International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

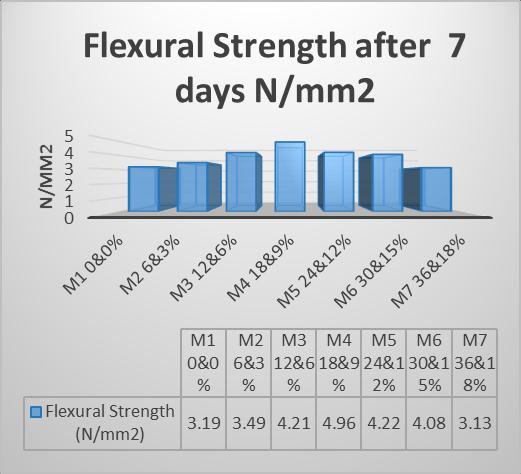

Abstract - The growth in population has placed an enormous need for more and more infrastructure and it keepsgrowing.Theoutcomeofthisdemandistheincrease inproductionofcement.Massiveamountofwastematerials andby-productsareproducedbymanufacturingenterprises suchassilicafumes,ricehuskash,andmineralslagandso on. As a result, waste management has become a huge problem for our environment. The wastes that are of economicimportancearebagasse,molasses,andfilterpress mud. Bagasse is the fibrous residue remaining after the extraction of the cane juice from sugarcane. Sugarcane bagasseconsistsofapproximately50%ofcellulose,25%of hemicellulose, and 25% of lignin. In a lot of sugarcane industries, the bagasse generated is usually used as fuel while also reducing its volume for disposal. One of the residuesfromacigarettefactoryistheTobaccostem,andit is easy to collect as its production is concentrated in cigarette factories. This has led to a serious waste of resourcesandenvironmentalproblemsasmorethan95% of the tobacco stems end up in landfills or incineration. Tobacco waste ash (TWA) is produced by burning these unwantedtobaccostems.Theresearchworkheredealswith the partial replacement of cement by mass with SBA and TWAincombinationinpercentagesof6%,12%,18%,24%, 30%,and36%.ThepercentagereplacementsforRHAand TWAare3%,6%,9%,12%,15%and18%respectively.After mixing,castingandcuringthecharacteristicstrengthofthis newconcretearecomparedwithconventionalconcreteof M40grade.Theexperimentalinvestigationsarecarriedout forcompressivestrength,splittensilestrengthandflexural strength for curing period of 7, 14 and 28 days. The experimental results show that the for a combined replacementpercentage of 27%,which includes 18%SBA and9%TWA,thevaluesofcompressivestrength,flexural strength and split tensile strength were higher when comparedtootherreplacementpercentages.

Keywords: SBA (sugarcanebagasseash),TWA(Tobacco waste ash), Compressive strength, Flexural strength and Splittensilestrength.

Concreteisthemostversatilebuildingmaterialcomposedof coarseaggregate,sand,cement,andwater.Themixtureofall

theingredientsofconcretearemixedinaratiowhichthen can be poured into any shape and size of mould that on hardeningproducesamasslikesolidstonesolid,furtherthe strengthofhardenedsolidmasscanbeincreasedbyadding admixtures The mineral admixtures which are used to partially replace cement can be natural or artificial dependingontheuseoftheconcrete.Theadmixtureswhich areusedcanbeindustrialwastesorby-productswhichcan lead the industry to be eco friendlier and sustainable. For decades industrial by-products and wastes, such as, silica fume,flyashandgroundgranulatedblastfurnaceslaghave been successfully used as mineral admixture in concrete technology. The performance of the addition of mineral additivescanbedividedinphysicalandchemicalparts.In orderunderstandthephysicalpartofthisbehaviouronehas to only look at the shrinking of size of the voids in the interferencebetweencementandtheaggregate.Chemical compositionofthemineraladmixtureinordertobeusedin cement and concrete should constitute of these main compoundsSiO2,Al2O3andFe2O3ingreaterpercentage. The action of these additives depends on the presence of minerals and oxides in weakly crystalline or amorphous state.

Sugarcanebagasseashisasolidwastegenerated fromthe sugarmanufacturingindustry.Indiaproduced342.56million tonnesofsugarcaneintheyear2011-12,makingitoneofthe world’s biggest cane producers. The sugar manufacturing processgeneratessugarcanetrash,bagasse,bagasseflyash, pressmud,andspentwash[14,26,27].Thewastesthatare of economic importance are bagasse, molasses, and filter pressmud.Bagasseisthefibrousresidueremainingafterthe extraction of the cane juice from sugarcane. Sugarcane bagasseconsistsofapproximately50%ofcellulose,25%of hemicellulose, and 25% of lignin. In a lot of sugarcane industries,thebagassegeneratedisusuallyusedasfuelwhile also reducing its volume for disposal. This residual ash generatedfromburningorincinerationiscalledbagasseash inclusive of both bottom and fly ashes. In most modern plants,thebottomashgetsmixedwithflyashinthewater channel that comes from the gas washer. This waste is typicallydisposedofintopitsandisalsoappliedonlandas soilamendmentinsomeareas.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

OneoftheresiduesfromacigarettefactoryistheTobacco stem, and it is easy to collect as its production is concentratedincigarettefactories.Thishasledtoaserious waste of resources and environmental problems as more than 95 % of the tobacco stems end up in landfills or incineration.Thusthereisaneedtodisposethisresidueina waywhichisenvironmentalfriendly.Tobaccowasteashis produced by burning these unwanted tobacco stems. Tobacco waste ash displays properties such as fineness, amorphousformandhighsilicacontentandthusneedstobe investigated with its potential to show high pozzolanic activity. The ashes are not pozzolanic material, they have pozzolanic activity, but this activity is less than that in pozzolanic material. The ashes exhibit the “filler effect”, whichiscomposedoftwophenomena,thenucleationand packingeffectsthatprimarilydependonthefinenessofthe materials. The nucleation effect occurs when the small particlesarespreadinblendedcementpaste,leadingtoan enhancedhydrationreaction,whilethepackingeffectoccurs when the voids in pastes are filled with fine particles. Tobacco waste ash is not a pozzolanic material but it has beenknowntodisplaysomepozzolanicactivities.

tensile.Theresultsofthesetestshowedthathecompressive andsplittensiletestsvaluesofthespecimensincreasesby addingat10%ofWasteglasspowderand10%oftobacco wasteash,whereasflexuralstrengthtestvaluesincreasesat the 12.5% of waste glass powder and 12.5 % of tobacco wasteash.Theauthorfinallyconcludedthatthepresenceof silicafromtheglasswastepowderincreasedthestrengthof concreteitfurthermadetheconcretemoredurableandalso increaseditstoughness.Theuseoftobaccowasteashmade the concrete more workable thus reducing the amount of waterrequired.

(S.celikten, M. Canbaz 2017) Inapaperentitled“AStudy ontheUsageofTobaccoWasteAshasaMineralAdmixture in Concrete Technology” studied the effects of partial replacementofcementwithtobaccowasteash.Thetobacco wasteashwastaken from two sources and the tests werecarriedoutoneachofthespecimenofthetwotobacco waste ash. The partial replacement was done in the percentageof10,15and20byweight.Themortarsamples were then tested. The tests that were done included compressive strength and flexural strength test. From the resultsofthesetestsunitweight,ultrasoundpulsevelocity, dynamicmodulusofelasticvaluesofthemortarspecimen wascalculated.Therewasseenadecreaseinthevaluesof these results as the percentage of tobacco waste ash was increased.Oncomparingthevaluesofthespecimenwiththe controlspecimentherewasadecreaseinbothcompressive and flexural strength, though in the case of compressive strengththedecreasewasmore.Thustheauthorcametothe conclusionthatwiththepartialreplacementof10percent cement with tobacco waste ash there are ecological and economicbenefits.

(Naveen Kumar A, Vivekananthan, Chithra 2019) In a paperentitled“StudytheEffectsofTobaccoWasteAshand WasteGlassPowderasapartialreplacementofcementon StrengthCharacteristicsofConcrete”partialreplacementof cementwithtobaccowasteashandwasteglasspowderwas done.Thereplacementwithtobaccowasteashwasdonein thepercentageof5,7.5,10and12.5whilethereplacement withwasteglasspowderwasdoneinthepercentageof5,10, 15 and 20. The tests which were done on the specimen included compressive strength, flexural strength and split

(Rafael Fragozo, Sergio Vesga 2018) Ina paperentitled “Tobacco waste ash: a promising supplementary cementitiousmaterial”studiedtheuseoftobaccowasteash as a cementitious material. The experiment were done at variouspercentageofreplacementandattheendofwhich the author came to the conclusion that the compressive strengthofthespecimenincreasedwhentherewasapartial replacement of cement at 10 percent. The experiments achieved a compressive strength more than 51 percent of the control specimen. The author states that this improvement in compressive strength is due to the “filler effect”andthepozzolanicactivityoccasionedby10percent replacementofcement.

Jayminkumar A. Patel1, Dr. D. B. Raijiwala 2015 Therein this analysis the ecological and environmental effect of cementisconsideredasofmuchconcernasitgeneratesalot ofcarbondioxidealsoontheotherhandsugarcanebaggase ashisseriousissueoflandfills.InthisstudySCBAisusedin M25grade ofconcrete byreplacingcement5% byweight andcomparewithnormalM25gradeofconcretetosquared thepossibilityofSCBAinconcrete.Thisanalysisrevealsthat SCBAcanbeusedaspartialreplacementofcement”.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

R.Srinivasan 2010 “In this paper, Bagasse ash has been partiallyreplacedintheratioof0%,5%,15%and25%by weight of cement in concrete. Fresh concrete tests slump conetestweredonealsotestonthehardenedstateconcrete likecompressivestrength,flexuralstrengthandmodulusof elasticity split tensile strength at 7 and 28 days was obtained. There was an increase in the strength of the concreterevealsthestudy.

Sumrerng Rukzon(2011) Thiscementisconsideredasof muchconcernsitgeneratesalotofcarbondioxidealsoon the other hand sugarcane bagasse ash is serious issue of landfills. It suggest SCBA as a pozzolanic material for generating high strength cement concrete. Cement is partiallyreplacedwithSCBAinpercentages10%,20%and 30% of BA respectively. The study reveals the addition of SCBAupto30%replacementcanincreasestheresistanceto chloride penetration.Also theuse of 10%ofBAproduced concretewithgoodstrengthandlowporosity.Forproducing highstrengthconcreteSCBAcanbeusedupto30%.

In this research work the cement that was used was the ordinaryPortlandcementof43grade.Thecementusedin thisresearchwaspurchasedfromalocalcementstoreand the cement was Khyber cement, which is being manufacturedbyKhyberCementPrivateLimited.

The fine aggregate which was used in this research was purchasedfromJammuandKashmir.Fineaggregatearethe fillersoftheconcrete,theseoccupymostofthevolumeina concrete mix formulae. The composition, shape, size and other properties of fine aggregate influence the concrete. The properties of concrete which are influenced by fine aggregate are the shrinkage, elastic modulus, abrasion resistance as well as mixing proportions and hardening properties.Fineaggregatearedividedintozoneswhichare zone1,zone2,zone3andzone4asperIS:383-1970.

The coarse aggregate which is used in this research was purchasedfromgrindingmil.Thesearetheaggregateswhich areretainedona sieve ofsize4.75mm.The propertiesof coarseaggregatesuchasshape,size,waterabsorptionand strengthinfluencethepropertiesofconcrete.Thegreaterthe size of the coarse aggregate less is the demand of water. Round aggregate are more economical to use but angular coarse aggregate are desired in case of high strength concrete.Thuscoarseaggregateareimportantforincreasing thestrengthanddurability ofconcrete. Theaggregate are categorized on size rather than chemical and mechanical

properties.Thesetestswerecarriedoutoncoarseaggregate tocheckthequalityofcoarseaggregateused.

3.4 Sugarcane bagasse ash

Table -1 Chemical composition of SBA

Sio2 71.0 81.42

Al2O3 1.9 10.41

Fe2O3 7.8 1.54 CaO 3.4 3.35

MgO 0.3 0.76 NA2 3.4 1.36 K2O 8.2 1.31

Table -2 Chemical composition of TWA

SiliconDioxide(SiO2) 25.67

AluminumOxide(Al2O3) 0.16

FerricOxide(Fe2O3) 0.31 SodiumOxide(Na2O) 0.49 CalciumOxide(CaO) 25.54

MagnesiumOxide(MgO) 4.6

SulphurTrioxide(SO3) 7.04 PotassiumOxide(K2O) 17.84

Alltheingredientsofconcretearemixedtogetherhowever this mix should be homogenous and uniform in color and consistency.Themixingcaneitherbedonebyhandorwith theuseofmixer.

Thorough mixing of the materials is essential to produce uniform concrete. The mixing should make sure that the mass become homogeneous, uniform in consistency and colour.Therearetwomethodsadoptingformixingconcrete oneishandmixingandotherismachinemixing.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Beforeremovingthemould,itisdriedfor24hours,andthen specimens are placed in a water tank made to cure specimens.Thespecimensmustbemarkedforidentification so that there must not be any error. The specimens are removed from the tank and dried before putting in the testing machine. The specimens are kept in the tank for 3,7,28days.

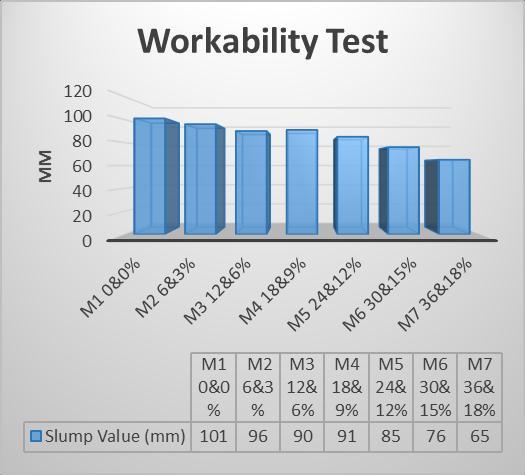

It can be used in site as well as in lab. This test is not applicableforverylowandveryhighworkabilityconcrete.It consistsofamouldthatisintheformoffrustumhavingtop diameterof10cm,bottomdiameterof20cmandheightof 30cm.Theconcretetobetestediffittedinthemouldinfour layers. The each is compacted 25 times with the help of tampingrod.Afterthemouldiscompletelyfilleditislifted immediatelyintheverticallyupwarddirectionwhichcauses theconcretetosubside.

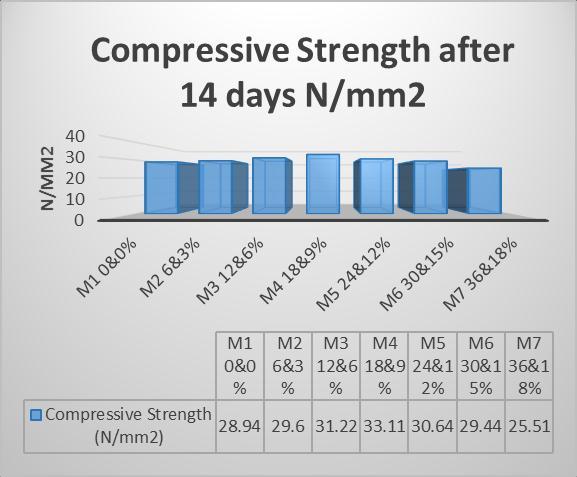

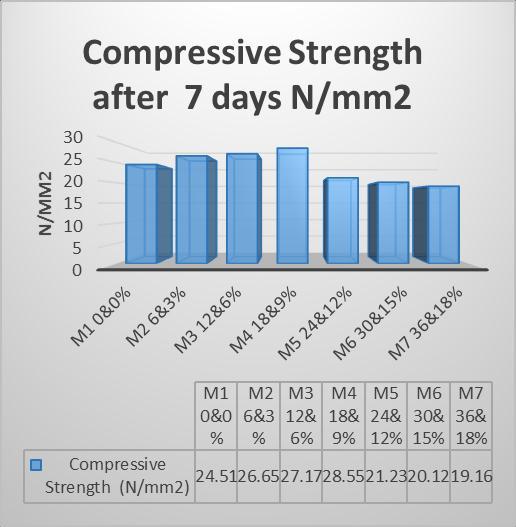

Fig -4: COMPRESSIVESTRENGTHTEST7

Thenfreshconcreteisfilledinmouldin4layersandafter fillingeachlayertampingshouldbedone35timesincaseof cube and 25 times in case of cylinder by using standard tamping rod. Once the mould is filled then leveled top surfaceofconcretewithtrowel.Afterthedaythemouldwill removedandspecimenaredroppedinthecuringtankunder standard temperature of 27±2° c. After 7,14 days and 28 daysinthisresearch.

Fig -5: COMPRESSIVESTRENGTHTEST14

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

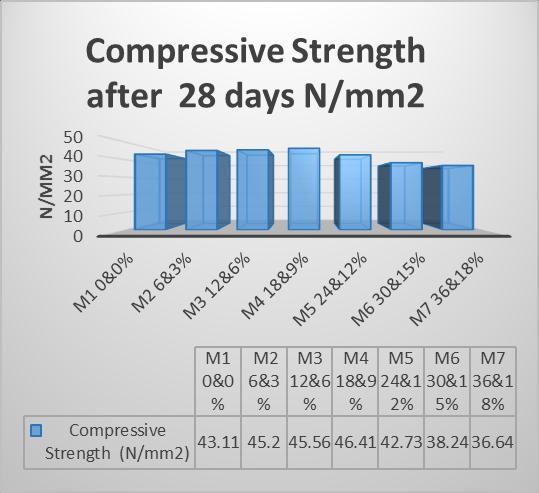

Fig -6: COMPRESSIVESTRENGTHTEST28

The specimen used for this test is cylindrical and its dimensionis150mmindiameterand300mminlength.The instrumentusedforthistestingisuniversaltestingmachine. Thefreshconcreteispreparedinaccordingtotherequired gradesandrespectivemixproportion.Thefreshconcreteis filled in mould in layers and each layer is tamping with standardtampingrodwith25blowsforeachlayer.Afterthe day the mould is removed and specimen is placed in the curingtankfor7,14daysand28daysinthisresearchatthe temperature27+2°c.Thendrawthelineonthespecimen.

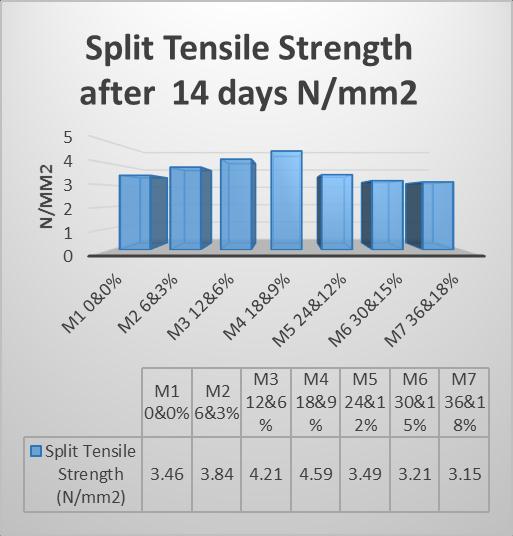

Fig -8: SPLITTENSILESTRENGTHTEST14

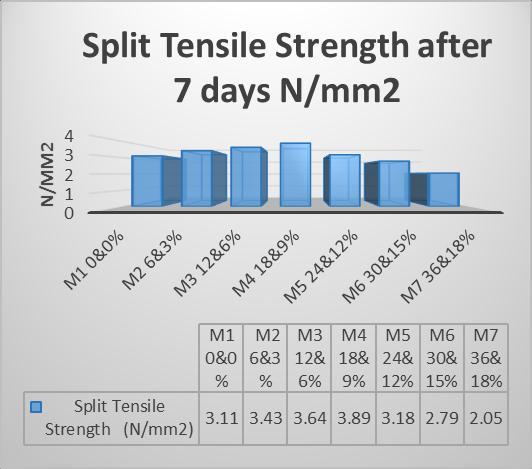

Fig -7: SPLITTENSILESTRENGTHTEST7

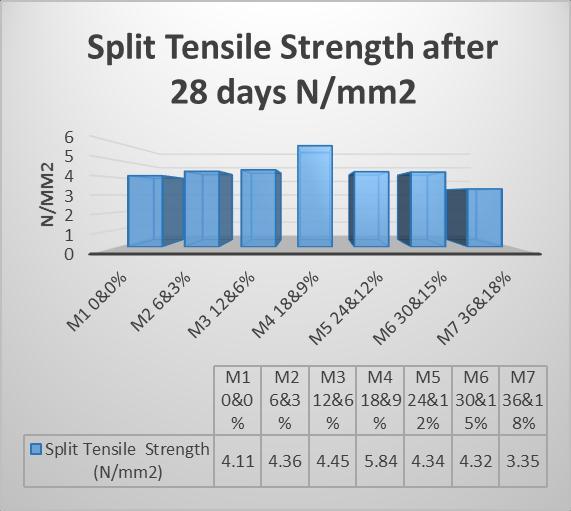

Fig -9: SPLITTENSILESTRENGTHTEST28

Theconcreteispreparedatrequiredrateofmasselement the mould is filled with concrete in layers and blows 25 timeswithstandardtampingrod.Afterthedayorwecansay 24hoursthemouldisremovedandspecimenplacedinthe water tank for curing at a temperature of 27 + 2 C. Depending upon the requirement the test specimen is

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Fig -12: FLEXURALSTRENGTHTEST28

•The use of Tobacco waste ash and bagasse ashas partial replacement of cement should be taken up for acceptable andenvironmentalfriendlyconstruction.

•By using these easily available and agricultural waste materialsinconstruction,wecaneasilydecreasethecostof construction up to a certain level and overcome the environmentalhazards.

•This investigation has also demonstrated that the use of Tobaccowasteashandbagasseashbycertainpercentage can produce positive results when partially replaced by cement.Thuscanbeusedinconstructionpurpose.

•The max compressive strength is achieved by replacing cement with 18% replacement of bagasse ash and 9% replacementofTobaccowashashwithcementon28thday as 46.43 Mpa compared to 43.11 Mpa as of standard concrete

•Thesplittensilestrengthisoptimumat18%replacementof bagasseashand9%replacementofTobaccowashashwith cement.Afterafurtherincreaseinreplacement,itkeepson decreasing. 28th day split tensile strength at this replacement is 5.84 Mpa compared to 4.11 Mpa as of standardconcrete.

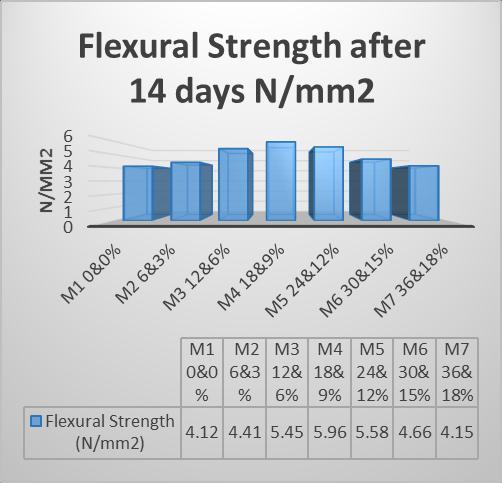

• The flexure strength is optimum at 18% replacement of bagasseashand9%replacementofTobaccowashashwith cement.Afterafurtherincreaseinreplacement,itkeepson decreasing.28daysflexuralstrengthatthisreplacementis 7.39Mpacomparedto5.32Mpaasofstandardconcrete.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

•Hencefromthisresearchwork,itcanbeconcludedthatthe optimumvalueofstrengthfordifferenttestsperformedon concreteobservedat18%replacementofbagasseashand 9%replacementofTobaccowashashwithcement.

1. Payá, J., Monzó, J., Borrachero, M. V., Díaz-Pinzón, L., andOrdónez, L. M. (2002).“Sugarcanebagasseash(SCBA): Studiesonitspropertiesforreusinginconcreteproduction.” J.Chem.Technol.Biotechnol.,77(3),321–325.

2.Cordeiro, G. C. (2004). “Influenceofmechanicalgrinding onthepozzolanicactivityofresidualsugarcanebagasseash.” Proc.,Int.RILEMConf.ontheUseofRecycledMaterialsin BuildingStructures,E.Vázquez,C.F.Hendricks,andG.M.T. Janssen,eds.,18.

3.Naveen Kumar A, Vivekananthan V, Chithra P “Study theEffectsofTobaccoWasteAshandWasteGlassPowderas apartialreplacementofcementonStrengthCharacteristics of Concrete” International Journal of Multidisciplinary ResearchTransactions,2019.

4.Çelikten, Serhat & Canbaz, Mehmet “A Study on the Usage of Tobacco Waste Ash as a Mineral Admixture in Concrete Technology”, International Conference on Engineering Technologies (ICENTE'17), at konya, turkey 2017

5.Moreno, P., Fragozo, R., Vesga, S. et al. “Tobaccowaste ash: a promising supplementary cementitious material”, International Journal of Energy and Environmental Engineering,9,pages499–504,2018

6.T.Öztürk and M. Bayrak “The Possibilities of Using Tobacco Wastes in Producing Lightweight Concrete”. AgriculturalEngineeringInternational:theCIGREjournal. Vol.VII.ManuscriptBC05006.August,2005.

7.Mohamed Ansari et al., Studyonreplacementofcement using Bagasse powder, SSRG International Journal of Civil Engineering,Volume3,Issue3,March2016.[11]Ramasamy, V.“CompressivestrengthanddurabilitypropertiesofRice HuskAshconcrete“KSCEJournalofCivilEngineering16(1), January2011,

8.Ali, K., Amin, N., and Shah, M. T. (2009). “Physicochemicalstudyofbagasseandbagasseashfromthe sugar industries of NWFP Pakistan and its recycling in cementmanufacturing.”J.Chem.Soc.Pak.,31(3),375–378.

9.AtextbookonConcreteTechnologyTheoryandPracticeby M.S.Shetty.

10.A textbook on Materials Science and Engineering by WilliamCallister.

11.IS2386-(PartI):1963MethodsofTestforAggregatesfor Concrete.

12.IS2386–(PartII):1963MethodsofTestforAggregates forConcrete.

13.IS2386–(PartIII):1963MethodsofTestforAggregates forConcrete.

14.IS383:1970SpecificationsforCoarseAggregateandFine Aggregate.

15.IS10262:1982GuidelinesforMixDesignProportioning.

16.IS10262:2009GuidelinesforMixDesignProportioning.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |