International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume:9 Issue:08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume:9 Issue:08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Shakir zahoor mir1, Dr. Prashant garg2, Er. Amandeep singh3

1M.TECH (Geotechnical engineering), Guru Nanak Dev Engineering College Ludhiana, Punjab

2Associate professor, Dept. Of Civil Engineering, GNDEC ldh. Punjab, India

3 Associate professor, Dept. Of Civil Engineering, GNDEC ldh. Punjab, India ***

Abstract - Clayey soil has a high concentration of the mineral illite, which changes size when exposed to moisture, that’s the reason for structure's fractures, which is based on this kind of soil. Low bearing capacity and high volume change are characteristics of the clayey soil. This research focuses on enhancing the soil's load bearing capacity by adding gypsum and sugarcane bagasse ash(SCBA). The controlled burning of sugarcane straw yields the sugarcane bagasse ash. The soil for this investigation came from a locality in the Punjab region of Ludhiana. Compaction test, California Bearing Ratio (CBR) & Unconfined Compressive Strength (UCS) tests were conducted in this study on materials containing varied percentages of gypsum (3%, 5%, 7%, and 9%) as well as sugarcane bagasse ash (8%,12% and 16% ). Gypsum addition results in an increase in OMC values and decrease in MDD values. But, it also improves the value of UCS & CBR when sugarcane bagasse ash is added at a 12% concentration and 7% gypsum concentration.

Key Words: clayey soil, gypsum, SCBA, Compaction test, California Bearing Ratio (CBR) ,Unconfined Compressive Strength (UCS).

Thestrengthofthefoundationdecideswhetheritwillnot failtosupportthestructureofthebuildingconstructedover it.Thus, making the bearing capacityofa soil an essential element in infrastructure development, like as road construction. Because all of the loads in the structure will concentrate on the foundation, the soil has to have a high bearing capacity. Clay soils usually have a low bearing capacitysoproblemswiththesoilmightarise.Thiscanbe seenthroughtheCBR(Californiabearingratio)values.Ifthe soil'sbearingcapacityislow,theCBRvaluewillbelowas well, and stabilising material can be added to the soil to increase it. This stabilising element may take the form of wasteproducts,chemicals,orothersubstancesthatimprove thesoil'sbearingcapacity. Onthe basisofstrength,soil is dividedintothreetypes:softsoil,mediumsoil,andhardsoil. It is quite challenging to establish a structure on soft soil because,assoonasaloadisplacedthroughoutthedifferent phases of construction, the earth begins to compress and settlewhichcausesthestructuretobegintomove.Forthis reason,thebuildingsarebuiltoneitherhardormediumsoil. Ifthereissoftsoilpresent,thesite'ssoilconditionsmustbe

improvedbytakingtheappropriatesteps.Forthemajority ofbuildingprojects,clayeysoilsarefrequentlyutilized.They havegoodplasticcharacteristicsandaresoftsoils,thusas the moisture content rises, so do their shear strength, compressivestrength,andvolumechanges.Theuseofrefuse and industrial effluent and their subsidiary goods as alternativestobuildingmaterialsmayeffectivelycontribute to environmental restoration and minimize their negative effectsonenvironment,especiallyinlightofthemillionsof tonsofwasteproducedyearlyacrossthenation,whichnot only causes the problem of disposal but also adds to environmentalcontaminationandhealthrisks.

Sugarcane bagasse ash is a pozzolanic substance with extremely high levels of silica and aluminium. Calciumhydroxidesilicate,whichhascertaincementitiousqualities, combineswiththepozzolanicpropertiesofmaterialsinthe presenceofwater.Bagasseashiskeptindampenvironments. Thebagassepileispartiallydriedbytheexothermicprocess causedbythesugarresidue'sminordeterioration.Bagasse ashisaveryhomogenoussubstance.1,48,000hectaresare now under cultivation for sugarcane. Moreover, it is predictedthateachhectareofsugarcanewouldproduce100 tonnes ofsugar. Accordingto this, 4 to5 milliontonnesof sugarcaneareproducedannually.Bagasseashwascreated fromsugarcaneintheproportionof40%.

