International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

1,P.G Student , Annamacharya Institute of Technology and Sciences ,Tirupati,India 2,4Assitant Professor , Annamacharya Institute of Technology and Sciences ,Tirupati,India 3Professor , Annamacharya Institute of Technology and Sciences ,Tirupati,India *** -

Abstract - Concrete is the most widely used construction material in the modern world. Concrete incorporates a large amount of natural resources as aggregates and cement with water. Nowadays, the heat of hydration from concrete structures is the major environmental effect. Cement production also consumes huge energy and natural resources and causes about 7% of total greenhouse gas emissions in the world The main objective of this investigation is comparative study on strength between Fly Ash based concrete andNormal Concrete in M20,M30 and M40 grades of concrete. Here inthis study the fly ash is fixed to 30% replacement of cement. By using Fly ash the strength property is increased when compared with the normal concrete andalsothis researchwas focused on rebound hammer test and ultra sonic pulse velocity test

Key Words: Compressive strength,M20,M30,M40 grades of concrete,UPV Test, Rebound Hammer test

ItiswellrealizedthatthedevelopmentofPortlandconcrete consumessignificantenergyandsimultaneouslycontributes a huge volume of CO2 to the environment. The environmental change because of an Earth-wide temperatureboosthasturnedintoasignificantconcern.The an Earth-wide temperature boost is brought about by the emanation of ozone depleting substances, like carbon dioxide (CO2), to the climate by human exercises. The concretebusinessisconsideredanswerableforaportionof theCO2discharges,inlight ofthefactthatthe creation of onetonofPortlandconcretetransmitsroughlyoneton of CO2intotheair.Nonetheless,Portlandconcreteisasyetthe fundamentalfastenerinsubstantialdevelopmentprovoking aquestforadditionalharmlesstotheecosystemmaterials.A few endeavorsareunderwaytoenhancetheutilization of Portland concrete in concrete to resolve the an unnatural weather change issues. These incorporate the use of beneficial establishing materials, for example, fly debris, silicarage,granulatedimpactheaterslag,rice-huskdebris andmetakaolin,andtheimprovement of elective folios to Portlandconcrete.

One potential option is the utilization of antacid enacted fastener utilizing modern side-effects containing silicate materials. In 1978, Davidovits (1999) suggested that fastenerscouldbecreatedbyapolymericresponseofbasic fluidswiththesiliconandthealuminuminsourcematerials oftopographicalbeginningorresultmaterials,forexample, flydebris,GGBSandricehuskdebris.Henamedthesefolios as geopolymers. The most well-known modern results utilized as folio materials are fly debris (FA) and ground granulated impact heater slag (GGBS). The intensity deliveredbyconcreteduringsubstantialrelievingiscalled intensity of hydration. This exothermic response happens when water and concrete respond. How much intensity createdduringtheresponseisgenerallyconnectedwiththe sythesis and fineness of the concrete. Substantial temperaturecheckingisbasictoguaranteethedrawnout strengthandsteadinessofsubstantialdesigns.

Rama Mohan Rao [2010] :- In this examination the consideration of fly debris in glass fiber built up concrete decreases the ecological contamination and works on the usefulnessandsolidnesspropertiesofcement.Inthetrial examinationglassstrandsinvariousvolumepartswith25% and 40% substitution of concrete by fly debris has been utilized to concentrate on the impact on compressive strength, split elasticity, flexural strength of cement. The expansionofstrandsintheplainsubstantialwillcontrolthe breaking due shrinkage and furthermore decrease the drainingofwater.

P. R. Wankhede [2014] :-InthispaperexaminationEffect of Fly Ash and Properties of Concrete the impact of fly debris.Extremecompressivestrengthofcementcontinues diminishing with expansion in w/c proportion of cement. Drooplossofcementcontinuesexpandingwithincrementof amount of fly debris. Concrete with 20% and 30% supplanting of concrete with fly debris shows great compressive strength for 28 days than typical cement for 0.35w/cproportion.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Finetotal isthefundamental fixinginsubstantial that comprises of regular sand or squashed stone. The quality andfinetotalthicknessunequivocallyimpactthesolidified properties of the substantial. The substantial or mortar combinationcanbemademoresolid,moregroundedand lessexpensiveassumingyoumadethechoiceoffinetotalon premise of reviewing zone, molecule shape and surface, scrapedareaandslideobstructionandingestionandsurface dampness

SieveNo.

