesthefeeatwhichthe fabricisremoved.Itsimilarlysuggeststhat,thisdependency isadditionallyinfluenced withtheaidofthenature ofthe material.Theperspectiveofhaveaneffectondeterminesthe relativemagnitudeofthetwofactorsofthehaveanimpact onspeednamely,thethingregulartothefloorandparallel tothesurface.Theordinaryissuewilldecidehowlongthe have an effect on will ultimate (i.e. contact time) and the load. The product of this contact time and the tangential (parallel) speed factor determines the quantity of sliding that takes place. The tangential speed aspect additionally affordsashearloadingtothesurface,whichisinadditionto theregularloadthattheordinarypaceissuecauses.Hence asthisperspectiveadjustmentsthequantityofslidingthat takeslocationadditionallymodificationsasdoesthenature and magnitude of the stress system. Both of these factors impact the way a metallic wears. These modifications suggestthatdistinctkindsofclothwouldshowcaseexclusive angulardependency.

•Erosionchargewithrecognizetoattitudeofhaveanimpact onismostat30degreeandminimalat90degree.

•ErosionpricewithappreciatetoPressurewillincreaseas thepriceoferosionincreases.

•Fromtheanticipatedmechanismitisdeterminedthatthe erosionconductislegitimateforductilematerials.Henceour statementadditionallyfollowstheidenticalrule.

Havingcalculatedtheperfectattitudeofcontact,pressureof impingement and the distance of fall for an Mild Steel, Aluminium, Stainless Steel, we would now be in a role to predict the circumstance that have to be maintained to reduce wear. However it must be referred to that put on being distinctly precise to geometry, bodily properties, metallurgy and a host of different elements all our predictionswillpertaintothesamplesusedonly.Assuchit can't be generalized to all samples. This is one of the importantimpedimentstoputonstudies.Alsoasindicated putonmayadditionallyhappenduetoa rangeofmotives andmodesthenagainwewouldbeinaroletofindoutabout solely one mode i.e. erosion put on .Hence all our predicationswillbemadebeneaththeassumptionthatput onishappeningsolelyduetoerosionandnodifferentthing ormodeiscomingintoeffect.

[1] Effectoferodentpropertiesonerosionwearofductile typematerials

•ARTICLEWear,Volume261,Issues7-8,20 October2006,Pages914-921GirishR.Desale,Bhupendra K.GandhiandS.C.Jain

[2] Erosion wear behaviours of SiC/(W,Ti)C laminated ceramicnozzlesindrysandblastingprocesses •ARTICLE Materials Science and Engineering: A, In Press, Corrected Proof,Availableonline25September2006,

[3] Development and Characterization of Metal Matrix Composite using red mud and Industrial waste for wear resistantapplications

[4]Erosionwearmechanismsofcoal–water–slurry(CWS) ceramic nozzles in industry boilers • SHORT SURVEY MaterialsScienceandEngineering:A,Volume417,Issues12,15February2006,Pages1-7DengJianxin,DingZeliang andYuanDongling

[5]Nominalparticlesizeofmulti-sizedparticulateslurries forevaluationoferosionwearandeffectoffineparticles• ARTICLEWear,Volume257,Issues1-2,July2004,Pages7379BhupendraK.GandhiandSatishV.Borse

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

[6]Effectofannealingandchemicalstrengtheningonsoda limeglasserosionwearbysandblasting •ARTICLEJournal of the European Ceramic Society, Volume 23, Issue 2, February 2003, Pages 331-343 Chabane Bousbaa, Abderrahim Madjoubi, Mohamed Hamidouche and NourredineBouaouadja

[7]Levy,A.V.Theerosioncorrosionbehaviorofprotective coatings,Surf.andCoat.Techn.,v.36.p.387–406,1988

[8]MechanicalWearPredictionandPrevention,RaymondG Bayer

[8] Erosion wear behavior and model of abradable seal coating • ARTICLE Wear, Volume 252, Issues 1-2, January 2002,Pages9-15YiMaozhong,HuangBaiyunandHeJiawen

[9]FEManalysisoferosivewear•ARTICLEWear,Volume 250,Issues1-12,October2001,Pages779-784K.Shimizu,T. Noguchi,H.Seitoh,M.OkadaandY.Matsub

[10] Erosion- and wear-corrosion behavior of Fe–Mn–Al alloys in NaCl solution • ARTICLE Materials Science and Engineering A, Volume 292, Issue 1, 15 November 2000,Pages90-95Her-HsiungHuangandTung-HanChuang

[11]Erosivewearbehaviourofaluminiumbasedcomposites •ARTICLEMaterialsandDesign,Volume 18, Issues4-6, 1 December1997,Pages389-393Q.Fang,P.SidkyandM.G. Hocking

[12] Sand erosion of wear-resistant materials: Erosion in chokevalves•ARTICLEWear,Volumes186-187,Part1,July 1995,Pages179-188K.Haugen,O.Kvernvold,A.Ronoldand R.Sandber