REPLACEMENT OF

Ashish padha1 , Sourabh lalotra2

Abstract - Concreteisacompositematerialconsisting of cement,fineaggregate,andcoarseaggregate,anddemand foritisincreasingduetoconstructionpracticesata large scale.Asofnow,weareabletousewastematerialsuchasfly ashinthemanufacturingofcement,butfineaggregateand coarseaggregatearemadeavailablefromnaturalresources andaregettingdepleteddayafterday.So,theneedofanera istofindoutsomemorewastematerialthatcanbeusedin place of these materials or can be replaced in a suitable amount,leadingtothebio-conversionofwastematerialinto usableenergyandreducingtheenvironmentalpollution.So, thematerialusedforreplacementinthisresearchiswashed bottomashinplaceofsandandGroundnutshellashinplace of cement. The main objective of this research is to determine the workability, compressive strength, split tensilestrength,andflexurestrengthofconcreteprepared byusingwashedbottomashandGroundnutshellash.The test will be conducted to determine the compressive strength,splittensilestrength,andflexurestrength.Based on previous research, a comparison of strength and propertiesofconcretemadewithreplacementcomparedto the standard concrete is made. Cement is replaced by Groundnut shell ash by 0%,6%,12%,18%,24%,30%,36%, and natural sand is replaced by washed bottom ash by 0%,8%,16%,24%,32%,40%,48%Basedonthepropertiesof materials, the M35 grade of concrete mix is prepared. Differentspecimensofthematerialaretestedforstrength. Theresultshowsthatconcreteworkabilityisfineandwithin limitsafterreplacingcementwithGroundnutshellashand naturalsandbywashedbottomash.However,workability gets reduced at higher replacement of materials. The strengthparameterssuchascompressivestrength,flexural strength,andsplittensilestrengthalsoincreaseandshowan optimum value at 24% cement replacement and 32% replacement of natural sand by Groundnut shell ash and washed bottom ash, respectively. After this, there is a decreaseinthestrengthofconcrete.So,afterthisresearch work,wefindoutthatthereplacementcanbedonetosome extent.

Keywords: GSA (Groundnut shell ash), WBA (washed bottomash),workability,compressivestrength,SplitTensile strength,Flexuralstrength.

1. INTRODUCTION

Asthedemandforthesematerialsisescalatingdayafterday duetoever-goingconstructionalactivitiesworldwide,from small buildings to multi-storey buildings, utilization of naturalsandincreases,leadingtothecontinuousextraction ofnatural sandfromriver beds.Thisextractioniscausing severedamagetothenaturalresources,whichposeasevere threat and impact on the environment, such as loss of aquaticlife,losingwaterretainingsoilstratum,causingbank slides, loss of vegetation on the banks of rivers, and the society,etc.So,thedifferentstatesinIndiahaveimposeda baronthenaturalextractionofsandbecauseofitsadverse effects.Also,naturalsandisbecomingverycostlynowadays; in this situation, the need arises to find some readily available alternative that can also reduce the cost of construction.Variousmaterialsthathaveearlierbeenused to replace natural sand, such as fly-ash, quarry dust or limestone, filtered sand, and copper slag, are used in concreteaswellasformortarmixtures. Oneofthematerials whichcanalsobeeffectivelyusedasareplacementforsand inconcreteisWashedBottomAsh(WBA),andGroundnut shellashcanbeusedasareplacementforcementbecause thechemicalcompositionofGroundnutshellashandcement were found to be comparable which largely comprise of calciumcarbonate(90%).Bothofthesematerialsarewaste products, so they are cost-effective and efficient in waste management and do not pose any serious threat to the environment. Also, both of these materials are present in abundance in our country. Using these materials in the construction practices, the disposal problem of these materialscanbereducedtoalargeextent.Theotherfactor thatcontributestotheiruseintheconcreteistheirlowcost. So,usingwastematerialasanalternatematerialcanmake theprojecteconomical.

1.1 WASHED BOTTOM ASH (WBA)

The increasing oil and natural gas prices have made coal more economical, especially in a country with vast coal resourcessuchasIndia.Thehighdemandforcoalproduction duetoitsuseinelectricitygenerationhasresultedintheera ofenormousamountsofindustrialwastesuchasflyashand bottomash.Washedbottomashisnearly20%oftheresidual materialofcoalcombustioninapowerplant,boiler,furnace,

©

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page791

PG Scholar, Sri Sai College of Engineering and Technology, Pathankot, India 2 Assistant Professor, Sri Sai College of Engineering and Technology, Pathankot, India ***

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

or incinerator. The portion of the ash that escapes the chimneyisreferredtoasflyash(80%),andtheclinkersthat fall under their weight in the bottom hopper is termed as bottomash(20%)whichiscooledbywaterwashingandis termed as Washed Bottom Ash (WBA). Currently, India producesabout100milliontonnesofcoalashperyear,of which 15-20% is bottom ash. Fly ash is generally used in cement production, but bottom ash has not been used effectivelytilldateandcontinuestopollutetheenvironment indifferentways.Thismassiveamountofwastegenerated aftercoalcombustionhasbecomeaglobalissueofconcern for developing and developed countries. The disposal of bottom ash landfills has posed a severe environmental problem. The way to deal with this concern is to use the bottom ash effectively. In latest years the utilization of bottomashhasgainedsignificantattentionduetoitsusein engineering construction works as a replacement of fine aggregate.

2. LITERATURE REVIEW

Meghana. K et al. (2019): Inthisstudiesthepropertieslike compressive strength, flexural strength, tensile strength, shearstrength,andimpactstrengthbyvaryingtheratioof bottomashinreplacementofsandinconcretemixtureand the grade of concrete used is M30. The workability characteristicsoftheconcretewithvaryingratioofbottom ash werealsostudiedthroughslumpconetest,compaction factor test, Vee-Bee consist meter test.The bottom ash is addedinconcretetoreplacenaturalsandby0%,20%,40%, 60%,80%,and100%.Thesilicafumeby20%replacementis also added by weight of cement. The outcome of this experimentworkshowsthatthesandcanbereplacedwith bottomashupto40%,andthedesiredstrengthofconcrete canbeachieved.

1.2 GROUNDNUT SHELL ASH

The GSA waste is one of the major concerns of the agriculturalindustrywhichthecommonmethodofdisposal inNigeriaisbyburninginopenairwhichcausespollution and destroys the soil nutrients. The management of this abundantwasteinanenvironmentallysafewayischallenge thatmustbemet.Torecyclethewastematerialinceramic industry is an advantage of environmental protection and alsosavingtherawmaterials.Ceramicbodies,suchaswhite ware, are heterogeneous materials, consisting mainly of naturalrawmaterialswithwiderangeofcomposition.For this reason, such bodies could tolerate different types of alternative raw materials, even in high percentages. Utilization of these agro-wastes for formulation of white warebodywillbringaboutreductionintheuseofnatural rawmaterials,reducesproductioncost,energyconsumption aswellasservingasameansofsafedisposaloftheseagrowastes.

Vikas R Nadig et al. (2015): carriedoutinvestigationson the characteristics properties of concrete integrated with washed bottom ash as a partial replacement for fine aggregates.Themainfocusisonmechanical propertiesof concrete such as compressive strength, splitting tensile strength, flexure strength, etc. The outcome of this study showsthatreplacingsand with washed bottomashin the rangeof30to50%at90daysattainsahighercompressive strengthandflexuralstrengththanconventionalconcrete's strengthat28days.WaterabsorptionismoreinBottomash ConcreteascomparedtoconventionalConcrete.Thestudy also concluded that the strength of concrete made with bottom Ash replacement could be improved by adding suitablefibresandincorporatingothermaterials.

Buari T.A et. al. 2019 Thisstudyhighlightstheeffectsof incorporating waste glass(WG) and groundnut shell ash(GSA)on both fresh and hardened properties of selfconsolidating high performance concrete in sulphate and chloride environment. A total of 180 concrete cubes of 100mm x 100mm x 100mm were produced with waste glass(WG) as aggregate and OPC/GSA as binder, with percentagesubstitutionsvariedbetween0%-40%forboth materialsintheconcrete.Theconcreteweredesignedand examined for fresh properties and hardened specimens tested through crushing to obtain their compressive strengthsatage7,14,21,and28daysaftercuringinwateras

©

Certified Journal | Page792

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008

Fig-1WASHEDBOTTOMASH

Fig-2GROUNDNUTSHELLASH

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

controlandtwootherdifferentmedia(CaCl2andMgSO4at 5%concentration).

B.A. Alabadan et. al. 2006 In this paper entitled as “Pozzolanic materials have long demonstrated their effectiveness in producing high-performance concrete. Artificial pozzolanas such as rice husk ash have gained acceptanceassupplementarycementingmaterialsinmany parts of the world. This work evaluates the potentials of groundnut shell ash (GSA) as a partial replacement for ordinary Portland cement (OPC) in concrete. Chemical analysisoftheashwascarriedouttoascertainwhetherit possessespozzolanicorcementingpropertiesandthepartial replacementofOPCbyGSAwasvariedfrom0%to70%in theconcrete.Thecompressivestrengthsofthecontroland thoseofothercombinationsincreasedwithcuringagebut decreased with increased ash percentage. Though, the strengthofthecontrolwashigher,replacementofcement withashupto30%wouldbemoresuitablethanothers.

Akshay C. Sankh et al.(2014): The papers evaluate the differentalternativestobeusedinreplacementofnatural sandbecauseoftheexhaustionofnaturalsandduetoitsuse in concrete. One of the alternatives used which is used during research work is Washed Bottom Ash (WBA). It is found out that the properties of concrete with 30% replacementofnaturalsandbywashedbottomashisfound tobeanoptimumusageinconcreteandtogeta favorable strengthandbetterstrengthdevelopmentpatternoverthe incrementages.

3. MATERIAL

3.1 CEMENT Therearemanytypesofcementavailablein themarketaccordingtotheneedandstrengthdesired.The cement we will use in this research work is 43 Grade Ordinary Portland cement conforming to IS: 8112 with brand name Ambuja Cement and the physical properties relatedtocementisprovidedbytheconcernedlab.

3.2 FINE AGGREGATES Fineaggregateconsistsofcrushed sand particles or natural river sand passing through a 4.75mm sieve. In general, river sand is used as a fine aggregatehavingaparticlesizeof0.07mm.Theextractionis donefromrivers,lakesorseabeds.

3.3 COARSE AGGREGATE The particles retained on a 4.75mm sieve are termed coarse aggregate. For making a goodconcretemix,coarseaggregatedmustbehard,clean, andfreefromanychemicalcoatingofclayanddustonthe surface.Crushedstonemakesthemajorityoftheparticleof coarse aggregate. Coarse aggregates angular in shape are used in this research work that is obtained from the local crusher.Gradingofcoarseaggregatewasdoneaccordingto IS:383-1970.AggregatesofNominalsize20mm&10mmto form a graded aggregate. The concerned lab provided the propertiesofcoarseaggregate.

3.4

GROUNDNUT SHELL ASH

Table -1 Chemical composition of GSA

S.no Elemental Oxide GSA (% by mass)

1.

CalciumOxide(CaO) 14.3

2. SiliconDioxide(SiO2) 62.7

3. AluminumOxide(Al2O3) 12.42

4. MagnesiumOxide(MgO) 2.0

5. FerricOxide(Fe2O3) 14.0

6. PotassiumOxide(K2O) 15.46

7. Manganesedioxide (MnO2) 2.0

3.5

WASHED BOTTOM ASH

Table2 - Chemical composition of WBA Chemical Composition (%)

Bottom Ash

SiO2 68 Al2O3 25 Fe2O3 2.18 CaO 1.66 TiO2 1.45 MgO 0.02 SO3 Nil

LossonIgnition 1.69

4. METHODOLOGY

4.1 MIXING CONCRETE

Thorough mixing of the materials is essential to produce uniform concrete. The mixing should make sure that the mass become homogeneous, uniform in consistency and colour.Therearetwomethodsadoptingformixingconcrete oneishandmixingandotherismachinemixing.

4.2 CURING

Beforeremovingthemould,itisdriedfor24hours,andthen specimens are placed in a water tank made to cure specimens.Thespecimensmustbemarkedforidentification so that there must not be any error. The specimens are removed from the tank and dried before putting in the testing machine. The specimens are kept in the tank for 3,7,28days.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

©

Page793

|

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

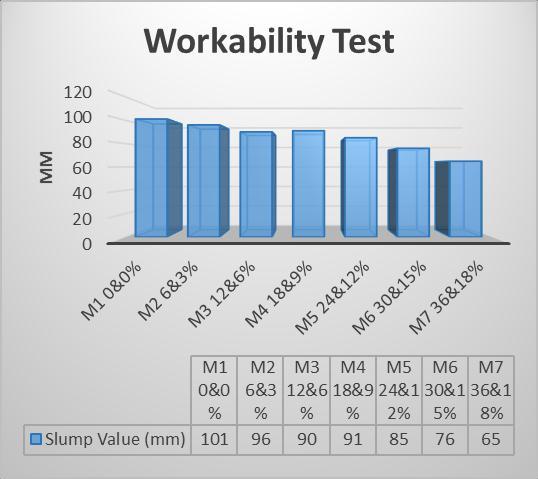

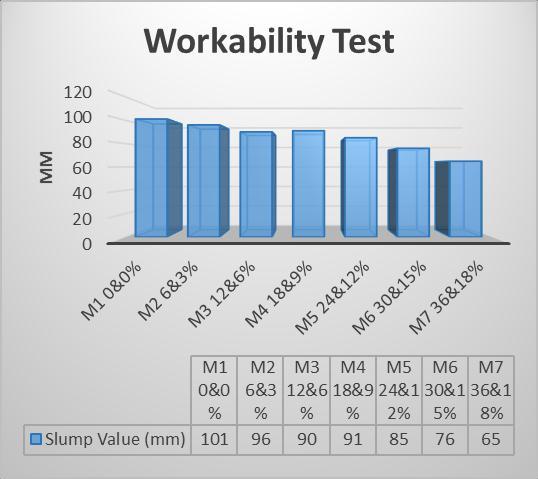

4.3 WORKABILITY TEST

It can be used in site as well as in lab. This test is not applicableforverylowandveryhighworkabilityconcrete.It consistsofamouldthatisintheformoffrustumhavingtop diameterof10cm,bottomdiameterof20cmandheightof 30cm.Theconcretetobetestediffittedinthemouldinfour layers. The each is compacted 25 times with the help of tampingrod.Afterthemouldiscompletelyfilleditislifted immediatelyintheverticallyupwarddirectionwhichcauses theconcretetosubside.

Fig-3:SLUMPCONETEST

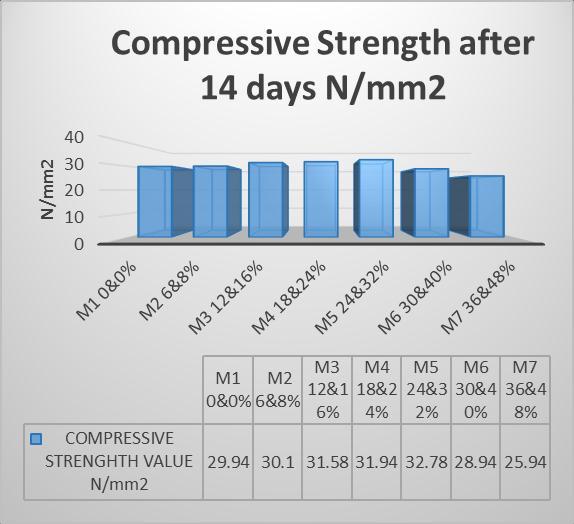

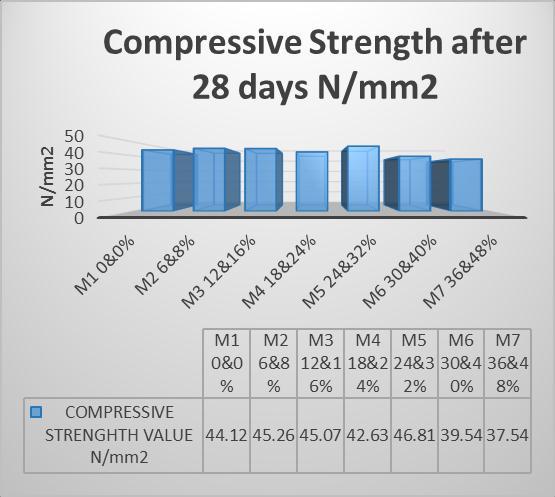

4.4 COMPRESSIVE STRENGTH TEST

Thenfreshconcreteisfilledinmouldin4layersandafter fillingeachlayertampingshouldbedone35timesincaseof cube and 25 times in case of cylinder by using standard tamping rod. Once the mould is filled then leveled top surfaceofconcretewithtrowel.Afterthedaythemouldwill removedandspecimenaredroppedinthecuringtankunder standard temperature of 27±2° c. After 7,14 days and 28 daysinthisresearch.

© 2022, IRJET |

|

Certified Journal | Page794

Impact Factor value: 7.529

ISO 9001:2008

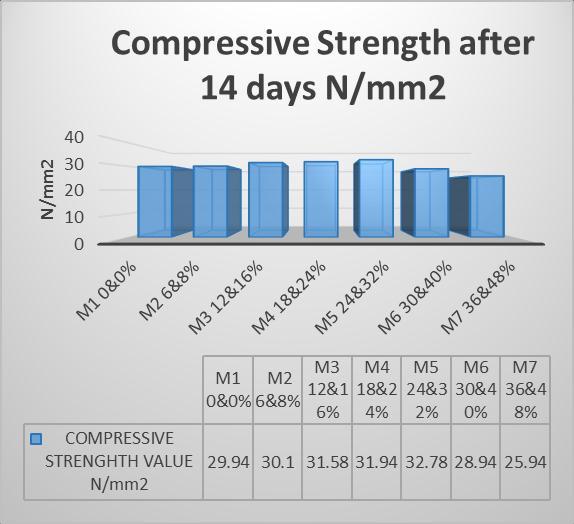

0 5 10 15 20 25 30 N/mm2 M1 0&0 % M2 6&8 % M3 12& 16% M4 18& 24% M5 24& 32% M6 30& 40% M7 36& 48% COMPRESSIVE STRENGHTH VALUE N/mm2 25.5526.7227.0727.7828.4222.1119.11 CompressiveStrength after 7 days N/mm2 Fig-4: COMPRESSIVESTRENGTHTEST7 Fig-5: COMPRESSIVESTRENGTHTEST14

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

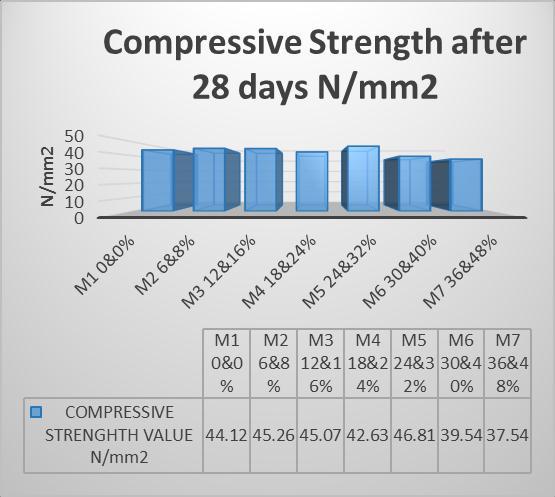

Fig-6: COMPRESSIVESTRENGTHTEST28

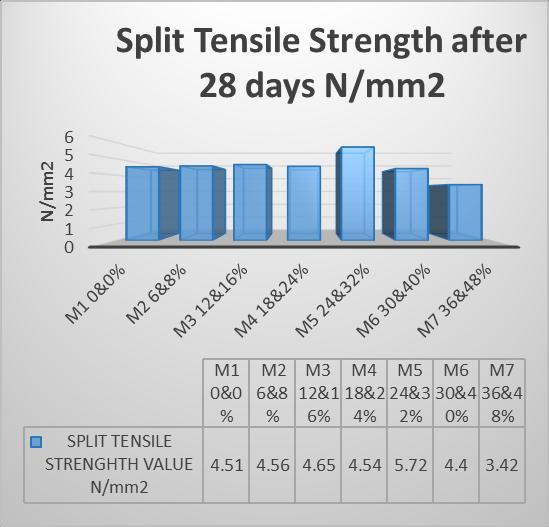

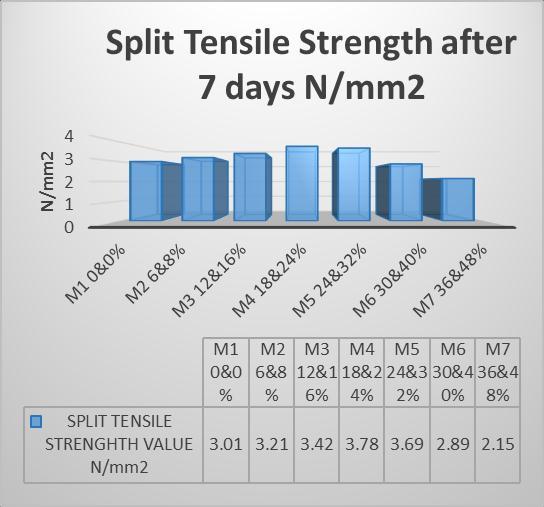

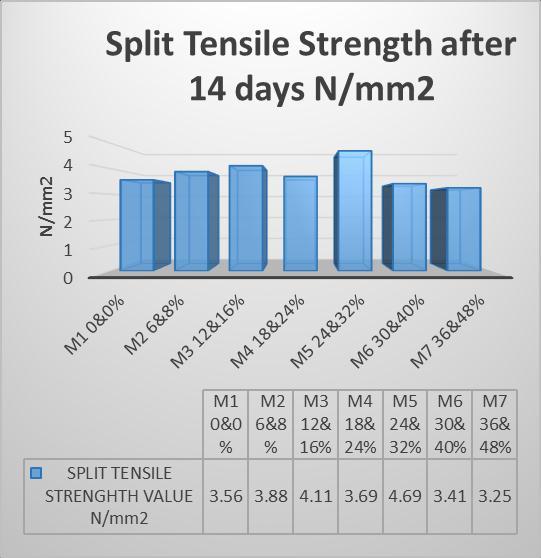

4.5 SPLIT TENSILE STRENGTH TEST

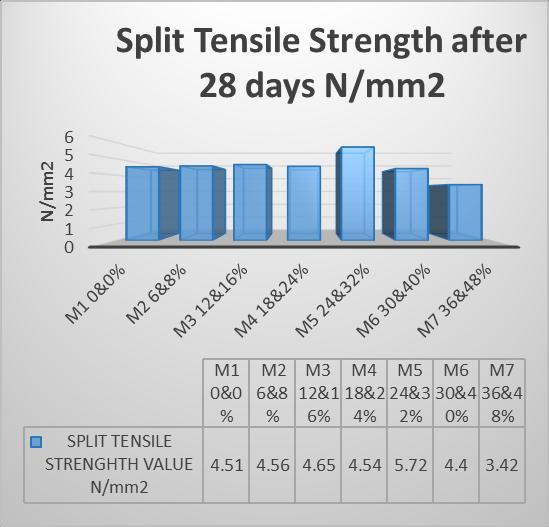

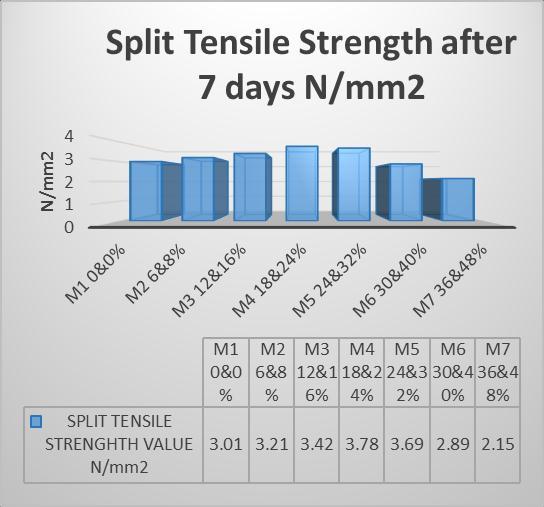

The specimen used for this test is cylindrical and its dimensionis150mmindiameterand300mminlength.The instrumentusedforthistestingisuniversaltestingmachine. Thefreshconcreteispreparedinaccordingtotherequired gradesandrespectivemixproportion.Thefreshconcreteis filled in mould in layers and each layer is tamping with standardtampingrodwith25blowsforeachlayer.Afterthe day the mould is removed and specimen is placed in the curingtankfor7,14daysand28daysinthisresearchatthe temperature27+2°c.Thendrawthelineonthespecimen.

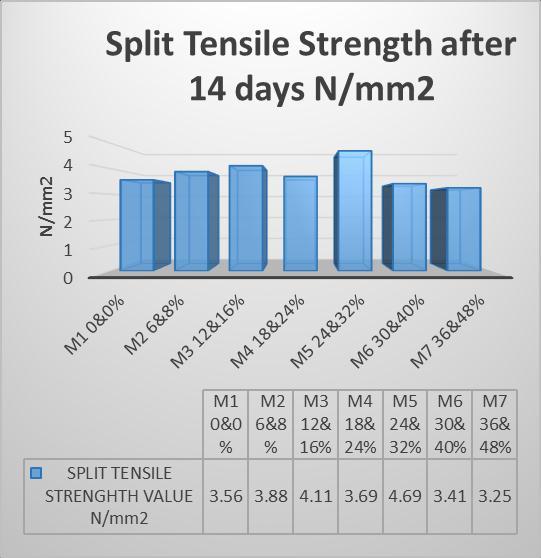

Fig-8: SPLITTENSILESTRENGTHTEST14

Fig-9: SPLITTENSILESTRENGTHTEST28

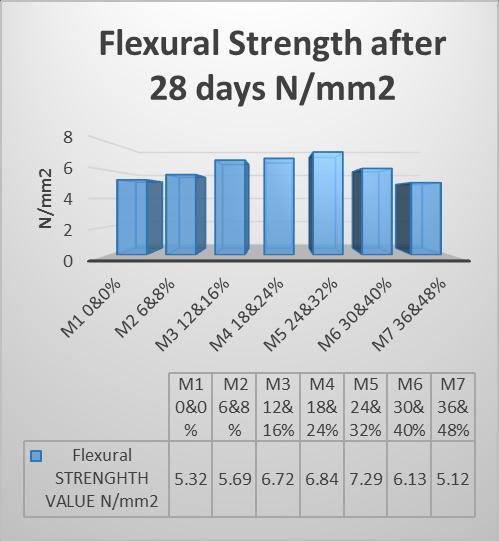

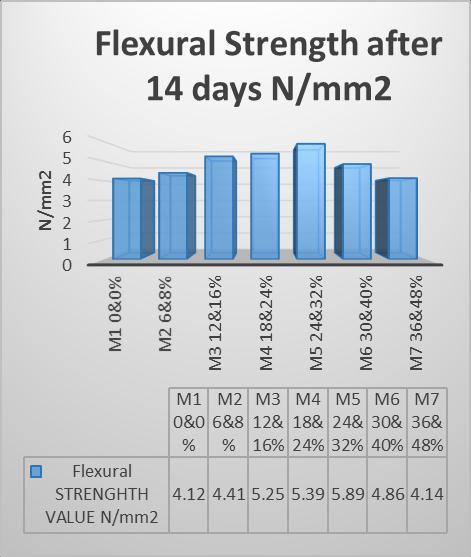

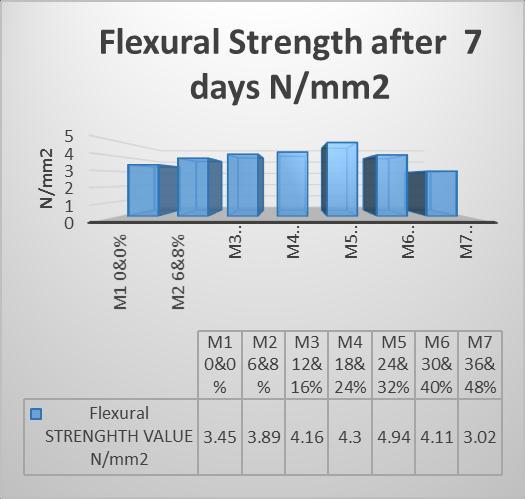

4.6 FLEXURAL STRENGTH TEST

Theconcreteispreparedatrequiredrateofmasselement the mould is filled with concrete in layers and blows 25 timeswithstandardtampingrod.Afterthedayorwecansay 24hoursthemouldisremovedandspecimenplacedinthe water tank for curing at a temperature of 27 + 2 C.

Fig-7: SPLITTENSILESTRENGTHTEST7

©

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page795

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Depending upon the requirement the test specimen is removedfromthewatertankandwipeitproperlyfor3,14 and28daysfortesting.

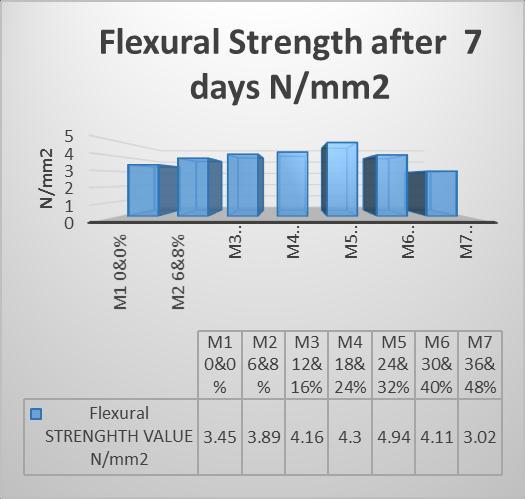

Fig-10: FLEXURALSTRENGTHTEST7

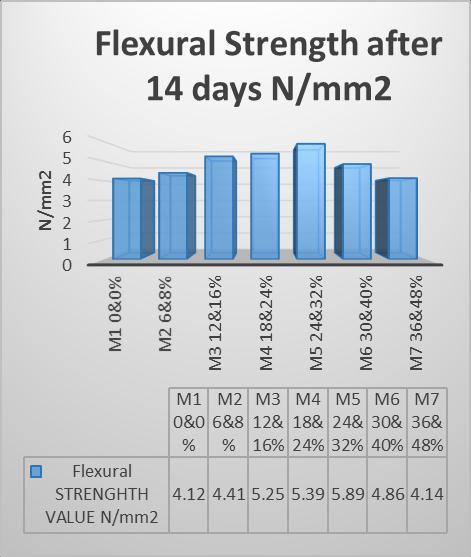

Fig-11: FLEXURALSTRENGTHTEST14

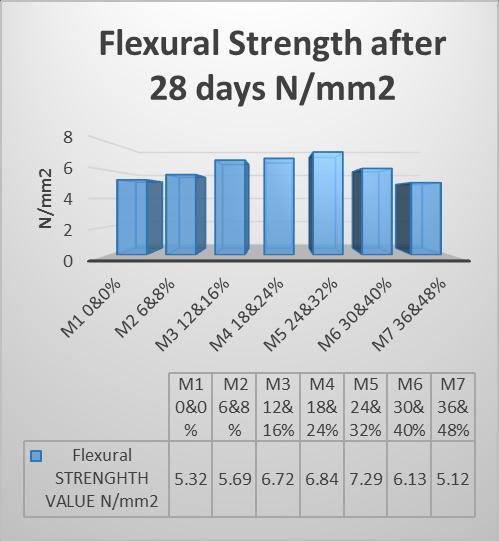

Fig-12: FLEXURALSTRENGTHTEST28

5. CONCLUSION

•Byusingtheseeasilyavailableleftoversandagricultural wastematerialsinconstruction,wecangreatlydecreasethe cost of construction up to a certain level and also not compromisingmuchonthequalitywhilealsoovercoming theenvironmentalhazards.

•Ingeneral,itwasalsoobservedintheexperimentthatthe workabilityofconcretedecreaseswiththeincreaseinthe percentageofGroundnutshellashandwashedbottomash theconcretewaslessworkable.

•AlltheconcretemixcontainingGroundnutshellashand washedbottomashshowsenoughworkabilitytobeeasily compactedandfinished.Itmustbenotedthatthematerial used as a replacement must be adequately grounded. Otherwise, the water absorption will increase, which will reducetheworkabilityoftheconcretemix.

•Thecompressivestrengthresultsshowthataswereplace cement with Groundnut shell ash and sand with washed bottomash,thereisanincreaseinthecompressivestrength, but at higher replacements, there is a decline in the compressivestrengthofconcrete.

• The max compressive strength is achieved by replacing cement with 24% Groundnut shell ash, and sand by 32% washedbottomashon28thdayas46.81Mpacomparedto 44.12Mpaasofstandardconcrete.

©

Page796

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

•Thesplittensilestrengthisoptimumat24%replacement by Groundnut shell ash and 32% replacement by washed bottomash.Afterafurtherincreaseinreplacement,itkeeps on decreasing. 28th day split tensile strength at this replacement is 5.72 Mpa compared to 4.51 Mpa as of standardconcrete.

•Theflexurestrengthisoptimumat12%replacementby Groundnut shell ash and 30% replacement by washed bottomash.Afterafurtherincreaseinreplacement,itkeeps ondecreasing.28daysflexuralstrengthatthisreplacement is7.29Mpacomparedto5.32Mpaasofstandardconcrete.

•Hencefromthisresearchwork,itcanbeconcludedthat theoptimumvalueofstrengthfordifferenttestsperformed on concrete observed at 24% replacement of cement by Groundnut shell ash and 32% replacement of sand by washedbottomash.

• Using washed bottom ash as an alternate material for naturalsandwillreducetheminingproblemanddepletion of natural resources. If using an alternative material as a replacement for cement, Groundnut shell ash powder will result in a decline in environmental pollution, and the problemoflandfilldumpingcanberesolvedtosomeextent.

6. REFERENCES

1.Meghana. K et al., Research conducted for studying the effect of replacement of sand by bottom ash and cement replacementbysilicafumeonthecharacteristicproperties of concrete, International Journal of Engineering and Technology,Volume6Issue1,Jan2019.

2.Mohamed Ansari et al., Study on replacement of cement using Groundnut shell ashpowder, SSRG International JournalofCivilEngineering,Volume3,Issue3,March2016.

3 VikasNadigR,SanjithJ,RanjithAandKiranBM,Studyof BottomAshasPartialReplacementinConcrete,IOSRJournal of Mechanical and Civil Engineering, Volume 12, Issue2, March-April2015.

4.Dilip Kumar et al., Research on use of bottom ash in the replacement of fine aggregate for making concrete, International Journal of Current Engineering and Technology,Volume4,Dec2014.

5 IS:383-1970,IndianStandardSpecificationforCoarseand FineAggregatefromNaturalSourcesforConcrete.

6IS:10262-2009,IndianStandardRecommendedGuidelines forConcreteMixDesign.

7 IS:2386-1963,MethodofTestsofAggregatesforConcrete.

8.IS:516-1999,MethodsofTestsforStrengthofConcrete.

9.TextBook:M.S.Shetty,ConcreteTechnologyTheoryand Practice,S.ChandandCompanyLtd.Publication.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

©

Page797