Table -1: ChemicalcompositionofSCBA

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume:9 Issue:08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Calcium sulphate dihydrate, or gypsum, is a soft sulphate mineral.ItschemicalformulaisCaSO4.2H2O.Itisextensively excavated,usedasmanure,andtheprimarycomponentof severalplaster,pavementorblackboardchalk,anddrywall products. Alabaster, a large-scale, fine-grained form of gypsumthatiseitherwhiteordelicatelycoloured,hasbeen employedforsculptingbyanumberofcivilizations,included Medieval England's Nottingham alabasters, Mesopotamia, Rome, and the Byzantine Empire. Gypsum has retrograde solubility,whichmeansitbecomeslesssolubleatincreasing temperatures, unlike the majority of other salts. At 25 °C, gypsum has a moderate water solubility of 2.0–2.5 g/l. Gypsumiscomposedoflayersofcalcium(Ca2+)andsulphate (SO24)ionsthatarecloselylinkedtogether.Whengypsumis subjected to high temperatures, results in water loss and initially transforms into calcium sulphate hemihydrate. Becausegypsumis150timesmoresolublethanlimesand contains23%calciumand18%sulphur,itprovidesanatural sourceofplantnutrients.

M. Carlina et al. (2021) Waste products in the form of eggshell powder and bagasseash wereusedas stabilizing materialsinthisinvestigation.Thebagasseashcombination employedinthis investigationhadvariations of7%, 10%, and13% plus3%eggshellpowderMoisturecontent,sieve analysis,specificgravity,consistencylimitations,compaction testing,andCBRtestingareallincluded.,thereisa92.303 %increaseintheCBRvalueofclaysoilusingastabilization mixture

Kumar Abhimanyu Bhardwaj et al. (2019) Thisresearch paper's goal is to examine the strength characteristics of naturally clayey soil reinforced with varying amounts of gypsum by soil weight and a fixed amount of calcium chloride as a binding agent. On both natural soil and reinforcedsoilwithdifferentamountsofgypsum(2%,4%, 6%, and 8 %) by weight and a set proportion of calcium chloride(1%),aseriesofStandardProctortest,Freeswell Index&CaliforniaBearingRatio(CBR)testwereconducted.

B. A. Mir et.al (2016) To assess the behavior of SCBA admixedcementstabilizedsoil,Laboratorytestsincludesoil grading,atterberglimits,compactioncharacteristic,andCBR tests.testspecimenswerepreparedwithsoilusingvarying percentagesofSBA(0,7.5%,15%,and22.5%)andcement (0, 3 %, and 6 % by wt of the soil) at 0.95γdmax and optimum moisture content and various tests as per the applicable standard operating procedures. Additionally, it was shown that adding SCBA cement mix at the ideal proportion of 7.5% SCBA and 6.5% cement produced exceptionalresults.

5.1 Mix proportions for experiments with varying percentages of different Stabilizing agent

Mixdesignaimstodeterminetheidealratioofgypsumand sugarcanebagasseashtostabilizethesoiltothe required strength. In varying ratios, soil, gypsum, and sugarcane bagasseashwerecombinedtoconductvarioustests.

Table -2: Mixproportion(soil%+gypsum%)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume:9 Issue:08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Thevalueoftheoptimized gypsumsample will serveasa fixedproportionforthefurthercalculationofthestrength parameters, and the behavior of the clay soil will also be examinedwithvariousadditionsofsugarcanebagasseash (SCBA).

Table -3: Mixproportion(soil&optimumgypsum%+ SCBA%)

SAMPLE SOIL + OPTIMUM GYPSUM CONTENT (%) SCBA (%) TOTAL (%)

1 92 8 100 2 88 12 100 3 84 16 100

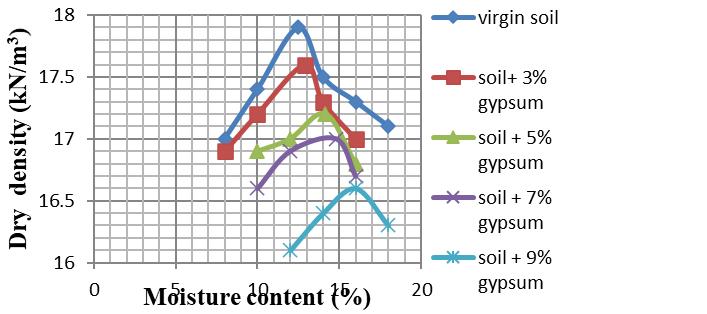

Table -5: OMC&MDDresultswithgypsum

S.No. Gypsum (%) MDD (kN/m3) OMC (%)

1 0 17.9 12.5 2 3 17.6 12.9 3 5 17.2 14.15 4 7 17.0 14.8 5 9 16.6 16

5.2

According to Indian Standard Classification of Soil, soil is usually divided in categories based on certain index properties.Thetablebelowtabulatesthegrouping.Thefirst letterindicatesthesoiltype,andthesecondletterdenotes thedegreeofcompressibility,forexample,theCLgroupof soildenotesclayandlowcompressibility.

Table -4: Index properties of Soil

SR.NO PROPERTIES VALUE

1 Specificgravity 2.63

2 Liquidlimit(LLin%) 30.20 3 Plasticlimit(PLin%) 17.95 4 Plasticityindex(Ip in%) 12.25

5 Soilgroup(asperIS:1498) CL

Chart -1: Variationincompactioncharacteristicswith gypsum

Gypsumreducesthemaximumdrydensitywhileincreasing the soil's optimum moisture content up to a specified admixturecontent%.Thedecreaseindrydensityisbrought onbysoilparticleflocculation.Thesoilgetslooserandmore challengingtocompress.Whiletheadditionoffinerparticles likesgypsumincreasedthesoil'ssurfacearea,whichinturn improved the optimal moisture content. More water is neededtomoistensoilparticleswithgreatersurfaceareas.

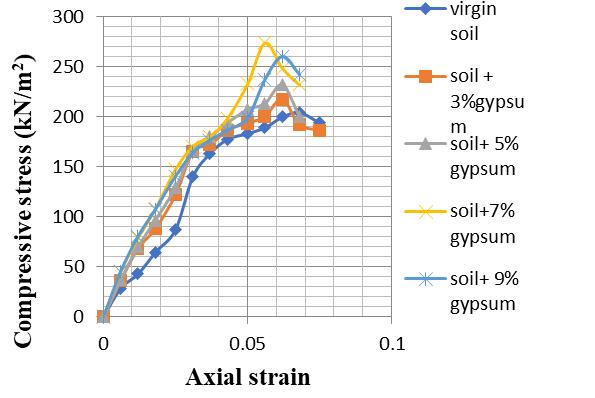

5.4 Unconfined compressive strength (UCS) of soil sample with Gypsum

ResultsoftheUCStestwithvariousgypsumpercentagesare displayedandsummarizedinthetablebelow:

Table -6: UCSresultswithgypsum

The value of OMC and corresponding MDD with different percentageofgypsumaresummarizedinthetablebelow-

S.No Gypsum (%) UCS (kN/m2) 1 0 204.76 2 3 217.71 3 5 232.20 4 7 273.93 5 9 260.34

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

The percentage increment in UCS values at varying percentages3%,5%,7%&9%ofgypsumarefoundtobe 6.32%,13.4%,33.78%&27.14% respectively,morethanthe virgin soil samples. The maximum value is found at 7% whichis273.93kN/m2

Chart -2: VariationinUCSwithgypsum

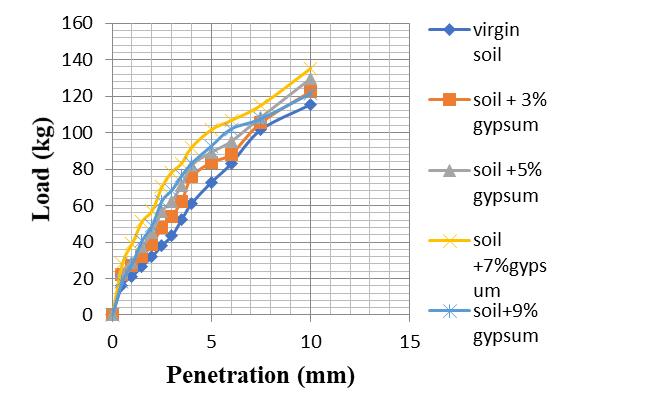

5.5 California bearing Ratio (CBR) of soil sample with gypsum

CBR values with different percentages of gypsum is given below

Table -7: CBRresultswithgypsum S.No. Gypsum (%) CBR (%) 1 0 3.53 2 3 4.06 3 5 4.33 4 7 5.12 5 9 4.55

Chart -3: Californiabearingratiotestvariationswith gypsum

5.6

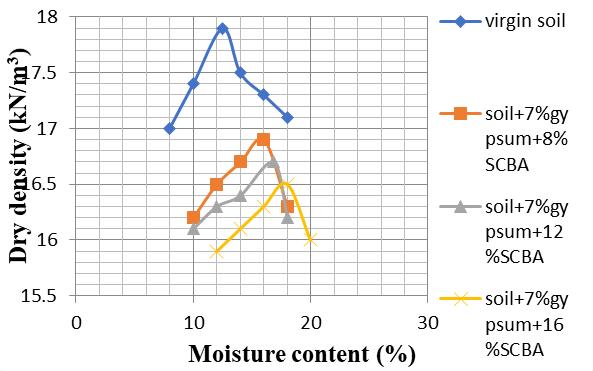

The values of OMC & MDD after adding significant proportionofsugarcanebagasseashinpercentageof8,12& 16%withoptimumvalueofgypsumwhichistakenas7%is summarizedbelow

Table -8: OMC&MDDresultswithSCBA

S.No. SCBA(%) OMC(%) MDD(kN/m3) 1 8 16 16.9 2 12 16.8 16.7 3 16 18 16.5

Chart -4: Variationincompactioncharacteristicswith gypsum&SCBA

Maximumdrydensitytendstoriseandoptimummoisture contentgraduallydeclineatadmixturecontenthigherthan optimallevels.Thisdiscrepancyinresultsisexplainedbythe fact that at greater admixture contents, the soil structure tends to spread, increasing maximum dry density and decreasingoptimummoisturecontent.

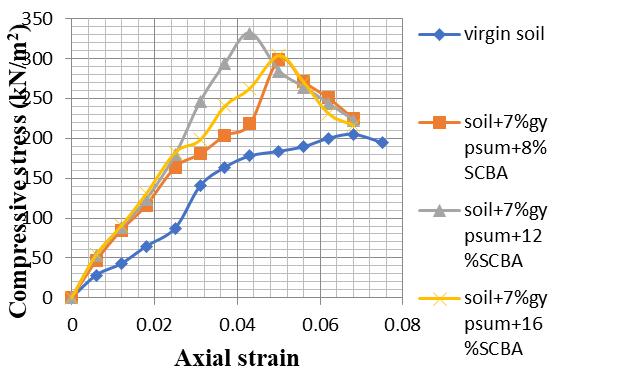

5.7 UCS of 7% gypsum mixed with sugarcane bagasse ash (SCBA)

The value of UCS with different percentage of SCBA are compiledbelow

Table -9: UCSresultswithSCBA

S.No. SCBA(%) UCS(kN/m2) 1 8 298.82 2 12 331.50 3 16 303.85

Volume:9 Issue:08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1108

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume:9 Issue:08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

The value of CBR indicates adrop with an increase in sugarcanebagasse ash, but a very little decrease with gypsum.Thegypsumparticlesize,whichfillsthespacesin clayey soil, is to blame for this behavior. While in case of sugarcanebagasseash,CBRvaluedecreasesifmorebagasse ash is applied than is optimal. The CBR decreases with higherashadditions,whichmaybecausedbythequantityof ashthatdoesn'treactandformcrystals.Asaresult,youhave unreactedashgrainsratherthansoilgrains,whichdonot increasesoilresistance.

Following conclusions from tests were drawn during the investigationandexperiments

Chart -5: Variation in UCS with gypsum & SCBA

With the addition of gypsum and bagasse ash to soil, unconfinedcompressivestrengthofthesoilhassignificantly increased. After reaching an appropriate proportion of admixture, unconfined compressive strength starts to decline.Thisvarianceisrelatedtothesoil'stransitionfrom flocculated to the dispersed structure after exceeding an optimum admixture proportion. Additionally, the ideal moisturelevelisrisingaswell.

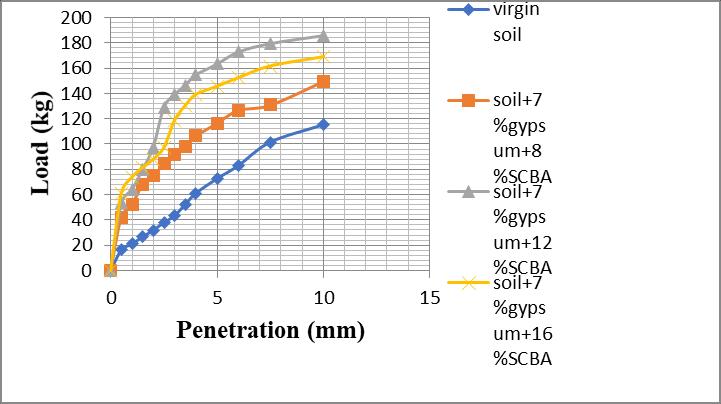

5.8 CBR of 7% gypsum with different percentage of SCBA

TheCBRvaluesatdifferentpercentagewithSCBAisshown below

AdditionofgypsumresultedinincreaseOMCanda declineincompressibilityvalueintermsoftheMDD parameter, OMC of virgin soil is 12.5% and MDD 17.9kN/m3,withadditionofgypsumandSCBAthe value of OMC increases while MDD decreases considerably. The change in soil matrix, which showsamorerandomlyflocculatedstructuredueto the presence of CaO in SCBA and the addition of gypsumcontent,mayberesponsiblefortherisein moisturecontent.

TheUCSishighestat7%gypsumwhichis33.78%. UCS with the combination of gypsum (7%) and sugarcanebagasseash(12%)showsthepeakvalue thatisfoundas 331.50kN/m2.TheincreaseofUCS whencomparedwithuntreatedsoilis61.89%.

CBRvalueofvirginsoilisfoundoutas3.53%.The value of CBR of the soil having addition with 7% gypsumis5.12%,thepercentageincrementinCBR valuewhencomparedtovirginsoilis45.04%.The CBRvalueofcombinedsoilsamplewith7%gypsum &12%SCBAis9.42%,whichisa166.85%increase inCBRvalueovervirginsoil.

[1] Adeyanju,E.A.,&Okeke,C.A.(2019,November).Clay soil stabilization using cement kiln dust. InIOP Conference Series: Materials Science and Engineering(Vol.640,No.1,p.012080).IOPPublishing.

[2] Bhardwaj,K.A.,&Kumar,S.(2019).Stabilizationofsoil withcalciumchlorideusinggypsum.Int.J.Res.Appl.Sci. Eng.Technol,7,117-124.

Chart -6: Californiabearingratiotestvariationswith gypsum&SCBA

[3] Carlina, M., Apriyanti, Y., & Fahriani, F. (2021, November).TheEffectofAdditionofBagasseAshand Eggshell Powder on CBR Value of Clay Soil. InIOP Conference Series: Earth and Environmental Science(Vol.926,No.1,p.012102).IOPPublishing.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume:9 Issue:08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

[4] Hidalgo, F.Saavedra, J.Fernandez, & Duran, G. (2020, February).Stabilizationofclayeysoilforsubgradeusing ricehuskash(RHA)andsugarcanebagasseash(SCBA). InIOP Conference Series: Materials science and engineering(Vol.758,No.1,p.012041).IOPPublishing.

[5] IS: 2720-part 4 (1985). Determination of grain size distribution,BIS,NewDelhi.

[6] IS: 2720-part 1 (1980), Indian Standard Code for preparationofsoilsamples,BIS,NewDelhi.

[7] IS: 2720-part 3(2) (1980). Determination of specific gravity of fine, medium and coarse grained soils, BIS, NewDelhi.

[8] IS: 2720-part 5 (1985). Determination of Atterberg limits,BIS,NewDelhi.

[9] IS:2720-part8(1980).Determinationofwatercontentdrydensityrelationusingheavycompaction,BIS,New Delhi.

[10] IS: 2720-part 16 (1979), Method of test for soils: Laboratory determination of CBR, Bureau of Indian standards,NewDelhi.

[11] Lal,D.,Kumar,M.J.,Kumar,K.N.,Sindhu,K.,&Kumar,A. (2020).Soilstabilizationusingbagasseash.InAdvances inGeotechnicalandTransportationEngineering(pp.2128).Springer,Singapore.

[12] Mir,B.A.,K.Gupta,andJ.N.Jha."SomeStudiesonThe Behavior of Sugarcane Bagasse Ash Admixed With CementStabilizedSoil."InternationalConferenceonSoil andEnvironment.2016.

[13] Mishra, S., Sachdeva, S. N., & Manocha, R. (2019). Subgradesoilstabilizationusingstonedustandcoarse aggregate: a cost effective approach.International JournalofGeosyntheticsandGroundEngineering,5(3), 1-11.

[14] Pushpakumara, B. H. J., & Mendis, W. S. W. (2022). Suitability of Rice Husk Ash (RHA) with lime as a soil stabilizer in geotechnical applications.International JournalofGeo-Engineering,13(1),1-12.

[15] Roohbakhshan,A.,&Kalantari,B.(2013).Stabilizationof clayey soil with lime and waste stone powder.InternationalJournalofScientificResearchin Knowledge,1(12),547.

M.TECH(Geotechnicalengineering), GuruNanakDevEngineeringCollege Ludhiana,Punjab,INDIA

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |