1

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

1

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

2

Abstract - In this investigation an attempt has been made to investigate the effect of m-sand by partial replacement of fine aggregate along with fibre reinforcement on the surface properties of concrete such as abrasion resistance. Abrasion caused in concrete surface mainly due to heavy steel wheel movement in the industrial areas and also in hydraulic structures by water born particles and debris flow. In this study abrasion resistance was measure as per IS 1706:1972 using surface abrasion testing machine. Compressive strength of concrete also determined along with abrasion resistance. Result of this investigation concluded that the compressive strengthisproportionaltothesurfacewearresistanceand using m-sand partially as fine aggregate improves the surface abrasion resistance. Fibre reinforcement improves the abrasion resisting property of concrete. The comparison between compressive strength and abrasion resistance has been made in terms of R2 of the linear regression

Key Words: Abrasion resistance, steel fibre, manufacturedsand,polypropylenefibre.

Abrasion erosion is a significant issue from the perspective of strength in structures that support hydraulicdynamics,suchasdams,spillways,andunderwater piles loaded with debris that frequently flow in hilly areas. Additionally, industrial pavements that sustain heavy steel wheel traffic and pavements in mountainous areas that frequently need to be de-iced with de-icing salts require abrasion resistance. The primary goals of this analysis are to examine the abrasionresistanceofconcreteusingmanufacturedsand at its appropriate content and to look into the impact of steel and polypropylene fibres. In the construction of pavementsandotherbuildings,riversandhasprimarily beenemployedasfineaggregate.Theneedforriversand is necessitated by the world's accelerating rise ofinfrastructuraldevelopment.Additionally,thepriceof the sand is rising as the supply of suitable natural sand material close to the construction site is depleted. Therefore, it is necessary to find an alternative for river sand, and the finer materials from crushing operations

***

areabetteroption.Riversandisinshortsupply,andits continuous supply cannot be guaranteed, hence using manufacturedsand(m-sand)asasubstitutehasbecome necessary[1] Due to the sliding and scraping action of thewheels,pavementssufferwearandtearandabrasion when cars drive across them. Therefore, when the concrete pavement is exposed to such abrasive forces, abrasion resistance of the concrete is a crucial requirement. It is challenging to measure the damage brought on by various abrasion forces, and no one test approach is adequate to gauge concrete's resistance to wear[2]. The compressive and flexural strengths of concrete increase when m-sand particle surface roughness increases, but flexural strength of concrete decreases as m-sand particle crushing value increases. The compressive strength of m-sand concrete and its crushingvaluedonotappeartobecorrelated.Duetothe naturally rough and angular nature of m-sand particles, m-sand PCC usually exceeds river sand PCC in terms of flexural strength and abrasion resistance as long as the crushing value of m-sand particles is less than 26.5 percent[3]. In this investigation, incorporation of steel fibre and polypropylene fibre was done on separate specimens to check the effect of fibre reinforcement on theabrasionresistanceofconcrete.Boththeflexuraland compressive strengths were significantly increased by the addition of steel fibres. This increase might be related to theimproved compaction ability. Addition of steel fibre (156 kg/m3) reduced weight loss by 42 percent due toabrasion and 19 percent increase shownin flexuralstrength. The superplasticizer and improvedfibredosecanhavebetterphysicaleffectsata given paste contentand mechanical synergistic outcomes with sufficientqualities of flow[4]. Ultrahighstrength steel fiber-reinforced concrete's strength and resistance to abrasion were studied by Febrillet et al. in 2000.Intheirresearch,theimpactofsteelfibreaddition, water-binder ratio, and compaction method on the mechanicalandabrasionresistanceofultrahigh-strength steelfiber-reinforcedconcretewasexamined.Theycame to the conclusion that abrasion resistance is best improvedbycombiningtheinclusionofsteelfibreswith hot-press compaction for ultrahigh-strength mortar[5]. In 2001, Sadegzadeh et al. published the findings of a comparative study on the effects of three types of

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

fibreglass, polypropylene, and steel on various physical characteristics of concrete. Four dosage rates 1, 5, 10, and 20 kg/m3 of concrete were used, one for each type of fibre. Their experimental results have clearly shown thatthedosagerateswereakeydetermining elementin thesignificantincreasesinabrasionresistancethatwere brought about by the inclusion of all three types of fibre[6] Because of the linear relation between compressive strength and abrasion resistance, compressive strength parameter plays a vital role to determine abrasion resistance of concrete. In the first phase of the investigation, optimization of m-sand was done on the basis of compressive strength. And then appropriate content of steel fibre and polypropylene fibre along with m-sand was determined on the basis of compressive strength analysis. After optimization of all material, specimens with all optimum materials were prepared for abrasion test using abrasion testing machineasperIS1706:1972[7].

2.1 Cement

This concrete mixture contains Portland pozzolana cement byUltratech thatconformswithIS1489.1:1991. According to IS 4031.1988, all cement property tests were carried out in laboratories. Cement specifications aregivenintable1.

Table - 1: cementspecifications.

Test Values Requirements as per IS 12269:2013

fineness 7percent <10percent Normal consistency 28percent 25-35percent

Initial setting time 105minutes >30minutes

Final setting time 203minutes <600minutes

Soundness of cement 1.65mm <10mm Specificgravity 3.15

2.2.1

M-sand and natural river sand are the two types of fine aggregate employed in this experiment. Both fine aggregate classified in Zone II according to IS 383:2016[8].Riversandhadaspecificgravityandwater absorption of 2.65 and 1.4 percent, respectively, while m-sandhad2.68and1.62percent.

2.2.2

The primary matrix of the concrete is made of coarse aggregate. In this experiment, 20mm and 10mm natural coarse aggregate was employed, and it was tested in accordance with IS 2386-1963. The specific gravity was foundtobe2.7,anditswaterabsorptionratewas1%.

2.3

2.3.1 Steel fibre

Hookedendsteelfibrewasusedinthiswork,table2and figure1indicatethespecificationsforthesefibres.

Table - 2:Endhookedsteelfibrespecifications.

Specifications Value

Length 30mm Leastdimension 0.60mm Aspectratio 60 Density 7850kg/m3

Chart – 1: Endhookedsteelfibre(30mm)

2.3.2 Polypropylene fibre

In this experiment, monofilament fibre of 24 mm in lengthwasemployed,providedbyJOGANIIMPEXLLP.

Fig.2:polypropylenefibre(24mm)

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

ThisconcretemixturecontainsSikkaviscocrete5207NS, whichhasaspecificgravityof1.12.

Concrete mix was prepared as per IS 10262:2019 [9] with the w/c ratio of 0.39 using M35 grade of concrete. Toinvestigatetheoptimumdosageofm-sand,specimens were prepared with varying dosage of m-sand. Cubes of 150mm3 were casted for compressive test. As per previous literature abrasion resistance was increased with lower w/c ratio and increased characteristic strength of concrete. So, it is considered that specimen with high compressive strength may show better abrasion resistance. So, the optimization of all admixtures was done on the compressive strength viewpoint. Five specimens with 15%, 30%, 45%, 60%, 75%ofm-sandwereprepared alongwith a specimenof conventional concrete. Compressive test was performed using CTM with cubical specimens of 150mm3 as per IS516:1959. After optimization of m-sand, steel fibre at therateof0.5,0.75,1.0and1.25percentbyvolumewas usedtocastnewspecimenswithoptimumcontentofmsand that is 60 percent. And for optimization of polypropylene fibre content, cubes for compressive test were casted with 0.5kg/m3, 1.0kg/m3, 1.5kg/m3 , 2.0kg/m3 with 60 percent m-sand. After optimizing all admixtures content, cubes of 70.6mm3 were casted for abrasion test. The abrasion test was performed on abrasion testing machine as per IS 1706:1972. First fix the specimen in the holding device and abrasive dust (corundum aluminium Oxide Al2O3) of 20 ± 0.5 g was spread over the disc. Total 220 revolution was made in 10 parts with 22 revolutions in each. Abrasion testing setupshowninfigure4.

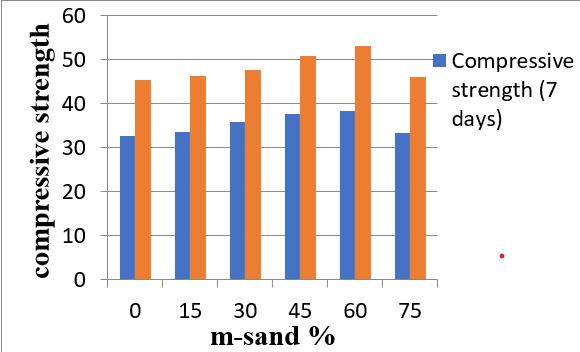

Concrete shows better compressive strength with 60% m-sand as fine aggregate. Compressive strength increased by 16 percent with 60 percent m-sand as showninfigure5

Chart – 5: compressivestrengthofconcretewith increasingpercentageofm-sand.

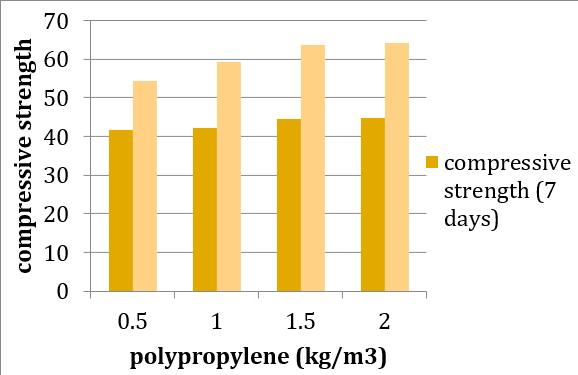

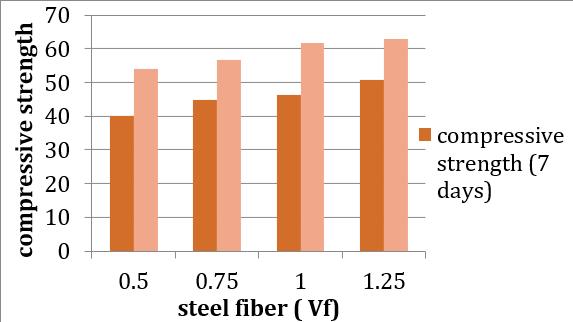

It clearly indicates that 60 percent of m-sand is the appropriateproportionforconcretemix.Followingthat, several percentages of steel fibre and polypropylene were used with the optimal amount of m-sand Figure 6 and 7 represents the compressive strength of concrete specimens with various volume fractions of steel fibre andvariousdosageofpolypropylenefibre.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

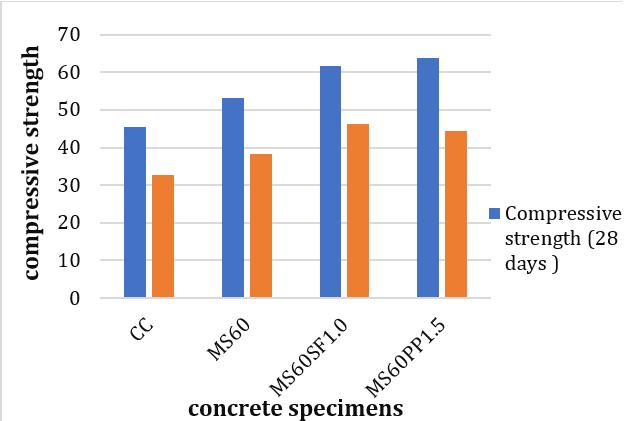

Abbreviations:CC-conventionalconcrete,MS60-concrete with 60% m-sand, MS60SF1.0- concrete with 60% msandand1%steelfibrebyvolume,MS60PP1.5-concrete with60%m-sandand1.5kg/m3 polypropylene.

chart -6: compressivestrengthofconcretewith60%msandandvaryingpercentageofsteelfibre.

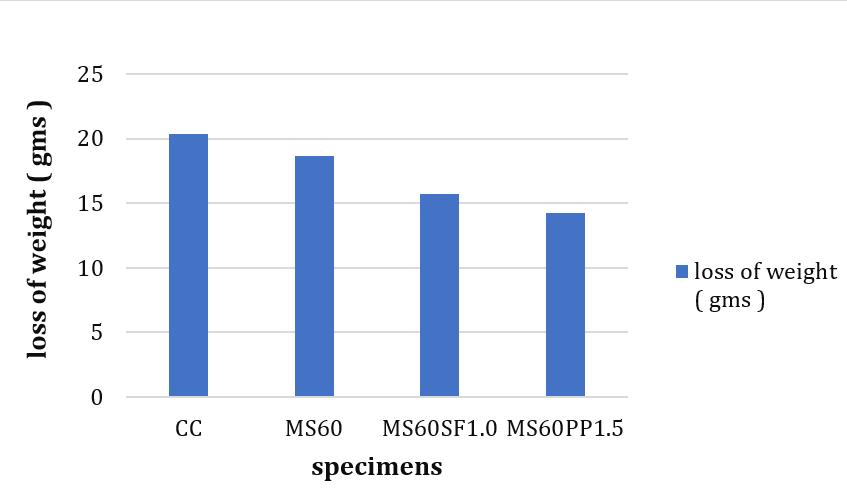

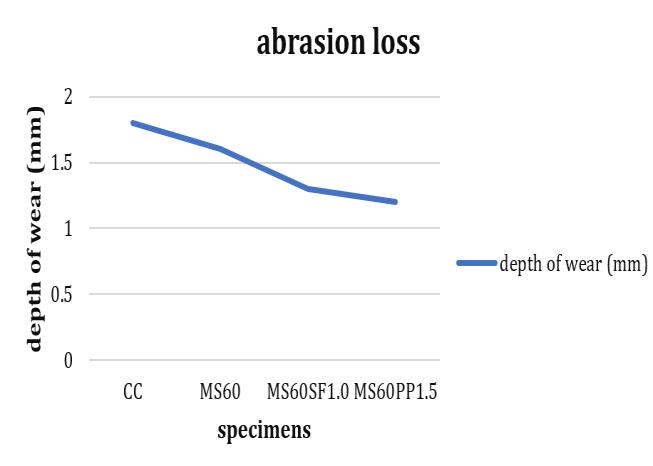

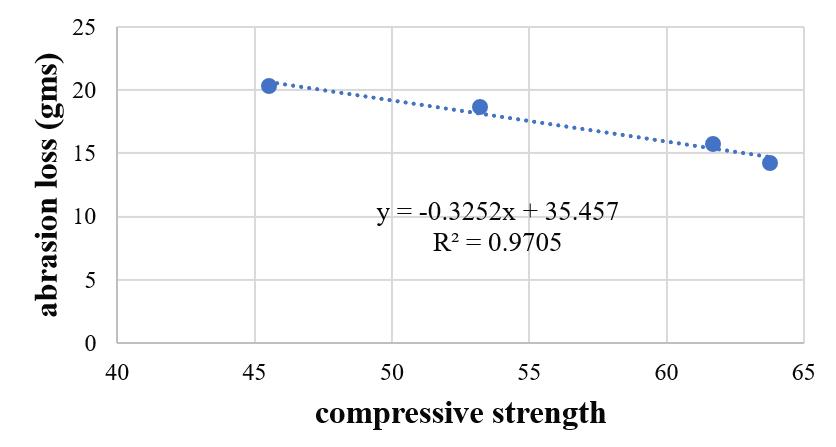

Forthe abrasiontestofconcrete, 4groups ofspecimens were prepared. One for conventional concrete, second for 60 percent of m-sand as fine aggregate, third and fourthgroupwiththeoptimumcontentofsteelfibreand polypropylene fibre with 60 percent m-sand in both. Abrasion resistance of concrete was found better with polypropylene fibre. And steel fibre also improves the abrasionresistanceofconcretewhenitusedatoptimum dosage. Depth of wear and total loss in weight had been measured for all four specimens. Loss in weight for conventional concrete comparing with steel fibre and polypropylenefibreattheiroptimumdosagearegivenin figure 9 Relation between abrasion loss and compressive strength was determined using linear regression analysis in terms of regression coefficient R2 , and strong relation shown between compressive strength and abrasion loss of concrete. As compressive strength increases, loss of weight due to abrasion decreasesshowninfigure11.

chart – 7: compressivestrengthofconcretewith60% m-sandandvaryingdosageofpolypropylene

As per result shown in figure 6 and 7, compressive strength initially increased with increasing steel fibre from 0 to 1 percent by volume of concrete. Exceeding steel fibre volume fraction from 1 percent does not improve compressive strength more efficiently. So, as perresultstheconsideredoptimumcontentofsteelfibre is 1 percent by volume of concrete. And in case of polypropylene fibre reinforced concrete, optimum content for the same fibre was adopted 1.5kg/m3 as per investigationresults.

Fig.9:lossofweightduetoabrasioninvariousconcrete samples

Fig.8:compressivestrength

Fig.10:depthofwearduetoabrasioninvarious concretesamples

ofvariousspecimenswith optimumdosageofmaterials.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

pp. 3849–3853, 2011, doi: 10.1016/j.conbuildmat.2011.04.004.

[4] B.Felekoǧlu,S.Türkel,andY.Altuntaş,“Effectsof steel fiber reinforcement on surface wear resistance of self-compacting repair mortars,” Cem.Concr.Compos., vol.29,no. 5,pp.391–396, 2007,doi:10.1016/j.cemconcomp.2006.12.010.

Fig.11:relationbetweenabrasionloss(gm)with compressivestrengthofvariousconcretesamples

Aspertheresultsofthisinvestigation,m-sandis the better replacement of river sand at its optimum content of 60 % by weight of fine aggregate. As compressive strength of concrete associatedwithm-sandisquitehighascompare toconventionalconcrete.

[5] Febrillet, N., Akihiro, K., Yukihiro, I., and Kouji, I. _2000_. “Strength and abrasion resistance of ultra-high strength steel fiber reinforced concrete.”Trans.Jpn.Concr.Inst.,22,243–252.

[6] Sadegzadeh, M., Kettle, R. J., and Vassou, V. _2001_. “Influence of glass, polypropylene and steel fibres on physical properties of concrete.” Proc.,1stInt.Conf.onConcreteandDevelopment C and D, Ministry of Housing and Urban Development,Tehran,Iran,483–492.

[7] IS 1706:1972, "method for determination of resistancetowearbyabrasionofnaturalbuilding stones",BureauofIndianStandards,p.1-7,1972

Concrete with 60 percent m-sand by weight of fine aggregate and 1 percent of steel fibre by volume of concrete reduces abrasion loss about 23 percent as compared to conventional concrete

[8] IS:383:2016, “Coarse and Fine Aggregate for Concrete-Specification,” Bureau of Indian Standards, pp.1–21,January,2016.

Polypropylene is better suited fibre to made concrete more abrasion resistance as it also improves compressive strength. Reduction in abrasion loss with 1.5kg/m3 ofpolypropyleneis about30percent.

[9] IS 10262:2019, Concrete Mix ProportioningGuidelines, Bureau of Indian Standards, January 2019.

Abrasion resistance of concrete have strong relation with compressive strength. As per regression analysis, it shows abrasion loss decreaseswithincreasingcompressivestrength.

[1] S.K.Rao,P.Sravana,andT.C.Rao,“Investigating theeffectofM-sandonabrasionresistanceofFly Ash Roller Compacted Concrete (FRCC),” Constr. Build. Mater., vol. 118, pp. 352–363, 2016, doi: 10.1016/j.conbuildmat.2016.05.017.

[2] J. J. B. A.M. Neville, concrete technology. 2010. doi:10.6004/jnccn.2015.0201.

[3] B. Li, G. Ke, and M. Zhou, “Influence of manufactured sand characteristics on strength and abrasion resistance of pavement cement concrete,” Constr. Build. Mater., vol. 25, no. 10,