International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume:9 issue:08| Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume:9 issue:08| Aug 2022 www.irjet.net p-ISSN: 2395-0072

1

Abstract - Soil stabilisation is the process used for improving strength properties of soil. In india because of different tropographical regions, improving soil strength is now a difficult task. In the current study, black cotton soil stabilisation was accomplished using resources that were readily available in the area. The impact of lime and wood ash on the black cotton soil was examined in current study. Lime is widely used to stabilise black cotton soil, but further research is needed to determine how lime and wood ash interact. Lime and wood ash were combined to create 24 soil samples at various percentages. This study focuses on improving the physical properties of black cotton soil by stabilising its atterberg limits, standard proctor, unconfined compressive strength and California bearing ratios in accordance with Indian standards. Variation of lime, wood ash was separately and combined in study was investigated, with replacement rates of 2 %, 4 %,6 %, up to 8 %, and 8 %, 16 %, up to 24 %, respectively. When lime was added, it was found that OMC increased while MDD reduced. When the two were combined, OMC marginally increased while MDD also somewhat decreased. In both instances, the increment in CBR value tends to rise up to the optimum value and then begin to fall after it. The greatest increase in the lime case was 266.92 %. Additionally, when both additions were employed in various combinations, the ideal ratio of 6% lime and 16 % wood ash was discovered, increasing the CBR value by 594% . The UCS value of virgin black cotton soil, which was 191.7 kN/m2, increased to roughly 414.9 kN/m2 for lime (6 % optimum). The optimal ratio of lime and wood ash (6 % and 16 %, respectively) in black cotton soil had a noticeable impact (514.5kN/m2) on the soil's UCS value.

Key Words: Black cotton soil , Lime, Wood Ash, OMC&MDD,UCS,CBR.

Thestrengthofthefoundationdecideswhetheritwillnot Heavyclaysoil,oftenknownasblackcottonsoil,canrange incolourfromlighttodark greyandcan be eitherclayor loam. With soil like this, cotton can growIn general, the centralandsouthernregionsofIndiahavethebestsoil.It is a basalt-derived residual soil that has undergone chemical weathering and contains a significant amount of theclaymineral montmorillonite.Black cottonsoil,which are mainly unconnected to the immediate impact of

***

loading by the structure, is a geotechnical engineering term. Due to its volumetric variations, black cotton soil is unsuitable for use in building With a change in water content, it abnormally swells and contracts. Due to the smallclaydribletspresent,thatexpandascomeintotouch withwater,thesoilhasthispropensitytoalternatelyswell and contract, which causes differential settlement of structures.

Consequently the stabilization for In this research, lime andwoodashhavebeenusedtostabilizetheblackcotton soil. Reduced soil permeability and compressibility are further benefits of soil stabilization. Any inexpensive substance with cementitious qualities is used to stabilise thesoil,whichlowersthecostofconstruction.Because of its low permeability and compressibility, strong swelling property, and other unfavourable characteristics, BCS is regarded as one of the least acceptable soils for engineeringprojects.,Thissoilisextremelytoughtowork with due to its highly plastic character. BCS is stabilised using a variety of techniques, including lime, mechanical stabilisation, and chemical stabilisation. There are numerous stabilising substances that are employed in bothmechanicalandchemicalstabilisation.

They are soft, extremely expansive soils that have a high tendency to contract or expand in response to changes in moisture. During dry seasons, the rigorous swellingshrinkingtendenciescauseopeningsin thesurfacecracks. Due to their dark brown appearance and appropriateness for cotton cultivation, they are sometimes referred to as "Black Cotton Soils" in popular culture. They are black because of iron and aluminium compounds. The central and southern regions of India have the best soil. It is a basalt-derived residual soil that has undergone chemical weathering and contains a significant amount of the clay mineral montmorillonite. It has a dark colour and is suitableforgrowingcotton.Itexhibitsgreatplasticity,high compressibility, high swelling shrinkage, and low shear strength. There is a lot of clay in the black cotton soil. Chemically, soils for black cotton are composed of lime, iron, magnesium, alumina, and potash, but they are deficientinorganicmatter,nitrogen,andphosphorus.They

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume:9 issue:08| Aug 2022 www.irjet.net p-ISSN: 2395-0072

are useful for cotton farming due to their ability to retain water.Thename"blackcottonsoil"waschosen.

Table -1: Engineeringpropertiesofblackcottonsoil

Wooden ash is the fine dust that remains after burning wood, whether it be in a fireplace, a campfire, or a commercial power plant. Along with other noncombustible trace elements found in the wood, it is primarilymadeofcalcium compounds. Woodenashhas a large amount of silica in its chemical makeup. The strength, compressibility, and permeability of the wood ash-soilmixtureareallcontrolledbyitsdrydensity,which isacrucialfactor.

Table-3 Constituentsofwoodash

S. No Chemical Composition Percentage

Limeknownforitslargeconcentrationsofcalciumand/or magnesium carbonate, dolomite (calcium and magnesium carbonate), and only trace amounts of other minerals, limestone is a naturally occurring and widely distributed sedimentary rock. All across the world, it is taken out of quarriesandundergroundmines.Thetechniqueofadding limetoblackcottonsoiltoincreaseitsfeatureslikedensity, bearing capacity, and Improvement in strength, greater resistance, permanent deformation, lowers swelling, and resistancetomoisture,isoneofthefinestmethodsforsoil stabilisation. The main components of lime, an inorganic calcium-containing substance, are oxides and hydroxides, typicallycalciumoxideand/orcalciumhydroxide.

S.No Chemical Composition Percentage

1

Calciumoxide,CaO 75.22

2 Aluminiumoxide,Al2O3 0.12 3 Magnesiumoxide,MgO 0.71 4 Ferricoxide,FeO3 0.16 5 SilicaSiO2 0.15 6 CalciumSulphateCaSO4 0.13 7 Phosphorusoxide,P2O5 0.07 8 LossofIgnition,LOI 23.31

1

Calciumoxide,CaO 28.80 2

Magnesiumoxide,MgO 5.15 3

Potassiumoxide,K2O 8.55 4 Ironoxide,Fe2O3 0.94 5 Sodiumoxide,Na2O 8.50 6 Silicaoxide,SiO2 23.8 7 Aluminiumoxide,Al2O3 15.62 8 Phosphorustrioxide,P2O3 2.23 9 Titaniumoxide,TiO2 0.80 10 LossofIgnition,LOI 2.60

Figure -1:Blackcottonsoil,lime&woodash

Vishal et al. (2018) Black cotton soils cover a significant amount of central India and a small piece of south India. The basalt and trap rocks that created these soils are residual deposits. The soils here are excellent for

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume:9 issue:08| Aug 2022 www.irjet.net p-ISSN: 2395-0072

cultivating cotton. High plasticity clays are found in black cotton soils. The soils exhibit significant shrinkage and swelling properties. The soils have a very low bearing capacity and shearing strength. The soil needs to be stabilised, and the strength needs to be high to prevent thesesituations.RHAisthefibrousriceresiduethatisleft behind after the rice husk is burned to produce ash. According to the chemical analysis of rice ash, silica, potassium,iron,calcium,magnesium,andaluminiumwere the primary components. when RHA is mixed by mass in percentagesof4%,8%,12%,and16%withblackcotton soil.Geotechnicalpropertiesarethenassessed.

Mishra et al. (2017) Studied resultsofseashrimpshells on the factors governing soil strength in clay. He found that the OMC falls off as the sea shell powder content increases,witha15%seashellpowdercontentproducing a 16.6% OMC. UCS and CBR values increase with the additionofseashrimpshells,andattheidealcontent,they increaseby 14times,or2.89timesthevalue ofthevirgin soil at its beginning. In comparison to the value of virgin soil, the UCS value increased by 14% for every 5% SSP in thesoil.

Harish (2017) The subgrade is a crucial part of the pavement's construction. It transfers the entire burden to thegroundoverabiggerregion.Thetypeofsubgradesoil and its engineering qualities have an impact on performance and resilience the pavement. Regur soil, sometimes referred to as expansive soil, is one of the troublesome soils that we encounter during construction. Improvements to geomechanical characteristics are crucialintheseinevitablecircumstances.Oneapproachof ground improvement techniques is stabilisation. In the current investigation, lime has been used to steady black cotton soil. The results have demonstrated the soil's toughnessqualitieshaveimproved,anditsflexibilityindex has decreased. There has been a noticeable increase in CBRvalue.

Manjunath et al. (2012) The adjustment or modification of one or more soil properties to enhance a soil's engineering qualities and performance is known as soil stabilisation. Low shear strength and high swell potential are two characteristics of black cotton soil. It is widely recognised to use cement or lime to stabilise such soil. However, only a small number of researchers have explored using the industrial waste known as blast furnaceslagforthispurpose.Thisinvestigation'sgoalisto ascertain the effects of GGBSon black cotton soil that containsminutelevelsoflime.Byutilisingindustrialwaste and lowering carbon footprint by avoiding cement, it is thought to be particularly beneficial for the intended applicationaswellasfortheenvironment.

Saranjeet et al. (2011) In order to enhance engineering capabilities of regursoils, the study suggests solid waste removal as a practical and affordable solution (B. C.

soil). Rice husk and FA were applied to the soil in an effort to promotesoil stabilityRHP. AccordingtoIS 2720, tests of UCSand (LL,PL) were conducted. Natural soil is givena15%FAandRHPconcentrationfor28days,which causes a rise in UCS from 198 Kpa to 253 Kpa. Its results demonstrate that the strength qualities of the soil were not improved by the addition of FAand RHpowder at a weight-basedrateof12.5%.However,theresultsofthe1, 7, 14, 21, and 28 days cured indicate that the RHand FAmixture gradually gains strength with extended curing times.

The goal of the current study is to ascertain that soil engineering parameters may be improved by using lime andwoodash.

1. To evaluate compaction behaviour of black cotton soil treated bylimeandwoodash.

2.Tocalculatetheoptimumamountoflimeandwoodash forunconfinedcompressivestrength.

3. To calculate optimal amount of lime and wood ash in proportiontotheCaliforniaBearingRatio.

The procedure used in this study is covered in this section Step-by-stepstudieswereconductedwithvarious amounts of additives applied to the soil for all tests, such asUnconfinedCompressiveStrength,OMC-MDD,andCBR.

Specificgravitytest

Liquidlimit

Plasticlimit

Plasticityindex

StandardCompactionTest

UnconfinedCompressiveStrength (UCS)

CaliforniaBearingRatio(CBR)

Thepurposeofmixturedesignonfindingabsoluteamount oflimeandwoodashtostabilisetheblackcottonsoiland achievedesiredstrengthrequirements.Tosucceedmaybe desired. Different ratios of soil, lime, and wood ash were mixedtogethertoconductvarioustests.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume:9 issue:08| Aug 2022 www.irjet.net p-ISSN: 2395-0072

Table-4 Mixproportion(soil%+lime%)

SAMPLES SOIL(%) LIME(%) TOTAL(%) 1 100 0 100 2 98 2 100 3 96 4 100 4 94 6 100 5 92 8 100

The strength parameters will be calculated using the optimised lime sample in a fixed proportion, and the behaviour of the black cotton soil will also be examined with various amounts of wood ash (WA).As per the previous studies done on regur soil for various mixtures thepercentagefordifferentingredientswastakenintothe optimum percentage which I have taken above and the results were satisfactory that’s why I took the Lime percentageof2%,4%,6%,&8%.

Table-5 Mixproportion(soil&optimumlime%+WA%)

SAMPLES SOIL + OPTIMUM LIMECONTENT(%) WA(%) TOTAL(%)

1 92 8 100 2 84 16 100 3 76 24 100

As per the previous studies done on regur soil with different mixtures the percentage for different mixture ingredients were taken into the optimum percentage whichIhavetakenaboveandtheresultsweresatisfactory that’s why I took the mixture percentage of Lime and woodashof8%,16%,&24%.

Test results are summarized in given below tables and charts. Black Cotton Soil has been mixed with different proportion of lime 0%,2%, 4%,6% and 8% as shown in table6to8and figure2to4.TheOMCincreaseswhereas MDDdecreasesat6%limecontentitincreasesandat8% it decreases. In UCS the black cotton soil mixed with lime in different proportions the UCS increases maximum at 6% lime content after it decreases and in CBR the black cotton soil mixed with lime increases at 6% and at 8% lime content it decreases. Thus the optimum quantity of limeis6%formaximumeffectonOMC-MDD,UCSandCBR. Theblackcottonsoilmixedwithlime gradually increases maximum at 6% and at 8% lime content it starts to decrease.

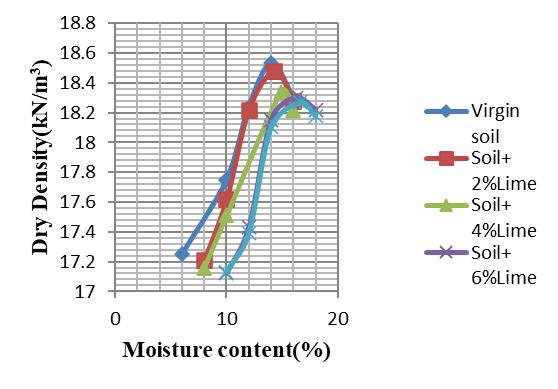

TABLE-6 OMC and MDDwith differentpercentagesof Lime

Sr. No PERCENTAGE OF LIME DRY DENSITY (kN/m3) OPTIMUM MOISTURE CONTENT (%)

1 0 18.53 14 2 2 18.48 14.3 3 4 18.34 14.9 4 6 18.30 16.2 5 8 18.27 16.6

Chart-1.OMCvsMDDofsoilwithdifferentpercentagesof lime

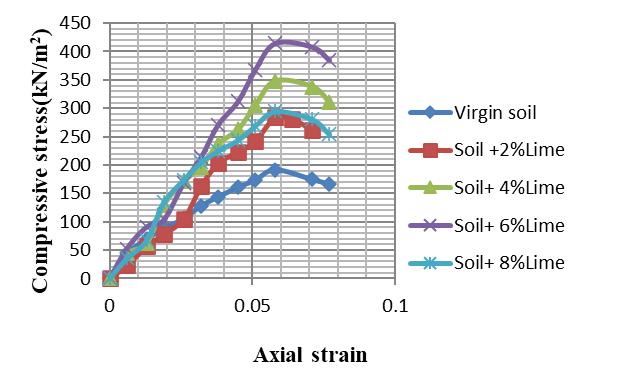

TABLE- 7 ResultsoftheUCStestwithvariousLime percentagechangearestatedintablebelow: Sr. No Percentage of Lime UCS (kN/m2 ) 1 0 191.7 2 2 284.6 3 4 348.5 4 6 414.9 5 8 294.6

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

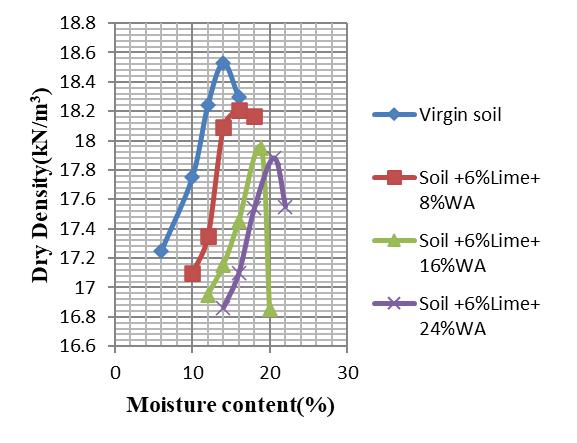

and24%mixedwith6%optimumlimearesummarizedin given below tables from 9 to 11 and charts from 1 to 6. The OMC increases where as MDD decreases , at 16% woodashcontentwith6%limeitincreasesandat24%it decreases. In UCS the black cotton soil mixed with wood ash at 6% optimum lime the UCS increases maximum at 16% wood ash and after it decreases .In CBR the black cotton soil mixed with 16% wood ash with 6% optimum limeit increasesat16%andat24%itdecreases.

Table-9 OMCandMDDafteraddingwoodashin percentagesof8%,16%and24%withoptimizedlimei.e. 6%isrepresentedbelow

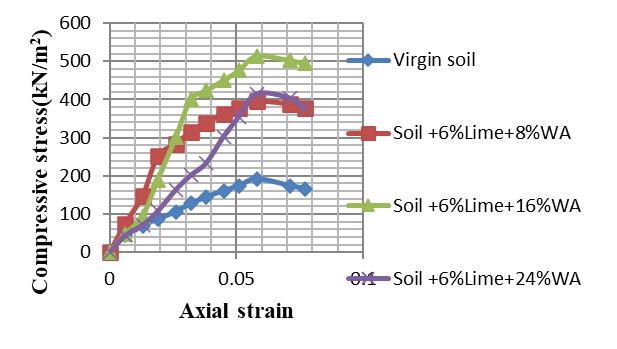

Chart -2 AxialstrainvsCompressivestressofsoilwith differentpercentageslime

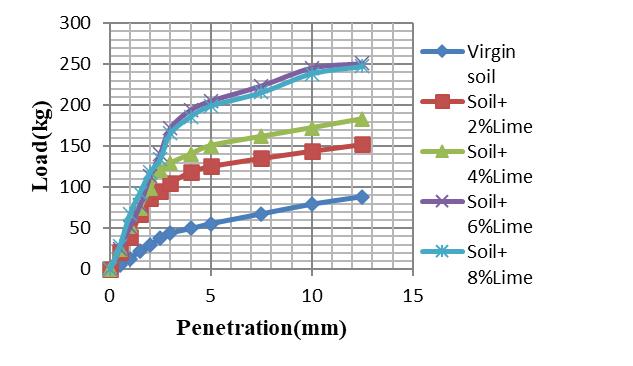

TABLE-8 ResultsoftheCBRtestwithvariousLime percentagechangearestatedintablebelow:

Sr. No PERCENTAGE OF LIME CBR (%) 1 0 2.79 2 2 6.95 3 4 8.85 4 6 10.24 5 8 9.79

Sr. No PERCENTAGE OF WOOD ASH DRY DENSITY (kN/m3)

OPTIMUM MOISTURE CONTENT (%)

1 8 18.21 16 2 16 17.95 18.9 3 24 17.88 20.5

2.1

Chart-3.LoadvsPenetrationofsoilwithdifferent percentagesoflime

LIME:

Test results of black cotton soil with mix proportion of wood ash and lime at different percentage are 8%,16%

Chart-4. OMC vsMDDofsoilmixedwithlimeandwood ashatdifferentpercentages

Table-10. UCS valueswith differentpercentage of wood ash

Sr. No Percentage of wood ash UCS (kN/m2 ) 1 8 3.951 2 16 5.145 3 24 4.149

Volume:9 issue:08| Aug 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume:9 issue:08| Aug 2022 www.irjet.net p-ISSN: 2395-0072

lime is 10.24 %; this is a 266.92 % improvement over virgin soil. The combined soil sample containing 6 % lime and 16 % wooden ash was found to have a soaked CBR value of 19.39 percent, which is an increment of 594.50 % to virginsoil

[1] Ghutke,Vishal,PranitaBhandari,andVikashAgrawal. "Stabilizationofsoilbyusingricehuskash." Int. J. Eng. Sci (2018):92-95.

Chart-5. AxialstrainvsCompressivestressofsoilmixed withlimeandwoodashatdifferentpercentages

Table-11. CBRvalueswithdifferentpercentagesofwood ash

Sr. No PERCENTAGE OF WOOD ASH CBR (%) 1 8 16.09 2 16 19.39 3 24 18.25

It was observed that OMC increased by 15.71 % with an increase in the amount of lime in BCS (Soil: lime =94:6:0), whereas MDD tends to decrease by 1.25 %. According to the study, the MDD marginally decreased and the OMC slightly increased when both of the additives, lime and wood ash, were used in BCS at various ratios. It was determined that when lime and wood ash were added to soil in different concentrations, MDD was slightly lowered by 1.94 % (soil: lime:WA =84:16:6) and OMC was slightly raised by16.66%.

[2] Harish, G. R. "Studies on stabilization of black cotton soil using lime." International Research Journal of Engineering and Technology 4.6(2017):1725-1727.

[3] Hassan (2016). “Remediation of expansive soils using agriculturewastebagasseash”.NebraskaDepartment ofRoads-InhouseResearchJuly2016.

[4] IS27201987(Part16)“CaliforniaBearingRatioTest”.

[5] IS-2720 (Part 5) “Determination of Liquid limit and plasticlimit”.

[6] IS Code 2720 1991 (Part 10) “Unconfined CompressiveStrength”.

[7] IS-2720 1980 (Part 7) “Compaction by Standard ProctortestorLightcompactiontest”

[8] Jain, Ankit, and R. K. Yadav. "Effect of lime on index propertiesofblackcottonsoil." International Research Journal of Engineering and Technology (IRJET) 3.11 (2016):749-752.

[9] Mishra (2017). “Performance of sea shell powder on sub grade soil stabilization”. International Conference on Research and Innovations in Science, Engineering andTechnology.Vol.1.Pp.150-156.

Thepercentageofrisein estimationofUCSwhen testsweredone with2%,4%,6%,and8%lime wasfoundtobe48.46%,81.79%,116.43%,and 53.67 %, respectively, compared to the virgin soil.The increment in UCS is greatest at 6% lime is 116.43%.The experiment on the combined example of lime (6%) and wood ash (16%) reveals the highest estimate of UCS, which is found 514.5 kN/m2. When contrast with virgin soil,theincrementis168.38%.

[10] Manjunath, K. V., et al. "Stabilization of black cotton soilusinggroundgranulatedblastfurnaceslag." Proc., Int. Conf. on Advances in Architecture and Civil Engineering (AARCV 2012).2012

[11] Soni, Saranjeet Rajesh, P. P. Dahale, and R. M. Dobale. "Disposal of solid waste for black cotton soil stabilization." International journal of advanced engineering sciences and technologies Vol 8 (2011): 1113

Thevalueof CaliforniaBearingRatioofthevirgin black cotton soil is 2.79%.The California Bearing Ratio (CBR) value of the soil modified with 6%

[12] Singh,ParteShyam,andR.K.Yadav."Effectofmarble dust on index properties of black cotton soil." International journal of Engineering Research and science and Technology 3.3(2014):158-163.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume:9 issue:08| Aug 2022 www.irjet.net p-ISSN: 2395-0072

[13] Srikanth Reddy, S., A. C. S. V. Prasad, and N. Vamsi Krishna. "Lime-stabilized black cotton soil and brick powder mixture as subbase material." Advances in Civil Engineering 2018(2018).

[14] Singh, Shailendra, and Hemant B. Vasaikar. "Stabilizationofblackcottonsoilusinglime." Int. J. Sci. Res 4.4(2013):2090-2094.

IqbalJaveedLone M.TECH(Geotechnical Engineering).GuruNanakDev EngineeringCollegeLudhiana, Punjab,India.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |