International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

1Master of Technology in Civil Engineering, Lucknow Institute of Technology, Lucknow, India

2Assistant Professor, Civil Engineering, Lucknow Institute of Technology, Lucknow, India ***

Abstract - E trash, often referred to as electronic waste, is the term used to describe electronic equipment that has become outdated and has been discarded. These include, in variable amounts, waste products manufactured of plastic as well as waste products made of metal. Recycling trash that is made of metal, as opposed to recycling waste that is made of plastic, is a little bit less complicated and also results in less pollution than recycling waste that is made of plastic. Therefore, in order to lessen the amount of air pollutionthatis caused by the recycling of plastic garbage and electronic waste, we need to devise a different and more practical method of reusing it in its original form. This is necessary in order to reduce the amount of plastic garbage and electronic waste that is recycled. It is believed that each year, countries all around the globe create anywhere between 20 and 25 metric tonnes of electronic waste. This article discusses the findings of an experiment that was carried out to determine how the incorporation of plastic e-waste into concrete would affect the qualities of the concrete. The experiment was carried out to study the influence that such an incorporation might have. During the course of this research project, plastic from electronic waste was combined with M25 concrete by replacing the fine aggregate at the rates of 10 percent, 20 percent, and 30 percent by weight and also by replacing the coarse aggregate at the rates of 5 percent, 10 percent, 15 percent, 20 percent, and 25 percent by weight. This was done in order to determine the effects of combining the two materials. After seven and twenty-eight days, compressive strength was evaluated. The findings of the study showed that increasing the quantity of plastic e-waste that was mixed into the concrete resulted in a decrease in the material's compressive strength. This was proved by the findings of the study.

Key Words: Plastic e-waste, concrete, compressive strength,tensilestrength,Splittensiletest.

Duetothefactthatelectronicgarbageisbothlong-lasting and non-biodegradable, disposing of it may be a very challenging task. Getting rid of this electronic garbage by dumpingitinalandfillorpilingitupinstockpilesisnotan environmentally sound approach. We are up against a significant challenge in determining how to recycle the E garbage that cannot be thrown away. This issue may be remedied by including e-waste into the composition of

concreteinalimitedcapacitysuchthatitcanpartiallytake theplaceofbothfineandcoarseaggregate.Indiaisacountry thatisexpandingatarapidrateandisnowintheprocessof transitioningfromadevelopingnationtoadevelopedone. Therefore, in order to become a developed country, one's infrastructurehastoreachworld-classlevels.Accordingto thefindingsofaresearch,theconcretesectorinIndiaisnow using 370 million cum of concrete per year, and it is anticipatedthatthisnumberwouldriseby30millioncum every year (1). An further fact about this country is the rapidlyexpandingamountofelectronicgarbage.According toastudyreporttitled"E-wasteinIndia"(4)thatwasgiven intheRajyaSabhain2011,theamountofelectronicgarbage createdinIndiain2010wasaround4lakhtonnes,whichis an increase from the 1.47 lakh tonnes generated in 2005. The most significant amounts of electronic trash are producedinthemetropolitanareasofIndia'slargestcities, suchasDelhi,Mumbai,andBangalore.Morethansixty-five citiesinIndiaareresponsibleforproducingmorethansixty percent of the country's total electronic trash. Seventy percentofthecountry'stotale-wasteisproducedinonlyten ofIndia'sstates:Maharashtra,TamilNadu,AndhraPradesh, Uttar Pradesh, West Bengal, Delhi, Karnataka, Gujarat, Madhya Pradesh, and Punjab. These states are listed in alphabetical order. Top 10 cities creating e-waste include Mumbai, Delhi, Bangalore, Chennai, Kolkata, Ahmadabad, Hyderabad, Pune, Surat and Nagpur. "polychlorinated biphenyls,chlorofluorocarbons,polyvinylchloridearesome ofthehalogeniccompoundsandheavymetalslikearsenic, barium, beryllium, cadmium, chromium VI, lead, lithium, mercury nickel are typically present," according to the Environmental Protection Agency. E-waste also contains heavy metals such as nickel, lithium, and mercury. The purposeofthispieceistoinvestigatewhetherornote-waste mayberepurposedintoamaterialthatrepresentsoptimism for the twenty first century. The current effort is a component of a larger programme that includes experimentalstudiesthathavebeencarriedouttoevaluate the impact of replacing an expensive material with a less expensive alternative, in this case electronic trash, on the strength of concrete. In the course of this research, cubes wereproducedbycastingreplacementsforfineandcoarse aggregates using electronic trash. It was found that the compressivestrengthofconcretemadefromelectronictrash wasequivalenttothatofnaturalconcrete.Inordertocarry out this comparative study, cubes were cast with either 0 percent, 10 percent, 20 percent, or 30 percent of the fine

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

aggregate replaced by e-waste, and either 5 percent, 10 percent,15percent,20percent,or25percentofthecoarse aggregate replaced with e-waste. Both types of aggregate were then compared to one another. After 7 and 28 days, thesecubeswereexaminedforquality.Duringthetests,a design mix with the proportions 1:1.65:3 (where 3 is the percentageof10mmand20mmsizeaggregate)wasusedin ordertodeterminecompressivestrengthatawatercement ratioof0.46.

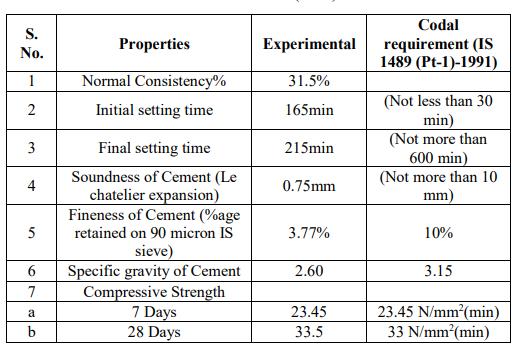

Thegoal ofthisstudyisto determinehowthestrength of concrete is impacted when electronic waste is used to partiallyreplacefineaggregateandcoarseaggregateinthe mixturethatgoesintomakingconcrete.Togetanideaofthe optimal percentage of e-waste that does not significantly affectthestrengthofnon-conventionalconcrete,anattempt has been made here to get the strength of cubes made up with different percentages of ewaste to the respective strengthofconventionalconcreteattheendof7,28daysof moist curing. This was done in order to determine the optimalpercentageofe-waste.Castingthecubesrequireda design mix of (1:1.65:3.00), where 3.00 refers to the proportion of 10mm to 20mm aggregate. Cubes with a measurementof100mmA.CementThematerialthatwas employed in this experiment was generated by using individual batchesofPozzolana PortlandCement(PPC) of the Prism brand during the length of the inquiry. In most cases,thePortlandcementthatweworkwithiscomposedof anargillaceouscomponentandacalcareouscomponentas itsprincipalconstituents.Thefindingsoftheexaminationof thePPC'sphysicalfeaturesareshowninthetablelabelled "Table1."Thecementsatisfiestheprerequisitesoutlinedin theIndianStandard1489:1991(IS1489:1991).Ontheother hand, Ankit et al. [2014] reported material characteristics thatwereveryclose.

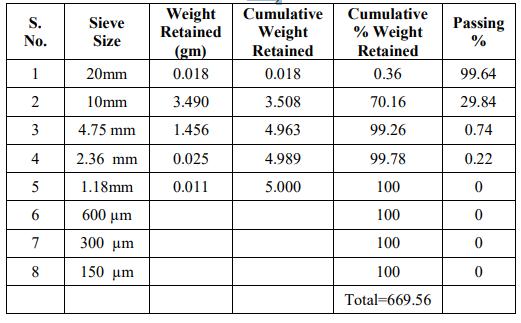

Thecoarseaggregatewasobtainedfromaquarrythatwas locatedinanareathatofferedconvenientaccess.Thequarry producedcoarseaggregateintwodistinctsizes;onefraction was able to pass through a sieve with a diameter of 20 millimetres, while the other portion was able to pass through a sieve with a diameter of 10 millimetres. Both fractionshaveaspecificgravityof2.77,whichistypicalof coarseaggregate.Thispropertyissharedbybothfractions. The grading of coarse aggregate with diameters of 10 millimetresand20millimetres,respectively,isprovidedin bothtable3andtable4.Itwasfoundthatthepercentageof aggregatewithasizeof20millimetresissixtypercent,while theproportionofaggregatewithasizeof10millimetreswas discoveredtobefortypercent.Ontheotherhand,Manish and colleagues [2014] discovered that the material had a greatdealofsimilaritiesinitsproperties.

Table-2: Sieve Analysis of Coarse Aggregate (10mm Size)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Boththemixingprocessandthecuringprocessneedtheuse of drinkable water. The water-to-cement ratio (w/c) that shouldbeusedis0.46,asfoundbytheinvestigation.Inthis particular experiment, a kind of concrete with the designationM25wasused,andthevolumeoffineaggregate asafractionofthetotalvolumeofaggregatewaskeptata constant proportion of fifty percent. The mix that was producedhadawater-to-cementratioof0.46,atotalof380 kg/m3ofcement,andacement-to-fine-aggregate-to-coarseaggregateratioof1:1.65:3.00(where3.00istheproportion of10mmand20mmsizeaggregate).Additionally,themix hadacement-to-fine-aggregate-to-coarse-aggregateratioof 1:1.65:3.00. It was determined that the ratio of fine aggregatetocoarseaggregateshouldbe1:1.65:3.00.

Sourcesofelectronictrashweregatheredfromprofessional recyclers intheform of electronicor electrical equipment thathadbeenabandonedinadisorganisedmanner,wasin excess,wasnolongerinuse,orwasdamagedinsomeway. Thisequipmentmightalsohavebeeninsomewaydamaged. Afterthat,everymetalthathadbeenphysicallylinkedtothe PCBwasfirstseveredfromit,thenpulverisedintoverysmall fragments,andfinallythrownaway.Whenbrokendowninto individualparticles,ithasbeenshownthatthediameterof waste E-plastic particles may vary anywhere from 1.18 millimetresto2.36millimetres.[Citationneeded]

SpecificGravity 1.03

Absorption(%) <0.2

Crushingvalue <2%

Impactvalue <2%

InadditiontothecompressivestrengthofE-wasteconcrete, thecompressivestrengthofreferralconcretewasmeasured forpartialreplacementoffineaggregateintable6,andfor partialreplacementofcoarsematerialintable6.Ascanbe seenfromthecomparisontable,thereplacementconcrete's strength is comparable to the strength of the reference concrete up to a percentage of twenty percent. However, beyondthatproportion,thereplacementconcrete'sstrength dramatically decreases as a result of the addition of electronictrash.Thisisduetothenatureofthewaste.The differenceincompressivestrengththatresultsfromusinga variablepercentageofe-wasteasapartialreplacementfor fine aggregate as opposed to utilising e-waste as a partial

replacementforcoarsematerial.Thecompressivestrength ofconcretewithandwithoutanadditionasafunctionofthe amount of time it is allowed to cure as a function of the amountoftimeitisallowed tocure.Aftersevendays,the compressive strength of PPC is 23.45 kN/mm2 when the ratio of water to cement is 0.46; after 28 days, this value climbsto33.5kN/mm2.

Whendeterminingamaterial'scompressivestrength,oneof theparametersthatistakenintoaccountisthecapacityof the material to survive failure in the form of cracks and fissures.Thisisbecausecracksandfissuresindicatethatthe materialhasbeencompromised.Duringthisparticulartest, the push force that is applied to both of the faces of the concretespecimenismeasured,inadditiontothemaximum compression that the concrete can withstand before it cracks. Both of these forces are applied to the concrete specimeninordertodetermineitsstrength. Theconcrete specimen is subjected to both of these forces so that the strengthoftheconcretemaybeevaluated.

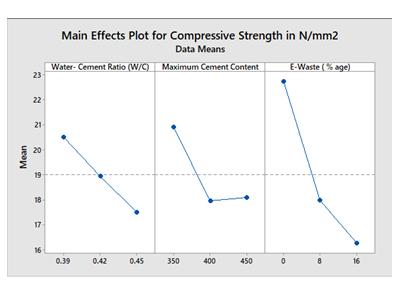

Theuseofmeansofresponseateachleveloftheparameter is necessary in order to generate main effects plots for compressive strength, as is seen from graph-1. This is because the parameter may take on a variety of values. Completing this step is necessary in order to determine which affects will be the most significant. It is possible to establish that an increase in the water-to-cement ratio, cementcontent,orE-wastescausesadeclineinconcrete's capacity to fulfil the function for which it was built and manufactured.Thismaybedoneviatheuseofanumberof differenttests.Onestrategyforachievingthisobjectiveisto make use of the evidence that may be gathered through scientificstudy.Ithasbeenshownthattheamountofimpact thatEgarbagehasonthepotencyoftheconcreteisrather

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1024

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

minimal, and this is something that should be taken into mind as it is something that has to be taken into account. Research led to the unveiling of this previously unknown information,whichhadbeenconcealedfrompublicviewup untilthispoint.

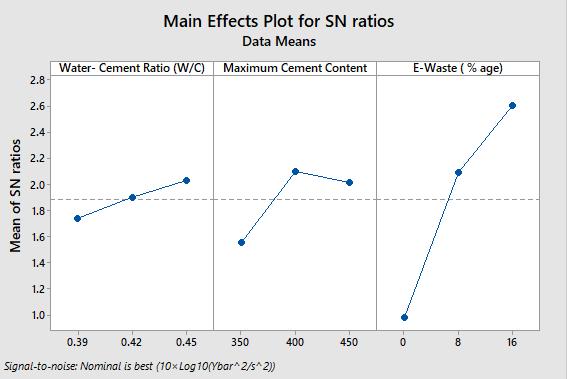

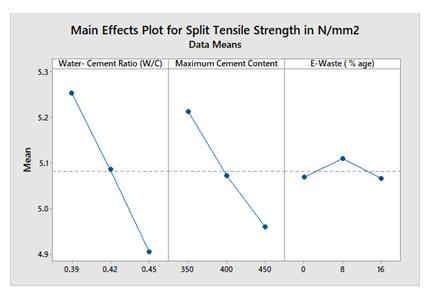

Anexaminationofthemeansofresponseateachlevelofthe parametersisoneofthemanystagesthatmustbetakenin ordertocompletetheprocessofcreatingmajoreffectplots for split tensile strength. This step is one of a number of requiredprocessesintheprocess.Theanalysisisshownin graph-2 for your viewing pleasure. The plots are the outcome of carrying out this operation in its entirety as describedintheprevioussentence.Ithasbeendiscovered that either increasing the water-to-cement ratio or the cementcontentresultsinadropinthesplittensilestrength of the material. [Citation needed] This is the case irrespective of whether or not the variable is altered. The factthatthevariableisbeingmademoreimportantdoesnot changethefactthatthisisthecase.Ontheotherhand,the influenceoftheEwasteonthesplittensilestrengthofthe materialisthelargest.

concrete has a direct correlation to the values of the parameters.Inordertoprovideabasisforrankingeachof the parameters, the difference in mean values that are obtained between the many levels of component levels is computed and used in the process. To calculate the delta, first determine the mean with the greatest possible value andthentakethatnumberandsubtractthemeanwiththe lowestpossiblevalue.Itmakessensefortheitemsthatcarry themostweighttobeinthemostprominentplace.

IllustrationsofthemostsignificantadversereactionstoSN intheformofdiagramsWhenselectinghowtoplottheratio ofnominaltobest,itisimportanttotakeintoconsideration theplethoraofcomponentsthatarepresentateachlevelin ordertoarriveatanaccurateresult.Itisvitaltobearinmind that an increase in the values of the parameters will, as a consequence, result in an increase in the strength of the concrete.Thisisbecauseanincreaseinthestrengthofthe

Inordertoprovidean explanationfortheimpactthatthe useofelectronicwastehasonconcrete,thefollowingpoints, which can be summed up based on the inquiry, may be employed.TheinformalrecyclingpractisesinIndiaarebeing negativelyimpactedbytheinvasionofe-wastecomingfrom the interior of the country as well as illicit imports from industrialised nations. The management of solid waste in India is already a challenging undertaking due to the environment in the country. This is because electronic garbage,oftenknownase-waste,mayberecycledusinga variety of various methods. It is needed to construct a comprehensiveassessmentsystemofthecurrentandfuture state of e-waste, and it is also essential to develop model facilities with environmentally friendly ways for the treatmentofe-waste.Bothofthesethingsareessential.In the past, studies have been carried out to evaluate the viabilityofutilisingrecycledglassandplasticasanaggregate inconcrete.Inlinewiththisspecificaspect,itwasrealised thatelectronictrashmaybedisposedofbyemployingitasa buildingmaterialinsomecapacity.Thiswasdoneinorderto remainwiththethemeofthisparticularfeature.Depending on the size of the E-waste particles, they could be appropriate for use as a non-active filler component in concrete.Thiswoulddependonthesizeoftheparticles.

Theoutcomesoftheinvestigationonthemanageabilityof concrete manufactured from e-waste indicated that

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1025

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

increasingquantitiesofe-wastematerialintheconcretedid not significantly affect the slump of the concrete. On the other hand, the probability of slumping increases in conjunctionwithanincreaseinthewaist-to-hipratio.

1. Murthi, P. and Sivakumar, V. “Strength-porosity relationshipforternaryblendedconcrete”,TheIndian ConcreteJournal,Vol.82,No.7,pp.35-41,2008

2. Alireza Mokhtarzadeh, and Catherine French, “MachanicalPropertiesofHigh-StrengthConcretewith ConsiderationforPrecastApplications”,ACIMaterials Journal,Vol.97,No.2,pp.136-147,2000.

3. Manikandan, R. and Ramamurthy, K. “Swelling Characteristic of Bentonite on Pettetization and PropertiesofFly-ashAggregates”,JournalofMaterials inCivilEngineering,Vol.21,No.10,pp.578-586,2009.

4. BibraGorai,Jana,R.K.andPremchand,“Characteristics and utilization of copper slag-a review”, Resources, Conservation and Recycling, Vol. 39, pp. 299-313, 2002.

5. Christian Meyer, and Ali Behnood, “Utilization of copper slag in cement and concrete”, Resources, Conservation and Recycling, Vol.52, pp.1115-1120, 2008.

6. JohnsonAlengaram,U.,MohdZaminJumaat,andHilmi Mahmud,“ComparisonofMechanicalPropertiesand Structural Behaviour of Palm Kernel Shell Concrete (PKSC) Beams withNormal WeightConcrete(NWC) Beams”,10thNCBInternational SeminaronCement andBuildingMaterials,pp.21-26,200

7. Rashid, M.A., Tanvir Hossain, and Ariful Islam, M. “Higher strength concrete using crushed brick as coarseaggregate”,TheIndianConcreteJournal,Vol.10, pp.18-23,2008.

8. Evangelista, L. and de Brito, J. “Mechanical behavior concretemadewithfinerecycledconcreteaggregates, Cement and Concrete Composites, Vol. 29, pp. 397401,2007.

9. Khatib,J.M.“Propertiesofconcreteincorporatingfine recycledaggregate”,CementandConcreteResearch, Vol.35,pp.763-769,2005.

10. Lilian Ribeiro de Rezende, and Jose Camapum de Carvalho, “The use of quarry waste in pavement construction”, Resources, Conservation & Recycling, Vol.39,pp.91-105,2003.

11. Reindl,J.Reportbyrecyclingmanager,Danecounty, Departmentofpublicworks,Madison,1998.

12. Caijun Shi, “Corrosion of Glasses and Expansion MechanismofConcreteContainingWasteGlassesas Aggregate”,JournalofMaterialsinCivilEngineering, Vol.21,No.10,pp.529-534,2009.

13. Bashar Taha, and Ghassan Nounu, “Utilizing Waste Recycled Glass as Sand/Cement Replacement in Concrete”, ASCE Journal of Materials in Civil Engineering,Vol.21,No.12,pp.709-721,2009.

14. SrinivasaRao,P.,SeshadriSekhar,T.andSravana,P. “Durability studies on glass fibre SCC”, The Indian ConcreteJournal,Vol.10,pp.44-52,2009.

15. Seung-Bum Park, and Bong Chun Lee, “Studies on expansionpropertiesinmortarcontainingwasteglass andfibers”CementandConcreteResearch,Vol.34,pp. 1145-1152,2004.

16. Alhozaimy, A.M., Shannag, M.J. “Performance of concretes reinforced with recycled plastic fibres”, MagazineofConcreteResearch,Vol.61,No.4,pp.293298,2009.

17. Elzafraney, M., Soroushian, P. and Deru, M. “Development of EnergyEfficient Concrete Buildings Using Recycled Plastic Aggregates”, Journal of ArchitecturalEngineeringVol.11,No.4,pp.122-130, 2005.

18. Shweta Goyal, Maneek Kumar, and Bhattacharjee, B. “Potential benefits of incorporating fly-ash in silicafumeconcrete”,TheIndianConcreteJournal,Vol.82, No.8,pp.38-46,2008

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |