International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

In the present electric vehicle scenario, diesel engines are playing a major role in heavy vehicles. This is the motivation for analyzing the influence of air in the combustion chamber of a diesel engine for Bio diesel with a modified engine head. This modified head provides immense excitement for a smooth mixture of air/fuel combustion. This may have an impact on the reduction of emission parameters like HC, CO, and NOx in diesel engines. Based on this, to comprehend engine behavioral patterns of bio diesel influence, along with engine head modification byair swirl.Toinitiate theswirl inside thecombustion chamber, various methods like changing the cylinder head, piston, and inlet manifold system is relevant. We select a diesel engine cylinder to modify in to generate air swirl. The air swirl ratio is assessed with conventional and modified cylinder heads. The performance of modified and conventional cylinder heads is compared in the experimental investigation work. Basedonthecomparison, theperformance parameters for modified cylinder headwithBiofuel have increased, likeBTE and otherefficiencies,BSFChaslowered,andemissionlevelssuchasHC,CO,andNOxcouldindeedbecompared.Whencompared totraditionalcylinderheads,modifiedcylinderheadswithbiodieselproducefewergreenhousegasemissions.

The spark-ignition engine initially invented in 1876 German inventor Nicolaus A. Otto, whereas the compression-ignition enginefirstinventedbyRudolfDieselin1892.Theyinvestigatedinternalcombustionenginesamongthefirsttodoso. Diesel engineshavebeenproventobemoreattractivetopetrolenginesbecauseoftheirlowerfuelconsumption,loweremissionsof carbonmonoxide,andhighertorques.However,theytooareamongofthemostapparentdriversofairpollutiontoxins,thusit iscrucialtolimittheirusetoaminimuminordertoavoidissuesfromairpollution.

EngineData

1500rpm, CR:18, 4-stroke, Single Cylinder, 220o is valveopen and closecrankangle

InletBoundary Velocity Inlet 6m/s is given by calculating it from enginerpm

LowandHighliftapproachisusedforValve,fullvalvelift is8mmand 110o is the crank angle at that position. Piston position is set correspondingly.

The following methodologies were investigated for studying the flow dynamics within the cylinder using CFD: Cylinder analysistestbench,creatinggenuineCADgeometryfromanexistingdiesellabengineforthevalves,cylinderhead,piston, and cylinder.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

•Atthisstage,theCADgeometrythatwillbeusedfortheanalysisisimportedintotheCFDapplication.

•Onlytheinternaldomainsintheinletandcylinderswouldbeevaluated;thisisknownasfluiddomainextraction.

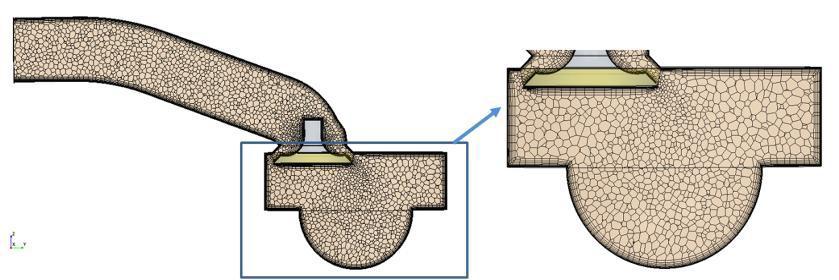

•After extracting the fluid domain, the surface is 2D meshed for later processing; a 3D volume cell is generated inside the domainusingthe2Dmeshing,andthegoverningequationsaresolved.

•After developing 3D volume cells, the cells' consistency will be evaluated to confirm that the governing equations are appropriately converging. A polyhedral shape volume cell is employed in this investigation. The figure below depicts the distributionofvolumecellsinthemodel.

Thefundamentalbenefitofpolyhedralmeshesisthateachcellhasahighnumberofneighbors,allowing forprecisegradient approximation. Furthermore, polyhedrons are less prone to stretching than tetrahedrons, resulting in greater mesh consistencyandnumericalstabilityofthesystem.Furthermore,numericaldiffusionisreducedduetomassinterchangeacross severalfaces.Asaresult,theanswerismoreexactwithasomewhatlowercount.

In this investigation, 62 cells with diameters smaller than 1mm were selected because the bulk of in cylinder experiments employthisnumber.

Thesolverconfigurationiscompleteafterthepreprocessingprocessesmentionedbelowaredone.

In this phase, the models required to solve the fluid flow are chosen, and boundary conditions are applied at the intake and outflow.Reportsandcontoursceneriesarealsogeneratedasneeded.Additionalinformationisprovidedinthetablebelow.

Air IdealGas Air flow in cylinder modeled as airmediumusingIdealgasapproach

Time TransientState Transient approach is approach is used in which flow field will vary with respect to time.

Turbulence K-Epsilon

To capture Turbulence in the model K- Epsilon model is used where K is turbulent kineticenergyandEpsilonisturbulentdissipation

FlowNature TurbulentFlow ReynoldsnumberofthisstudyisRe>3000

Table3.1:Modelsforaddressingflowfieldproblems.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

EngineData 1500rpm, CR:18, 4-stroke, Single Cylinder, 220o is valveopenandclosecrankangle

InletBoundary Velocity Inlet 6m/s is given by calculating it from enginerpm

ValveAndPiston LowandHighliftapproachisusedforValve,fullvalvelift is8mmand110o isthecrank angleatthatposition.Pistonpositionissetcorrespondingly.

Table3.2:Themodelintroducesaboundarycondition.

Contours and report generation: Prior to executing the event, reports are created to measure swirl, tumble, and TKE, and contourscanbegeneratedeitherduringorafterthisstep.

At this point, the simulation will provide results, and the next step will be to test the convergence of documents and flow variables.Reportvariablesandcontourinformationwillberetrievedifallconvergencerequirementsaresatisfied.

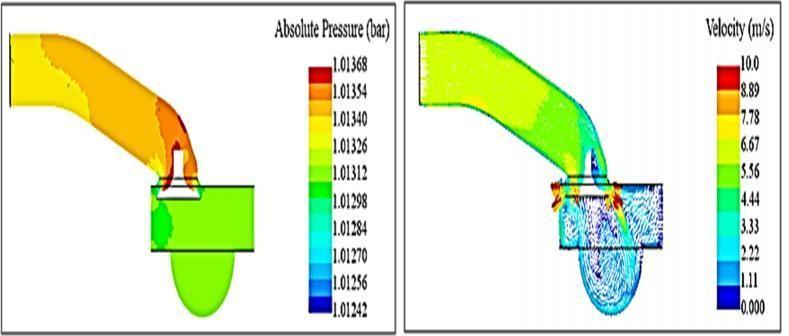

The first image illustrates strain, the second exhibits vector plots indicating flow direction, and the third depicts the vector plotitselfbutintheformoflinelinkingvectors;tinyfluctuationsintheflowfieldareseeninthisplot.

All three phases of modeling are completed using STAR CCM+ V12.02 technology. It is a CFD software industry leader, with applicationsspanningfromaviationtoelectroniccooling.

ThenameStarCCM+standsforSimulationofturbulentflowinanyregionusingcontinuumcomputationalmechanics.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

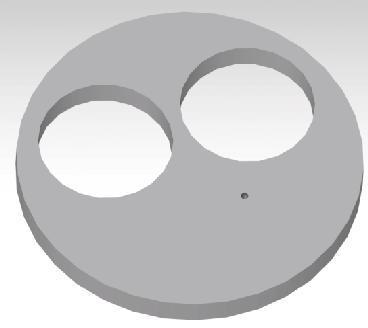

CAD Model of Head modification:

Circular cut cylinder head: Dimensionforcircularcut3x3mm.

1. Dieselenginewithasinglecylinder.

2. Aloadededdycurrentdynamo.

3. Asystemformeasuringfluidflow.

4. Amethodofwatercooling.

5. Motoroil.

6. ALV5EmissionTestingKit.

Procedure

1. Verifythereisenoughfuelfortheexperiment.

2. Onwaterwithaflowratesuitableforcoolingjackets.

3. Beforecommencingtheexperiment,removetheburden.

4. Takethenecessaryreadingsatcertainintervalsandgraduallyraisetheload.

5. Repeattheexperimentafter15-minuteintervals.

6. Calculatedataobtainedinatable

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

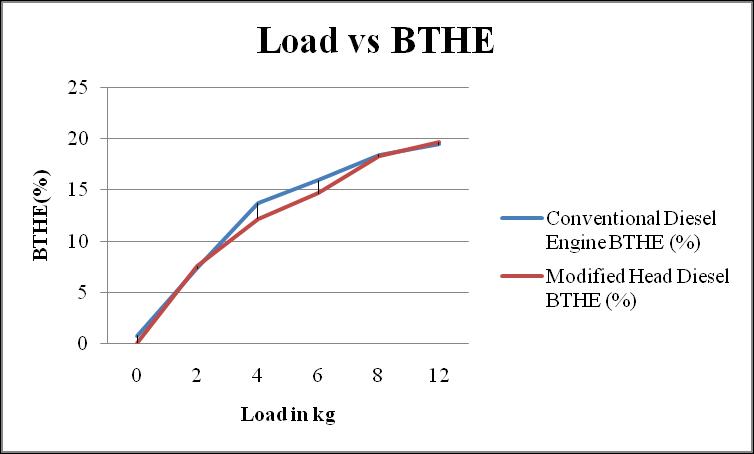

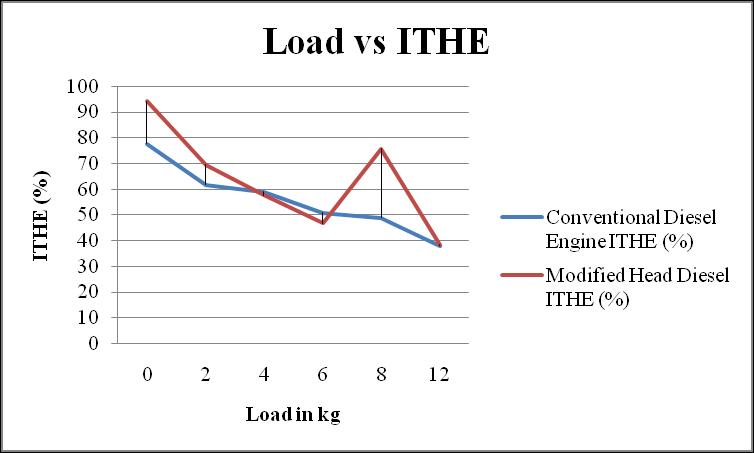

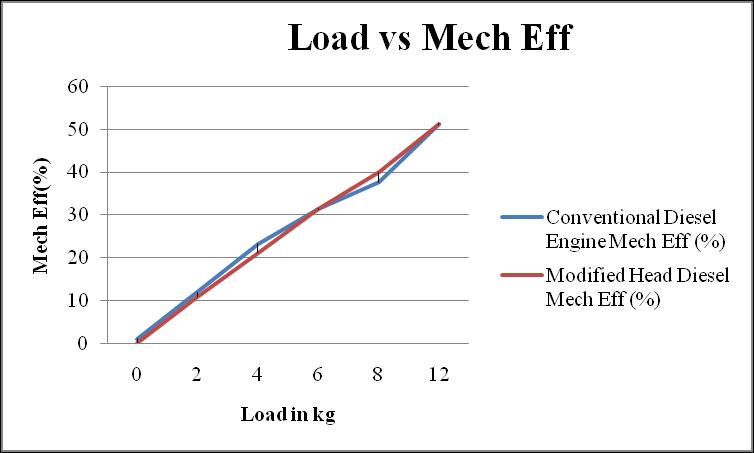

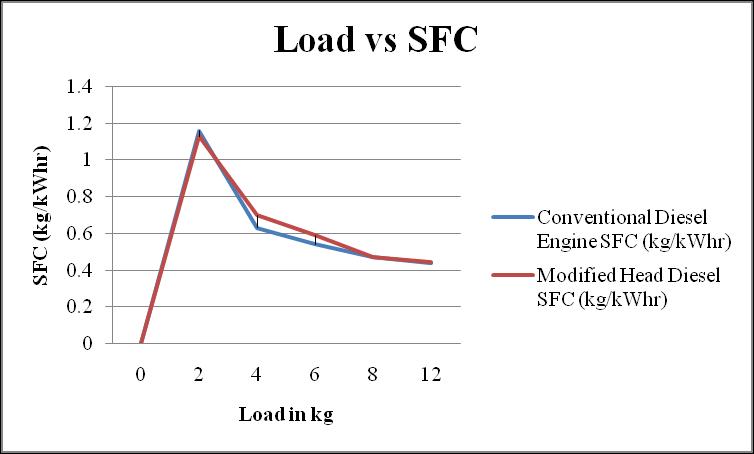

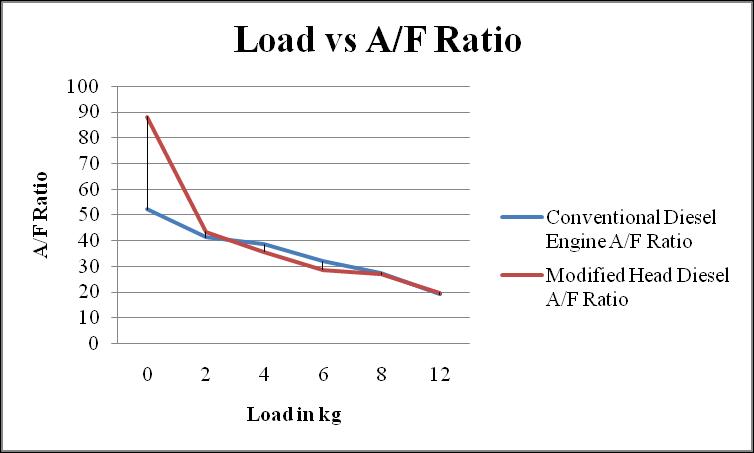

Astheresultsshowsthatthereisnochangeintheperformanceevenafterthemodificationofhead,thisisduetothatweare concentratingonlyontheemission.

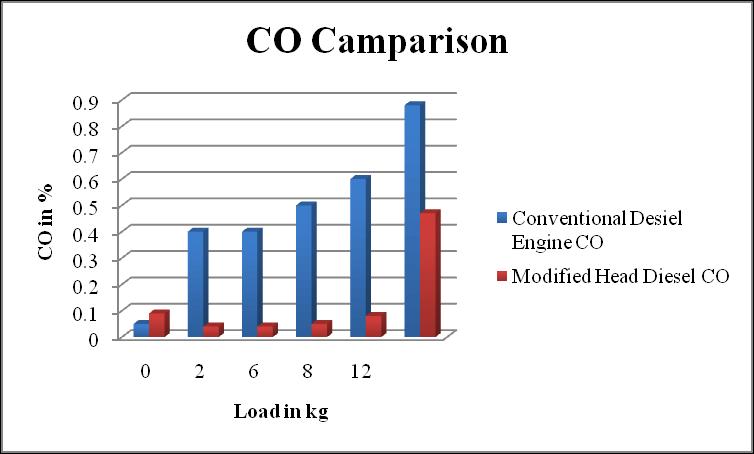

AscomparedCOemissionisreducedsignificantlyduetothecompletecombustionoccurringinsidethecombustionchamber.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

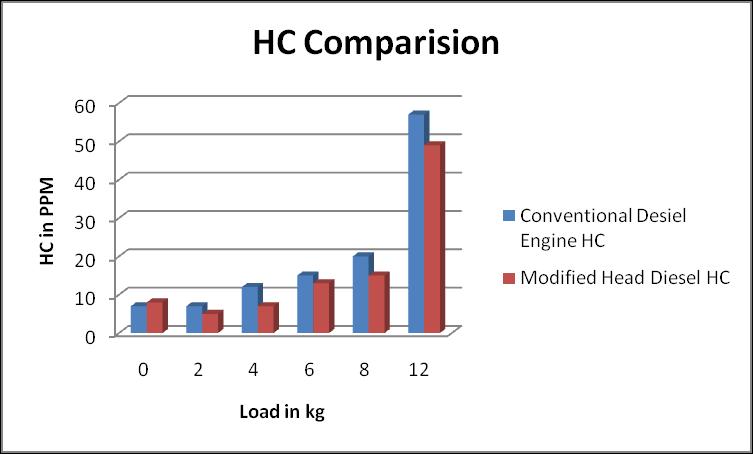

AscomparedHCemissionisreducedslightlyduetothecompletecombustionoccurringinsidethecombustionchamber.

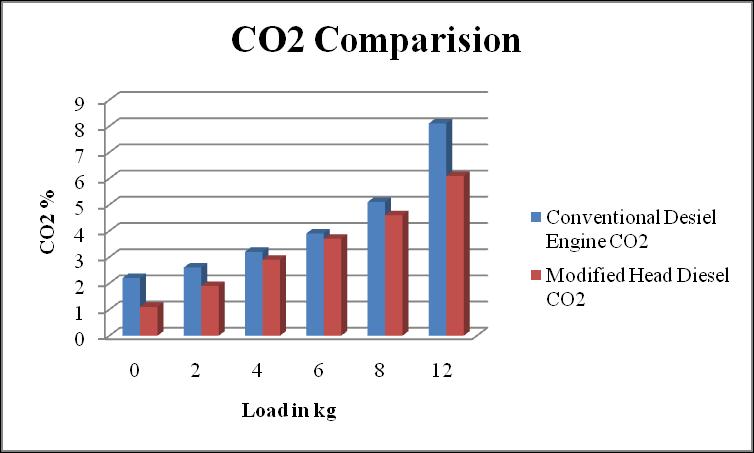

AscomparedCO2 emissionisreducedslightlyduetothecompletecombustionoccurringinsidethecombustionchamber.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

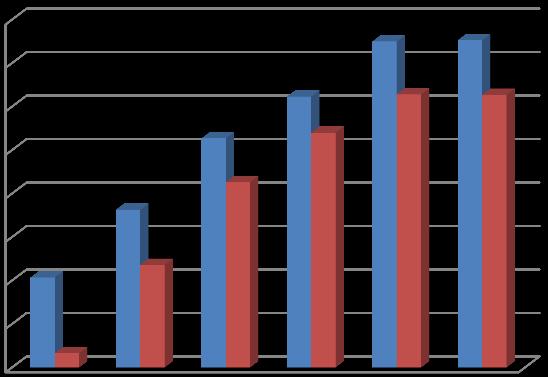

NOX Camparision

NO X in P P M

0 100 200 300 400 500 600 700 800 0 2 4 6 8 12

Load in kg

Conventional Desiel Engine NOX

Modified Head Diesel NOX

AscomparedNOX emissionisreducedduetothecompletecombustionandalsosufficientairispassedforburningwhichalso actascoolingagentthatreducestheinternaltemperatureofthecombustionchamber.

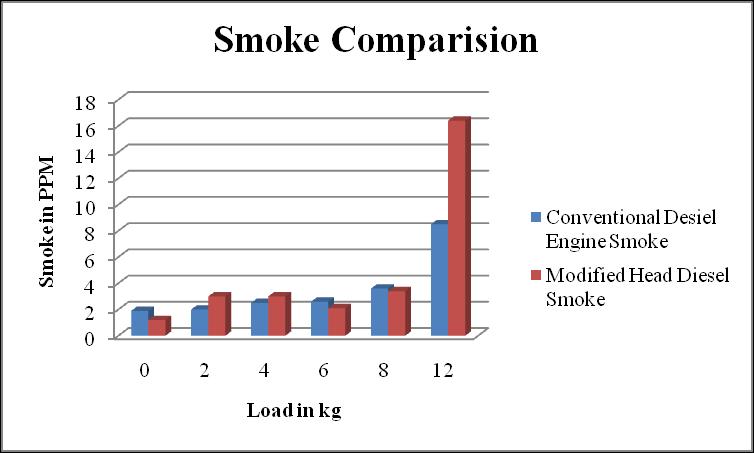

Duetocombustionofrichfuelinthemodifiedengineheadsmokeisslightlyincreasedwithload.

1. Duetothemodificationofengineheadtheperformanceisnotaffected,butemissionparameterisdrasticallyreduced.

2. ThereisaslightlydecreasesinBTHEandasmallincreaseinSFC.

3. COandHCemissionisdrasticallyreducedinmodifiedhead.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

4. NOXandCO2arereducedinmodifiedhead.

1. Headmodificationtoimproveperformanceaswellasemissionparameter.

2. UseofproperfuelinjectortomaintainA/Fratio.

3. Useofalternativefueltobedone.

1. Analysis of I.C. Engine to Improve Performance due to Grooves on Engine Cylinder Head - V.R.Deshmukh, A.B.Atpadkar.

2. Engine structure modifications effect on the flow behavior, combustion, and performance characteristics of DI diesel engine- Hadi Taghavifar Shahram Khalilarya Samad Jafarmadar.

3. MechanicalcharacterizationofaluminiumalloysforhightemperatureapplicationsPart1:Al-Si-Cualloys - R. Molina, P. Amalberto - Teksid Aluminum M. Rosso - Politecnico di Torino.

4. InternalCombustionengineby V GANESHAN 4th edition

5. InternalCombustionEnginefundamentalsby John B Heywood 2nd edition.