International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

STRENGTHENING OF RC BEAMS USING GLASSFIBRE REINFORCED POLYMER SHEETS AND COMPARISON OF U WRAP AND 90 DEGREE STRIP WRAP.

Mohammed iiSuneer, Er iiRajeev iV.S, Er iiSajan iijos1PG Student, iiDept. iiof iiCivil iiEngineering, iiUniversal iiEngineering iiCollege, iThrissur iKerala

2Assistant iiProfessor, iiDept. iiof iiCivil iiEngineering, iiUniversal iiEngineering iiCollege, Thrissur. Kerala. 3Assistant Professor, Dept. of Civil Engineering, Universal Engineering College, Thrissur. Kerala ***

Abstract:

Strengthening iiof iireinforced iiconcrete iibeams iiwith iiexternally iibonded iifiber iireinforced iicomposites iiis iia iitechnique iithat iihas iibeen iideveloped iiin iirecent iiyears. iiHere iiin iithe iipresent iistudy iiGlass iiFiber iireinforced iipolymer iisheets iiare iiused iifor iifinding iibehavior iiof iibeams iistrengthened iiwith iicomposite iimaterials. iEight iibeams iiare iicasted, iitwo iibeams iias iicontrol iibeams. iResin iimortar iiwith iipromoter, iicatalyst, iiand iiaccelerator, iiis iiused iias iia iibinding iimaterials iiin iivarious iipatterns. iAfter ii24 iihours iiof iiwrapping iiand ii7 iidays iiair iicuring iibeams iiare iitested ii.U iiwrapping, iiBottom iiwrapping, ii45 iidegree iiU iiwrapping, ii90 iidegree iiU iiwrapping, iiCombination iiof iiBottom iiwrapping iiwith ii90 iidegree iiu iiwrapping iiare iitested iiin iistatic iithree iipoint iiloading iiframe iiset iiup iThe iitest iiresults iiwere iievaluated iiin iiterms iiof iiload iideflection iibehavior, iiultimate iiload iicarrying iicapacity, iiultimate iideflection, iicrack iipatterns iiand iiassociated iifailure iimodes.iThe iiresults iiobtained iiclearly iidemonstrate iithe iieffectiveness iiof iistrengthening iiof iiRC iibeams iiusing iiGlass iireinforced iipolymer iisheets. iiThe iibeams iitreated iiwith iiResin iimortar iiwith iiaccelerator, iicatalyst iiand iipromoter iiimproved iithe iistrength iiand iiload iicarrying iicapacity.

Keywords: iiGlass iiFiber iireinforced iiPolymer ii(GFRP), iiStrengthening , iiRetrofitting iiThree iiPoint iiLoading iiFrame, iiCatalyst, iiPromoter, iiand iiAccelerator, iiLoad iiCarrying iiCapacity, iiWrapping.

1. iiINTRODUCTION

Reinforced iiConcrete ii(RC) iistructures iihave iibeen iione iiof iithe iimajor iistructural iimaterials iifor iiover iia iicentury iiand iiare iistill iithe iimost iipopular iimaterial iifor iipublic iistructures iiall iiover iithe iiworld.Reinforced iiconcrete iibeams iiare iistructural iielements iidesigned iito iicarry iitransverse iiexternal iiloads.These iiloads iicauses iibending iimoment, iishear iiforces iiand iitorsion iiacross iitheir iilength iiin iisome iicases. iConcrete iiis iistrong iiin iicompressioniiandiiveryiiweakiiiniitension.Thus,iisteeliireinforcementiiusediitoiitakeiiupiitensileiistressesiiiniiRC iibeams. iiIn iirecent iiyears, iithe iifield iiof iiconcrete iistructure iistrengthening iihas iibecome iia iihot iipoint. iiAs iia iiresult,iitheiirelatediistrengtheningiitechniquesiiofiiconcreteiistructureiihaveiibeeniianiiimportantiiresearchiifield iiin iistructural iiengineering. iiThe iiuse iiof iicomposites iifor iistrengthening iiand iirepairing iiRC iistructures iihas iigained iiimportance iiin iicivil iiengineering. iiStrengthening iiof iireinforced iiconcrete iistructures iiwith iiexternally iibonded iifiber iireinforced iipolymer ii(FRP) iicomposites iiis iia iinewly iideveloped iitechnique iiin iirecent iiyears. iiGenerally,iiFRPiistrengthenediiRCiibeamsiiconsistsiiofiifouriimaterialsiiieiiconcrete,iisteeliibars,iiadhesives,iiand iiFRP iireinforcement. iiBenefits iiof iiFRP iicomposites iiinclude iilight iiweight, iihigh iistrength iiand iihigh iimodulus, iidurability iiand iiimpact iiresistance. iiFRP’s iistructural iiproperties iiare iiuseful iiin iiabsorbing iiseismic iior iiblast iienergy, iiand iithis iiproperty iilets iithe iimaterial iito iiact iias iia iipolymer iidamper iiat iiflooring iiarea iiand iiconnectioniizone.iiTheseiiareiisuccessfullyiiimplementediitoiienhanceiitheiiperformanceiiofiistructuraliielements iiin iiflexure, iiaxial, iishear, iiand iitorsion. iiThe iicommonly iiused iiFRP iihas iisome iidrawbacks iilike iidebonding iiof iiFRP iifrom iithe iiconcrete, iipoor iibehaviour iiof iiepoxy iiat iihigh iitemperature, iiinability iito iiapply iion iiwet iisurface, iirelatively iihigh iicost, iietc. iiand iithese iican iibe iisolved iiby iiusing iiGlass, iifibers, iiBasalt iifiber, iiNylons iietc.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

2. iMATERIALS iiUSED

2.1 iiCONCRETE

ConcreteiiisiiaiiconstructioniimaterialiiofiiPortlandiicementiiandiiwateriicombinediiwithiisand,iigravel,iicrushed iistone, iior iiother iiinert iimaterial iisuch iias iiexpanded iislag iior iivermiculite. iiThe iicement iiand iiwater iiform iia iipaste iiwhich iihardens iiby iichemical iireaction iiinto iia iistrong, iistone- iilike iimass. The iiquality iiof iithe iipaste iiformed iiby iithe iicement iiand iiwater iilargely iidetermines iithe iicharacter iiof iithe iiconcrete. iiProportioning iiof iitheiiingredientsiiofiiconcreteiiisiireferrediitoiiasiidesigningiitheiimixture,iiandiiforiimostiistructuraliiworkiithe iiconcreteiiisiidesignediiCompressiveiistrengthsiiofii15iitoii35iiMPa.PozzolonaiiPortlandiicementiiwilliibeiiused. iiOrdinary iiclean iiportable iiwater iifree iifrom iisuspended iiparticles iiand iichemicals iiwill iibe iiused iifor iiboth iimixingiiandiicuringiiofiiconcrete.

2.2 iiREINFORCEMENT ii

The iilongitudinal iireinforcements iiused iiwere iihigh- iiyield iistrength iideformed iibars iiof ii10mm iidiameter iiand ii10 iimm iidiameter iiwere iiused iias iihanger iibars. ii. iiThe iistirrups iiwere iimade iifrom iimild iisteel iibars iiwith ii8mmiidiameter.

2.3 iiGLASS iiFIBRE iiREINFORCED iiSHEETS

Glass iifiber iireinforced iipolymer ii(GFRP) iiis iia iicomposite iiconstruction iimaterial iiresulting iifrom iithe iicombinationiiofiiunsaturatediipolyesteriibasediiresiniiusediiasiiaiibinderiiwithiiglassiifiber.Theiifibersiimayiibe iirandomly iiarranged, iiflattened iiinto iia iisheet ii(called iia iichopped iistrand iimat) These iiare iifibers iicommonly iiused iiin iithe iinaval iiand iiindustrial iifields iito iiproduce iicomposites iiof iimedium- iihigh iiperformance.Their iipeculiariicharacteristiciiisiihighiistrength.iGlassiiisiimadeiiupiiofiisiliconii(SiO2)iiwithiiiiiitetrahedraliistructure ii(SiO4).

Figii1.1:iiGlassiiFiberiiSheet

Table1.1:PropertiesofGlassfiberreinforcedpolymersheets.

Materialiicharacteristics

Glassiifiberiireinforcediipolymeriisheets

Densityii(g/cc) 2.60

TensileiiStrengthii(MPa) 2050

ElasticiiModulus 85

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

Theiimajoriiadvantagesiiofiiglassiifibersiiare:

Cheaperiiandiimoreiiflexibleiithaniicarboniifiber

Strongeriithaniimanyiimetalsiibyiiweight

Non-magneticiiandiinon-conductive

Highlyiiflexibleiiandiicaniibeiimouldediiintoiicomplexiishapes

Chemicallyiiinertiiunderiimanyiicircumstances

Inherentiistrength

Weather-resistantiifinish

Thermaliiresistant

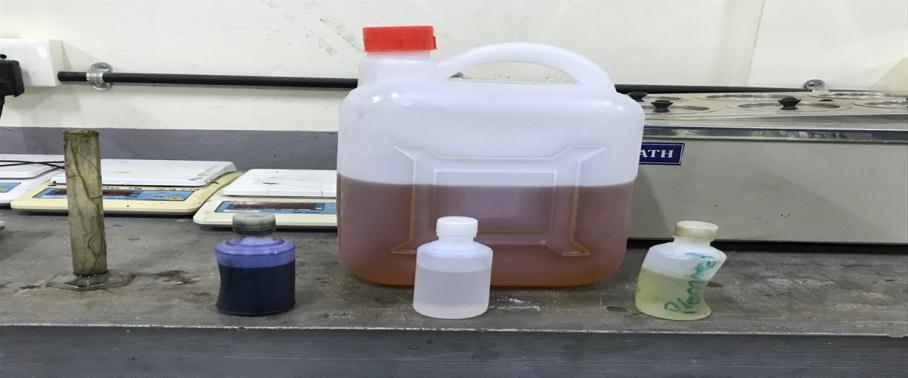

2.2 iiMORTAR iiRESIN

Epoxy iiMortar iiis iia iipolymer iibased iibonding iipaste iithat iicomprises iimaterials iisuch iias iiepoxy iiresinsii(Vinyl iiEster),iihardeneriiCobaltiiOcatate),iicatalystii(MEKP- KetoneiiPeroxide)iiandiiPromoter.

iiIt iiis iiused iito iibind iithe iiglass iifiber iisheets iiwith iiconcrete iispecimens iiin iithe iiform iiof iicoatings iifor iiresisting iidebonding iifailures. The iicompressive iistrength iiof iiresin iimortar iiis iilower iithan iiordinary iiPortland iicement.iiTheiitoughnessiiofiiepoxyiiresiniiisiibetteriithaniiordinaryiiPortlandiicement.

iiiiiiiiiiiiiiiiiiiiiiiiiiiiii

Fig1.2.1:iiResiniimortariiwithiicatalyst,iihardeneriiandiicatalyst

3. iiRETROFITTING iiOF iiBEAMS

Beforeiibondingiitheiicompositeiifabriciiontoiitheiiconcreteiisurface,iitheiirequirediiregioniiofiiconcreteiisurface iiwas iimade iirough iiusing iia iicoarse iisand iipaper iitexture iiand iicleaned iiwith iian iiair iiblower iito iiremove iiall iidirt iiand iidebris. iiThen iiapply iicement iimortar iion iicracked iisurfaces iito iifill iicracks iiformed iidue iito iiaxial iiloading iiOnce iithe iisurface iiwas iiprepared iito iithe iirequired iistandard, iithe iiepoxy iiresin iiwas iimixed. iMixing iiwas iicarried iiout iiin iia iiplastic iicontainer iiand iiwas iicontinued iiuntil iithe iimixture iiwas iiin iiuniform iicolour. Wheniithis iiwas iicompleted iiandiitheiifabrics iihad iibeeniicutiitoiisize,iitheiiepoxyiiresiniiwas iiapplied iitoiithe iiconcrete iisurface iThe iicomposite iifabric iiwas iithen iiplaced iion iitop iiof iiepoxy iiresin iicoating iiand iithe iiresin iiwas iisqueezed iithrough iithe iiroving iiof iithe iifabric. iiThis iioperation iiwas iicarried iiout iiat iiroom iitemperature.iConcrete iibeams iistrengthened iiwith iiglass iifiber iifabric iiwere iicured iifor ii48 iihours iiat iiroom iitemperaturebeforeiitesting.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

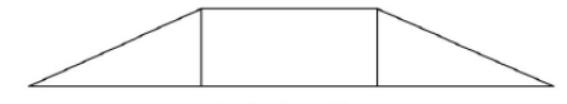

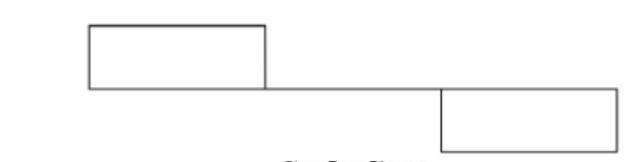

4. iTWO iiPOINT iiLOADING

In iitwo iipoint iiloading iithe iiload iiis iitransmitted iithrough iia iiload iicell iiand iispherical iiseating iion iito iia iispreader iibeam. iiThis iibeam iibears iion iirollers iiseated iion iisteel iiplates iibedded iion iithe iitest iimember iiwith iimortar, iihigh- iistrength iiplaster iior iisome iisimilar iispreader iiplates. The iiloading iiframe iimust iibe iicapable iiof iicarrying iitheiiexpected iitest iiloads iiwithoutiisignificant iidistortion. iiEaseiiofiiaccess iitoiithe iimiddleiithirdiifor

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

iicrack iiobservations, iideflection iireadings iiand iipossibly iiload iicorresponding iito iieach iideflection iiis iinoted. iiCrackiipatternsiiareiimarkediiwithiidifferentiicolouriipensiiwheniiformediiatiifailure,

Figii4.1:iiTwoiipointiiloadingiiofiibeams

Figii4.2:iiSheariiforceiidiagram

Figii4.3:iiBendingiimomentiidiagram

Figii4.4:iiExperimentaliisetiiupiiforiibeams

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

4 iiPROJECT iiPROCEDURES

4.1 iiCube iicompressive iistrength

Casting iiof iiconcrete iispecimens iiis iidone iias iiper iiIndian iiStandards. iiM20 iimix iiis iichosen iiand iidone iimix iidesign. iiMix iiratio iiobtained iiis ii0.47: ii1: ii1.67: ii2.79. iiCompressive iistrength iiof iiconcrete iiis iidetermined iiby iimakingiicubes iiofiisizeii150 iimmiixii150iimm. iiCubes iiareiimade iiby iifinding iioutiithe iirequired iiamount iiof iiquantities iiof iimaterials iiusing iimix iiproportion. iiMixing iiof iiconcrete iiis iicarried iiout iimanually. iiCompressive iistrength iiis iithe iicapacity iiof iia iimaterial iior iithe iiability iiof iia iistructure iito iiwithstand iiload iitending iito iireduce iisize. iiTotally ii15 iicubes iiwere iicasted iifor iidetermination iiof iicompressive iistrength. iiAfter ii24 iihours iitheiimouldiiwereiidemouldediiandiisubjectediitoiiwateriicuring iiBeforeiitestingiitheiicubesiiwereiidriediiforii2 iihours. iiAll iithe iicubes iiwere iitested iiin iisaturated iiconditions iiafter iiwiping iiout iisurface iimoisture. iiThe iiload iiwas iiapplied iiwithout iishock iiand iiincreased iicontinuously iiuntil iithe iiresistance iiof iithe iispecimen iito iithe iiincreasingiiloadiibreaksiidowniiandiinoiigreateriiloadiicaniibeiisustained.iiTheiimaximumiiloadiiappliediitoiithe iispecimeniiwasiitheniirecorded;iithreeiicubesiieachiiwereiitestediiatiitheiiageii7iidaysiiandii28iidaysiiofiicuring iiforiiconcreteiicompressioniitesting.

Figii4.1.1:iiUnmouldediispecimeniiforiitesting

Fig4.1.2:Compressiontestforcubespecimen

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

Tableii4.1.1:iiCompressioniitestiivalues

CubeiiNo. C/Sii(mm2) 7iidaysiiStrength ii(N/mm2) 28iidaysiiStrength ii(N/mm2)

Cubeii1 150iixii150 14.66 28.88

Cubeii2 150iixii150 15.11 28.88

Cubeii3 150iixii150 15.12 30.22

Average 14.96 29.47

4.2 iiTESTING iiOF iiCYLLINDERS

Casting iiof iiconcrete iispecimens iiis iidone iias iiper iiIndian iiStandards. iiM20 iimix iiis iichosen iiand iidone iimix iidesign.iiMixiiratioiiobtainediiisii0.47:ii1:ii1.34:ii2.29.iiCompressiveiistrengthiiofiicylindersiiofiisizeii150iimmiix ii300 iimm iix ii150 iimm iiis iidetermined. iiCylinders iiare iimade iiby iifinding iiout iithe iirequired iiamount iiof iiquantitiesiiofiimaterialsiiusingiimixiiproportion.iiMixingiiofiiconcreteiiisiicarriediioutiimanually.ii

First iithe iicoarse iiaggregate iiand iifine iiaggregate iiare iimixed. iiAfter iithat iithe iicement iiis iipoured iiinto iithe iimixer. iiRequired iiamount iiof iiwater iiis iiadded. iiAnd iithe iiresulting iiconcrete iiwith iiuniform iiappearance iiis iitransferrediitoiimoulds.iiIniiassemblingiitheiimouldiiforiiuse,iitheiijointsiibetweeniitheiisectionsiiofiimouldiiis iithinly iicoated iiwith iimould iioil iiand iia iisimilar iicoating iiof iimould iioil iiis iiapplied iibetween iithe iicontact iisurfaces iiofiitheiibottom iiofiitheiimouldiiandiithe iibaseiiplateiiin iiorderiito iiensureiithat iino iiwater iiescapes iiduring iithe iifilling. iiTheiiinterior iisurfaces iiof iithe iiassembled iimould iiare iithinly iicoatediiwith iimould iioil iito iiprevent iiadhesion iiof iithe iiconcrete.iAfter ii24 iihours iiof iiair iicuring iithe iispecimens iiare iitransferred iito iithe iicuringiitank.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

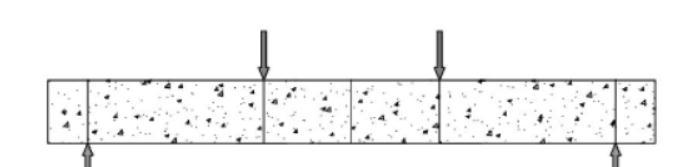

4.3 iiSPECIMEN iiPREPERATION iiAND iiTESTING

Formiwork iimakingiiuse iiofiiplywoodiiwas iiprepared iiforiitheiibeamiiofiisizeii1700mmiix150iimmiix i200mm iisize.iiAiitotaliiofii8iibeamsiiwereiicastiiwhereiiinii2iiwereiicontrollediispecimensiiandii2iiwereiisubjectediito iiU-wrappingiiandiiotherii2iispecimensiiwereiisubjectediitoii90iidegreeiistripiiwrappingiiandii2iiwereiisubjected iito ii45 iidegree iistrip iiwrapping iiEach iiof iithe iispecimens iiwere iisingly iireinforced iiand iiunder iireinforced iisection. iiWithout iidelay iiafter iithe iibeam iicast, iithe iibeams iiwere iicovered iiwith iiplastic iisheet iito iiminimize iithe iievaporation iiof iiwater iifrom iithe iisurface iiof iithe iibeam iispecimen. iiAfter ii24hours, iithe iisides iiof iithe iiformwork iiwere iiremoved iiand iithe iibeams iiwere iilowered iiinto iia iicuring iitank iifor ii28 iidays, iiafter iiwhich iitheiibeamsiiwereiileftiialoneiiuntiliitheiitimeiiofiitest.ii

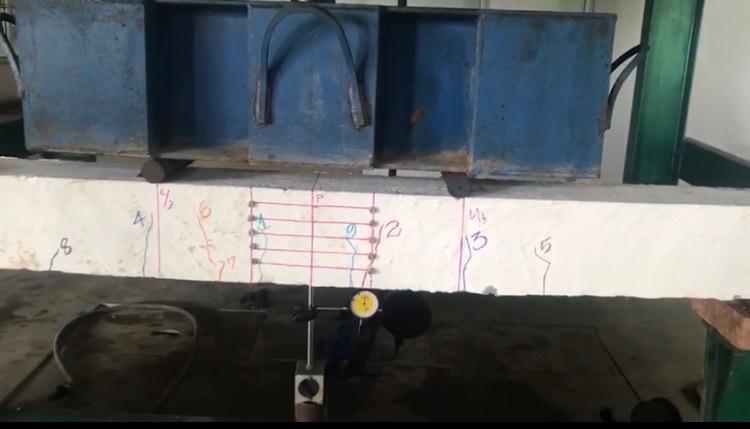

Beforeiitesting,iibeamsiiwereiiwhitewashediiandiitheniitheiisurfaceiiwasiirubbediiwithiisandiipaperiiandiitested iiin iitwo iipoints iiloading iiwith iia iimaximum iicapacity iiof ii30 iitons iiThe iibeam iiwas iiplaced iiover iithe iitwo iisteel iirollers iibearings iileaving75 iimm iifrom iithe iiboth iisides iiof iibeam. iiRest iiof iithe iipart iiwas iiequally iidividediiiniitoiithreeiiequaliiparts.iiLoadiiwasiiappliediibyiiloadingiicelliiofii1000iikN.iiTwoiidialiigaugesiiwere iiused iifor iirecording iideflection. iiOne iidial iigauge iiwas iiplaced iiat iicenter iiand iiother iiwas iiplaced iiunder iithe iioneiiofiitheiipointiiloadiitoiinoteiitheiideflection.iiBeamsiiwereiitestediibeforeiiandiiafteriiretrofitting.iiFirstiiof iialliicontroliibeamiiwasiitestediiwithiifulliiloadiitoiigetiitheiimaximumiicollapseiiload,iitheniiafteriiotheriibeams iiwereiitestediiwithiiloadiiofii75%iiofiicollapseiiload.

Figii4.3.1:iiTestingiiofiibeamsiibeforeiiretrofittingiiandiiinitialiicracksiiareiimarked

4.4 iiWRAPPING iiPATTERNS ii

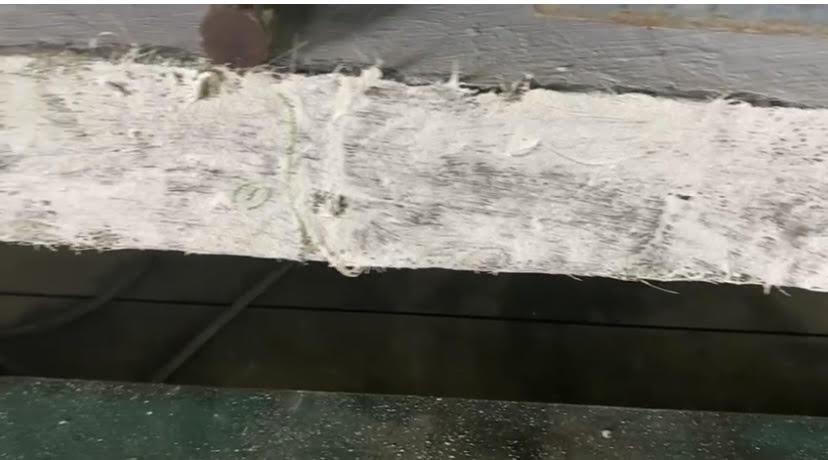

Totallyiiweiihaveiisixiibeamsiifromiiwhichii2iiforiiUiiwrapping,ii2iiforii45iidegreeiistripiiwrappingiiandii2iifor ii90 iidegree iistrip iiwrapping. iiHere iiU iiwrapping iiand ii90 iidegree iistrip iiwrapping iiare iiconsidered iifor iithe iistudy.90 iidegree iiand iiU iiwrapping iiare iithe iitwo iipatterns iiof iiwrapping iibeams iiusing iiglass iifiber iisheets. iiFor iithe ii90 iidegree iistrip, iiwrapping iithe iiglass iifiber iisheet iiis iicut iiin iito iistrips iiof ii5mm iipieces iiand iipasted iioniitheiisurfaceiiofiieffectiveiilength iiofiicollapsed iibeamiiinii5mm iiofiispacingiitoiisaveiithe iicost iiof iimaterials.iiItiirequiresiionlyii0.36iisquareiimeteriiofiiglassiifiberiitoiiwrapiioneiibeamiispecimen.

Strips iiare iipasted iion iithe iibeam iiusing iiresin iimortar iiby iiflat iiblade iiin ii90 iidegree iiU iishaped iiexcluding iitopiisurfaceiiandiikeepiiwrappediibeamsiiiniiroomiitemperatureiiforii48iihoursiiandiitested.iiForiiUiiwrapping iiglass iifiber iisheet iiis iicut iiin iito iishape iiof iiU iiand iiis iipasted iion iithree iisides iiof iieffective iilength iiof iicollapsed iibeam iiusing iiresin iimortar iias iibonding iiagent. iiFor iiU iiwrapped iibeam iiit iirequires iione iisquare iimeter iiof iiglass iifiber iito iiwrap iithe iibeam iispecimen iiAfter ii48 iihours iikeeping iispecimens iiat iiroom iitemperature,iitwoiispecimensiiofiiUiiwrappediiandiitwoiispecimensiiofii90iidegreeiistripiiwrappediibeamsiiare iitestediiiniitwoiipointiiloadingiiframeiiandiicomparediitheiiresultsiibyiitakingiibestiiofiitwoiireadings.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

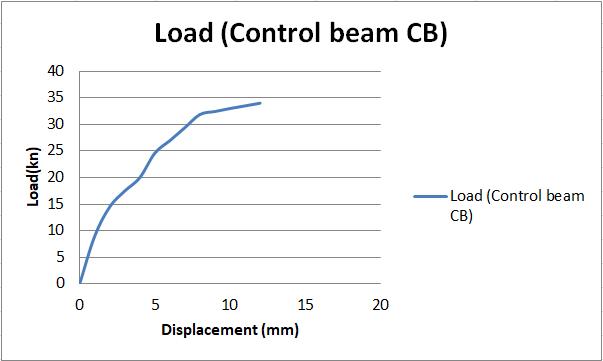

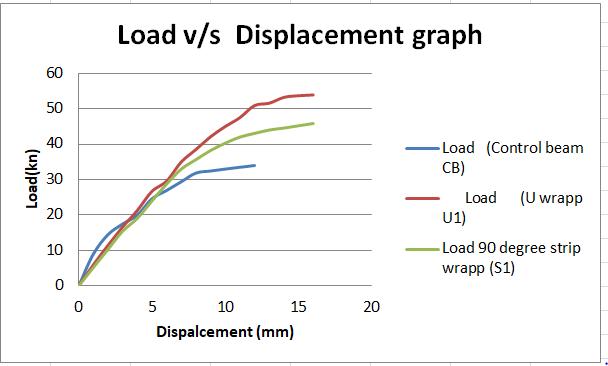

Figii4.5.1:iiLoadiiv/siidispalcementiigraphiiofiicontroliibeamii(CB)

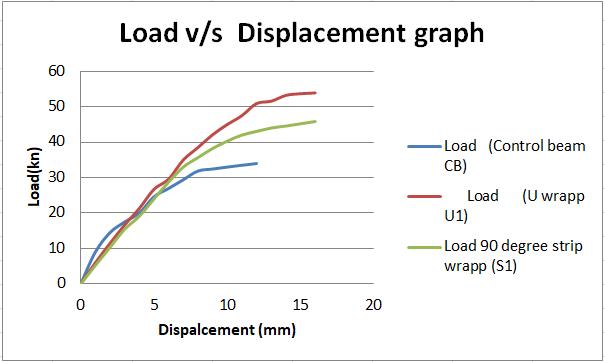

Figii4.5.2:iiLoadiiv/siideflectioniigraphiiofiiUiiwrapiibeamii(U1)iiv/sii90iidegreeiistripiiwrapiibeamii(S1)

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

Figii4.5.3:iiLoadiiv/siidisplacementiigraphiiofiiControliibeamiiCBiiv/siiUiiwrapiibeamii(U1)iiv/sii90iidegree iistripiiwrapiibeamii(S1)

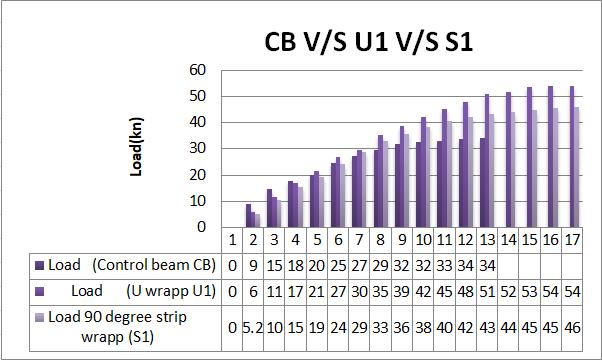

4.6: iiCOMPARITIVE iiSTUDY

Here iiwe iitaken iithree iibeams iifor iithe iicomparative iistudy.1.non iiretrofitted iicontrol iibeam ii(CB) ii2.retrofitted iibeam iibyiiUiiwrapii(U1) ii3.retrofitted iibeamiibyii90iidegreeiiwrapii(S1).Control iibeamiiis iitheiimotheriibeam iiwhichiiisiifullyiicollapsediiwithiiaiiultimateiiloadiicapacityiiofii34iikNiiandiiotheriitwoiibeamsiiareiiloadediiby ii75 iipercentage iiof iicollapsed i.Here iiwe iitaken iibest iione iiof iitwo iireadings iion iieach iiwrapping iistyles. iiAfter iiretrofitting iione iiof iipartially iiloaded iibeam iispecimen iiby iiU iiwrap iiusing iiglass iifiber iion iieffective iilength iiexcluding iitop iilayer iiwe iiget iimaximum iiload iicarrying iicapacity iiof ii54 iikN iiand ii90 iidegree iistrip iiwrapped iibeamiibyii46iikN.

Tableii4.6.1:iiLoadiicarryingiicapacityiiofiiCB,iiU1&S1

SPECIMEN LOADiiCARRYINGiiCAPACITY(kN)

Controliibeamii(CB) 34

Beamii1ii(U1) 54

Beamii2ii(S1) 46

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

Figii4.6.1:iiBariigraphiiofiiCB,iiU1&iiS1

5. iCONCLUSION ii

A iitotal iiof iisix iibeams iiwere iicast iiout iiof iiwhich iitwo iiwere iicontrolled iibeams iiand iitwo iiwere iiretrofitted iior iiwrapped iiby iiU iiwrap iiand iithe iiother iitwo iiby ii90iidegree iistripiiand iitaken iibestiivalue iiofiitwo iireadings iiAfter iiapplying ii75% iiof iithe iiUltimate iiLoad iiNo iihorizontal iicracks iiwere iiobserved iiat iithe iilevel iiof iithe iireinforcement, iiwhich iiindicated iithat iithere iiwere iino iioccurrences iiof iibond iifailure. iiOther iiimportant iiconclusions iiareiiasiifollows:

The iiload iicarrying iicapacity iiobtained iitwo iipatterns iiare iigood iiand iican iibe iiconsidered iias iigood iisolution iifor iistrengthening iiof iiRC iicollapsediibeams.

There is iiconsiderably iiincrease iiin iiload iicarrying iicapacity iiof iiU iiwrapped iibeam iiby ii20% ii iicompared iiand ii90 iidegree iiwrapped iibeam iiby ii12ii%iicomparediitoiicontroliibeam.

The iiload iicarrying iicapacity iiof iibeams iiwrapped iiby iiU iiwrap iiis iilarger ii(54kN) iias iicompared iito iithe ii90 iidegree iiwrapped iibeam iifor iistrengtheningiioriiretrofitting.AsiieconomicaliipointiiofiiviewiieachiiUiiwrappediibeamiicoversiianiiarea iiof ii0.36 iimeter iiglass iifiber iimaterial iiis iivery iilarge iias iicompared iiwith ii90 iidegree iiU iiwrapped iibeam.

So iiit iiis iiexperimentally iiproved iithat ii, iiif iiU iiwrapped iibeam iihave iiload iicarrying iicapacity iiof ii54 iikN iiby iiconsuming iione iisquare iimeter iiglass iifiberiiandii90 iidegreeiiwrappediibeam iiofii46iikN iiby iiconsuming iiveryiiless iiarea iiofiimaterial iiieii0.36,ii90iidegreeiiwrapiipatterniiisiigoodiiandiieconomicaliiforiistrengtheningiiofiicollapsediibeam.

Control iibeam iiloses iiinitial iistiffness iiwhile iicollapsed, iibut iiwe iiwrapped iior iiretrofitted iicollapsed iibeams iiit iigains iisome iistiffness iiand iidhowsiiductilityiisufficientiibehaviouriiasiicomparediitoiicontroliibeam

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

ACKNOWLEDGEMENTS

TheiiauthorsiiwouldiilikeiitoiiacknowledgeiiGodiiAlmightyiiforiiHisiieternaliigraceiiandiguidanceiiasiiwelliiEr iiNithiniiMohan.,iPHDiiScholar,IITiiBombayandMrsAnimaP,AssociateProfessor,UniversalEngineeringCollege, Thrissur.Kerala,iiforiiallamazingiguidancesiiandiisupport.

REFERENCES

1.Grace,iiN.iiF.,iiA.iiK.iiSoliman,iiG.iiAbdel-Sayed,iiandiiK.R.iiSalehii(1999a),ii"StrengtheningiiiiiiiiofiiContinuous iiBeams iiUsing iiFiber iiReinforced iiPolymer iiLaminates," iiProceedings iiof iithe iiFourth iiInternational iiSymposium iioniiFiberiiReinforcediiPolymeriiReinforcementiiforiiReinforcediiConcreteiiStructures.

2.Bazaa,iiI.iiM.,iiM.iiMissihoun,iiandiiP.iiLabossierii(1996),ii"StrengtheningiiofiiReinforcediiConcreteiiBeamsiiwith iiCFRPiiSheets”.

3.Banthia, iiN., ii“Fiber iiReinforced iiPolymers iiin iiConcrete iiConstruction iiand iiAdvanced iiRepair iiTechnologies”, iiProfessor iiand iidistinguished iiUniversity iiScholar, iiDepartment iiof iiCivil iiEngineering, iiUniversity iiof iiBritish iiColumbia,ii2324iiMainiiMall,iiVancouver,iiBC,iiCanada,iiV6Tii1Z4

4.Huang iiYue-lin, iiHUNG iiChien-hsing, iiYEN iiTsong, iiWU iiJong-hwei iiand iiLIN iiYiching. ii2005. IiStrengthening iiReinforced iiConcrete iiBeams iiusing iiPrestressed iiGlass iiFiber-Reinforced iiPolymer-Part iiI: iiExperimental iiStudy. iiJournaliiofiiZhejiangiiUniversityiiScience.

5.Chajes,iiM.iiJ.,iiT.iiAiiThomson,iiJR,iiandiiB.iiTarantinoii(1995),ii“ReinforcementiiofiiConcreteiiStructuresiiUsing iiExternallyiiBondediiCompositeiiMaterial”.

6. Obadiah iiYT, iiSusanne iiH, iiOla iiD, iiGhazi iiA, iiYahia iiA, ii“Retrofitting iiof iireinforced iiconcrete iibeams iiusing iicompositeiilaminates”,iiConstructioniiandiiBuildingiiMaterials”.

7. Zhang, iiA., iiJin, iW., iiand iiLi, iiG. ii(2006), ii“Behaviour iiof iipreloaded iiRC iibeams iistrengthened iiwith iiCFRP iilaminates”,iiJournaliiofiiZhejiangiiUniversityiiSCIENCEiiA

8. Saadat imanesh, iiH., Ehsani, iiM. iiR., iiLi iiM. iiW. ii(1994), ii“Strength iiand iiductility iiof iiconcrete iicolumns iiexternallyiireinforcediiwithiifibreiistraps”,iiACIiiStructuraliiJournal