International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

1Dr HIREGOUDAR YERRENAGOUDARU, 2SHADAB KHAN, 3 SUHAS BHAT, 4MOHAMMED SAIFUDDIN.

1,2,3,4 Rao Bahadur Y Mahaballeswarappa Engineering Collage Ballari 583104 ***

Abstract – Experimentally, the effect of piston shape and swirl intensity on the performance of a direct injection (DI) diesel engine was explored. To create optimal swirl for better fuel-air mixing, changes in piston geometry have been recommended. The shape of the combustion chamber, as well as the fuel spraying and mixing process, has a big impact on diesel engine combustion and emissions. For diesel engines, in-cylinder air motion governs both air–fuel mixing and combustion, which is characterized by swirl and turbulence. A modified piston was used to assess the overall performance of a DI diesel engine. Furthermore, the engine's performance was compared for modified piston with convectional diesel. When compared to a regular piston, the modified piston enhanced brake thermal efficiency and brake specific fuel consumption for the same operating conditions. Both standard and modified pistons have their HC, CO, and NOx emissions measured.

Key Words: Engine piston modification, Diesel

Internal combustion engines (ICE)are the most common form ofheat engines, as they are used in vehicles, boats, ships, airplanes,andtrains.Theyarenamedassuchbecausethefuelisignitedinordertodoworkinsidetheengine.[1]Thesamefuel andairmixtureisthenemittedasexhaust.Thiscanbedoneusingapiston(calledareciprocatingengine),orwithaturbine.

ICEnginesetupundertestisResearchDieselhavingpower3.50kW@1500rpmwhichis1Cylinder,Fourstroke,Constant Speed, Water Cooled, Diesel Engine, with Cylinder Bore 87.50(mm), Stroke Length 110.00(mm), Connecting Rod length 234.00(mm),CompressionRatio18.00,Sweptvolume661.45(cc)

SpecificGasConst(kJ/kgK):1.00,AirDensity(kg/m^3):1.17,AdiabaticIndex:1.41,PolytrophicIndex:1.20,NumberOf Cycles:10,CylinderPressureReferance: 5,Smoothing2,TDCReference:0

OrificeDiameter(mm):20.00,OrificeCoeff.OfDischarge:0.60,DynamometerArmLegnth(mm):185,FuelPipedia(mm): 12.40,AmbientTemp.(DegC):27,PulsesPerrevolution:360,FuelType:Diesel,FuelDensity(Kg/m^3):830,CalorificValue OfFuel(kj/kg):42000

PistonDetails:

PistonDimensionsPistondiameter:87.5mmPistonbowldiameter:52mmPistonlength:100mm.

The piston is a critical component in internal combustion engines. It turns heat energy into mechanical power through a reciprocatingmotion.Whentheengineproducespower,itgoesupanddowninsidethecylinder.Thepiston'sjobistostopgases

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

fromexpandingandsendingthemtothecrankshaft.Theforceoftheexplosionistransferredtothecrankshaft,whichrotatesas aresult.

Fig.1-Modifiedpistonof2cutoutsand2protrusionsonpistonandpistonbowl

Fig.2-Experimentalsetup

4.1 The Testing set-up consists of:

1. Fourstrokedieselenginewithsinglecylinder. 2. Eddycurrentinjectionkitforcurrentloading. 3. Transmittersareusedformeasuringfuelflowandairflow. 4. Rotametersareusedformeasuringcooling. 5. Fuelmeasurementunitandfueltank. 6. Adeviceforemissiontesting.

1. Fillthefueltankwithdiesel. 2. Checkflowofcoolingwatertotheengine. 3. Keeploadofengineat0Kg. 4. PutONthemainsupply. 5. Forinitialcondition,runtheengineat0kgandtabulatethereadings. 6. Graduallyincreasetheloadinstepsof2Kgsandtabulatethereadings

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

5.1.1

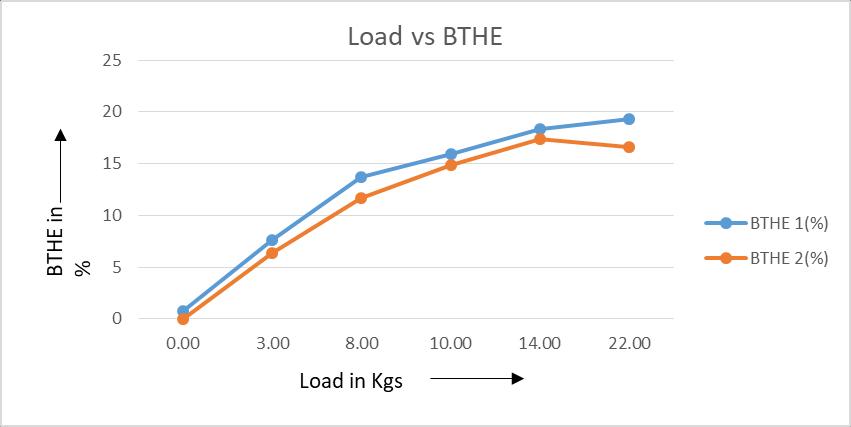

Chart -1:LoadvsBTHE

Inference: BrakethermalefficiencydependsonBrakepowerandspecificfuelconsumption.HereSpecificfuelconsumptionis increasinginanenginewithmodifiedpistonastheflowoffuelismorethanair.Hencebrakethermalefficiencyisincreasing withincreasingload.Brakethermalefficiencyisnearlysameasthatofdiesel.

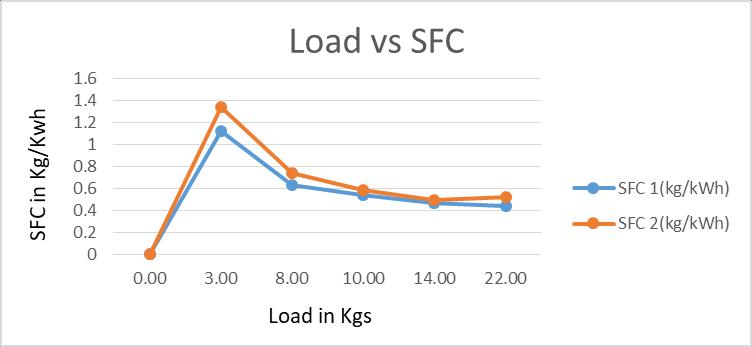

5.1.2 Load vs Specific fuel consumption

Chart2 -:LoadvsSFC

Inference: Thespecificfuelconsumptionofconventionaldieselengineislowerthanthatofenginewithmodifiedpiston.This isbecauseofthehigherviscosityandpoormixtureformation

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

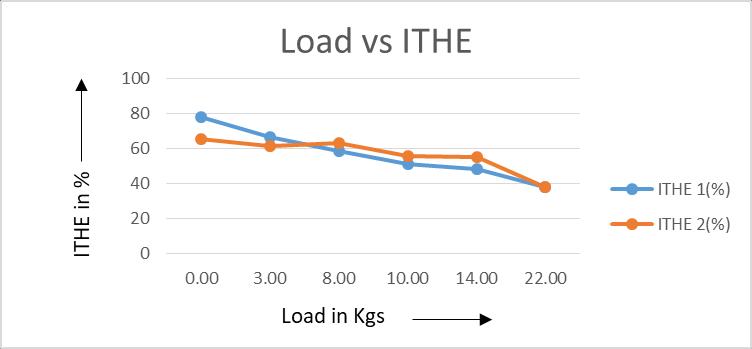

Inference: Indicatedthermalefficiencydependsontheindicatedpowerwhichinturndependsontheindicatedmeaneffective pressure.Indicatedmeaneffectivepressureistheaveragepressureinthecylinderforacompleteenginecycle.Asindicated meaneffectivepressureismorefordieselenginewithmodifiedpistonindicatedthermalefficiencyatlowload&moreasload increases.

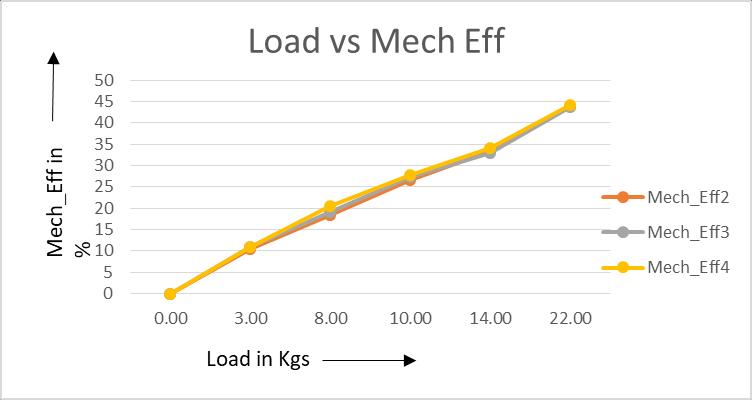

5.1.4 Load vs Mechanical efficiency

Inference: Mechanicalefficiencyisobtainedbytheratioofbrakepowertotheindicatedpower.Astheindicatedpoweris increasinginanenginewithmodifiedpistonwithbiodieselhencemechanicalefficiencyisdecreasing.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

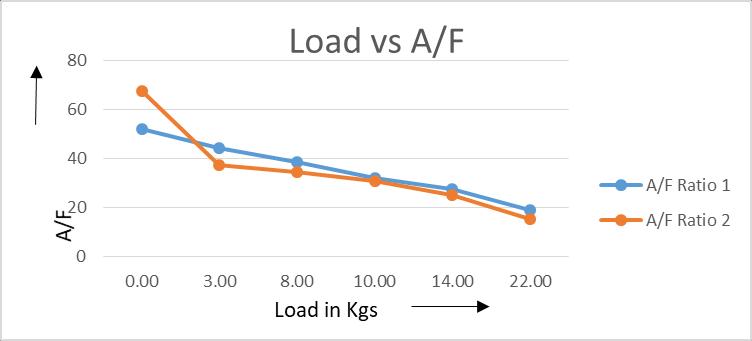

5.1.5

Chart

Inference: Theairfuelratioislessinconventionaldieselengineanditisincreasinginanenginewithmodifiedpistonbecause oflessairflowresultinginrichmixture

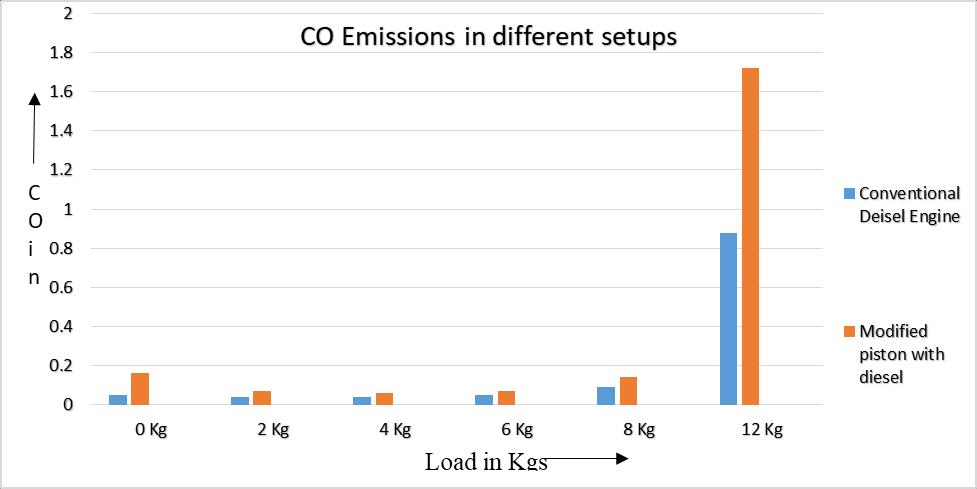

5.2.1 Load vs CO Emission

Inference: Higherfuel/airratiocausestheemissionofCO.DuringtheinitialloadstheCOemissionsarecomparativelysmall andthereisslightdifferencebetweendifferencesetups.Butathigherloadsitisincreasingbecausewithincreaseintheload thefuel/airrationincreasesThiscausesrichfuel/airmixturehenceresultinginCarbonmonoxideemissions

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

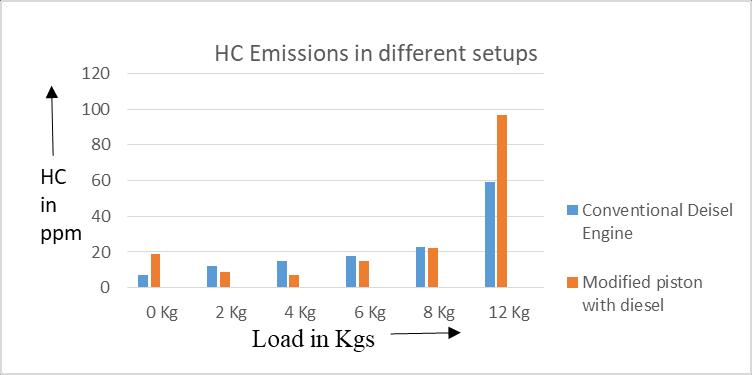

5.2.2

Chart -7:HCEmissions

Inference: Higherfuel/airratiocausestheemissionofHC.DuringtheinitialloadstheHCemissionsarecomparativelysmall andthereisslightdifferencebetweendifferencesetups.Butathigherloadsitisincreasingbecausewithincreaseintheload thefuel/airrationincreasesThiscausesrichfuel/airmixturehenceresultinginhydrocarbonemissions

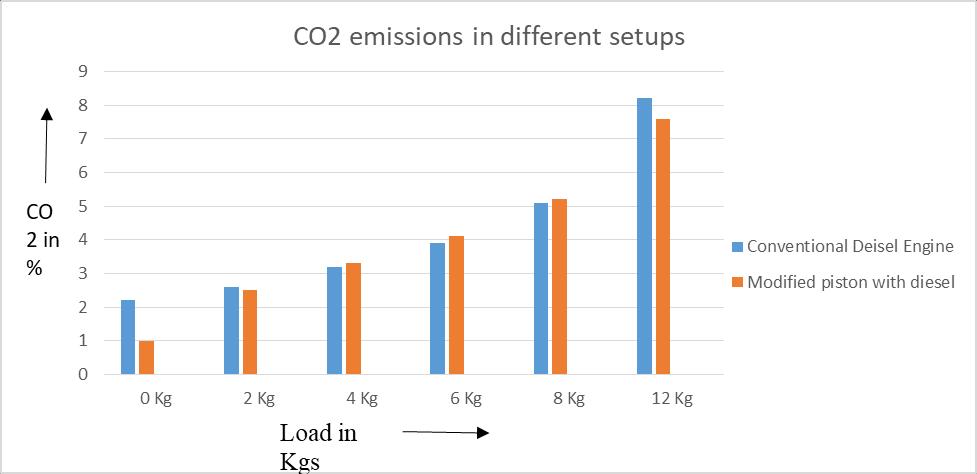

5.2.3 Load vs CO2 emission

Chart -8:CO2

Inference: Thecombustionprocesscausesamixingofcarbonwithoxygeninairresultingintheformationofcarbondioxide. ThechangeofCO2emissionisalmostsameinallthesetups

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

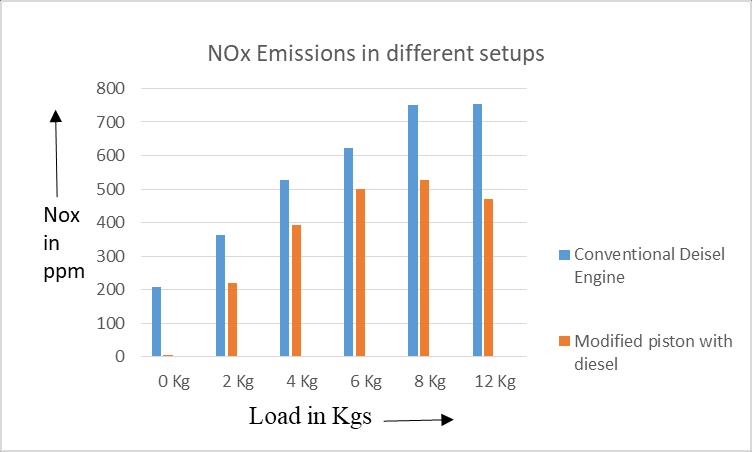

5.2.4 Load vs NOx emission

Chart -9:NOxEmissions

Inference: NOxemissionsarelesscomparedtoconvectiondieselengineatvariousloadsforwithmodifiedpistonbecauseof richmixtureburning

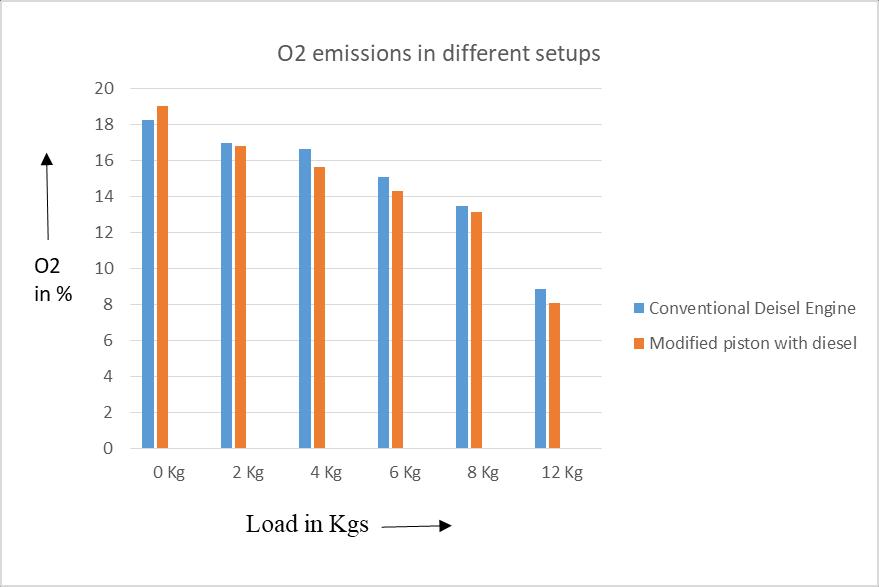

5.2.5 Load vs O2 Emission

Chart -10:O2Emissions

Inference: Withincreasingloadoxygenemissionisreducingindifferentsetupswhichresultsingoodcombustionoffuel.O2 emissionisalsonearlysamefordifferentsetups.

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page820

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

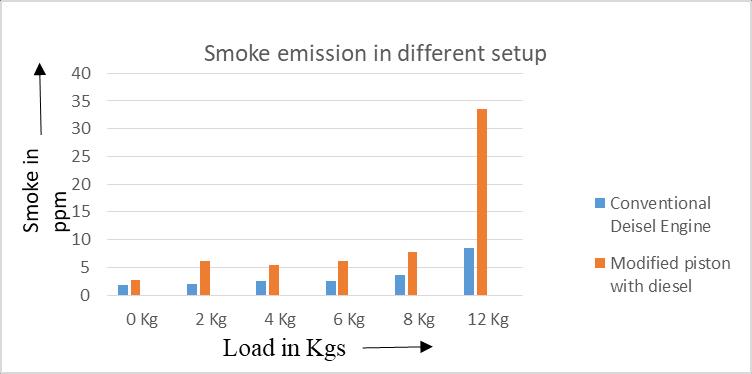

Inference: Smokeemissionisthepartofcombustionprocess.Smokeisincreasingwithincreasingloadbecauseofrichair/fuel mixture.

Theexperimentalresultsshowtheimprovementinemissionparametersofsinglecylinderfourstrokedieselengine withmodifiedpiston

ThemodifiedpistonwithbiodieselhasgoodimpactonNOx&O2emission.

ThemodifiedpistongoodimpactonCO2,HC&COEmissionsatlessloadscomparedwithconvectiondiesel

Brake thermal efficiency, Indicated thermal efficiency and Specific fuel consumption of Biodiesel is nearly same comparedtoDiesel

CFDanalysiscanbedone. Swirlratiocanbecheckedbyswirltestrig. Geometrycanbevarieddependingupontherequiredparameters.

1. AlanC.Hansen,QinZhangandPeterW.L.Lyne,“Ethanol–dieselfuelblendsareview”, Bioresource Technology, Volume 96, Issue3,February2005,Pages277-285.

2. HanbeyHazar,“Effectsofbiodieselonalowheatlossdieselengine”, Renewable Energy 34 (2009)1533–1537.

3. NevenVoca,BorisVarga,TajanaKricka,DuskaCuric,VanjaJurisicandAnaMatin,“Progressinethanolproductionfromcorn kernelbyapplyingcookingpre-treatment” BioresourceTechnologyVolume100,Issue10,May2009,Pages2712-2718.

4. AvinashKumarAgarwal,“Biofuels(alcoholsandbiodiesel)applicationsasfuelsforinternalcombustionengines” Renewable Energy, 27November2006.

5. Hakan,Bayraktar “Experimentalandtheoreticalinvestigationofusinggasoline–ethanolblendsinspark-ignitionengines”, Renewable Energy,2005; Volume 30, Issue 11:pp1733-1747.

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page821

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

6. JasonJ, DanielMarc,RosenA,“Exergetic EnvironmentalAssessmentofLifeCycleEmissionsforvariousAutomobilesand Fuels,Energy 2(2002)283-294

7. Hwanam Kima, Byungchul Choi, “Effect of ethanol–diesel blend fuels on emission and particle size distribution in a common-raildirectinjectiondieselenginewithwarm-upcatalyticconverter”,Renewable Energy 33 (2008)2222–2228.

8. Baker,Q.A., “UseofAlcohol-in-Diesel Fuel EmulsionsandSolutionsina Medium-SpeedDiesel Engine”, SAE Paper No. 810254

9. InternalcombustionenginesbyVganesan4thedition.

10. InternalcombustionenginesfundamentalsbyJohnBHeywood.

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page822