International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

Runwal1(Student), Prof. Nutan Pathak2 ME (Structural Engineering), (Department of Civil Engineering, MIT World Peace University Pune, Maharashtra, India) ***

Thisresearchinvestigatestheuseofmagnetizedwaterinconcretecastingusingdemolitionwasteasanaggregate. Manystudies haveobservedthatdemolitionwastecan beusedasaggregatefor manufacturing ofconcretewhichcanbe usedforvariouspurposeslikepavementblocks,benches,shearwallsetc.becausetheexpectedcompressivestrengthwas not able to achieve using this type of concrete hence, we focused on increasing the compressive strength of this demolished concrete without replacing the demolished aggregate. We studied magnetized water and used in casting concrete to further study and investigate the effect of magnetized water on properties of concrete like compressive strengthetc.

1.1

Theenvironmentalprotectionandpromotion havebeenamongthe cross-cuttingissuestobetackledbymany countries, anditwasincludedindifferentSustainableDevelopmentGoals. Everycountryhasputalotofefforts,enforcingmeasures andstrategies,andallocatelargebudgetsonenvironmentalmanagementprograms.However,environmentaldegradation is still one of obstacles to green economy. One of causes for those issues is the increased growth of construction works countrywide which resulted in the consumption of a vast number of natural aggregates used as components for bricks, concreteblocksasphaltandotherconstructionmaterials.

There is a huge amount of solid waste is being generated as development countries requires a large amount of construction materials, land sites etc. The waste which is being generated from different activities like agricultural, domestic, industrial are causing major problems to the environment as they are not disposed in a right way. As the constructionindustryisgrowingtheoldbuildingsandstructuresaredemolishedandnewbuildingsareconstructedorthe existingbuildingsareretrofitted.Theconstructionactivityrequiresseveral materialssuchasconcrete,steel,brick,glass, wood etc. out of which concrete is considered as the most important construction material. Concrete is made of coarse aggregate,fineaggregate,cementandWaterinspecificmixproportions.

Buildings have long lifespan and their impacts affect the lives of many generations of our ancestors and stretch into the future of unknown resources, pollution and unstable climatic conditions. Several investigations have shown that the consequencesontheenvironmentinstigatedbybuildingactivitiesaresevereandrequire tobeinhibited.Buildingsector contributes majorly in the development of the society. While acknowledging this fact, it is also being professed as a key contributor to environment deterioration. Some of its negative effects on the society are land depletion, energy requirement and use, solid waste production, discharge of dust and gas, noise pollution, and utilization of natural resourcesincludingnon-renewableresources.

ToStudyofeffectofmagnetizedwateroncompressivestrengthofconcrete.

Toenhancequalityofwaterusedforconcreting.

Torecycleandreusedemolitionwaste.

Tominimizecostofconstructionbyusingwastematerialinsteadofnaturalaggregate

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

Sr. No. Title of Paper

1 Experimental Investigation of ceramic waste concrete using magnetizedwater

2 Performance evaluation of magnetic field treated water on convectional concrete containingflyash

Conference/Journal

InternationalResearchjournalof Engineeringandtechnology10October 2017

Remark Pg no.

Volume4Issue10 e-ISSN23950056 p-ISSN23950072

196200

International journal of science technologyandmanagement Internationalpaper 69-74

3 Effect of Magnetic Water on PropertiesofConcrete ResearchgateMay2017 Internationalpaper 1186411866

4 Experimental Investigation of Concrete with Recycled Aggregates for Suitability in ConcreteStructures

Appl.Sci.2019,9(23),5010 Internationalpaper 35-41

5 RecycledConcreteAggregates International Research Journal of EngineeringandTechnology Internationalpaper 125128

6 Utilization of Demolished Waste as Coarse Aggregate in Concrete

3.1 Methodology steps:

Civil Engineering Journal Vol. 5, No. 3, March,2019 Internationalpaper 541551

Toachievetheintendedobjective,inadditiontotheliteraturereviewconductedwithpurposeforBackgroundinformation onthestudyfield,thisstudyfollowedthebelowmentionedmethodology.

Theresourceinputincludesmaterialssuchthatconcreteandmasonryrubble,naturalaggregateswaterandcement.Other inputs are labor, energy and information. Labor and energy are mostly labor-based (i.e. manual). Information includes structural requirement, age at which strength is required, concrete block specifications, standards and codes of practice. Thisstudy,concreteblockswithloadbearingcapacitythatproducedfromrecycledC&Dwasteusingmagnetizedwater.

i. Water-cementratio.AccordingtoIScodesreferred,thewater-cementratiowhichisnormallyusedforstiffconcrete(i.e., concreteblocks)rangesfrom23%to30%(byweight).Concreteblocksareoneofthestiffconcretematerials Inthisstudy, thewater/cementratioof0.35(byweight)wasused.

ii. Inthisstudy,thecement/aggregatesratioof1:9byvolumesuggestedbySchoneretal,(1987)wasused.Byapplyingan analytical method of combining aggregates (Raju, 2002; Schoner and Mwita, 1987), the fine and coarse aggregates fractions were estimated. Out of nine parts of aggregates, the fine/coarse aggregates ratios were in the ratio of 5:4. This showsthatthecement-aggregatesratiousedwas1:5:4(cement:fine(sand):gravelpartsinvolume).

Thisratioisequivalentto1:4:3.3partsinweight,respectively.Theweightsofwater,fine,andcoarse aggregateinabatch wereobtainedastheproductof50kg(1bag)ofcement.

3.4

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

ThecrushingofC&Dconcretewasteswasdonemanuallyatproductionsitebyuseofheavyhammers.Afterthecrushing, the sieve was conducted in order to get a uniform sample that would maintain the uniformity of manufactured new concreteblock.

AccordingtoRwandanbuildingcode,whichisalsoinlinewithinternationalpractice,thewater/cementratiowastakenas 0.35 (by weight). The manufacturing of recycled concrete block: according to practice of professional concrete block producersinRwanda,thewholemixturewassubjectedtothemechanicalcompactionmachineinordertoprovidealater higherloadbearingcapacityandaestheticstothenewblock. fromthemachine.After24hours,theconcreteblockswere cured in water (immersed) for 26 days.Then they were taken out of the water for surface drying for one day before the laboratorytesting.Themanufacturingprocessofthenewblockispresented.

Cement:ThebindingmaterialofOrdinaryPortlandcement(OPC)of53gradewereusedinthepresentstudyforconcrete mix.ItwasusedintheexaminationforphysicalandchemicalpropertiesasperIS:12269-2013

Aggregates. Aggregateisa termforanyparticulatematerial.Theaggregatessuchasgavel,crushedstones,sandetc.The two main elements in the concrete is fine aggregate and course aggregate. Fine aggregate and coarse aggregates used in thisstudyarefreefromimpuritiesandthespecificgravityoffineaggregatewasfoundtobe2.6byconductingexperiment as per IS 2386 (Part III) – 1963. Coarse aggregate was obtained by crushing the demolition waste collected from construction sites and passing through 20 mm and it is angular and graded coarse aggregate as per IS 383 -1970, the specificgravitywasfoundtobe2.7byconductingexperimentasperIS2386(PartIII) –1963.Thetestresultofcrushing value was 21, impact value was 19 and Los Angeles abrasion value was 24, and the test results confirmed that the aggregatewasgoodqualityandthesamewasusedforprojectwork.

Normal Water (Tap water). Onethemostimportantelementintheconcreteiswater.Formixingandcuringofconcrete waterisessential.Forthisstudytapwaterwereusedforconventionalconcreteblockcastingandthechemicalproperties confirmingtoIS:3025-1986andIS:456-2000.

Magnetized water Thetwomagnetsaretobeplacebelowtheglassbeakerandrepletewithnormalwaterfor24hours magnetization.Inthetimeofmagnetization,themagneticfluxpenetratesthroughtheglassbeakerintothewater,thus wateralterstomagnetizedwater.Inthisstudy,themagnetizedwaterwasusedindemolitionwasteconcreteblockto examiningthestrengthpropertiesofconcrete.

In this project the process followed to cast the concrete is same as the conventional concrete only the difference is we replaced fine and coarse aggregate with natural and demolished aggregate by crushing it into 4 to 20mm. After manufacturingconcreteblocksof150x150x150mmsizearecastedandfollowedtheprocedureasmentionedinIScode.

This was done with purpose to check the new block affordability. It is clear that the main difference in cost would be experienced in the purchasing of cement, natural sand and coarse aggregates and the cost of crushing and transporting C&D concrete wastes, for ordinary concrete block and recycled concrete block, respectively. The cost estimation for one block was calculated using the quantities estimation, where the unit cost of each component was considered. From the localliteratureandsurveyinlocalconstructionindustries,itwasestablishedthatC&DConcretewasteswereestimatedat around 34% of total construction wastes. This was considered as a good quantity as it was exceeded only by bricks and blocksdemolishedwasteswhichweregeneratedataround49%.Asmentioned,untiltodaymostofthegeneratedconcrete wastes at the rate of around 65% were taken to land fill and therefore that was contributing to environmental degradation. Regarding other potential uses, the research established that 32% of experts suggested that C&D wastes should use for preparation of new concrete blocks while 38% confirmed that these wastes should be used as wall filling materials.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

Crushed aggregates usually cannot be used directly to produce a new concrete structure since it has a porous structure. This is due to the high-water absorptions rate compare to normal aggregates. Therefore, recycled aggregates have to be treated using epoxy resin to reduce the water absorption inside the aggregate. Firstly, the epoxy resins have to mix togetherbeforeplacingtheaggregateinsidethecontainer.Thentheaggregateswereimmersingintotheepoxyresinand dryit.Theprocessoftreatingrecycledaggregatesusingepoxyresin.

Samplepreparation wasdoneforbothfreshandhardenedconcrete.Meanwhile,about 18sampleswerebemadeforthe tests involving hardened concrete. These samples are used for compression test. The formworks used to prepare the sampleswascubicalsize150mmx150mmx150mm.Thesizeofaggregateswasusedduringtheexperimentalworksare 5mm,10mm,14mm,20mmand37.5mm.Allthespecimenswereconductedfor7-and28-dayscuringtime.

ThedirectproduceofrecyclingofC&Dwasteare:

I. Differentsizes(5-10mm,10-20mm,20-40mmorasrequired)

II. Recycled Aggregates (RA) of different sizes (5-10 mm, 10-20 mm, 20-40 mm or as required) Results for ReplacementofNaturalCoarseAggregatewithRecycledCoarseAggregateinConcrete,

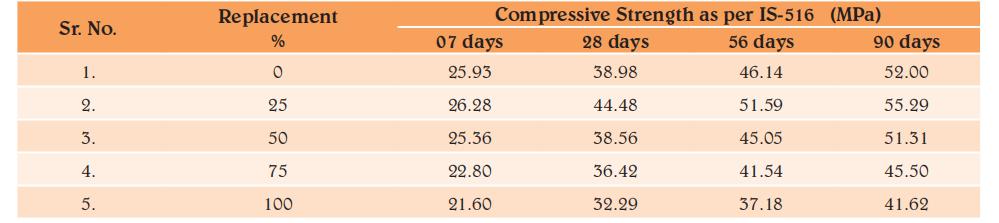

Table1.Compressivestrengthwithrespecttoreplacementofpercentageofrecycledaggregate. ResultsforReplacementofNaturalFineAggregatewithRecycledCoarseAggregateinConcrete,

The analysis results were presented in the form of tables and graphs in this part. The recycled aggregates were treated with25%epoxyresinandtheremaining75%constitutesrecycledaggregates.

For fresh concrete, the slump test was used to determine the flow of concrete mixing. The values of the slump test fall withinthe rangeof30mm – 60mm. Thehighest value recorded approximately50mmforaggregatesize of5 mmand 10 mm and the lowest slump value was 40mm for size of 20mm and 37.5mm. The small-scale sizes of aggregates were absorbed less water compared to the larger size of aggregates. This happened because of the less surface area for small scale size aggregates will be less water absorption in the aggregates. Furthermore, the large-scale size of aggregates has harshersurfacesthatabletowithstandthebettergripcomparedtootheraggregatesduringtheslumptest

Theresultsforcompressivestrengthin7daysincreaseddramaticallyfrom14MPa(5mm)upto29.6Mpa(10mm).The sizeof20mmaggregatewasrecordedthehigheststrengthat33.1MPa,followedbythesecondhigheststrengthachieved approximately32.5MPaforsizeof37.5mm.Theaggregatesizeof14mmwasalsoamongthehighestranksinthecategory at31.3MPa.Forthespecimenscuredfor28days,thecompressivestrengthsharplychangedfromsizeof5mm(13.8MPa)

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

up to aggregates size 10 mm (41.1 MPa). Then, the graph shown fluctuate between the 14mm aggregates at 37.8 MPa, 20mmaggregatesat38.8Mpaand37.5mmaggregatesat37.7MPa.

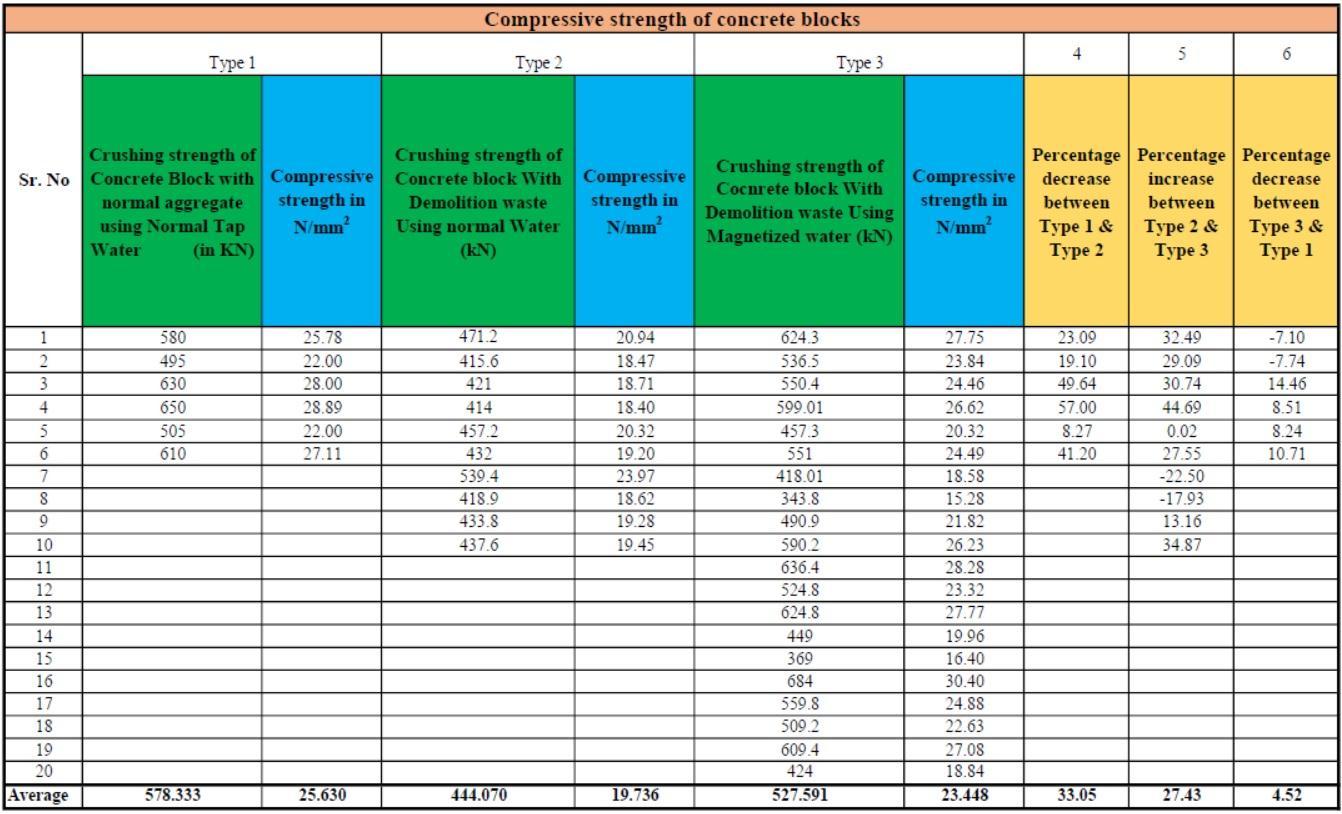

Table 3: Results Table

Table2.

Comparisonofcompressivestrengthconventionalofconcreteanddemolitionconcreteanddemolition concreteusingmagnetizedwater

0.00 5.00 10.00 15.00 20.00 25.00 30.00

Compressive strength (in N/mm2)

Compressive strength (in N/mm2)

Compressive strength (in N/mm2)

Graph1.Graphicalrepresentationofcompressivestrengthcomparisonbetweenconcretewithdifferentmaterial

Intabletype1columnisofconcretewithnaturalaggregateandnormalwater.

Type2isofconcretewithdemolitionaggregatewithnormalwater.

Type3isofconcretewithdemolitionwasteandusingmagnetizedwater.

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page866

Comparison betweenconventional concrete and concrete with demolitionaggregateand normal water isshown incolumn4whichindicatesthatthestrengthofdemolitionaggregateconcretehasdecreasedthanthestrengthof conventionalconcrete.

International Research Journal of Engineering and Technology (IRJET)

e-ISSN:2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN:2395-0072

Comparison between demolition aggregate concrete and concrete with demolition aggregate and magnetized waterisshownincolumn5whichindicatesthatthestrengthofdemolitionaggregateconcretehasincreasedthan thestrengthofdemolitionaggregateconcrete.

Comparison between conventional concrete and concrete with demolition aggregate and magnetized water is shownincolumn6whichindicatesthatthestrengthofdemolitionaggregateconcretewithmagnetizedwaterhas littlebitlessstrengththanthestrengthofconventionalconcrete.

Strengthofconventionalconcretereducesby 33.05% when,demolishedaggregateisusedforcastingofconcrete.

Strength of concrete increases by 27.43% when magnetized water is used along with demolished aggregate in concretecasting.

Thoughstrengthofconcreteincreaseswhenmagnetizedwaterisusedalongwiththedemolishedaggregatestill, thestrengthofthisconcreteislessthanthestrengthofconventionalconcreteby 4.52%.

From the above points it can be concluded that concrete blocks can be manufactured using building demolition waste. Natural aggregate can be 100% replaced by demolished aggregate without much loss in strength and durability parameters when used along with magnetized water, However M-sand can be replaced up to 20% by RFAwithoutmuchcompromiseinstrengthanddurabilityparameters.

Demolishedconcretecanbeusedforlessusefulpurposesforexample,potholeandfoundationbackfilling.Bythis replacement and reuse of recycled aggregates, the aim is not only to reduce down-cycling but also to solve the rising problem of material shortages. In this research, the recycled aggregates for both fine and coarse replace naturalaggregatesby100%intheconcreteblocksproduction.

1. Thestrengthstudyshowsthatmagnetizedwatershowedstrengthdevelopmentcomparedwithnormaltapwater. The compressive, Split Tensile and Flexural strength of magnetized water enhanced as the maturity of the concreteincreasesbyvirtueofcontinueshydrationmechanismwhichreducestheporosityoftheconcrete.

1. Experimental Investigation of Properties of Concrete Cast in Magnetized Water International Journal of Science Technology & Engineering IJSTE -Manuscript IDIjSTEV317011 Publication date 1/2/2017 Volume 3 | Issue 07 | January2017ISSN(online):2349-784XPageNo.1-6

2. Lokuge WP and Aravinthan T. Mechanical properties of polymer concrete with different types of resin. In: 22nd AustralasianConferenceontheMechanicsofStructuresandMaterials(ACMSM22),2013.

3. YaqubM&ImranB.EffectOfSizeOfCoarseAggregateOnCompressiveStrengthOfHighStrengthConcretes.31st ConferenceonOurWorldInConcrete&Structures,2006.

4. Abdul Rahim M, Ibrahim NM, Idris Z, Ghazaly ZM, Shahidan S, Rahim NL, Sofri LA, and Isa NF. “Properties of Concrete with Different Percentange of the Rice Husk Ash (RHA) as Partial Cement Replacement,” Mater. Sci. Forum,vol.803,pp.288–293,2014.

5. AndreuGC,MirenE.Effectsofusingrecycledconcreteaggregates ontheshrinkageofhigh-performanceconcrete. ConstructionandBuildingMaterialsVolume115,2016.

6. Nikola T, Snezana M, Tina D & Milos S. Multicriteria optimization of natural and recycled aggregate concrete for structuraluse.JournalofCleanerProductionVolume87,2015.