International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

1Dr HIREGOUDAR YERRENAGOUDARU, 2SHADAB KHAN, 3 SUHAS BHAT, 4MOHAMMED SAIFUDDIN.

1,2,3,4 Rao Bahadur Y Mahaballeswarappa Engineering Collage Ballari 583104 ***

Abstract - Experimentally, the effect of piston shape and swirl intensity on the performance of a direct injection (DI) diesel engine was explored and also use of Biofuels. To create optimal swirl for better fuel-air mixing, changes in piston geometry have been recommended. The shape of the combustion chamber, as well as the fuel spraying and mixing process, has a big impact on diesel engine combustion and emissions. For diesel engines, in-cylinder air motion governs both air–fuel mixing and combustion, which is characterized by swirl and turbulence. A modified piston was used to assess the overall performance of a DI diesel engine. Furthermore, the engine's performance was compared for modified piston with convectional diesel & Biofuels. When compared to a regular piston, the modified piston enhanced brake thermal efficiency and brake specific fuel consumption for the same operating conditions. Both standard and modified pistons have their HC, CO, and NOx emissions measured.

Key Words: Engine piston modification, Bio-diesel, Mahua oil, Karanja oil, 20% blend with diesel

Internal combustion engines (ICE)are the most common form ofheat engines, as they are used in vehicles, boats, ships, airplanes,andtrains.Theyarenamedassuchbecausethefuelisignitedinordertodoworkinsidetheengine.[1]Thesamefuel andairmixtureisthenemittedasexhaust.Thiscanbedoneusingapiston(calledareciprocatingengine),orwithaturbine.

Biofuelisarenewableandclean-burningfuelthatismadefromwastevegetableoils,animalfats,orrecycledrestaurantgrease foruseindieselvehicles.Biodieselproduceslesstoxicpollutantsandgreenhousegasesthanpetroleumdiesel.Itcanbeusedin pure form(B100) or can be blended with petro-diesel in the form of B2 (2% biodiesel, 98% petroleum diesel), B5 (5% biodiesel,95%petroleumdiesel),B20(20%biodiesel,80%petroleumdiesel)andB100(purebiodiesel).

Thisprojectintroducesamodificationinpistonanduseofdifferentnonediblebiodieselblends

HereMahuabiodieselandkaranjaBiodieseleachblendedwithrawdieselinB20form(20%biodieseland80%diesel)are used.

Themainobjectiveofusingbiodieselinthisprojectistoreducetheemissionsfromtheengineandalsoitcanbeusedasan alternativefuelintheupcomingdays.

Finally,comparisonisdonebetweenthedifferentfuelsused.

1.3 Oil Specifications: SlNo. Parameter

1 Ash,max 0.01% 2 CarbonResidue(Ramsbottom)on10%residue,maxa 0.3% 3 CetaneNumber(CN),min 48b 4 CetaneIndex(CI),min 46b

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

5 Distillation95%vol.Recoveryat°C,max –6 FlashpointAbel,min 35°C 7 KinematicViscosityat40°C 2.0–5.0cst 8 Densityat15°C 820–860(820–870)bKg/m3 9 TotalSulfur,max 500mg/Kg 10 Watercontent,max 0.05%volmg/Kg 11 Coldfilterpluggingpoint(CFPP) a)Summer,max b)Winter,max

18°C 6°C 12 Totalcontaminations,max –13 Oxidationstability,max –14 PolycylicAromaticHydrocarbon(PAH),max –15 Lubricity,correctedwearscardiameter(wsd1,4)at60 °C,max 460microns 16 CopperStripcorrosionfor3hrsat50°C NotworsethanNo.1

Table -1: DieselOilSpecification

SlNo.

Parameter Specification 1 Moistureandinsolubleimpurities 0.10% 2 RefractiveIndexat400C 1.459 3 SpecificGravityat300C 0.862 4 SaponificationValue 187-196 5 IodineValue 58-70 6 Unsaponifiablematter 2% 7 AcidValuemax. 0.5 8 Titre 400C 9 FlashPoint 2500C

Table -2: MahuaOilSpecification

S.No Parameter

SpecificationRanges 1

KaranjanContent <20,000 2 SpecificGravity 0.925-0940 3 Refractiveindex 1.4734-1.4790 4 AcidValue 20 5 SaponificationValue 186-196 6 IodineValue 80-90 7 Unsaponifiablematter Max1.5%

Table -3: KaranjanOilSpecification

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page805

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

ICEnginesetupundertestisResearchDieselhavingpower3.50kW@1500rpmwhichis1Cylinder,Fourstroke,Constant Speed, Water Cooled, Diesel Engine, with Cylinder Bore 87.50(mm), Stroke Length 110.00(mm), Connecting Rod length 234.00(mm),CompressionRatio18.00,Sweptvolume661.45(cc)

Combustion Parameters:

SpecificGasConst(kJ/kgK):1.00,AirDensity(kg/m^3):1.17,AdiabaticIndex:1.41,PolytrophicIndex:1.20,NumberOf Cycles:10,CylinderPressureReferance: 5,Smoothing2,TDCReference:0

Performance Parameters:

OrificeDiameter(mm):20.00,OrificeCoeff.OfDischarge:0.60,DynamometerArmLegnth(mm):185,FuelPipedia(mm): 12.40,AmbientTemp.(DegC):27,PulsesPerrevolution:360,FuelType:Diesel,FuelDensity(Kg/m^3):830,CalorificValue OfFuel(kj/kg):42000

PistonDetails: PistonDimensionsPistondiameter:87.5mmPistonbowldiameter:52mmPistonlength:100mm.

Thepistonisacriticalcomponentininternalcombustionengines.Itturnsheatenergyinto mechanical powerthrougha reciprocatingmotion.Whentheengineproducespower,itgoesupanddowninsidethecylinder.Thepiston'sjobistostop gasesfromexpandingandsendingthemtothecrankshaft.Theforceoftheexplosionistransferredtothecrankshaft,which rotatesasaresult.

Fig.1-Modifiedpistonof2cutoutsand2protrusionsonpistonandpistonbowl

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page806

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

4.1 The Testing set-up consists of:

1. Fourstrokedieselenginewithsinglecylinder.

2. Eddycurrentinjectionkitforcurrentloading.

3. Transmittersareusedformeasuringfuelflowandairflow.

4. Rotametersareusedformeasuringcooling.

5. Fuelmeasurementunitandfueltank.

6. Adeviceforemissiontesting.

1. Fillthefueltankwithdiesel.

2. Checkflowofcoolingwatertotheengine.

3. Keeploadofengineat0Kg.

4. PutONthemainsupply.

5. Forinitialcondition,runtheengineat0kgandtabulatethereadings.

6. Graduallyincreasetheloadinstepsof2Kgsandtabulatethereadings

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

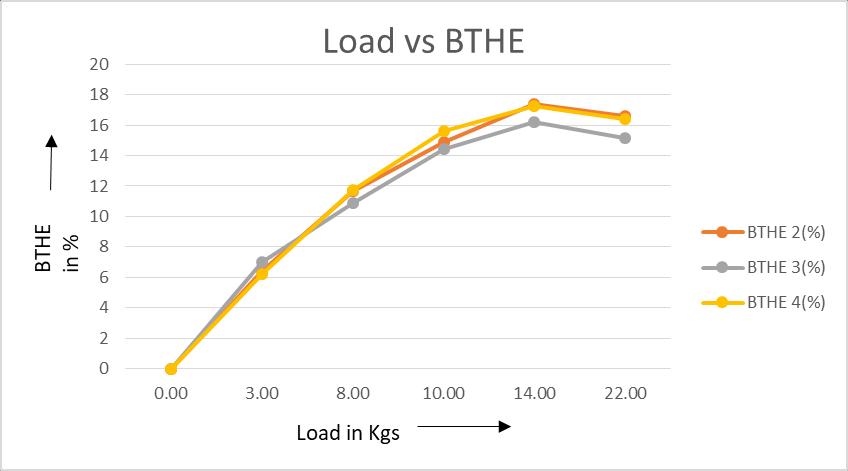

Inference: BrakethermalefficiencydependsonBrakepowerandspecificfuelconsumption.HereSpecificfuelconsumptionis increasinginanenginewithmodifiedpistonwithbiodieselastheflowoffuelismorethanair.Hencebrakethermalefficiency isincreasingwithincreasingload.BrakethermalefficiencyofBiodieselwillbesameasthatofdieselatlowload.

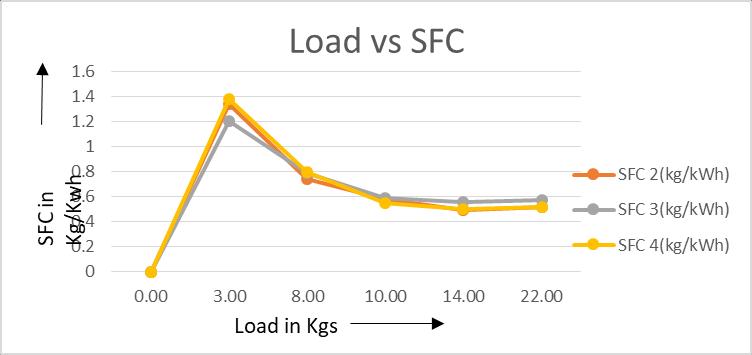

5.1.2 Load vs Specific fuel consumption

Inference: Thespecificfuelconsumptionofconventionaldieselengineislowerthanthatofenginewithmodifiedpistonwith biodieselThisisbecauseofthehigherviscosityandpoormixtureformationofbiodiesel.

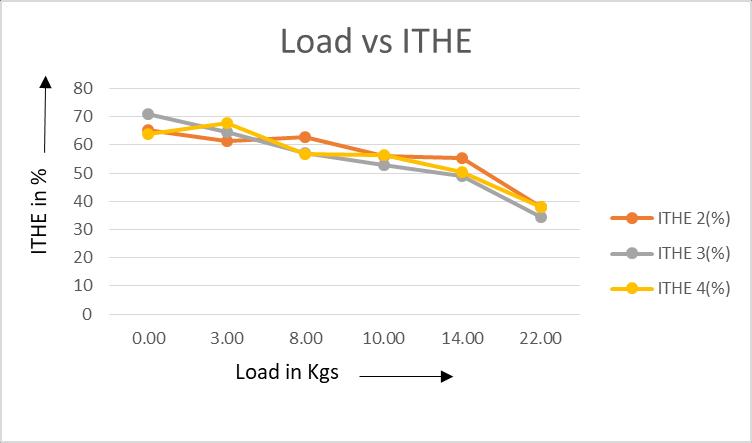

5.1.3 Load vs Indicated thermal efficiency

Inference: Indicatedthermalefficiencydependsontheindicatedpowerwhichinturndependsontheindicatedmeaneffective pressure.Indicatedmeaneffectivepressureistheaveragepressureinthecylinderforacompleteenginecycle.Asindicated meaneffectivepressureisincreasingfordieselenginewithmodifiedpistonwithbiodieselindicatedthermalefficiencyisalso increasingbyusingbiofuels

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

5.1.4

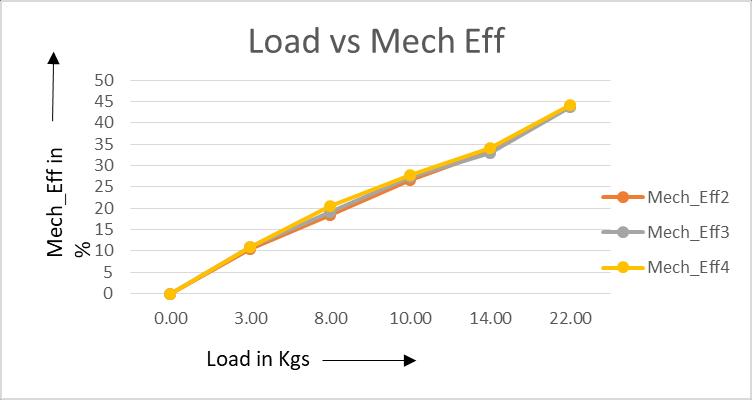

Chart -4:LoadvsMech_Eff

Inference: Mechanicalefficiencyisobtainedbytheratioofbrakepowertotheindicatedpower.Astheindicatedpoweris increasinginanenginewithmodifiedpistonwithbiodieselhencemechanicalefficiencyisdecreasing.

5.1.5

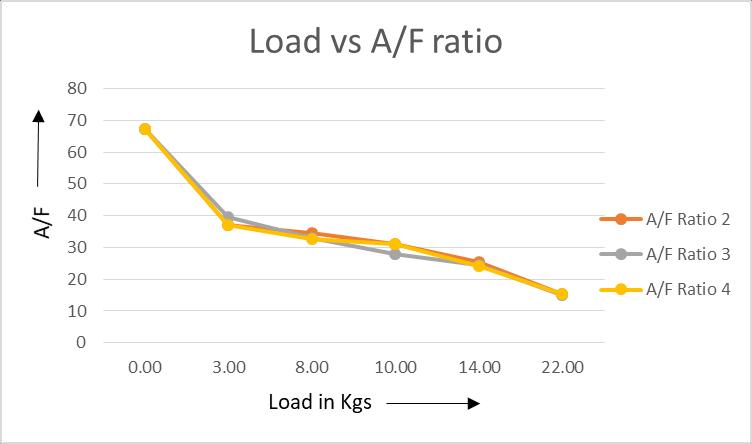

Chart -5:LoadvsA/Fratio

Inference: Theairfuelratioislessinconventionaldieselengineanditisincreasinginanenginewithmodifiedpistonwith biodieselbecauseoflessairflowresultinginrichmixture.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

5.2.1

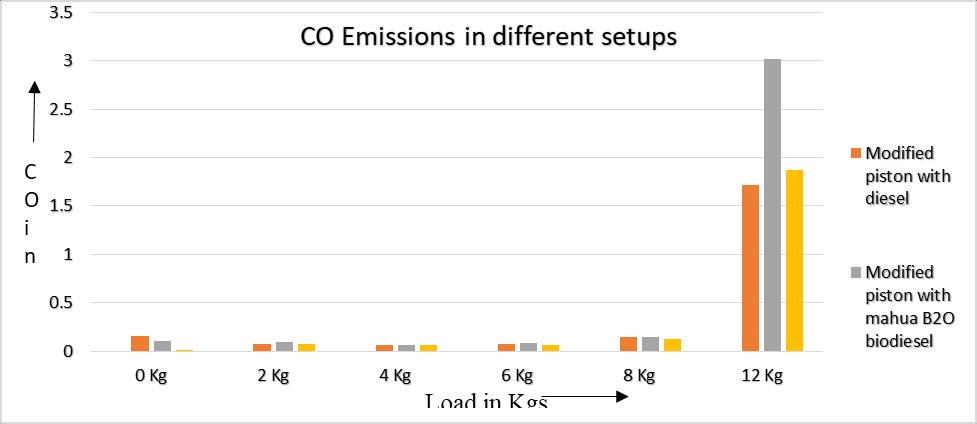

Chart -6:COEmissions

Inference: Higherfuel/airratiocausestheemissionofCO.DuringtheinitialloadstheCOemissionsarecomparativelysmall andthereisslightdifferencebetweendifferencesetups.Butathigherloadsitisincreasingbecausewithincreaseintheload thefuel/airrationincreasesThiscausesrichfuel/airmixturehenceresultinginCarbonmonoxideemissions.

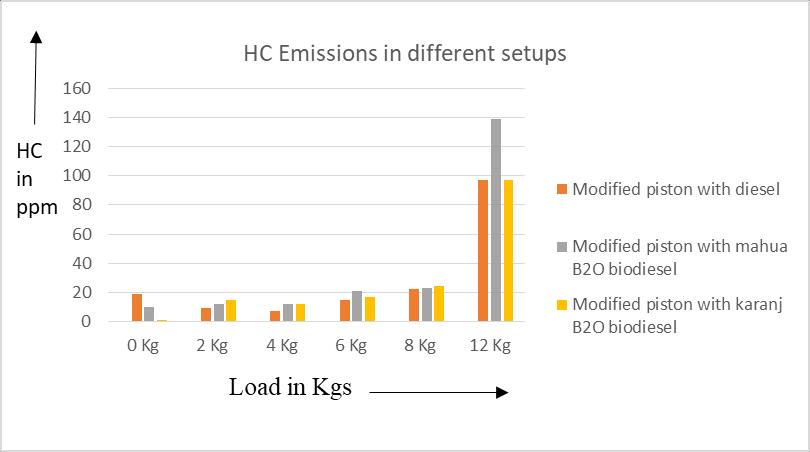

5.2.2 Load vs HC Emission

Chart -7:HCEmissions

Inference: Higherfuel/airratiocausestheemissionofHC.DuringtheinitialloadstheHCemissionsarecomparativelysmall andthereisslightdifferencebetweendifferencesetups.Butathigherloadsitisincreasingbecausewithincreaseintheload thefuel/airrationincreasesThiscausesrichfuel/airmixturehenceresultinginhydrocarbonemissions.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

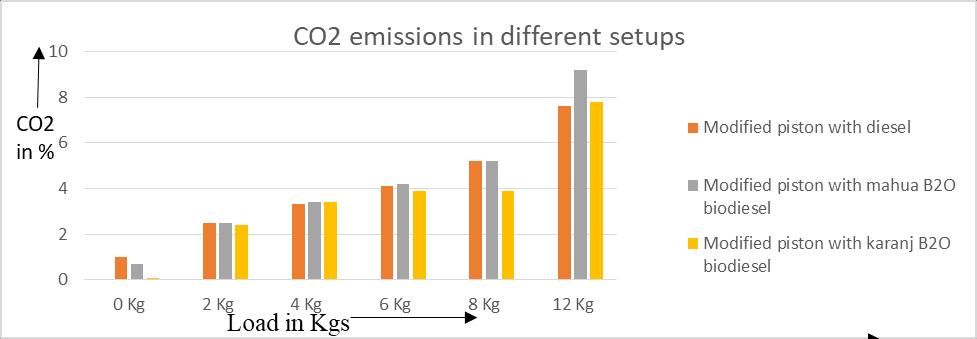

5.2.3 Load vs CO2 emission

Chart -8:CO2Emissions

Inference: Thecombustionprocesscausesamixingofcarbonwithoxygeninairresultingintheformationofcarbondioxide. ThechangeofCO2emissionisalmostsameinallthesetups

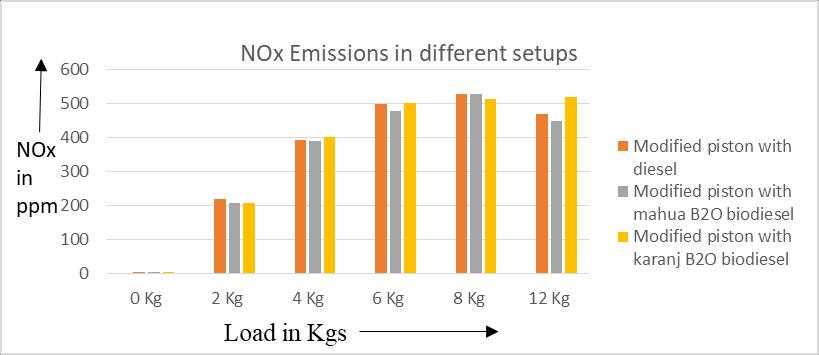

5.2.4 Load vs NOx emission

Chart -9:NOxEmissions

Inference: NOxemissionsarelesscomparedtoconvectiondieselengineatvariousloadsforMahua&KaranjBiodieselwith modifiedpistonbecauseofrichmixtureburning,lowercombustiontemperatureinsidethecylinderandlowerCalorificvalueof thebiodiesel.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

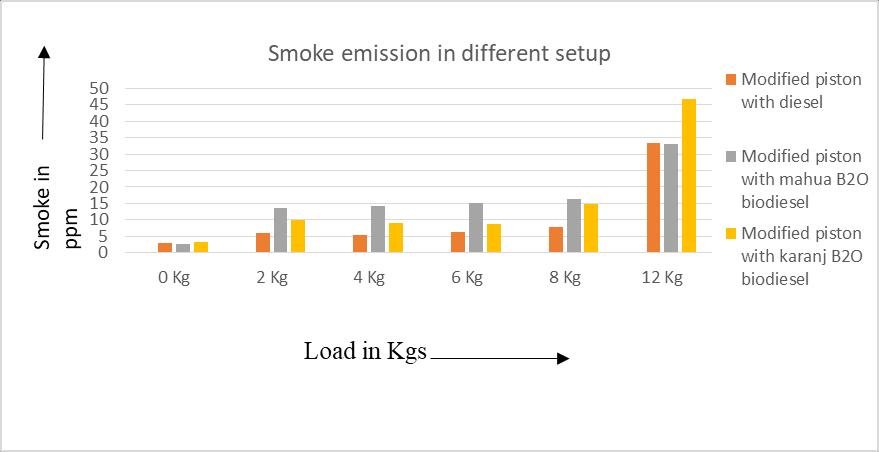

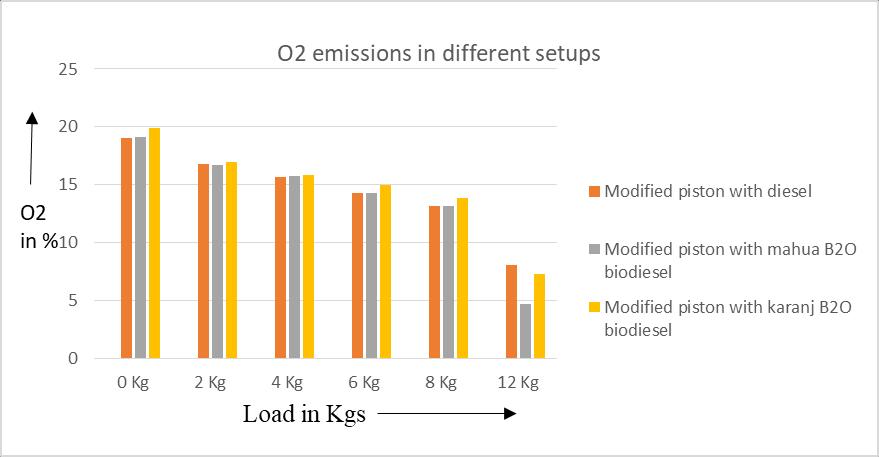

5.2.5

Inference: Withincreasingloadoxygenemissionisreducingindifferentsetupswhichresultsingoodcombustionoffuel.O2 emissionisalsonearlysamefordifferentsetupsandfuels.

Inference: Smokeemissionisthepartofcombustionprocess.Smokeisincreasingwithincreasingloadbecauseofrichair/fuel mixtureandalsoduetothebiodieselblend.

Theexperimentalresultsshowtheimprovementinemissionparametersofsinglecylinderfourstrokedieselengine withmodifiedpistonbyusingMahuaB20andKaranjaB20Biodiesel.

ThemodifiedpistonwithbiodieselhasgoodimpactonNOx&O2emission.

The modified piston with biodiesel has good impact on CO2, HC & CO Emissions at less loads compared with convectiondiesel

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Brake thermal efficiency, Indicated thermal efficiency and Specific fuel consumption of Biodiesel is nearly same comparedtoDiesel

Biofuelpercentageindieseltobevariedandchecked. Similarexperimentcanbeconductedbyusingdifferentnonediblebiofuels. CFDanalysiscanbedone. Swirlratiocanbecheckedbyswirltestrig. Geometrycanbevarieddependingupontherequiredparameters.

1. AlanC.Hansen,QinZhangandPeterW.L.Lyne,“Ethanol–dieselfuelblendsareview”, Bioresource Technology, Volume 96, Issue3,February2005,Pages277-285.

2. HanbeyHazar,“Effectsofbiodieselonalowheatlossdieselengine”, Renewable Energy 34 (2009)1533–1537.

3. NevenVoca,BorisVarga,TajanaKricka,DuskaCuric,VanjaJurisicandAnaMatin,“Progressinethanolproductionfromcorn kernelbyapplyingcookingpre-treatment” BioresourceTechnologyVolume100,Issue10,May2009,Pages2712-2718.

4. AvinashKumarAgarwal,“Biofuels(alcoholsandbiodiesel)applicationsasfuelsforinternalcombustionengines” Renewable Energy, 27November2006.

5. Hakan,Bayraktar “Experimentalandtheoreticalinvestigationofusinggasoline–ethanolblendsinspark-ignitionengines”, Renewable Energy,2005; Volume 30, Issue 11:pp1733-1747.

6. JasonJ, DanielMarc,RosenA,“Exergetic EnvironmentalAssessmentofLifeCycleEmissionsforvariousAutomobilesand Fuels,Energy 2(2002)283-294

7. Hwanam Kima, Byungchul Choi, “Effect of ethanol–diesel blend fuels on emission and particle size distribution in a common-raildirectinjectiondieselenginewithwarm-upcatalyticconverter”,Renewable Energy 33 (2008)2222–2228.

8. Baker,Q.A., “UseofAlcohol-in-Diesel Fuel EmulsionsandSolutionsina Medium-SpeedDiesel Engine”, SAE Paper No. 810254

9. InternalcombustionenginesbyVganesan4thedition.

10. InternalcombustionenginesfundamentalsbyJohnBHeywood.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |