International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Ms. Sowmmiya S1 , Dharunesh S2

Ms. Sowmmiya S1 , Dharunesh S2

Asst. Professor, Dept. of Fashion Technology, Bannari Amman Institute Of Technology, Tamil Nadu, India UG Scholar, Dept. of Fashion Technology, Bannari Amman Institute Of Technology, Tamil Nadu, India ***

Abstract - Study have been made to use air-vortex spun yarn of 40s count s sewing thread by using 1%, 3% and 5% concentrationsoflubricant Yarnstrength,elongation,hairiness,dryheatshrinkage,yarnabrasion,snarlingofyarnafterheat setting,loopstrengthandknotstrengthofair-vortexspunsewingthreadshavebeenstudied.Itisobservedthatthesewing threadmadewith5%concentrationoflubricant performs better in comparison to that made with 3% and 1% lubricationlevel Sewingperformanceofthreadshasalsobeenanalyzedbytestingseamstrength,seamefficiencyandthread breakage during sewing. Sewability of fabric depends on the low-stress mechanical properties and sewing thread properties.Thepolyestertexturedsewingthreadhashigherseamefficiencyandseampucker.However,useofcottonsewing threadforsyntheticfabricsreducestheirlifeduetopoorseamperformance.Sewingthreadmustbedesignedtomeettwo fundamentalfunctionalrequirements,vizsewabilityofthethreadand thread performance inseam. Good lubricationfinish is required to make threads run smoothly on high-speed machine, where temperature may reach over 300°C. Fast developmentinsewingtechnologyandever-increasingdemandfordiversifiedusesandapplicationsresultedindevelopment ofvarioustypesofsewingthreads.Selectingthecorrectsizeofthreadforaparticularapplicationisveryimportanttothe threadperformanceduringsewingandafterwardsintheseam

Key Words: Air vortex yarn, sewing thread, ring spun yarn, spinning methods, sewing thread lubrication, yarn twisting process, air vortex sewing thread, sewing thread application.

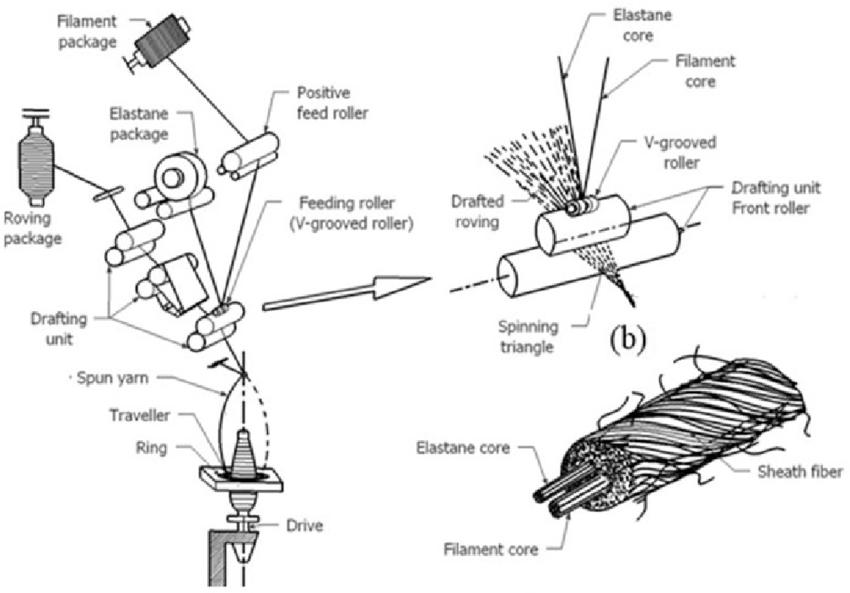

Yarnspinningistheprocess ofcreatingorconvertingfibreresourcesintoyarnsingeneral.Spinninghasbeenknownasa processoftransformingrawmaterialssuch as cotton and wool into yarns for creating textile fabric or items since afew centuriesago.Ring-spun,rotor-spun,twist-less,wrap-spun,andcore-spunyarnsareamongtheseveralspinningtechnologies usedtocreateyarns Ring-spunyarnsarethemostcommonwayofproducingstaple-fibreyarns Theoldestofthemodern spinning methodsis ring spinning. The ring-spinningmachine receives the fibre material in the form of roving. The roving's fibremassisdecreasedusingadraftingdevice Theinsertedtwistgoesrearwarduntilitreachesthedraftingunit's fibres Thefibresformconcentrichelicalpathwaysaroundoneanother

Undertensilestrain,theusualforcesexperiencedbythefibersincreasetheadhesiveforcesbetweenthem,preventingfibresfrom flyingorslippingpasteachother.Itistheprocessofdrawingoutrovingtotherequiredyarncount,twistingthefibreswitha rotatingspindle,andwindingtheyarn onto a bobbin. These three steps occur at the same time and in the sameorder A twistiscreatedbyamechanicallyoperatedspindleonwhichtheyarnpacketissecurelyheld.Thetravellerisheldinplaceby afixedringthatwrapsaroundthespindle.Theyarnisdrawnunderthetravellerandthenledtotheyarnpackagefromthe draftingunit Thetravellermustcooperatewiththespindleinordertowoundthetwistedyarnonabobbintubecarriedby thespindle.Thetravelleristransportedalongtheringbytheyarnitisstrungwith,ratherthanbyanyphysicalforce The

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

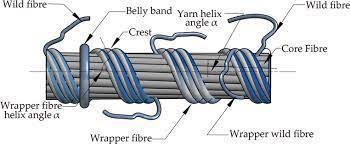

travellerspinsataslowerratethanthespindle,allowingforyarnwindingonthetube.Theshapeoftheyarnpacket,knownas aCoporBobbin,isdeterminedbyaregulatedupanddownmovementofthering.Theyarncountsthatcanbeproducedby ringspinningtechnologyarethemostdiverse.Duetoitsslowerproductionspeedsandtheadditionalprocedures(rovingand wrapping)requiredtoproduceringspunyarns,ringspinningisaratherexpensive operation. Ringspun yarns are highquality yarns that are mostlymadeinthefine(60Ne,10tex)tomediumcount(30Ne,20tex)ranges,withatinynumber madeinthecoarsecount(10Ne,60tex) High-qualityundergarments,shirting,andtowelsareexamplesofendapplications Theringyarn'sfibresareveryparallelandhelicalincharacter,andthefibrearrangementisconsistentthroughouttheyarn's thickness Withnowrappingorloopedfibres,theyarnhasacompactstructure.Theself-lockedstructureiscausedbyintense fibre migration, which is impacted by the spinning zone's triangular geometry and high spinning tensions The yarn's remarkableaxialstrengthisduetoitsuniqueself-lockedstructure.

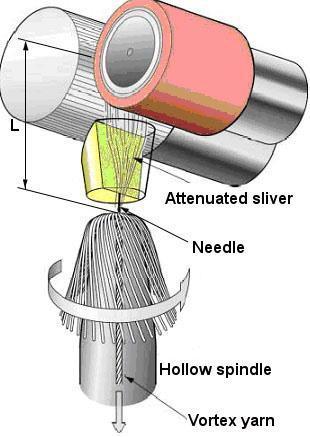

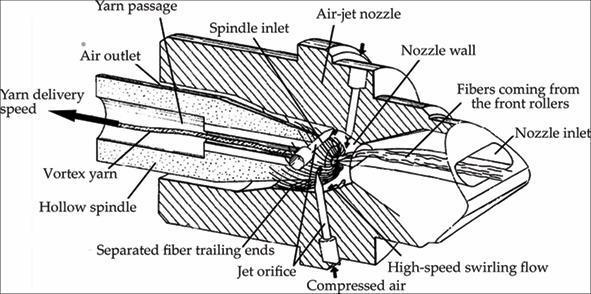

Vortexspinningisayarn-spinningtechniquethatemploysanairvortex.Thefibrescreatedbytheseairfluxeshaveadistinct structure,whichgivestheyarnawiderangeoffunctions.Vortexspinningusesafour-rolleraprondraftingmethodtodraught pulledcottonslivertotheappropriateyarncount(fineness) Thedraftedfibresarethendrawnintoanozzle,wheretheyare swirledaroundtheoutsideofahollowstationaryspindlebyahigh-speedairvortex.Thefibrescreatedbytheseairfluxes haveadistinctstructure,whichgivestheyarnawiderangeoffunctions.Sinceitispossibletoeliminatemoveableelements such as thespindle andtraveller in ring spinning orthe centrifugein rotor spinning, air-jet spinningsystems have been developed.

TheperformanceoftheMuratavortexspinning(MVS)system,whichisthenewesttechnologyafterallinvestigationsofair-jet systems,hasbeenveryencouraging,particularlyfortheabilitytospin100percent cotton at high speeds (500 m/min) and the yarn structure resemblingringyarnsratherthanrotoryarns

Muratavortexspinning(MVS)isbasedonMurata'scurrentair-jetspinningtechnology,howeveritdiffersfromMuratavortex spinning(MJS)inprincipledue to the geometry of the air-jet twisting device employed. A nozzle blockwithinjectorsfor swirlflowcreation,aneedleholder,ahollowspindle,andaguidemembermakeupthisair-jetdevice.Asketchedsliverisfed toafour-linedrawingsystemintheMVSsystem.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Thefibres migrate tothe air-jet nozzle after exiting the front rollers. The twistingmotiontendstoflowupwardtowardthe frontrollersofthedraftingunit,eventhough the fibres are orientated to be twisted with the pressurized air effect;here, theguideelementprojectingfromthefibrebundlepassagepreventsthisduringyarncreation.Thevortexchambergeneratesa high-speedwhirlingaircurrentintowhichthepressurizedairisinjected.Thesectionsthatwilleventuallybecomecorefibres aredraggedintothevortexspunyarnpath.Thehighersectionsofsomefibresseparatedfromthefrontrollers'nippoint,on theother hand, are left open. After the trailing ends leave the nip point, they passviathespiralfibrepassageand,dueto thewhirlingforceoftheair-jetstream,they twine around the hollow stationary spindle and become the wrappingfibres.

Cotton(fiberlength32mmandfineness36micronaire)andpolyester(fiberlength40mmanddenier1)wereblendedina70 percentpolyester/30percentcottonratiotomakethe sliver androving.Then, usinganair-vortexspinningmachine,these materials wereemployed tocreate yarns withcountsof 30Neand40Ne.Thesliver'shankwas0.14Ne. Thesingleyarn createdbytheair-vortexspinningmethodwaswoundandthenturnedintosewingthread.Thevortexyarnwasconditioned toeliminatesnarlingandprovidezerolivelinesstotheyarn.Twovortexsingleyarnswerewindedinparallelandjoinedinthe machine. When feeding single yarn directly into a ply twisting machine, parallel winding prevents the single yarn from knotting.IntheTFO(TwoForOne)machine,theplyyarntwist was set at 14.2TPI for 30Neand 15.36TPIfor 40 Ne.Thedyeingwasdoneaccordingtotheusualprocessparameters Thefinishingprocesslubricatestheyarn,resultingina lowercoefficientoffriction.Inthisstudy,acommerciallubricantcalled"T23"withconcentrationsof3percentand5percent wasemployed.Previously,finishingwasdoneonawindingmachine,andtheadd-on%wasalteredbychangingthemachine's settings Inthisexperiment,2gofthreadwasdriedina110°Covenfor10minutesbeforetheweightwasdetermined.The threadwasthensteepedin100mLpetroleumetherfor15minutesbeforedryingfully.Thethreadweightwasmeasuredafter ithaddried.Thefollowingformulawasusedtocalculatethelubricationcontent;

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Abrasiontests,rubs 4800 2600 6900 3700

Looplength,N 60 40 90 65

Knotstrength,N 5 4.5 5.2 5.7 Yarnhairinessindex 5 4.5 4.1 3.3

It has been discovered that as the lubricant concentration rises, yarn strengthrises as well This could be because the friction between the yarn is reduced,whichenhancestheload-sharingabilityoftheunder-stressedyarn.30Sair-vortex spunyarnshaveagreateryarnstrengthratingthan40Sair-vortexspunyarns.Theinternalparallelbundleisheldtightly together by the number of wrappers. Vortex yarn has a greater strength value due to these underlying structural arrangements.Elongationpercentageisinfluencedbythelubricantlevel.Inthiscase,lubricationlevelof3percentleadsin moresewingthreadelongation.However,whenthelubricantlevelis5%,thesewingthreadelongationislow,andthesurface ofthesewingthreadissmooth.

However,duetothelowelongationandsmoothsurface,nobreakageoccursduringsewing.Atalubricantlevelof5percent, heatgenerationintheneedleduringsewingisalsoreduced.Forstitching,theelongationofthesewingthreadshouldbekeptto a minimum Thelower elongation valuesin thevortex yarnstructure could be owing to a reduction in or prevention of slippageasaresultofimprovedwrappergripontheyarnsurface,resultinginalowerelongation.Yarnswithalubricantlevel of3percentshrinkmorethanthosewithalubricantlevelof5percent Normalring-spunyarnhasatwistedstructurethathasa springy qualityto it and is prone to shrinking. There is no twisted structure inVortexyarn; Asa result of thisstructural difference,thevortexyarnhasafarlowershrinkingproblem.Duetoitsyarnstructure,thevortexyarnhasalowersnarlvalue thantheotheryarns

Theyarnhasverylittlesnarlingduetotheuntwistedcorefibers.Becausetheuntwistedfibersarecloselyfoldedtogetherwith thehelpoflubrication,yarnsnarlislowat5percentlubricantconcentration.Yarninthe40shasaminimalyarn-to-yarn abrasionbecauseitcontains3percentlubricant. For30sand40svortexyarns, 5 percent oflubricantresultsinahigher numberofabrasioncycles.Sincethesewingyarngoesthroughtheneedleatarapidpace,heatbuildsupintheneedle,causing thethreadtobreak.Asaresult,thesewingthreadtreatedwith5percentlubricationlevelpreventsthreadbreakingandruns smoothlyduringsewing.Thehigheryarnstrengthisresponsibleforthehigherloopstrengthof30ssewingthreads.Onthe otherhand, asthe lubricant concentration rises,theloopstrengthfor both 30sand 40svortex yarnsincreases. Theknot strengthofasewingthreadisusedtodeterminethethread'sbrittleness.Theknotstrengthisalsoareflectionofthethread's performance aftersewing. Knotstrength increasesaslubricant concentrationrisesfor both30sand40svortex yarns.In comparedto30ssingleyarn,40ssingleyarnhaslesshairinessbecausethewrapperfibersareentirelyboundonthesurfacein 40syarn,resultinginlesshairiness.Hairinessdecreasesasthelubricantcontent risesinboth30sand40syarn.Withan increaseinlubricantcontent,thewrappedandprojectingfibersareheldtightlytogether,resultingindecreasedhairiness.

1. Sowmmiya. s, Das, subrata. Application of air-vortex thread in sewing operation, http://op.niscair.res.in/index.php/IJFTR/article/view/31194

2. Gizem karakan günaydin and ali serkan soydan. Vortex Spinning System and Vortex Yarn Structure, https://www.intechopen.com/chapters/53651

3. Mazharul islam kiron. Murata Vortex Spinning (MVS) Process, Principle of Vortex Spinning Technology, https://textilelearner.net/vortex-spinning-system/

4. Lekhani tripathi and Bijoya kumar behera. Comparative Studies on Ring, Compact and Vortex Yarns and Fabrics, https://irispublishers.com/jtsft/pdf/JTSFT.MS.ID.000646.pdf

5. Mayur s. choudhari, Saket totala and Akash s. deshmukh. Effect of ring and vortex spinning technologies, https://www.textiletechnology.net/technology/trendreports/dkte-societys-textile-and-engineering-institute-effect-ofring-and-vortex-spinning-technologies-on-viscose-yarn-characteristics-30889

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

6. Seval uyanik & Pinar duru baykal. Effects of fiber types and blend ratios on Murata Vortex yarn properties, https://www.researchgate.net/publication/321297004_Effects_of_fiber_types_and_blend_ratios_on_Murata_Vortex_yarn_p roperties

7. Seval uyanik & Pinar duru baykal.Effects of Fiber types and fiber blends ratio on vortex yarn properties, https://www.researchgate.net/publication/318882349_EFFECTS_OF_FIBER_TYPES_AND_FIBER_BLENDS_RATIO_ON_VOR TEX_YARN_PROPERTIES

8. Gunaydin karakan gizem. A research on tensile properties of vortex yarns, https://www.researchgate.net/publication/318582957_A_research_on_tensile_properties_of_vortex_yarns

9. Pranaydutta,Mohammedabusuffian.Effectofairpressureonthecotton/polyesterblendedvortexspunyarnpropertiesin terms of uniform yarn count, https://www.researchgate.net/publication/350687243_EFFECT_OF_AIR_PRESSURE_ON_THE_COTTONPOLYESTER_BLEN DED_VORTEX_SPUN_YARN_PROPERTIES_IN_TERMS_OF_UNIFORM_YARN_COUNT

10. GuldemetBasalandWilliamOxenham.Vortexspunyarnvs.air-jetspunyarn,http://autexrj.com/cms/zalaczone_pliki/103-3.pdf

11. EvaMouckova,IvaMertova.PropertiesOfViscoseVortexYarnsDependingOnTechnologicalParametersOfSpinning, https://www.researchgate.net/publication/276502351_Properties_Of_Viscose_Vortex_Yarns_Depending_On_Technologica l_Parameters_Of_Spinning

12. Nazan Erdumlu, Bulent Ozipeck. The structure and properties of carded cotton vortex yarns, https://journals.sagepub.com/doi/full/10.1177/0040517511433150

13. Subrata das, Sowmmiya. Study on the performance of air vortex sewing thread, https://www.researchgate.net/publication/349883098_Application_of_air-vortex_thread_in_sewing_operation

14. YesilpinarS.AnalysisofthePerformanceofSewingThreadsManufacturedfromConventionalandCompactRing-spun Yarns, https://www.researchgate.net/publication/298985108_Analysis_of_the_Performance_of_Sewing_Threads_Manufactured_f rom_Conventional_and_Compact_Ring-spun_Yarns