International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

1 , J.Thivya 2, J.

Vijayaraghavan3

1 P.G Scholar, Department of Structural Engineering, Anna University Regional Campus Madurai, Madurai, Tamilnadu-625019,

2 Assistant Professor, Department of Civil Engineering, University College of Engineering Dindigul, Dindigul, Tamilnadu,

3 Assistant Professor, Department of Civil Engineering, University College of Engineering Ramanathapuram, Ramanathapuram Tamilnadu. ***

Abstract - The creative mind of a world without concrete is unthinkable. Concrete is a spirit of frameworks. Concrete is important to acquire strength in structures. Traditional cement, which is the combination of concrete, fine aggregate, coarse aggregate, and water, needs relieving to accomplish strength. Thus, it is expected to solution for a base time of 28 days for good hydration and to accomplish target strength. Absence of appropriate relieving can gravely influence the strength and toughness. Self-curing concrete is one sort of current cement, whichfix itself by holding water (dampness content) in it. The utilization of polyethylene glycol in conventional concrete as an admixture helps better hydration and subsequently the strength of concrete. In this undertaking review, to concentrate on the mechanical characteristics of concrete like compressive strength,tensile strength, and flexural strengthbyfluctuatingthe measurements of 1 %, 1.5%, 2%, and 2.5% of PEG - 4000 by weight of concrete for M50 grade of cement. This paper covers an exploratory program to examine the impact of utilizing copper slag as a substitution of sand on the properties of Self curing concrete (SCUC). Concrete mixeswere assessed for compressive strength, tensile strength, and flexural strength. This current review plans to decide the most reasonable level of PEG-4000 to be included self-curing concrete. For testing M 50 grade concrete is to be utilized.

Key Words: Self-curingconcrete,Polyethyleneglycol-4000, Copperslag,M50,Strength.

Concrete is perhaps of the most consumed and least expensive material in development field among any remaining materials. The desire of interest for the substantial in development and modern field made the exploration to foster the high performing concrete with greater practicality. The relieving of cement is predominantly expected to keep up with the dampness content to guarantee the persistent hydration of the concrete. Accordingly, the ceaseless hydration process

begins to dial back when the inside relative moistness contentabatementsandforallintentsandpurposesstops whenitdiminishesunder80%.

Self-Curing concrete is a sort of substantial which will fix exclusively by dampness content. Internal Curing is the methodologyisadding/givingadditionalwatertorestoring. Concreteconsolidatingself-Curingrepresentarecentfadin the substantial development in the new thousand years because of the expanded utilization of superior execution concrete.Afewstrategiesmay,possiblybeutilizedforfuse ofinnerrestoringwaterinconcrete.

Afewscientistshaveproposedtheutilizationofsoakedlight weight totals to give interior restoring to concrete. Then again, different analysts utilized poly-glycol items in substantial blends as self-curing agent. The usage of selfcuringconcreteactuallytookoninwatershortageregions. Presently two significant strategies can be taken on for inwardrestoringof cement. OneisLWA-lightweight total. Watersupplantedbycompoundshrinkageduringconcrete hydration,anothersortisutilizationofPolyethyleneGlycol, whichdeclinethedissipationcyclefromsubstantialsurface andhelpsinwaterkeepingprogress.

Essentiallygreatrestoringofcementisn'tattainableasarule becauseofinaccessibilityofreasonablenatureofwaterand numerousothercommon-sensehardships.Duringthemost recenttwentyyears,substantialinnovationhasbeengoing through fast Improvements. With ordinary fixings it is feasible to configuration sensibly great quick track substantialcombinationutilizingadmixtures.Insiderestored cementcanbeaccomplishedbyaddingSelfCuringAgents. Water dissolvable polyether's are by and large utilized as self-curingagents.Theobjectiveofinnercuringistofurnish water in the legitimate sum with a legitimate spatial disseminationsothewholethree-layeredmicrostructureof hydratingcementitiousgluestaysimmersedandautogenous tranquil.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Finetotalisacrucialpartofcement.Thechiefgenerallyused fine total is regular stream sand. The interest of regular waterway sand is exceptionally tall in created countries attributable to infrastructural improvement. The nonaccessibilityofsufficientmeasureofcustomarystreamsand formakingconcretecementisimpactingthedevelopmentof developmentindustryinvariouspiecesofthecountry.

CopperslagisgottenaswastefromtheSterlitebusiness.In theongoingconditions,considerationhasbeenattractedto theecologicaldangerspresentedviafossilfuelby-products and sand mining and the serious uneven characters in biologicalsystems.Differentexaminationshavebeenledto decreasetheseriouseffectontheclimate,theutilizationof side-effects,forexample,copperslagashalfwaysubstitutes forfinetotals.Havethereis anabundanceofinvolvement withutilizingcopperslaganalternativeforfinetotals.

In present day situation, vehicle transmissions and sand extraction have turned into an overwhelming test due to environmentalrisksandrealoff-kilternatureintheorganic framework.Someassessmenthasbeenfinishedtobindthe certified influence the earth, the usage of results, for instance,copperslagasapartialchoiceforfaultlesssums. Thereisvariousexperiencesinutilizingcopperslagasan improvement of current sums. It is a consequence of the coppercleaningandrefiningprocess.Intheeventthatthe copper slag is used as a trade for regular sand, we can prevailwithregardstogivingasubstitutematerialtonormal sand,whichcanbeeco-friendlyandconservativeconcerning concrete.

Thisdocumentistemplate.Weaskthatauthorsfollowsome simpleguidelines.Inessence,weaskyoutomakeyourpaper lookexactlylikethisdocument.Theeasiestwaytodothisis simplytodownloadthe templateand replace(copy-paste) thecontentwithyourownmaterial.Numberthereference itemsconsecutivelyinsquarebrackets(e.g.[1]). However, the authors name can be used along with the reference number in the running text. The order of reference in the runningtextshouldmatchwiththelistofreferencesatthe endofthepaper.

A self-curing concrete is given to retain water from environmenttoaccomplishbetterhydrationofconcretein concrete.Ittakescareoftheissuethatthelevelofconcrete hydrationisbroughtduedowntonorestoringorill-advised relievingandinthiswayunacceptablepropertiesofcement. Oneself restoring specialist can retain dampness from climate and afterward discharge it to concrete. One selfcuring substantial implies that no curing is expected for cement, or even there is no outside provided water is expectedinthewakeofsetting.Thepropertiesofthisselfcuringconcreteofthisinnovationareessentially

equivalenttoand,surprisingly,betterthanthoseofcement withconventionalcuring.Theinwardwateriskeptupwith by in participating oneself restoring specialist which decreasesthedissipationofwaterfromthesubstantial,in this manner expanding the water maintenance limit of cement. In past many years, the impact of Self Curing Concretehasfurtherdevelopedpropertieswhilecontrasting withindistinguishablyrestoredcontrols.Itwasfoundthat, underlyingsurfaceretention,chlorideentrance,carbonation, consumption potential and freeze and defrost obstruction attributes were similarly better via air relieved self-cure concretethantheairrestoredcontrol.

Consistent dissipation of dampness happens from a presented surface because of the distinction in synthetic possibilities (free energy) between the fumes and fluid stages. The polymers included the blend predominantly structure hydrogen securities with water particles and decreasethesyntheticcapabilityoftheatomswhichthusly lessens the fumes pressure, subsequently diminishing the paceofvanishingfromthesurface.

Atthepointwhenthemineraladmixturesrespondtotallyin a mixed concrete framework, their interest for restoring water (outer or inside) can be a lot more prominent than thatinatraditionalnormalPortlandconcretecement.Atthe point when this water isn't promptly free, critical autogenous disfigurement and (early-age) breaking might result.Becauseofthesyntheticshrinkagehappeningduring concretehydration,voidporesaremadeinsidetheconcrete glue,promptingareductioninitsinsiderelativestickiness andfurthermoretoshrinkagewhichmightcauseearly-age breaking.

The goal is to concentrate on the mechanical attributes of cementbyshiftingthelevelofPEG-4000from1%to2.5%by weightofconcreteforM50gradeconcrete.Tofindtheideal extent of copper slag that can be utilized as a trade/substitutematerialforfine total.Totrackdownthe compressivestrength,splitrigidity,andflexuralstrengthof copperslagsupplantedsubstantialexamples

Magda I. Mousa et al., have concluded that the indirect rigiditywasinthescopeof6.4%to8.5%forallself-curing concrete and flexural strength addressed 10-14.5%of compressivestrengthofallself-curingconcrete.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Ahmad Mustafa Sabaoon and Navinderdeep Singh have concludedthatUtilizationofself-curingspecialistincement can expand the strength of concrete contrasting with ordinaryconcrete

AnkitNainwaletal.,haveconcludedthatwiththeexpanded percentageofcopperslag,concretedensityismovedalong.

MaheshV.PatilandYogeshD.Patilhaveconcludedthatat 30%substitutionthemodulusofelasticityisfound9.52and up to 90% substitution it continues expanding then conventional concrete. The permeabilitytestresultshows that it decreased up to 30% and after that it is expanded from40to100percent.

MadhuraSridharanandT.Ch.Madhavihaveconcludedthat theidealsubstanceofcopperslagthatcanbeutilizedasan electiveforriversandinconcreteforupgradedmechanical behavioris40%.

Dr.U.B.ChoubeyandGajendraRaghuvanshihaveconcluded that PEG- 400 was viewed as compelling as a self-curing agent.Itwasfoundthateachgradeofcementhasoneideal levelofdosewhichitrequirestoinvigoratethegreatest.It wasviewedthatastheidealdoseofPEG-400forM20was 1%,forM30itwas1%andforM40itwas0.5%.

Blending of concrete parts was finished utilizing a level blender.Everyoneofthedryconstituentswereblendedfor 2mintoguaranteeconsistencyoftheblend.Abigpartofthe blending water was added step by step during blending. Anyway, on account of SCUC, self-curing agent such as polyethylene-glycol and 40 % of copper slag was added continuouslyduringblending.Blendingofallfixingswenton for a time of 2 min. In the wake of blending, two sizes of examples were projected utilizing (150 X 150 X 150) mm cubic molds and (150 X 300 ) chamber molds. After the moldshadbeenfilledofcementandcompacted,theouter layerofcementwasevenedout,andafterward,demolded examples were kept in dry air (25 C) during the trial in a research center. Compressive and tensile were done on cubesandcylindersspecimenswhileflexuralstrengthwas performedonbeamspecimens(150X150X750mm)which loadedatthecenterthirdwithtwoequivalentpackedloads inflexuraltest.Compressivestrength,tensilestrengthand flexuralstrengthwereexaminedat7daysand28days

Portland concrete cement is the most comprehensively involved advancement material in underlying planning exercises all over the planet. The assessment was coordinated using standard Portland cement of 53 grade,

whichisbyandlargeavailableintheclosebymarket.The properties of concrete are: Specific gravity of 3.12, initial settingseasonof28minutes,Finalsettingtime532minutes, Consistencyof33%andfinenessmodulusof2.5

M-sand is an improvement complete made by crushing hardstonesintolittlesandestimatedjauntyformedparticles, then, washing and authoritatively inspecting them. It is a betterchoiceconversely,thanriversandoradvancement. ThepropertiesofFineaggregateareasfollow:Grading of sandasZoneII,Specificgravityof2.62,finenessmodulusof 2.46andwaterabsorptionof1.5%

Themostoutrageousabsolutesizeisregularly10mmandis confined to 20mm. Utilizing a particularly evaluated cubicalorthenagainchangedaggregateisbetter.Absolute oughttobeofdependablequalitywithrespecttoshapeand assessing. The properties of coarse aggregate are specific gravity of 2.70, water absorption of 2% and fineness modulusof6.2

Development requires the utilization of water. The Ph of water ought to be something like 6. All through the examination,compactwater wasusedasperIS 456-2000 rules.

Polyethylene glycol is a polymer created by buildup of ethyleneoxideandwaterhavinganoverallsubstancerecipe of (OCH2CH2) n OH, where n is the typical number of rehashingoxyethylenebunchescommonlygoingfrom4to around180.Thecondensing(PEG)isutilizedinmixwitha numericpostfixwhichdemonstratesthetypicalsub-atomic weight.PEG- 4000isutilizedin thisreview. Itisliberated from chlorides and produces an inside film, which safeguards and forestalls new cement against over quick waterdissipation.OnenormalelementofPEGseems,byall accounts, to be the water-solvent substance. Stake is nonharmful,scentless,greasingup,unbiased,non-unpredictable and non-disturbing and is utilized in different pharmaceuticalworks.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

FIG- 1:PEG-4000

CopperslagutilizedinthisworkwaspurchasedfromSterlite businesses(India)ltd,Tuticorin,TamilNadu,India.Atthe pointwhenthecoppersettlesdowninthesmelter,ithasa higher thickness, pollutants stay in the top layer and afterward are moved to a water bowl with a low temperatureforhardening.Thefinishedresultisastrong, hard material that goes to the smasher for additional handling. Copper slag is generally disposed of in landfills; nonetheless,itverywellmaybesecurelyreusedinconcrete as a piece of fastener or total stage. One of the significant elements of copper slag is its smooth and shiny surface, whichcanpromptimprovementsinthefunctionalityofnew concreteormortar.

Table -1: Slumpconetestvalues

Slump cone test is completed to decide the workability of concrete.Theshapeforthetestisasthefrustumofacone havinglevel30cm,basemeasurement20cmandtopwidth 10cm.Thepackingpoleisofsteel16mmbreadthand60cm longandadjustedtowardoneside.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

heap will be applied to different sides of the solid shape fashioned.Theexampleisadjustedhalfwayonthebaseplate ofthemachine.Thentheversatilepartispivotedtenderly thehardway,soitcontactsthemostnoteworthysurfaceof the example. A definitive burden at which the substantial getsdisappointmentisnoted.

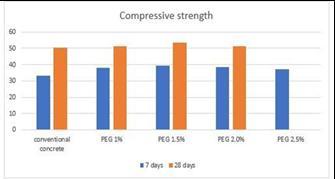

Table -2: Compressivestrengthat7and28days

PEG 4000 (%) by cement

Copper slag (%) by fine aggregate

Compressive strength at 28 days N/mm2

10.2Tensile

Concreteisreadyinthenecessaryextentsandtheexampleis madebyfillingthesubstantialintheidealformstateof15cm x30cmchamberwithappropriatecompaction.Exampleis setinthepressuretestingmachineforthepredetermined fluctuate.Thecompressedwoodstripsarekeptonthelower plateandtheexampleisput.Theexampleisadjustedsothe linessetapartonthefinishessquaremeasureverticaland designated over extremely modest plate. Other pressed wood strip is put over the example. The upper plate is brought down to contact the pressed wood strip. The breakingload(P)isnoted.

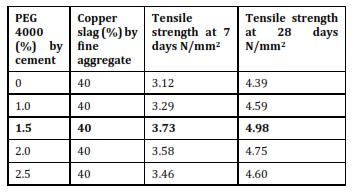

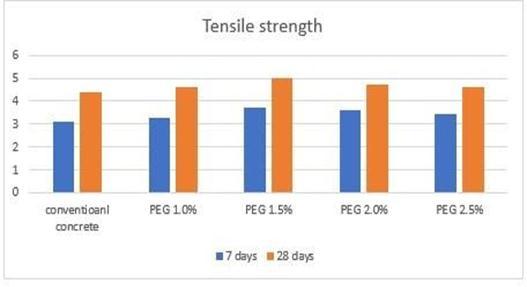

Table -3: Tensilestrengthat7and28days

FIG- 4: Averagecompressivestrengthat7and28days

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

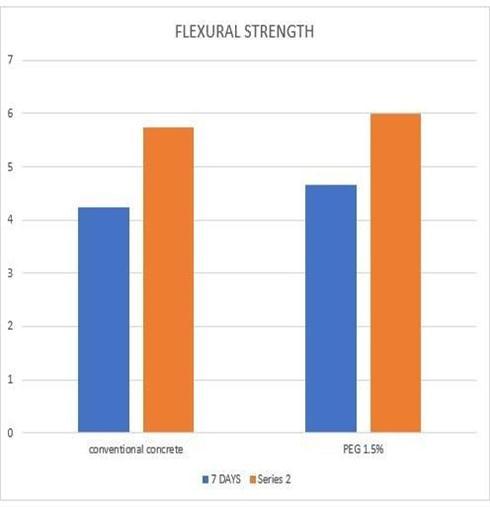

Itteststhecapacityofunreinforcedcementfooterorchunk toenduredisappointmentinbowing.Theconsequencesof flexural test on concrete communicated as a modulus of burstwhichmeansas(MR)inMPaorpsi.Theflexuraltest oncementcanbedirectedutilizingeitherthree-pointload test(ASTMC78)orfocuspointloadtest(ASTMC293).

FIG- 8:Averageflexuralstrengthat7and28days

Fig-9:Flexuralstrengthtestonconcrete

InSelfcuringconcretethegreatestoutcomesaccomplishat 1.5%ofPEG4000with40%ofcopperslagasafractional tradeforfineaggregate.Strengthofself-curingconcretewith incompletesubstitutionofcopperslagasfineaggregateis moderately high when contrasted and conventional concrete.Themostextremecompressivestrengthat28days in self curing concrete (53.58N/mm2) at 1.5% of PEG is morethanthatoftheordinaryconcrete.Themostextreme tensile strength at 28 days in self curing concrete (4.98N/mm2) at 1.5% of PEG is more than that of the ordinaryconcrete.Themostextremeflexuralstrengthat28 daysinselfcuringconcrete(5.99N/mm2)at1.5%ofPEGis morethanthatoftheordinaryconcrete.Self-curingconcrete isthefeasibleresponsetonumerousissueslookedbecause ofabsenceoflegitimatecuring

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

[1]Abhishek Maharishi , S.P. Singh , Lalit Kumar Gupta , Shehnazdeep (2020),” Strength and durability studies on slag cement concrete made with copper slag as fine aggregates”,Materialstoday:Vol38,part5,Pp:2639-2648

[2]AegulaShravanKumar,R.Gopi,K.Murali(2021),”Comparativ estudiesonconventionalconcreteandself-curingconcrete”, Materialstoday:Proceedings,Vol46,part17,Pp:8790-9794.

[3] Ahmad Mustafa Sabaoon and NavinderdeepSingh (2019),”ExperimentalInvestigationofSelf-CuringConcrete byUsingNaturalandChemicalAdmixtures”,IndianJournal ofScienceandTechnologyvolume:12Issue:5

[4]AitorC.Raposeiras,DianaMovilla-Quesada,OsvaldoMunozC˜aceres´, Valerio C. Andr´es-Valeri, Manuel Lagos-Varas (2021),”Productionofasphaltmixeswithcopperindustry wastes: Use of copper slag as raw material replacement” , JournalofEnvironmentalManagement,Vol293.

[5]AjayRana,KshitijJassal(2020),”AReviewonImpactof PolyethyleneGlycol in Self Curing Properties of Concrete”,International Research Journal of Engineering andTechnology(IRJET)volume:07Issue:12

[6]AnkitNainwal,PankajNegi,PavanKumarEmani,Mahesh Chandra Shah, AnkitNegi,VivekKumar(2020),”An experimental investigation to substitute coppers lagin concretewithBeasriverfineaggregate”,Materialstoday,Vol 46,part20,Pp:10339-10343.

[7]Choubey Dr.U.B, Gajendra Raghuvanshi (2017),” International Research Journal of Engineering and Technology(IRJET)volume:04Issue:10

[8]FarshadAmeri,ParhamShoaei,HamidRezaMusaeei, Seyed Alireza Zareei , CheahCheeBan (2020),”Partial replacement of copper slag with treated crumb rubber aggregates in alkali-Activated slag mortar”,Elsevier, ConstructionandBuildingmaterials,Vol256.

[9]JosephP.Rizzuto,MounirKamal ,HanaaElsayad,Alaa Bashandy,ZeinabEtman,MohamedN.AboelRoos,Ibrahim G. Shaaban (2020),”Effect of self- curing admixture on concretepropertiesinhotclimateConditions”,Construction andBuildingmaterials,Vol261.

[10]KamalM,M.A.Safan,A.A.Bashandy,A.M.Khalil(2018),”Expe rimental investigation onthe behaviorof normal strength and high strength self-curing self- compacting concrete”, Elsevier,JournalofBuildingEngineering,Vol16.

[11]KhushpreetSingh(2020),“Mechanicalpropertiesofselfcuring concrete studied using polyethyleneglycol-400:Areview”,Elsevier,Materialstoday:Proceedings,Vol37,part 2,Pp:2864-2871

[12]Madhura Sridharan , T. Ch. Madhavi (2020),” Investigatingtheinfluenceofcopperslagonthemechanical behaviorofconcrete”,Materialstoday:Proceedings,Vol46, part9,Pp:3225-3232

[13]MaheshBabuK,ARavitheja(2019),“Effectofcopperslag as fine aggregate replacement in high strength concrete”, Materialstoday:Proceedings,Vol19,part2,Pp:409-414

[14]MaheshV.Patil,YogeshD.Patil(2020),”Effectofcopper slagandgranitedustassandreplacementontheproperties of concrete”, Materials today, Proceedings, Vol 43, part 2, Pp:1666-1677.

[15]MohamedAmin,AbdullahM.Zeyad,BassamA.Tayeh, IbrahimSaadAgwa(2021)“Engineeringpropertiesofselfcured normal and high strength concrete produced using polyethylene glycol and porous ceramic waste as coarse aggregate”,ConstructionandBuildingmaterials,Vol299

[16]SasiRekha ,Jagadheeswari , Arunprasath , Sumathy (2020),” Durability properties of copper slag and fly ash based concrete for a sustainable environment”, Materials today,Proceedings,Vol37,part2,Pp:2535-2541.

[17]SriRamaChandMadduru,KhajaSameerShaik,Ramesh Velivela , Vijay Kumar Karri(2019),”Hydrophilic and hydrophobic chemicals as self-curing agents in self compacting concrete”, Elsevier, Journals of Building Engineering,Vol28

[18]SriRamaChandMadduru,SwamyNagaRatnaGiriPallapoth u,RathishKumarPancharathi,RajeshKumarGarje,Raveena Chakilam (2016),” Effect of self-Curing chemicals in self compactingmortars”,ConstructionandBuildingmaterials, Vol107

[19]UshaKrantiJ,A.NagaSai,A.RamaKrishna,K.Srinivasu (2020) ,” An experimental investigation on effect of durabilityonstrengthpropertiesofM40gradeconcretewith partial replacement of sand with copper slag”, Elsevier, Materialstoday,Proceedings,Vol43,part2,Pp:1626-1633.

[20]VijayanD.S,S.Arvindan,D.Parthiban,R.SanjayKumar, B.Saravanan,YumnamRobert(2020),“Anexperimentalstudy onmechanicalanddurablepropertiesofselfcuringconcrete byaddingadmixture”,Materialstoday:Proceedings,Vol33, part1,Pp:496-501

[21]J. Vijayaraghavan, A. Belin Jude & J. Thivya (2017), “ Effect of copper slag, iron slag and recycled concrete aggregate on the mechanical properties of concrete” , ResourcesPolicy,Vol.53,pp-219-225.(ISSNNO:0301-4207, IF:3.986,Sep2017)