International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 8 | August 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 8 | August 2022 www.irjet.net p-ISSN: 2395-0072

1, 2Mechanical Engineering student at Sharad Institute of Technology College of Engineering, Yadrav, Maharashtra, India

3Electronics and Telecommunication Engineering Student Sanjay Ghodawat University Kolhapur, Maharashtra, India

4Electronics and Telecommunication Engineering Student at Walchand College of Engineering, Sangli, Maharashtra, India

5, 6Instrumentation Engineering Student at Padm. Vasantraodada Patil Institute of Technology, Sangli (Budhgaon), Maharashtra, India ***

Abstract - In this modern era, the additive manufacturing technique 3D printing is expanding day by day and playing a significant role in the manufacturing industry. The utilization of additive manufacturing 3D printing is very broad as they are being used in the Aerospaceindustry,Automotiveindustry, Food industry, Healthcare and medical industry, Architecture, building, and construction industry, Fabric and Fashion Industry, Electric and Electronic Industry. This paper demonstrates how 3D printing is being used with different types of materials in various fields of manufacturing such as ABS, PLA, PVA and PC. As the various types of material used in 3D printing for different applications,itisrequiredthatthe3D printed product should be superior and better than other products that are manufactured form other production technique. So it is mentioned what typeofcompositematerials are utilized in 3D printing and how they are useful to add more value than other materials. Composite materials are created and utilized in a broad range of applications in additive manufacturing 3d printing to increase material strength and other features such as stiffness, impact strength, durability, temperature resistivity, chemical resistivity, insulating property, elasticity, and so on. To advance the process of additive manufacturing 3D printing it is enabled with the Internet of Thing that it makes the process more efficient and make it ease to operate. The IoT thing made possible to print the prototype wireless on the network. The advanced system also used to scan the product make it as actual by 3D printing. In 3D scanning, an object is scanned, transformed to a cad file, and then 3D printed by converting it to a STL file. The main purpose of this article istodemonstrate how 3D printing technology may be used in conjunction with other advanced technologies such as composite materials, the Internet of Things (IoT), and 3D scanning that may bring manufacturing industry at next level in the future.

Key Words: 3DPrinting,Materials,Compositematerial,3D scanning,3Dprintingapplications,IoT,etc.

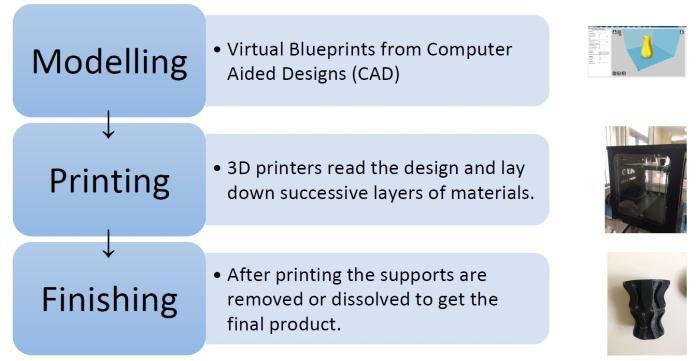

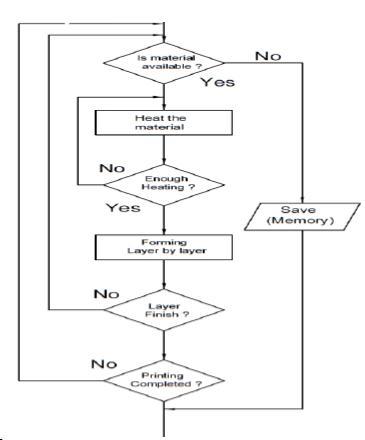

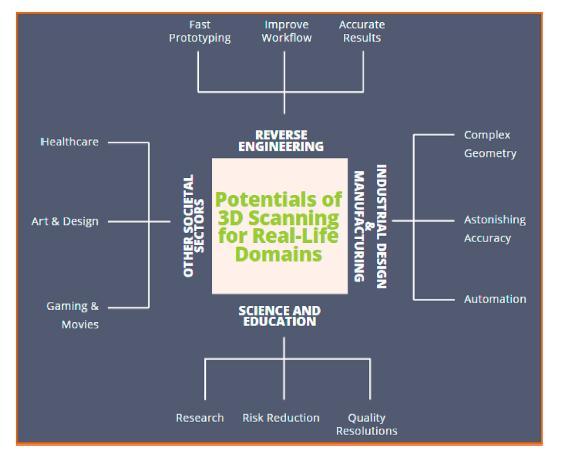

The principle of 3D printing was first sketched forth by DavidE.H.Jonesin1974.ChuckHallofthe3DGrowthInthe organization filed his own invention in 1984. Objects are createdbyprintinglayersofa specific layerontopofone anothertill thewholeobjectisformed[1]. Inlatest years, additive manufacturing (AM) has emerged as a viable manufacturingoption.3Dprintingisalsoknownasadditive manufacturing, provides for more manufacturing options becauseitcanmanufacturecomplicatedgeometricshapes using software applications [2]. An object is built in an additivemanufacturingprocessbylayingdownthematerial untilthecomponentiscomplete.Someoftheselayerscanbe regarded as a horizontally cross-section of the finished product, thinly sliced. Stereo lithography (SLA), laser sintering(SLS),andfuseddepositionmanufacturingarethe technologyusedinALM(FDM).Thefilamentisa string of composite mass used in the FDM printing process. This filamentisroutedfromaspoolattachedtothe3Dprinterto aheatednozzlethatmeltsthematerialwithinthe3Dprinter. Once the material has melted, it can be extruded along a preciseandpredefinedpathcreatedbycomputerprograms [3] IoTandembeddedelectronicsarenowbecominghighly popular as a result of their numerous applications in residential, industrial, and industrial sites. Since of developmentsinportabledevices,integratedandubiquitous communicationdevices,cloudcomputingservices,anddata analysis techniques, the term IoT (Internet of Things) has recently become more relevant to the actual world. The InternetofThings(IoT)isatermthatreferstotheabilityto communicate about everything in our environment. Machine-to-machine communication, wireless sensor networks, sensor networks, 2G/3G/4G, GSM, GPRS, RFID, WIFI, GPS, microcontrollers, and microprocessors are all examples.[4]Inavirtualworldwithprecisedimensions,3D scanning digitally recreates information about physical elements.Whensomethingcomestomeasuringgoodsin3D, there are a few methods. Laser scanners, light scanners,

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 8 | August 2022 www.irjet.net p-ISSN: 2395-0072

coordinatemeasurementmachines(CMMs),andcommercial computed tomography (CT) scanners are all part of this category. 3D scanning technology gather raw data in the form of point clouds and transform it into user-friendly formats such as CAD models [3] In traditional manufacturing, a strategy for dealing with enormous amounts of difficult and high-dimensional data was established.TheGray-Level Co-occurrenceMatrix(GLCM) andselectedHaralickfeatureswereusedtoofferamethod for real-time observation of the status of the 3D printing process. The method was demonstrated using images producedbyscanningthe3Dprintedplates[2]

formofhybrid,composites,oressentiallyclassifiedmaterials canallbeprintedasfullyoperationalpartsusing3Dprinting technology(FGMs).highlydevelopedFDMprinterscanprint specialized materials with better heat resistance, impact resistance,chemicalresistance,andrigidity.[6]3Dscanningis used in production for a long period. To reach quality standards for all parts, industries required dimensional measurements[7] Thereareindeedavarietyofindustriesin which we can implement this technology, including Aerospace industry, Automotive industry, Food industry, Healthcareandmedicalindustry,Architecture,building,and constructionindustry,FabricandFashionIndustry,Electric andElectronicIndustry[6]. Elevatedseamlessplastermolds of aerospacedesignare developed usingSLAand material jetting. Our automotive manufacturers are rapidly developing, and new innovations are emerging from the industry.3Dtechnologycanalsobeusedinmedicalscience forprintingskinbones,drugorgan,medicalequipment,and tissues [1] Today's world, a 3D printer can establish any complicatedjewellerydesignwhilealsoremovingafewsteps fromconventionalmethod.Foodproductscouldbeprinted utilizingsemisolid,powder,andviscousliquidfoodproducts using a 3D printer. Food manufacturing with even to cartridges has a long lifespan and a controlled amount of nutrients,makingitagreatchoiceforprovidingastronauts withfreshfood[5].3Dprintingtechnologyisanecofriendly derivative that provides infinite geometric sophistication momentofrealizationpossibilities.3Dprintingtechnology couldbeusedtoprintentirehousesorcreateconstruction elements in the construction sector. Building Information Modeling(BIM)willhelp3Dprintingtechnologybeusingit efficiently. Different 3D printing technologies are now commonlyusedforstructuralelectronicequipmentsuchas active electronic materials, electrodes, and devices with customized products and flexible design by embedding conductorsinto3Dprintedequipment[6]

Fig -1: Flowchartof3dprinteroperation[1]

In the early 1980s, the first publicized observations of 3D printingweremadeinJapan.HideoKodamasetouttocreate arapidprototypingsystemin1981.Heinventedalayer-bylayer manufacturing methodbased ona photographic film epoxy that was modified by UV light [5]. The most widely usedFDM3DprintingmaterialsareABS,PLA,PVA,PCand variouscontaminants.3dprintingtechnologybuildobjectsor productsoutofpowderedmaterials.Withintheprinter,the powdersaremeltedandspreadinlayersuntilthepreferred depth and structure are reached. In printers, a variety of powders are used, and the most popular are Polyamide (Nylon), Alumide. Typically, 1.75mm or 3mm diameter filamentisusedfor3Dprinting.Thismaterialcomesinthe formofwire,whichisfedintotheextruderbyamotor.[1]. Ceramic, metallic, polymers,and their combinations in the

Fig -2: Threemajorstepsinvolvedin3Dprinting[16]

Composite materials are created and utilized in a broad rangeofapplicationsinadditivemanufacturing3dprinting to increase material strength and other features such as stiffness,impactstrength,durability,temperatureresistivity,

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1200

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 8 | August 2022 www.irjet.net p-ISSN: 2395-0072

chemicalresistivity,insulatingproperty,elasticity,andsoon. Composite materials are mostly employed in areas that require significant strength and stiffness while also being lightweight. The lack of advanced polymer materials and Nanocompositestomeetallofthecriteriaisthesignificant issue in AM. As a result, many organizations have concentratedtheirresearcheffortsoninventingnewhighperformancematerials,increasingtheefficiencyandspeed of the process, and expanding the range of qualities and applications[8].ThereareseveralmethodsofAMsuchas fused deposition modelling (FDM), directed energy deposition(DED),selectivelasersintering (SLS)areusing thermoplasticcompositematerials.BecauseFDMhasbeen utilized to make polymer-based fibre composites, adding fibretothethermoplasticmatrixincreasesmodulus,tensile strength,andbendingstrengthwhencomparedtothepure thermoplastic material [9]. Carbon fibre composites are lightweight,high-strengthmanufacturedmaterialsthatmay be up to ten times stronger than steel and eight times strongerthanaluminiumwhileonlyafractionoftheweight [10].

Theuseofcompositematerialsisnotrestrictedtoindustrial applications;theyarealsobeingutilizedsensiblyinmedical applications to produce tailored equipment for a specific patientortodevelopa new organoranypartofthebody with tissues to give the patient new life and appearance. Basically, the desired human object is scanned using 3D scanningtechnology,thenitisconvertedintoa3Dcadfile, modified as per requirements, and manufactured using additivemanufacturing3Dprintingtechnology.3-Dscanning isusedfordatagatheringandanalysisofanobject'spresent 3-Dshape,anditmaybeutilizedforthingslike3-Dvision and modelling, cloud- to-cad comparisons, prototyping, architectural data demands, and digital archival. The polymers that are presently utilized in 3D printing are polycarbonate (PC), nylon, thermoplastic Polyurethane (TPU), chlorinated polyethylene (CPE), acrylonitrile butadienestyrene(ABS),andpolylacticacid(PLA).Except for PLA, all of the polymers described are expensive and difficulttobreakdownfromfossilbasematerials[11].The useof3Dprintingtechnologyisbecomingmoreprevalentin a variety of sectors. 3d printing has been utilized in the pharmaceuticalindustrytocreatetailoredmedications,oral dosageforms,medicinaldevices,andtissueengineering[12]. Polycaprolactone(PCL)isabiocompatiblepolyesterthathas been utilized in wound dressings, tissue engineering, and drug delivery, resulting in the FDA approval of many PCL drugdeliverydevices[12].Anothertechnologyinadditive manufacturing3Dprintingisnowimmergingandbeingused with great efficiency that is 3D printing with nanoclay. Nanoclay can increase the dimensional flexibility of polypropylene filamentsandminimizethedeformation of 3Dmodels[11].

[7]

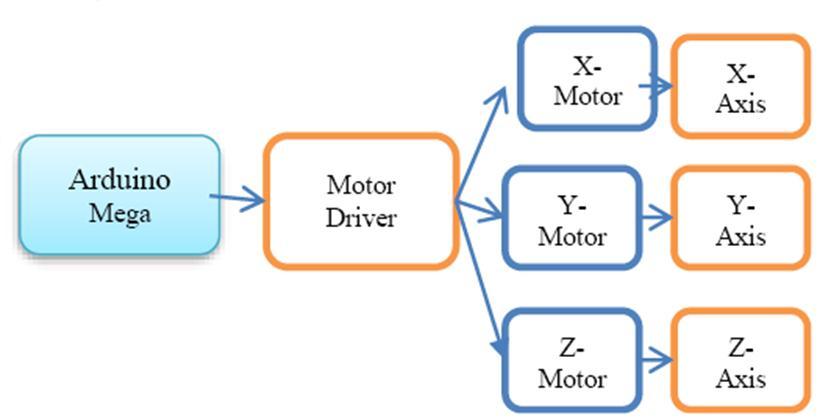

IoTandEmbeddedsystemelectronicsisgettingmoreand morepopularduetoitsversatileapplications.Howeverthe electronics or electrical system that were built earlier requiressomeenclosuretoprotectitfromenvironmentand someotherconcerns.Authorshavedonethedemonstration oftheprojectanddocumentationrelatedtorapidprototype formakingitcustomizedIoTsensorstepbystep.Thiswill help to summarize the strengths and weaknesses faced in thistechnology.Nowadaysexistingtechnologiesaregetting replaced by new technology. Also the traditional technologies are effective and efficient while additive technology is added that can be adapted without major changesinthestructure.Peoplenowconsiderthisadditive technologyastheirsmallbusinessesbutasforIoTsensored projectweneedtoprotecttheelectronicproductincaseof hardware and also need to add the asthetics to the prototype.HencethroughmodellingtheFDMtechnologylike 3Dprintingwecanprintthecaseaccordingtotheselected assembly and the placements of the components. As this technologyisidealforrapidprototypingofcustompackages itiselaboratedthatascomparedtolowcostcapitalsfoe3D printers this technology is most beneficial for mass production[13].Additivemanufacturingtechnologylike3 printer often has potential to accelerate innovation, compresssupplychain,minimizematerialandenergyusage and reduce waste. This was originally developed at MassachusettsInstituteofTechnologyin1993.3Dprinting technologyformsthebasisofZCorporation’sprototyping process. 3D Printing technology is a technology is a technology that makes use of liquid blinder to create 3D physicalprototypeofsolidifiedlayerofdepositedpowder. 3D printer printing process has shown a versatility and rapidness in adapting the geometry due to varying complexity in hundreds of different applications, and supportingmanytypesofmaterials.ZCorp.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 8 | August 2022 www.irjet.net p-ISSN: 2395-0072

Has helped to develop the commercial use of 3D Printer technology and evolved 3D printers to lead the manufacturers use to produce early concept models and productprototypes.Useof3DPrintertechnologyandZCorp. hasdeveloped3Dprintersthatoperateatunknownspeeds, extremely low costs, and within a broad range of applications [14]. 3D printers can be built up by using raspberrypitoprintthethingsremotely.Turnyourprinter offandonthencheckthestatusoftheprints,andwatchyour prints with a live video feed and more. 3D printing technologyisaprocessesofjoiningandthensolidifyingthe material under the control of computer to create 3 dimensionalobject.Objectdesignsmayhavecomplexshapes or geometrical errors and are produced from a digital 3D model oraCADfile.Then itisnecessarytoconvertaCAD modelintoanSTLfile.Thentherecomestheslicerprogram thattakestheSTLfileandconvertitintoG-code.G-codeis nothing but the numerical control (NC) programming language. The IoT based octoprint system provides a web interfaceforcontrolling3Dprintersandallowstheusersto startprintingjobbysendingG-codeto3Dprinterconnected viaUSB.Raspberrypiisusedtomonitoralltheaspectsof3D printerandperformremotelyonoctoprint.Asthesystemis IoTbasedoctoprintprovidesawebinterfaceforcontrolling 3Dprinters.Wireless3Dprinterhasnumberofadvantage overthetraditionalwiredsetup.Thereisnolongerneedto use an SD card to copy files from the computer to the 3D printer.Ithasmadepossibletoprinttheprototypewireless onthenetwork[15].

3D printing has helped the mankind in various fields like aerospaceandautomotiveindustry,foodindustry,medical industry, architecture, fabric and fashion industry, electric andelectronicindustry.

[1] Shinde,A.A.,Patil,R.D.,Dandekar,A.andDhawale,N.M., 2020. 3D Printing Technology, Material Used For Printing and its Applications. International Journal of Scientific&EngineeringResearch(IJSER).ISSN(Online), pp.2229-5518.

[2] Delli, U. and Chang, S., 2018. Automated process monitoring in 3D printing using supervised machine learning.ProcediaManufacturing,26,pp.865-870.

[3] MP, G., Shinde, Y., Madaki, R. and Nadaf, S., 2019. IoT based3DPrinter.

[4] Dhawale, N.M., Ghewade, D.V., Patil, S.S., Gangatirkar, R.S. and Inamdar, N.A., An Application of 3D Printing Technology for Rapid Prototyping of an IoT Enabled SensorEnclosure.

[5] Savaliya, Jatin & Parikh, Harikrishna & Sidapara, A & Gosai, K. (2021). 3D Printing Technology: A Future Perspective.

[6] Shahrubudin, N., Lee, T.C. and Ramlan, R., 2019. An overview on 3D printing technology: Technological, materials,andapplications.ProcediaManufacturing,35, pp.1286-1296.

[7] Javaid,M.,Haleem,A.,Singh,R.P.andSuman,R.,2021. Industrial perspectivesof3Dscanning:features,roles andit'sanalyticalapplications.SensorsInternational,2, p.100114.

[8] Valino, Arnaldo D., John Ryan C. Dizon, Alejandro H. EsperaJr,QiyiChen,JamieMessman,andRigobertoC. Advincula. "Advances in 3D printing of thermoplastic polymercompositesandnanocomposites."Progressin PolymerScience98(2019):101162

withAurdinomega[14]

In this article the various possible technologies and techniquesusedforimplementing3Dprintingtechnologyare stated. It can be built using ALM (FDM) method where it includes(SLA)Stereolithography,(SLS)lasersintering,and fuseddepositionmanufacturingtechnologies.TheInternetof Thing technique of building 3D printing has evolved the earlierconceptsofthemodelandtheprototypeofproduct whichusesraspberrypi,wirelesscommunication,GPS,GPRS etc.Thusthesetechniquesofbuildingadditivemanufacturing

[9] Monfared,Vahid,HamidRezaBakhsheshi-Rad,Seeram Ramakrishna,MahmoodRazzaghi,andFilippoBerto."A Brief Review on Additive Manufacturing of Polymeric CompositesandNanocomposites."Micromachines12, no.6(2021):704.

[10] Fox,Bronwyn,andAleksanderSubic."AnIndustry4.0 Approach to the 3D Printing of composite materials." Engineering5,no.4(2019):621-623.

[11] Chikkangoudar,R.N.,T.G.Sachidananda,andNiranjan Pattar. "Influence of 3D printing parameters on the dimensional stability of polypropylene/clay printed

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

partsusinglaserscanningtechnique."MaterialsToday: Proceedings44(2021):4118-4123.

[12] Goyanes,Alvaro,UsaneeDet-Amornrat,JieWang,Abdul W. Basit, and Simon Gaisford. "3D scanning and 3D printing as innovative technologies for fabricating personalizedtopicaldrugdeliverysystems."Journalof controlledrelease234(2016):41-48.

[13] NandkishorM.Dhawale,DinkarV.Ghewade,SanketS. Patil , Rajiv S. Gangatirkar, Neeraj A. Inamdar “An Application of 3D Printing Technology for Rapid Prototyping of an IoT Enabled Sensor Enclosure”InternationalJournalofInnovativeResearch inScienceEngineeringandTechnology,Volume11,Issue 2,February 2022,11781185,10.15680/IJIRSET.2022.1102038

[14] TejeshGawas,SaurabhJadhav,YogeshUparkar,Bhavna Gunjal,Dr.VarshaShah,IOTBASED3DPRINTER,Journal of Emerging Technologies and Innovative Research (JETIR) www.jetir.org,Volume 8, Issue 5,May 2021,d789-d791,JETIR2105498

[15] Prof.Gujar.M.P.,YogitaShinde,RuksarMadaki,Smina Nadaf,IoT based 3D Printer,International Research JournalofEngineeringandTechnology(IRJET),Volume: 06Issue:04,Apr2019,1015-1020.

[16] Sharma,Sunil,andShaktiA.Goel."3Dprintingandits future in medical world." Journal of Medical Research andInnovation3,no.1(2019):e000141-e000141.

[17] Velu,R.,Raspall,F.andSingamneni,S.,2019.3Dprinting technologies and composite materials for structural applications. In Green composites for automotive applications(pp.171-196).WoodheadPublishing.

Volume: 09 Issue: 8 | August 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1203