3.1.

Cumulativepercentpassing

Fine aggregate IS: 383-1970 – Zone II requirement

3/8”(10mm) 100 100

No.4(4.75mm) 98.6 90-100 No.8(2.36mm) 95.8 75-100

No.16(1.18mm) 71.6 55-90

No.30(600μm) 49.2 35-59

No.50(300μm) 15.2 8-30 No.100(150μm) 2.0 0-10

Aconcreteisacover,asubstanceutilizedfordevelopment that sets, solidifies, and sticks to different materials to tie them together. Concrete is rarely utilized all alone, but instead to tie sand and rock (total) together. Concrete blendedinwithfinetotalproducesmortarforbrickwork,or withsandandrock,producesconcrete.Concreteisthemost generallyinvolvedmaterial inpresenceandisbehindjust waterastheplanet'smost-polishedoffasset.

Concretes utilized in development are typically inorganic, frequently lime or calcium silicate based, which can be described as non-pressure driven or water powered separately,contingentuponthecapacityoftheconcreteto setwithinthesightofwater(seewaterpoweredandnonpressuredrivenlimemortar).

Table 3.2 PhysicalPropertiesofcement

CharacteristicsTestResults ValuesasperBIS:12269-2013

Grade 53 53

Fineness 6.5% <10%

Specificgravity3.12 3.15

Standard consistency 32% 30%-35%

Initialsetting Time 50min >30min

Finalsetting Time 450min <600min

Soundness 1.2mm <10mm

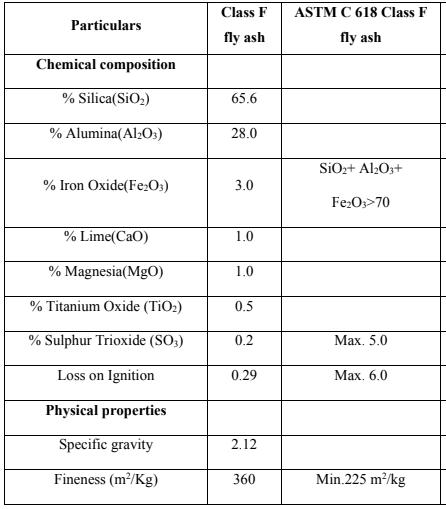

AccordingtoASTMC618(2003),ClassFflyashproduced fromRayalaseemaThermalPowerPlant(RTPP),Muddanur, A.P was used. The chemical and physical properties are presentedintheTable3.3

Table 3.3 chemical and physical properties

ConcretecubesofM20,M30andM40gradebased concreteandisbeingcasted.

Mouldshavebeenremovedandallowedforcuring after24hoursofcasting.

UPVandcompressivestrengthwillbeevaluatedfor 7daysand28daysaftercuring.

The compressive strength (f’c) of the specimen was calculated by dividing the maximum load applied to the specimenbythecross-sectionalareaofthespecimen.

Fig 3.1 Compressive strength

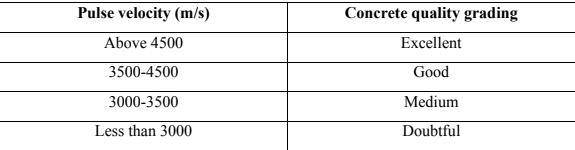

Thetestinvolvesdeterminationofultrasonicpulsevelocity (UPV) through concrete as per procedure give in ASTM C 597-02.

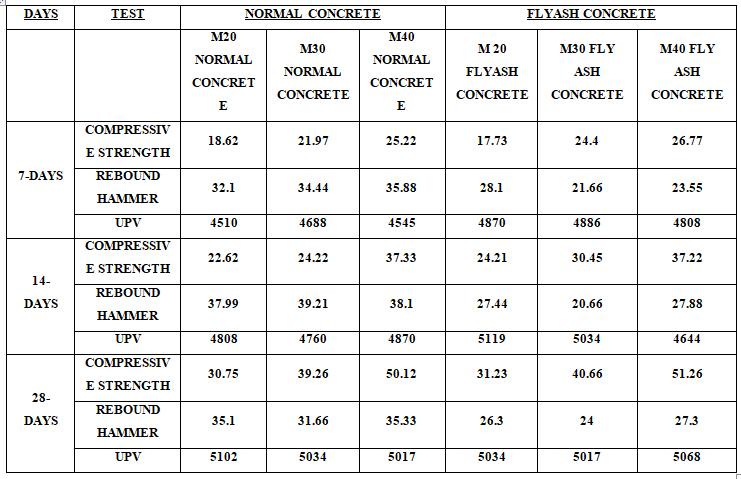

Table 4.1 Compressive Strength ,Rebound Hammer number, Ultasonic pulse velocity Result

Fig 3.2 Ultrasonic pulse velocity test setup

Thepropertiesviz.compressivestrength,ultrasonicpulse velocityandReboundHammertestweremeasuredafter7 and28daysofcuring.

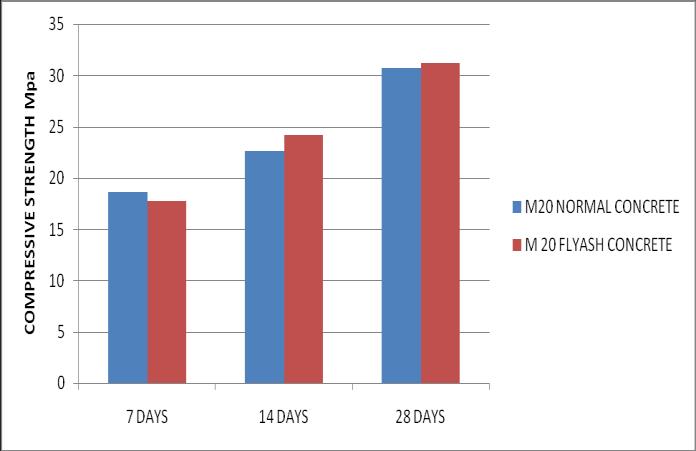

Fig 4.1 Comparison of compressive strength between normal concrete and fly ash concrete for M20 grade

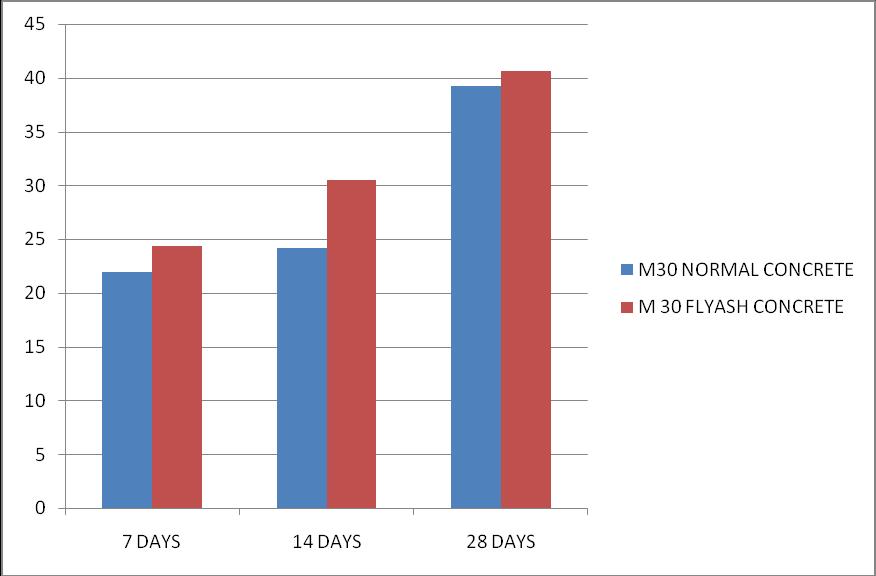

Fig 4.2 Comparison of compressive strength between normal concrete and fly ash concrete for M30 grade

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

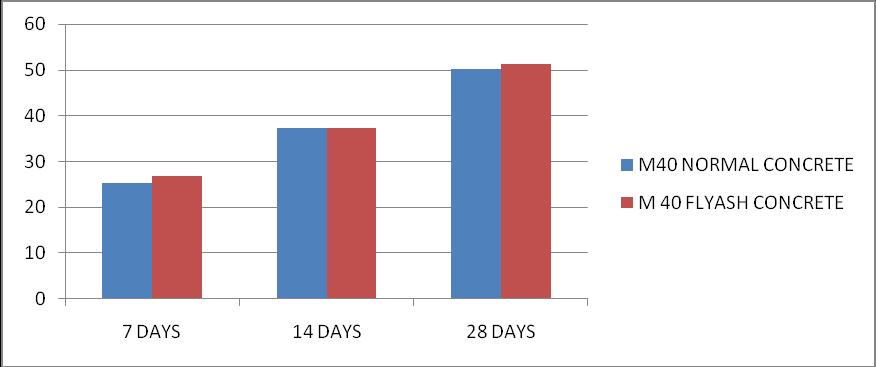

Fig 4.3 Comparison of compressive strength between normal concrete and fly ash concrete for M40 grade

Adding30%offlyashamineraladmixtureincreasesthe compressivestrengthresultsforallgradesofconcrete

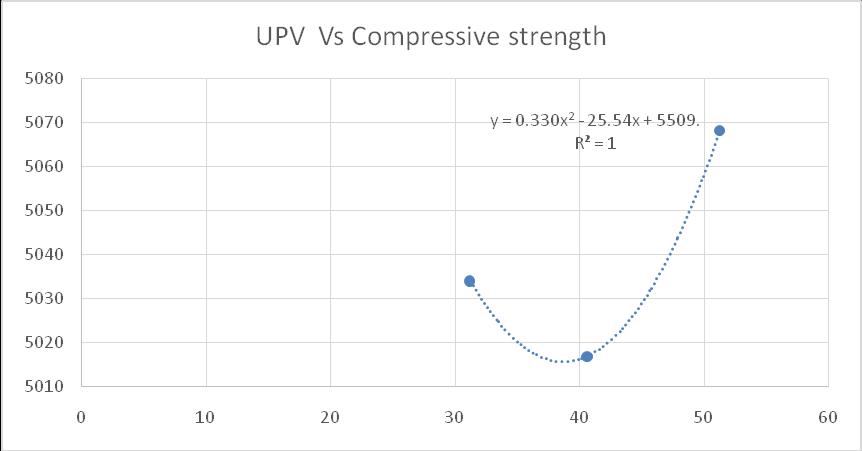

Fig 4.6 Correlation between compressive strength of normal concrete and UPV

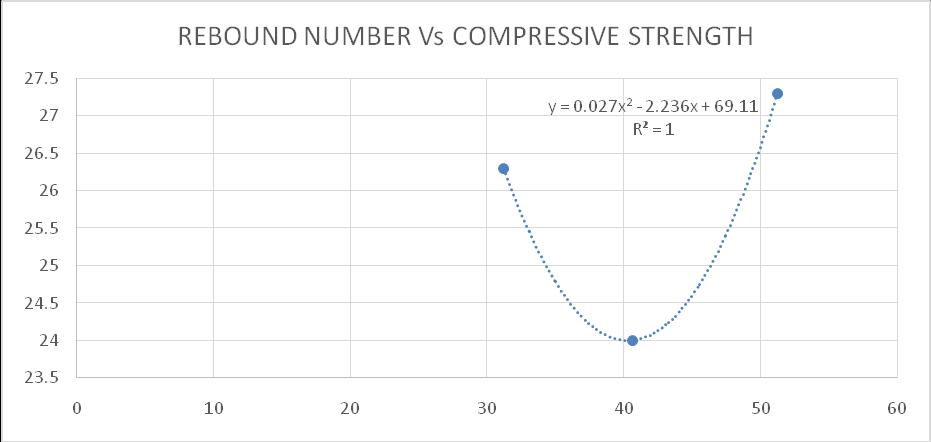

Fig 4.4 Correlation between compressive strength of normal concrete and Rebound number

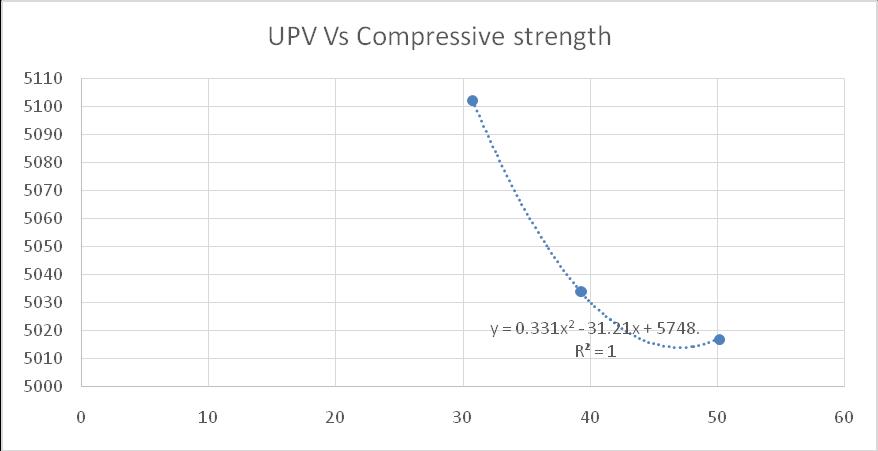

Fig 4.7 Correlation between compressive strength of Fly ash concrete and UPV

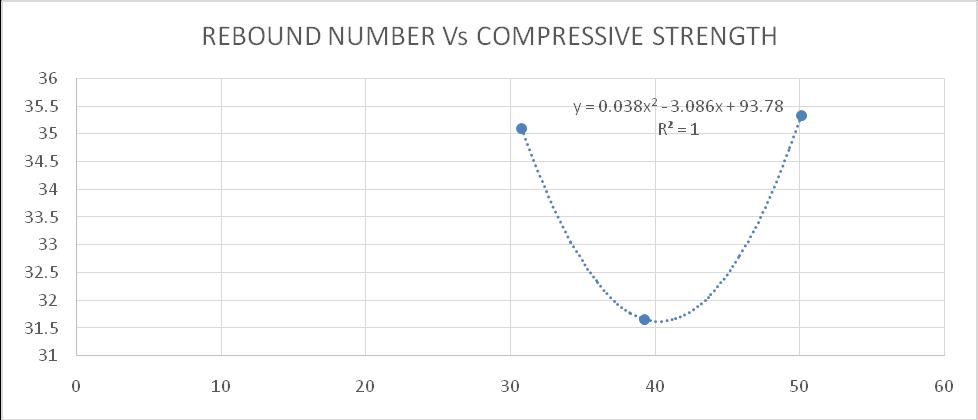

An attempt was made establish the relation between compressivestrength(MPa)andReboundhammertestand compressivestrengthwithUPV.Asitcanbeseenfromfig’s that there is direct correlation between compressive strength with UPV and Rebound hammer number. Polynomial regression analysis was performed and the resultisshowninFigure.Correlationbetweencompressive strengthwithReboundhammernumberandUPVshowedRsquared value of 1. Following equations are proposed for predictingthecompressivestrengthofconcrete.

y=0.038x2 -3.086x+93.78

y=0.027x2 -2.236x+69.11 y=0.331x2 -31.21x+5748 y=0.330x2 -25.54x+5509

Fig 4.5 Correlation between compressive strength of Fly ash concrete and Rebound number

Basedon the resultsof this experimental investigation, the followingconclusionscanbedrawn:

AfterAdditionofFlyashthecompressivestrength values are increasing with increasing grades of concrete.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Fly ash is good admixture for increasing the compressivestrength

For all grades of concrete there is increased in strength of fly ash when compared with normal concrete.

Goodcorrelationwasfoundbetweencompressive strengthWithReboundnumberandUPV.R-square valueisequalto1.

RamaMohanRao“EffectofGlassFibersonFlyash Based Concrete” Assistantprofessor (SG), CDMM, VITUniversity,Vellore,India(IJCIET)Volume1,No 3,2010.

P.R.Wankhede“.EffectofFlyASHonPropertiesof Concrete ” Assistant Professor, IBSS College of Engineering,AmravatiJuly2014

AbhishekJain“UseofFlyashasPartial replacement ofSandinCementMortor”InternationalJournalof Innovative Research in Science, Engineering and TechnologyVol.2,Issue5,May2013

Abdul Aleem, M. I., and Arumairaj, P. D., 2012, “Geopolymer concrete- A review, ” International Journal of Engineering Sciences and Emerging Technologies,ISSN:2231–6604,1(2),pp.118-122.

Bhosale,M.A.,andShinde,N.N.,2012,“Geopolymer concrete by using flyash in construction,” IOSR JournalofMechanicalandCivilEngineering(IOSRJMCE)ISSN:2278-1684,1(3),pp.25-30

Anuradha, R., Sreevidya,V., Venkatasubramani, R., and Rangan, B.V., 2012, “ Modified guidelines for geopolymer concrete mix design using Indian standard,” Asian Journal of Civil Engineering (BuildingandHousing),13(3),pp.353-364.

Factor value: