International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

1 Vidya Jyothi Institute of Technology, Hyderabad, Telangana, India

2 Assistant Professor, Vidya Jyothi Institute of Technology, Hyderabad ***

Abstract - A composite material is a combination of two or more different materials; it gives superior quantity than its constituents. Composite materialsnot onlyusedfor structural applications but also in various other applications such as automobile, aerospace, marine, etc.

This work describes an experimental mechanical characterization campaign on composite made out of unidirectional Basalt raw with 8 layers. The strength of the material is observed by performing mechanical tests. A core materialis introducedincombinationwithbasalttocheckthe mechanicalproperties ofrawbasaltwithcoreasingredient.In addition to that the influence of core on the strength and thickness of the material is also evaluated by knowing the percentage improvements in strength were the cost of the materialalsoreduces duetotheadditionofcorematerial.The work has used raw materials from commercial catalogues with no further modification. Compression mould is the manufacturing method used to prepare the sample. After mould process the sample is tailored to ASTM standards for testing

Key Words: Compressionmould,Mechanicalproperties, Basalt,Corematerial.

Theevergrowingrequestoflightermaterialsusedinhigh speedtrain,ships,spacecraftandsoon,isincreasingmore and more and the designers are challenged in the field of design and construction of composite materials. A crucial problem,whichdesignengineersarefacingintheaerospace industry, is how to attain better design ideas with the considerationofmechanicalenactmentandindustrialcost. The development and application of original, efficient compositestructureinanextensiverangeofindustriesare inspired by the continuing demands for reduced physical weight,superioreffectivenessandenhancedperformance. Compositestructuresarebecomingasuitablealternativeto metals in several industrial applications particularly for mass carriage where weight reduction is one of the key issuesindesignfactors,owingtotheirsuperioradvantages ofspecificmechanicalpropertiesandcorrosionresistance. To build structures where the weight is a main concern, composite materials are predictably used. Composite structure with less amount of weight, in order to save energy, is primordial for all varieties of transportation

industries such as aircraft, trains and cars ( Zinno et al. 2010).

Nowadays, in the transportation area and particularly in aerospace machineries, the use of improved lightweight constructions is very common. The first use of composite structureinmilitaryaircraftwasinthe1960sandthen in the 1970s, it was used in civil aircrafts. Nevertheless, the manufacturers of civil aircraft were slow to use the composite structure for primary structural application in aircraftuntilthe2000s.Inthe21stcentury,owingtotheir exceptionalmechanicalbehaviorsandmultifunctionaluses, composite materials are reflected as the most favorable multifunctionalconfigurationresources.Theymeetdesign and qualifications necessities and provide notable weight benefits as well as substantial cost diminutions. Fiber reinforced plastic composite structures are extra outstanding for constructing ultra-lightweight multifunctional configurations mainly for spacecraft (Katnametal.2013).

The modern energy crisis of the world and weakening atmospherehavestimulatedthefastimprovementofnew materials and structures such as composite materials and sandwich structures (Besant et al. 2001). Sandwich composite structures are widely used in aerospace, spacecraft, naval, marine vehicles, automobiles and other lightweightstructuresduetotheirhighstiffness,strength and energy absorption capacity. Sandwich structures are used not only to reduce the weight and cost but also to increase the structural performance. Typical sandwich compositeiscomposedoftwothinandstrongfacesheets separated from a lightweight core. They have distinct propertiessuchashighspecificmodulus,lightness,strength andlowcoefficientofthermalexpansion.Moreover,dueto theirdesignflexibilityandlightweightfeatures,sandwich compositesareusedmoreinadvancedaircraftcomponents andmarinestructure(Meoetal.2005).

Inthemidstofbestfavorablecompositestructures,dueto their attractive characteristics such as massive weight reduction, capability of energy absorption and power resistance, the honeycomb core sandwich panels, particularlyreinforcedwithcompositestructure,havebeen broadly utilized. Honeycomb sandwich structure is one of the dominant structures of the sandwich composite. The methodofusinghoneycombcorebetweentwofaces

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Sheets were first offered by Hugo Junkers in 1915 (Tijo Thomasetal.2019).Honeycombcompositestructuresare widely utilized in aircraft, space structure, satellites, automobiles,boatsandsoon,becauseoftheirlightdensity, high rigidity, good sound and high insulation capacity. Energy absorbing materials filled honeycomb sandwich panels can prevent or decrease the accumulation and trappingofwaterthroughoutuse,whichisamajorproblem especiallyinaeronautics.Honeycombsandwichcomposite structuresmanifeststaticpropertiessuchashighbuckling and high stiffness- to-weight ratio which are of great importanceintheaeronauticsfield.Thefacesheethasahigh strengthandelasticmodulusandthecorehasbendingand highshearrigidity.Becauseofthis,themomentofinertiaof the structure will increase and thus, the rigidity of the structurewillalsoincrease(Castanieetal.2008).

More or less unnoticed by the majority of designers, engineers and architects, throughout the last 50 years, sandwich structure has industrialized typically into an inexpensiveproductionmethod,whichcurrentlyalsofulfils high architectural necessities. Sandwich structure is recordingaremarkableprogress,asmostoftheengineers areusinglight metal towardsa decreasingtendencyat an alarmingspeed.Anextensiveinvestigationandprogressive effortsaremadeinsandwichconstructiontousemoreand moreofitinmanyareas,becausethetraditionalcoresthat are used in sandwich construction are economically not feasible.Althoughthereisanendlesseffortintheaerospace world for new materials improvements, there are several damagingaspectsandsubstantialcostsrelatedtothemand they are accepted at risk. Moreover, due to growing universalcompetition,aplentyofindustrieshaveastrong necessity to improve honeycomb cores for light weight sandwichpanels.Particularlyintermsofnovelty,thesecores shouldbeextracosteffectivetoconstructandpreserve.This canofferadesigneracomprehensivespectrumforselecting acoreforlightweightsandwichstructure.Allthesephases and the requirement to know systematically the complex mechanism involved afforded a reasonable motivation to takeupthistopicforadoctoralstudy.

Practically, all the bending and in-plane loads are carried by the facings. Facings also describe the flexural rigidity and flat wise compressive shear as well as compressivebehaviors.Moreover,facesheetsoughttohave acomparativelyhighdensity,astheyareproposedtooffer almost all the tension, compression and bending confrontation. Also, they should be kept at an adequate distancefromthemidplaneofthesandwichstructurepanel. Thus, the face sheets built with in-plane stiff as well as appropriateout-of-planerigidityaresignificant.Thelayup andthethicknessofthefacingsneedtobedesignedtomeet theparticularrequirement(Zinnoetal.2010)

Thechiefobjectiveofthecoreistoimproveflexuralstiffness of the whole structure with light weight. The low density core material plays a major role in offering high shear resistanceandstabilizesthefacesheettogetbetteradhesive bonding. Because, the face sheets and core interface is frequentlytheweakestpartofthesandwichpanels.Isotropic foamandanisotropichoneycombarethetwomajorsetsfor the core materials. Due to their lightweight, particular bendingrigidityandstrengthindistributedloads,thesetwo kinds of cores mainly utilized in sandwich composites for load-carrying purposes in aerospace, aeronautics, marine vehicles, transportation and military. In this regard, the densityandcorethicknessneedtobegivenimportanceina designanalysistofulfilanexplicitperformancerequirement (VictorBirman2018).

Theoverallcharacteristicsofsandwichpanelsdependupon the material behaviour of the components such as face sheets, epoxy resin and core, symmetrical measurements andnatureofloading.Undercommonbending,shear,andinplaneloadingsandwichstructuresexhibitdifferentfailure mechanism.Mainfailure modesinthesandwichpanelsin bending are face/core interface de-bonding, core shear failure, face sheet delamination, fiber breakage and skin fracture. Damage mechanisms and their beginning can be identified by performing a systematic stress analysis and applyingsuitablefailureprinciplesinthedangerousareasof thestructure.Thisanalysisishighlychallengingduetothe nonlinearandinflexibleperformanceoftheconstituentand the multifaceted interfaces of the damage mechanisms. Hence,itissignificanttodesignthesandwichpanelssuitably and conduct the experiments carefully in illuminating the physicalphenomenatosupporttheanalysis.

Corematerialplaysamajorroletoimprovetheproperties of the sandwich structures. The material properties of the core profoundly control the damage behavior of sandwich structure. The core can be divided into four main groups. Theyarecorrugated,honeycomb,balsawoodandfoams.In addition,thermalandacousticalinsulationpropertiesofthe sandwichcompositebasedonthematerialofthecore.

Corrugated cores that are prismatic in structures classically form open channels in one direction. The mechanicalandstructuralcharacteristicsofcorrugatedcores arestudiedtoaddresstheissuesofisotropicdesign,core-face reinforcement and dynamic response to applied external loads. In order to enlarge the possible application of corrugatedcores,numerousinventivedesignsofcorrugated structure are offered (Jian Xiong et al. 2019). Honeycomb

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

core sandwich structure that is usually closed cell configuration.Honeycombcoresthatarehexagonallyshaped structure are made up of aluminium alloy, titanium alloy, Nomexorcompositematerials.Nomexisthemostusedcore, which is made with phenolic resin infused aramid fiber. Honeycomb core made up of metal are cheap but extra resistant. Honeycomb core made up of nonmetal are not delicatetodecaybutgoodthermalinsulators.Duetoitslight density,highrigidity,goodsoundandhighinsulationcapacity honeycomb core structure are widely utilized in aircraft, spacestructure,automobilesandsoon.

Balsa wood that is highly anisotropic is made up of naturalsmallpiecesofsheetsjoinedtogether.Dueitsextra densitystrengthinthrough-thickness,balsawoodcorefinds specialareaofapplicationanditisattractiveagainstimpact loadings.Foamsareasolidonamacroscopiclevelanditis easy to prepare the surface, shaping and bonding to core blocks by adhesive. Polyurethane (PUR), polystyrene, polyvinylchloride(PVC)andpolymethacrylimide(PMI)are thevariouskindsoffoams.Amongthese,themostpopular foamsarepolyvinylchlorideandpolyurethanefoams.

Polyvinylchloride foam is a combination of air bubbles andhighvolumepolymerwithlessweight.Dueitslowwater absorption capacity, PVC is preferable than polyurethane foam. Through the action between isocyanate and polyol while using carbon dioxide as a blowing agent, the polyurethanefoamisformed.ManyvarietiesofPURfoams areformedfromsoftfoamfromopencellstorigidtypeswith predominantlyclosedcells.

Honeycomb core sandwich structure is one of the dominantstructuresofthesandwichcomposites.Thefoam filled honeycombcore provides coupledadvantages of the foamandthehoneycombcore,becausethecellwallsofferthe strengthandthefoamabsorbhighimpactenergy(Vaidyaet al.1998).

Sandwich composites with their stability and ease of repairs, find increasing use in many applications such as aerospace, automotive, water turbine industries, satellite launch vehicles, missiles and transportation engineering. Andalsothese materials,becauseoftheirlightweightand favourable cushioning properties, are used as shock absorbers in air planes and high speed trains. They have distinctpropertiessuchashighspecificmodulus,lightness, strengthandlowcoefficientofthermalexpansion.Moreover, due to their design flexibility and light weight features, sandwich composites are used more in advanced aircraft components and marine structure. In addition, sandwich structures have better bending stiffness, strength, and capableofabsorbinghighenergy(Kangetal.2006).

Inordertoobtainmorestiffness,strengthandcombined thermal insulation, sandwich composite also used in portionsofthestructureofGRPterrainvehicles.Oneofthe featuresofthisvehicleistoobtainlowstructuralweightso thatitisabletofunctionindeepsnowenvironments. There arealsoaseriesofpleasureboats,hulls,cars,shipsandtrain madeupofsandwichdesignwithanaimofreducingweight, emissionsandcosts(Yeetal.1988).

Honeycomb core sandwich structures can be used for several applications, in particular for aircraft structural applications such as airplane floors, doors, wings flaps, rudders and helicopter fuselages (Herrmann et al. 2005). Otheradvantagesofsandwichstructurearefireretardation, comfort of forming, simplicity of machining, high explicit strength,isolation,goodwearinessbehavioursanderosion resistance.Thesandwichmaterialsarealsousedinbuilding constructionsuchaswalls,ceilings,floorpanelsandroofing. Alsotheycan be used in dampedstructures to reducethe vibrational problems. Various degrees of damping can be solvedbasedonthepropertiesofcoreaswellaswavelength ofthevibrationmodebyusingavisco-elasticcoresandwich structures(Rizovetal.2006).

Therearedifferentmethodsusedinthemanufactureof compositessandwich.Themethodsarehandlay-up,Resin TransferMouldingmethod,Vacuum-AssistedResinTransfer Moulding (VARTM) and vacuum bag moulding methods (DanielBMiracle&Steven2001).

Thisisanopenmoldingmethodwhichcanbeusedforthe manufactureanextensivevariabilityofcompositesproducts. Hand lay-up method is a simple processing with low cost toolingmethod.Byusingthismethod,goodproductionrates andreliablequalityareachieved.Therearefourphasesin this process such as mold preparation, get coating, lay-up andcuring.Firstofall,thewastefromthemoldsurfaceis removed to avoid the sticking of polymer to the surface. Then,thereinforcementsareappliedbyhandonthemold. Thereinforcementmaybeanypreferablematerialsuchas aramid,carbonorglass.Toapplytheresinontothefibers, brushes are used. Consequently, to confirm the enriched interactionbetweenthefibersandtheresin,rollersareused torollthewetcomposite.Finally,thelaminatesarekeptto cure at room temperature. Without the external heat, the fiber reinforced composite is cured to get hardening. The handlay-uptechniqueismostlyutilizedinmarineaswellas aerospacestructures.However,moreworkersandtimeare requiredforthismethodthanadvancedfabricatingmethods.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Inthisprocess,thefiberwiththeresinisimpregnatedin theopenmouldtoolandthecoreislocatedinbetweenthe mats.Then,thewholelay-upiscovered,sealingaroundthe edges. For the composite to consolidate, the vacuum bag process is activated by sucking all the air inside. Without crushing the laminate part, the pressure is added by the vacuum bag. Pressure supplied by the vacuum bag to eliminatetheentrappedair,excessresinandcompressesthe laminate.Continuouslythisisdonetoassistwiththecuring of the resin. When the composite part is fully cured, the vacuum pump can be removed in order to remove the manufacturedcompositepart.

Fromtheliteratures,itisfoundthatmostofthecoresare made with metals and the enhancement of properties through sandwich is better when compared with solid laminates.Sinceapplicationsofbasaltfiberisfoundmuchin manyapplicationssuchasboathulls,anattempthasbeen madetodevelopahybridhoneycombsandwichpanelwith basalt fiber and core for structural applications. Also to improve the characteristics and to develop the innovative and novel light weight structures, it is proposed to incorporatethecorematerialinbetweenthefiber.Corealso acts as Energy absorbing materials, and also profoundly controls the damage behavior of sandwich structure, increases the impact resistance and absorbs high impact energy.

BasaltfabricasthereinforcementandLY556epoxyresin and HY 961 hardener as the matrix material are used to fabricatethesandwichcomposite.Thecorematerialhaving regularhexagonalcellconfigurationwithcellsizeof6mmis used in the fabrication of composite. The physical and mechanical properties of the face sheet have been determined as per the ASTM standards. As per ASTM standard, flat wise compression, three-point bending and charpyimpacttestsareconductedtodeterminetheelastic constants of the core and maximum load capability of the sandwichpanels.

Core material plays a major role to improve the mechanical properties of composite sandwich structures. Also,whentheweightisreduced,itiseasytoincreasethe payloadandreducethecost.Hence,itisverysignificantto selectthecorrectmaterialtominimizetheweightwithhigh quality.

Therefore,thebidirectionalfiberof210GSMwithathickness of0.2mmasareinforcingmaterialandEpoxyresinLY556 mixedwithHY951hardenerintheratioof100:10asbinding materialsareusedtofabricatebothfacesheetaswellasthe core.Inordertoobtaintheoptimumstrength,thefiberand resinratio65:35istakentomakethesandwichpanel.The splitmoldingtooldimensionsare310mminlength,300mm inwidth,30mminheightanditcontained30halfhexagonal inserted rows of core with the cell size of 6 mm. The bidirectionalhybridfiberisshowninFigure.

To analyze the effect of fillers on the core, two different samplesarepreparedwithdifferentcompositions.Bothare preparedwithdifferentstackingsequences.Thestudyisto knowthemechanicalcharacteristicsofthesampleswiththe additionofcorematerialandcomparingthesamewithraw basaltsample.

The Vacuum bag molding technique, in which the improvementofthehandlay-upusesthevacuumtoremove the captured air and extra resin, is used to fabricate the hybridfiberhoneycombcoresandwichmaterial.

There are many advantages in vacuum bag hand lay-up processwhenitiscomparedwithconventionalhandlay-up techniques.Sincetheprocesstakesplacewithintheclosed atmosphere,itvirtuallyremovestheunsafeVolatileOrganic Compound (VOC) emissions. Vacuum bagging process is used to add pressure without damaging the part and the vacuum is run into the sealed area. The resulting vacuum pressurepushesouttheextraresin.Moreover,byusingthis methodhigherstructuralstrengthandefficiencyisgained against the traditional methods. This method also offers better resin distribution and stronger bonding of the laminate. As a result, the mechanical behaviors of the sandwich panels are remarkably higher than the case of handlaminatingpanels.

The bidirectional fiber as reinforcement and LY 556 resin mixed with HY 951 hardener as the matrix materials are used to fabricate the basalt/ core laminate. The ratio of mixingoftheepoxyresinandthehardeneris100:10.When

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

the surface is cleaned and remaining particles of molding toolareremoved,theprocesscouldbestarted.

Afterconfirmingathoroughwettingofthehybridfiberand applying the resin mixture on the molding surfaces, the hybridfiberisimpregnatedinthehexagonalsplitmolding toolbyplacinghexagonmandrel,Toimprovethejoining,the load is applied onto the wet laid-up laminate. After this, a bagwithaVacuumValve(returnable)isattachedandtaped up,whichinstitutesthevacuumbaggingprocess.Tomerge and to increase the inter-laminar shear strength of the layers,aportforthevacuumisorganizedatonecornerof thebagwithsubjectedto450-500Hg/mm2ofpressurefor 120minutes

Inordertomakethesandwichpanel,threelayersofthefiber which are joined by resin mixture with the core material, Whencomparedwithhandlay-upprocess,thevacuumbag techniqueoffersgreaterreinforcementabsorptions,better adhesion between layers and control extra resin/hybrid ratio.Twodifferentvarietiesofpanelsarepreparedonewith rawbasaltandtheotherwithbasaltandthecorematerial.In ordertoimprovethemechanicalpropertiesandtocontrol the premature bending, shear failure and buckling of cell walls. The core material having regular hexagonal cell configuration of 6 mm cell size is used to increase the stiffnessandloadingcapacity.Thewallthicknessofthecore is3mm.

Adetailedunderstandingofthemechanicalbehaviorsofa materialthatisusedtodevelopthesampleisimportantto knowwhetherthematerialiscorrectandthebestmaterial forparticularapplication.Themechanicalbehaviorsofthe samples are examined as per ASTM standards. By performingtensile,flexuralandcompressiontests.

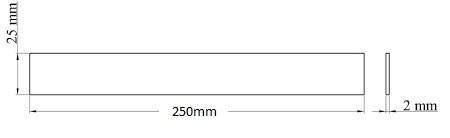

To determine the tensile strength of the composite, using universaltestingmachine,tensiletestisconductedatacross headspeedof1mm/minaspertheASTMD3039M-08.Test specimens are cut from the composite panels with the dimension of 25 mm width, 2 mm thickness and 220 mm

length.Figure3.8showsthe specimen(face sheet)during thetensiletest.Anaverageofthreespecimensisreportedin eachtypeofsandwichcompositestructures.

To determine the compression strength of the composite face sheets, using universal testing machine, compression testisconductedatacrossheadspeedof1mm/minasper the ASTM D 3410M-03. Test specimens are cut from the compositepanelswiththedimension20mmwidth,2mm thickness and 20 mm length. The compressive strength is found out by dividing the breaking load with the crosssectionalareaofthefacesheetspecimen.

Thetensiontestisgenerallyperformedonflatspecimens. The standard test method as per ASTM D 3039 has been used;lengthofthetestspecimenusedis250mm.Thetensile test is performed in universal testing machine. The tests wereperformedwithacrossheadspeedof10mm/min.For eachtestcompositeoffoursamplesweretestedandaverage valuewastakenforanalysis.Theresultsobtainedfromthe testsispresentedintable4.1

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Table -2:

S No Specimen Specification Gauge width (mm)

Fig -5:TensileSpecimen

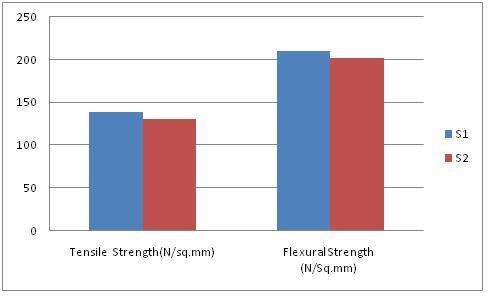

Table -1: TensileTestoutcomesofsamples

S No Samples Gauge Width (mm)

Thickness (mm)

Tensile Modulus (N/Sq. mm)

Tensile Strength (N/sq.mm)

1. S1 25 1.5 82.75 137.93

2. S2 25 3.5 65.0 130.78 S1: 6 layers of Basalt S2: 2-Basalt 1-core

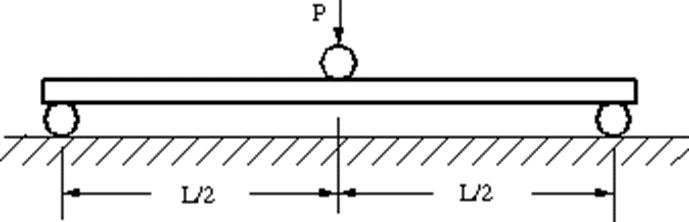

Flexural test was conducted on UTM machine in accordance with ASTM Standards. Specimens of 150mm lengthand20mmwidewerecutandwereloadedinThree PointBending.Thetestwasconductedonthesamemachine usedfortensiletestingusingaloadcellof5kNat2mm/min rateofloading.Theflexuralstressinathreepointbending test is found out by using equation (4.3). The results obtainedfromthetestsarepresentedintable4.2. ) (2 ) (3 2 max max bh L P (4.3)

WherePmaxisthemaximumloadatfailure(N),Listhe span (mm), b and h is the width and thickness of the specimen (mm), respectively. The flexural modulus is calculated from theslopeofthe initial portion of theloaddeflectioncurvewhichisfoundoutbyusingequation(4.4) ) (4 ) ( 3

3 bh mL E (4.4)

Wheremistheinitialslopeoftheloaddeflectioncurvefor each stacking sequence, five specimens are tested and averageresultisobtained.

Flexuralspecimendimensions:Span=160mm,Width=20 mm,Thickness=2mm

Fig

Thickness (mm)

Flexural Strength (N/Sq.mm)

1. S1 25 1.2 209.86

2. S2 25 3.4 202.03

S1:6layersofBasalt S2:2-Basalt1-core

Fig -7:GraphicalRepresentationofOutcomes

Tostudytheeffectofenergy-absorbingmaterialsunderthe flat wise compression test sandwich panels, at crosshead displacementrateof1mm/min.Itisnotedthatafterreaching themaximumload,itdropsandthisdenotesfailureinitiation inthesandwichspecimens.

Samples Load (kN) Load/Weight (N/N)

Compressive Strength (MPa) Compressive modulus(MPa)

S2 89.82 287.28×103 34.72 283.13

S1 90.58 295.26×103 37.43 298.24

Mechanical behavior of the hybrid core sandwich panels have been experimentally investigated under static mechanical testing’s such as Tensile strength, Flat-wise compression,Three-pointbending.Theobtainedconclusions fromtheaboveexperimentsarementionedbelow.

The average tensile strength achieved by S2 is 7.15 N/mm2 less than S1, Which is within the permissible limits.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

The 6-layers of raw basalt are exhibiting 137.93 N/mm2.Thesamestrengthcanbeachievedbyadding corematerialto2-layersofbasaltasshowninTable1

[6] ASTM C365M-11. Standard test method for flatwise compressive properties of sandwich cores. ASTM International,PA,USA.

By adding core material, strength of the sample S2 is increasedatthesametimethicknessisalsoincreased upto2mm,S1ismaintainingathicknessof1.5mm.

Experimental results indicated that the hybrid core sandwich panel improved the high strength, specific stiffness,criticalloadandrigiditymorethanrawbasalt sample.

[7] ASTMC393M-06.StandardtestmethodforCoreShear propertiesofsandwichconstructionsbyBeamFlexure. ASTMInternational,PA,USA.

[8] ASTM C3039M-08. Standard test method for Tensile properties of Polymer Matrix Composite Materials. ASTMInternational,PA,USA.

S1isachieved37.43MpawhereasS2is34.72Mpafrom experimentalresults.

Duetothestronginterfacebetweenthefiberandcore provided,thesandwichspecimenimprovedthethreepointbendingpropertiessignificantly.

[9] ASTM C790-10. Standard test method for flexural propertiesofunreinforcedandreinforcedplasticsand electricalinsulatingmaterials.ASTMInternational,PA, USA.

[10] Balcı,O,Çoban,O,Bora,MÖ,Akagündüz,E&Yalçin,EB 2017,‘Experimentalinvestigationofsingleandrepeated impactsforrepairedhoneycombsandwichstructures’, MaterialsScienceandEngineering:A,vol.682,pp.2330.

Thereisabigdifferenceinbendingpropertiesbetween basaltande-glassreinforcedwithcorematerial.

[1] Abbadi, A, Koutsawa, Y, Carmasol, A, Belouettar, S & Azari, Z 2009, ‘Experimental and numerical characterization of honeycomb sandwich composite panels’,SimulationModellingPracticeandTheory,vol. 17,no.10,pp.1533-1547.

[2] Abbadi, A, Tixier, C, Gilgert, J & Azari, Z 2015, ‘Experimental study on the fatigue behaviour of honeycomb sandwich panels with artificial defects’, CompositeStructures,vol.120,pp.394-405.

[3] Al-Shamary,AKJ,Karakuzu,R&Özdemir,O2016,‘Lowvelocityimpactresponseofsandwichcompositeswith differentfoamcoreconfigurations’,JournalofSandwich Structures&Materials,vol.18,no.6,pp.754-768.

[4] Anderson, T & Madenci, E 2000, ‘Experimental investigationoflow-velocityimpactcharacteristicsof sandwichcomposites’,Compositestructures,vol.50,no. 3,pp.239-247.

[5] Arunkumar, MP, Jagadeesh, M, Pitchaimani, J, Gangadharan, KV & Babu, ML 2016, ‘Sound radiation and transmission loss characteristics of a honeycomb sandwich panel with composite facings: effect of inherent material damping’, Journal of Sound and Vibration,vol.383,pp.221-232.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |