International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

1PG Student (MTech. Design Eng.), Department of Mechanical Engineering, SSGB College of Engineering & Technology, Bhusawal, Maharashtra.

2Principal (Professor), Department of Mechanical Engineering, SSGB College of Engineering & Technology, Bhusawal, Maharashtra. *** -

Abstract - As per the recent trends in designing a light weight and more power output equipment’s like compressor, automobile engines, aircrafts etc. are required which leads to excessive vibration on the system it can be a serious problem if resonance is occurs. The paper is intended to study and analyze the performance of composite isolators to minimize the vibration of air compressor. The composites of rubber, felt and cork are studied and analyzed. Rubber shows a least transmissibility whereas cork shows highest. From analysis it is seen that it is possible to enhance vibration characteristics by combining rubber with cork or felt.

Key Words: Compositeisolator,isolationtransmissibility

Theunwantedmotionsofthesystemarealwaysanuisance. Oneofthesimplestmeanstoreducethevibrationistouse thepadsofrubberfelt,corkandothervibrationabsorbing material.Thesematerialsarewidelyusedforthispurpose. However,thisstudyproposesthesandwich(composite)use ofthesematerialstocombinetheadvantageofthematerials thatcanbeobtainediftheyhavebeenusedseparately.

The purpose of this project is to determine the vibration causedbyacompressorandthenapplyingpassivecomposite vibrationisolatorstoreducethetransmissibilityi.e.,vibration transmittedtothebase.Thecombinationsofrubber,feltand cork have been used as isolators to reduce the vibration transmittedtothebaseofcompressor.Thevibrationwithout isolation is measured and then again measured by using isolator. The ratio gives transmissibility theoretically. For theoreticalanalysisthevalueofstiffness,dampingratioand massplaysamajorrolewhiletheaccelerationisdetermined experimentally by using FFT analyzer with and without isolator. In numerical simulation the amplitude ratios are comparedandthetransmissibilityisdetermined.

R. A. Ibrahim presented a paper “Recent advances in nonlinearpassivevibrationisolators”.Thispaperpostulatesa comprehensive assessment of recent developments of nonlinearisolatorsin theabsence ofactivecontrol means.

They are does not deal with other means of linear or nonlinear vibration absorbers. It is the basic concept and features of nonlinear isolators and inherent nonlinear phenomena. Specific types of nonlinear isolators are then discussed,includingultra-low-frequencyisolators.Invertical vibrationisolation,theEulerspringisolatorisbasedonthe postbucklingdynamiccharacteristicsofthecolumnelastic andaxialstiffness.Exactandapproximateanalysesofaxial stiffness of the post-buckled Euler beam are outlined. Nonlinearvisco-elasticandcompositematerialsprings,and smartmaterialelementsaredescribedintermsofmaterial mechanical characteristics and the dependence of their transmissibility on temperature and excitation amplitude. Thearticleisclosedbyconclusions,whichhighlightresolved andunresolvedproblemsandrecommendationsforfuture researchdirections.[1]

Chen Yang presented a preview study named “Study of Whole-spacecraft Vibration Isolators Based on Reliability Method”. In this study they said that, a method for whole spacecraftvibrationisolatordesignisstudiedbytheauthor. The WSVI stiffness problem and response problems are discussed. On the basis of the results computed with reliabilitytheoryandthedataobtainedfromexperiment,the controlmethodofWSVIstiffnessandthecouplingproblem are studied. The VIE problem is also discussed. From the reliability aspect, the NF of WSVI can be controlled over a large domain to avoid the possibility of spacecraft being resonantwiththelaunchvehicle.TheeffectofNFCandthe reliabilityofvibrationisolationcansatisfydifferentlaunching requirements. In the first part, the stiffness feature of the WSVI is studied with reliability analysis and experimental data.Inthesecondpart,theproblemsinducedbystiffness featurearediscussed.Thesimulatedandexperimentaldata show that the transmissibility, which is coupled with stiffness,canbereducedbyattachingthevibrationisolator betweenthespacecraftandthelaunchvehicle.[2]

Vibrationisolationofasystemmeanstoreducethevibration ofthesystembyusingsuitablemeansofisolatorsbetween the system to be isolated and the exciter or the source of vibration.Ifweconsideronlytheverticalmotion,itcanbe describedmathematicallybyasingledegreeoffreedom.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

mx+cx+kx=F(t) (1)

Where: m=massofsystem k=stiffness c=viscousdamping x(t)=verticaldisplacement F(t)=excitationforce

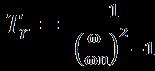

Ifweareneglectdamping,theverticalmotionofthesystem, x(t)canexpresstobe:

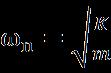

Where: (2)

Thesystemhasanaturalorresonantfrequency,atwhich itwillexhibitlargeamplitudeofmotion,forasmallinput force.InunitsofHz,thisfrequency, fnis: (3)

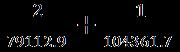

ForSinglelayerofRubber: Displacementfor5Kgis0.62mm. KR =5/0.62=8.06Kg/mm

∴ KR =8.06x9.81=79.1129N/mm.

∴ KR =79.1129x1000=79112.9N/m.

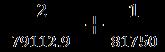

ForSinglelayerofFelt: Displacementfor5Kgis0.6mm. KF =81.750x1000=81750N/m.

ForSinglelayerofCork: Displacementfor5Kgis0.47mm. KC =104.3617x1000=104361.7N/m. Usingtheabovecalculation,thevaluesofstiffnessare calculated.

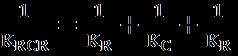

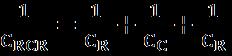

1.Rubber-Rubber-Rubber(RRR) = = =

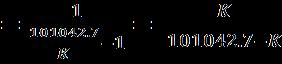

InunitsofRPM(revolutionsperminute),thecritical frequencyis: (4)

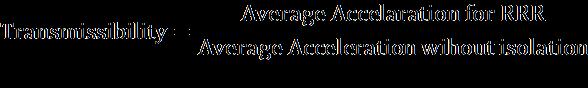

Theforcetransmittedtotheflooris: F = kx

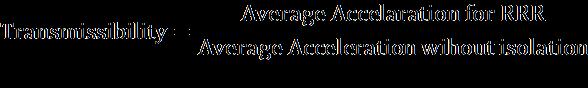

Theratiooftransmittedforcetotheinputforceiscalled transmissibility,T (5)

Where:

=ForceTransmittedtothebase

=ExcitationForce.

Thissameequationcanbeusedtocalculatetheresponse ofamachine X todisplacementofthefoundation, Y.

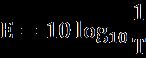

Theeffectivenessoftheisolator,expressedindBis: (6)

Theeffectivenessoftheisolator,expressedinpercentis:

%Isolation=(1-T)*100

A.CalculationofStiffness(K)

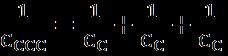

2.Felt-Felt-Felt(FFF) = = =

3.Cork-Cork-Cork(CCC) = = =

4.Rubber-Felt-Rubber(RFR) = = =

5.Rubber-Cork-Rubber(RCR) = = =

B.CalculationofDampingCo-Efficient(C)

Dampingratio(ℇ)ofmaterialsis: Rubber-0.075;Felt–0.06;Cork–0.06

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

ℇ=C/CC CC= C=ℇxCC

ForRubber

CR =ℇR xCCR

CR =0.075x

CR =266.83Ns/m.

ForFelt

CF =ℇF xCCF

CR =0.06x

CR =216.99≈217Ns/m.

ForCork CC =ℇC xCCC CC =0.06x

CC =245.17Ns/m.

1.Rubber-Rubber-Rubber(RRR) = = = 2.Felt-Felt-Felt(FFF) = = = 3.Cork-Cork-Cork(CCC) = = = 4.Rubber-Felt-Rubber(RFR) = = = ..

5.Rubber-Cork-Rubber(RCR) = = =

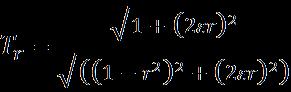

C.CalculationofTransmissibilitywithoutDampingEffect:

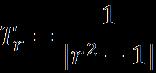

Thetransmissibilityofasystemwithoutdampingeffectis givenbytheequation: (7)

Wherer=ω/ωn ω=2πN/60=2πx480/60=50.26rad/s (m=40Kg=massoftestrig)

1.Rubber-Rubber-Rubber(RRR) K=26370.96N/m =0.3531

Similarly,thecalculatedtransmissibilityofallabovethe combinations.

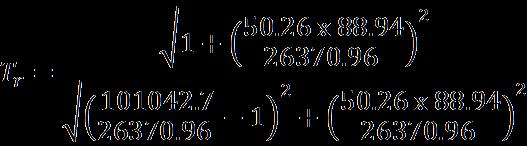

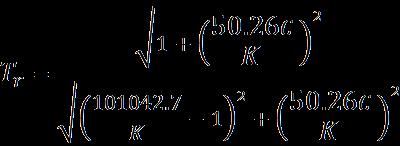

D.CalculationofTransmissibilitywithDampingEffect: Thetransmissibilityofasystemwithoutdampingeffectis givenbytheequation: (8)

1.Rubber-Rubber-Rubber(RRR) K=26370.96N/m,C=88.94Ns/m 0.3574

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Similarly,thecalculatedtransmissibilityofallabovethe combinations.

Thevaluesoftransmissibilityforthecompositesare showninthefollowingtable:

Mat erial

r= (ω/ ωn)

K (N/mm)

C (Ns/ m)

RRR 1.9 26370.9 88.94 0.3531 0.3574

FFF 1.9 27250.0 72.33 0.3692 0.3720

CCC 1.7 34787.2 81.72 0.5250 0.5276

RFR 1.9 26657.6 82.62 0.3583 0.3621

RCR 1.8 28684.2 86.39 0.3964 0.4002

Table.1.TheoreticalvalueofTransmissibility

ThecompositeofRubber,Felt,Corkandmaterialarehaving the low natural frequency for high loading and by these property vibrations are absorbed by the material. For the sakeofcomparingthefrequencyofpad,experimentalresults have to be checking. For that setup of unbalanced reciprocating mechanism is made with motor and belt transmissionsystem.ForexperimentationFFTanalyzeris use. The amount of vibration that machine is producing withoutanytypeisolationpad,andbyusingpadsisbeing calculatebyprovidingthesignalreceivingsensoratthetop of the base plate and at the bottom of the isolator for all layers.

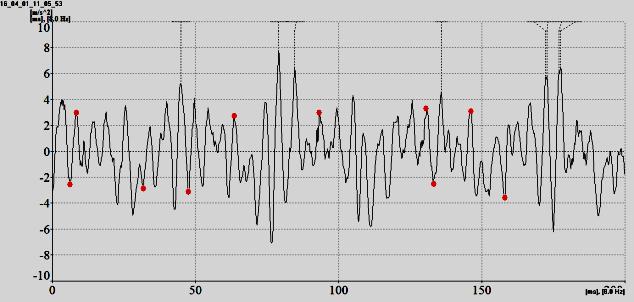

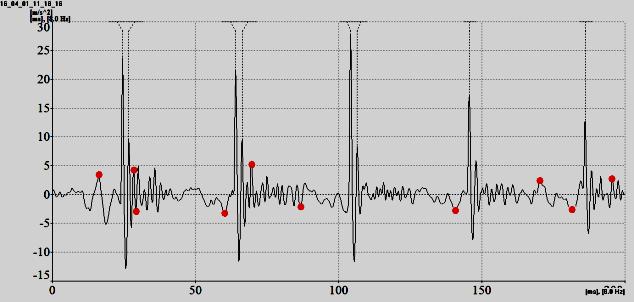

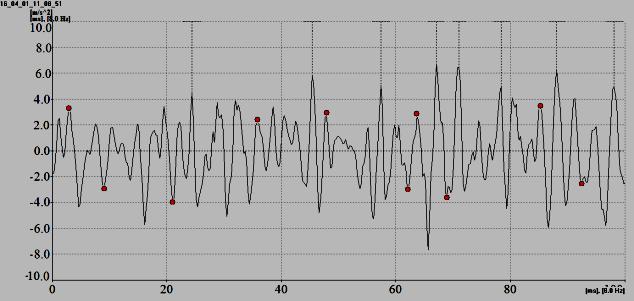

1.AccelerationPlotwithoutisolation.

Graph.1.AccelerationPlotwithoutIsolation.

Points 1 2 3 4 5 Positive Values 10 8 4 10 11 Negative Values 8 7 6 10 11

Table.2.AccelerationPointswithoutIsolation

AverageAccelerationwithoutisolation=85/10=8.5m/s2

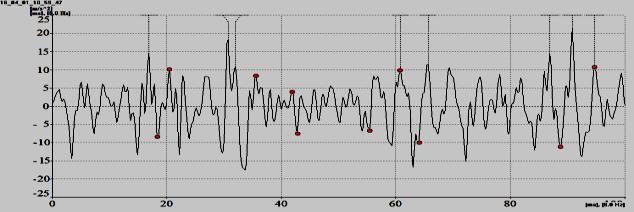

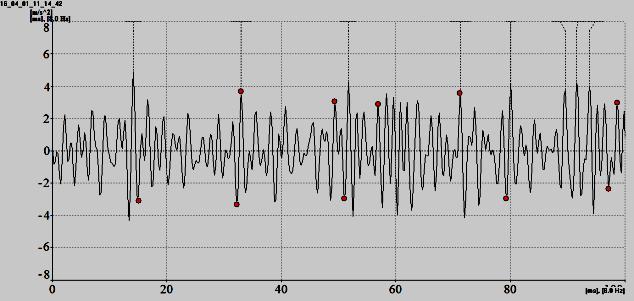

2.AccelerationPlotforRRR

Graph2 AccelerationPlotforRRR

Points 1 2 3 4 5

Positive Values 3 2.8 3.1 3.4 3.2 Negative Values 2.3 2.9 3.2 2.2 3.8

Table.3.AccelerationPointsforRRR

AverageAccelerationforRRR=29.9/10=2.99m/s2

Fig.1.ExperimentalSetup

Tr =0.3517

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

3.AccelerationPlotforFFF

Graph.3 AccelerationPlotforFFF

Points 1 2 3 4 5

PositiveValues 3.4 2.2 3.5 3.3 3.7 Negative Values 2.8 4 2.7 3.8 2.2

Table.4.AccelerationPointsforFFF

AverageAccelerationforFFF=31.6/10=3.16m/s2

Tr =0.5212

5.AccelerationPlotforRFR

Graph.5 AccelerationPlotforRFR

Points 1 2 3 4 5

Positive Values 3.8 3.2 2.9 3.7 3 Negative Values 3.2 3.4 2.9 2.8 2.3

Table.6.AccelerationpointsforRFR

AverageAccelerationforRFR=31.3/10=3.13m/s2

Tr =0.3717

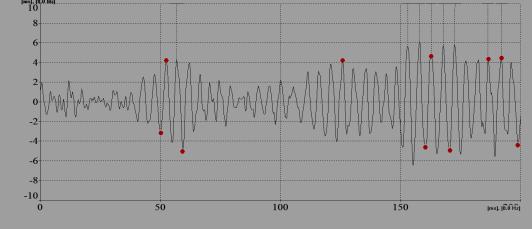

4.AccelerationPlotforCCC

Tr =0.3682

6.AccelerationPlotforRCR

Graph.4.AccelerationPlotforCCC

Points 1 2 3 4 5

Positive Values 4.2 4.3 4.7 4.4 4.5

Negative Values 3.3 5.1 4.6 4.7 4.5

Table5.AccelerationPointsforCCC

AverageAccelerationforCCC=44.3/10=4.33m/s2

Graph.6 AccelerationPlotforRCR

Points 1 2 3 4 5

Positive Values 4 4.8 5.2 2.5 2.8 Negative Values 3.4 3.6 2.3 3.2 2.6

Table.7.AccelerationPointsforRCR

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

AverageAccelerationforRCR=34.4/10=3.44m/s2

Tr =0.4047

TheValueoftransmissibilityisshowninthetable:

Sr. No. Material Analytical Experimental Without Damping With Damping WithDamping

1. RRR 0.3531 0.3574 0.3517

2. FFF 0.3692 0.3720 0.3717

3. CCC 0.5250 0.5276 0.5212

4. RFR 0.3583 0.3621 0.3682

5. RCR 0.3964 0.4002 0.4047

Theresultofdifferentcompositesshowsthetransmissibility ofthecombinationstestedexperimentally,numericallyand comparedwiththetheoreticalreadings.Rubberhasabetter isolationpropertyasthecompositeshavingrubberhaveless transmissibility. The readings obtained by theoretical, experimentalandnumericalmethodareincloseagreement with eachother.Felt issecond bestperformerandcan be usedforheaviermassofsetup.Thecorkcombinationsare found to have the highest transmissibility and hence the leastperformance.

Theperformanceofrubberisfoundtobebetterthanother isolatorsfor the aircompressorfollowed byfeltandcork. However,theapplicationoftheisolatorsdependsuponthe variables like weight of system, frequency of excitation, dampingco-efficientandotherfactors.Itisadvisabletouse rubber with felt, cork or other material to enhance the vibrationcharacteristics.Theperformancecharacteristicsof isolatorscanbeenhanced byusinglayers(composites) of theseisolators.

[1] “Recent advances in nonlinear passive vibration isolators” by R.A. Ibrahim, Journal of Sound and Vibration,371–452,14Mar.2008.

[2] “StudyofWhole-spacecraftVibrationIsolatorsBasedon Reliability Method” by Chen Yang, Chinese Journal of Aeronautics,153-159,2Feb.2009.

[3] “Forceanddisplacementtransmissibilityofanonlinear isolator with high-static-low-dynamic-stiffness” by A.Carrella and M.J.Brennan, T.P.Waters, V.LopesJr, InternationalJournalofMechanicalSciences55,22–29, 2012.

[4] “Force transmissibility of structures traversed by a moving system” E. Rustighi and S.J. Elliott, Journal of SoundandVibration,97–108,11Mar.(2008).

[5] “A study of the effect of floor mobility on structurebornesoundpowerTransmission”byC.M.Mak,Building andEnvironment,443–455,2003.

[6] “Vibration control of two degrees of freedom system usingvariableinertiavibrationabsorbers:Modelingand simulation” by S.M. Megahed, Journal of Sound and Vibration,4841-4865,29Mar.2010.

[7] “Effects of isolators internal resonances on force transmissibilityandradiatednoise”byY.Du,Journalof SoundandVibration,751–778,2003.

[8] “On the use of the transmissibility concept for the evaluationoffrequencyresponsefunctions”byAntonio P.V.Urgueira,MechanicalSystemsandSignalProcessing, 940–951,2011.

[9] “The development of a tunable vibration absorbing isolator” by N.F. du Plooy, International Journal of MechanicalSciences,983–997,4July.2005.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal