International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

1,2,3,4Dept of mechanical engineering, Rao Bahadur Y. Mahabaleswarappa engineering college Ballari-583104, Karnataka, India ***

Abstract - An Investigation project done with the objective to analyse the emission and performance of single cylinder four stroke diesel engine at different load conditions .In this project inlet air manifold is modified using swirl enhancer to generate the swirl of air so that efficient combustion is achieved This experiment is done aiming to improve thermal efficiency and decrease harmful emissions by maximizing the use of air fuel during the combustion process .

Key Words: Diesel engine, Swirl enhancer, Performance, Emissions, Combustion process

In todays world pollution is the major problem caused by emissions of harmful gases from different sources like automobiles and industries which pollutes the environment. The harmful gases may be CO,HC,CO2 and NOx etc. NOx emissions are greatly reduced by generating swirling air. Swirling air causes rapid mixing of fuel and air. Swirl is the ordered rotation of air entering the engine cylinder. Swirl can be generated in different ways, in our experent it is generatedusingswirlenhancerinstalledininletairmanifold.

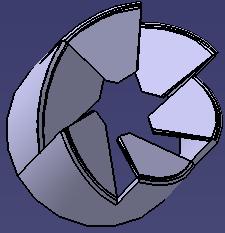

Fig-1: Modellingofswirlenhancer

Swirl Enhancer of 28mm diameter is inserted inside the Inlet air port of the engine head. The modification is done to createswirling.Itseffectonperformanceandemissionarediscussedintheresultssection.It ismadewithsheetmetalby cuttingthebladeonthefrontpartwhichfacesthecombustionchamber.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

10. Loadindicator:Digital,Range0-50kg

11. Rotameter:Caloriemetercooling25-250LPH;Engine40-400LPH.

1. Sheetmetalisusedformakingswirlboosterasitisdeformableinnature.

2. Itcan easilytaketheshapeof theinletairport.

3. Sheeetmetaloperationsrequirelessequipmentsandareeasierthanmachining.

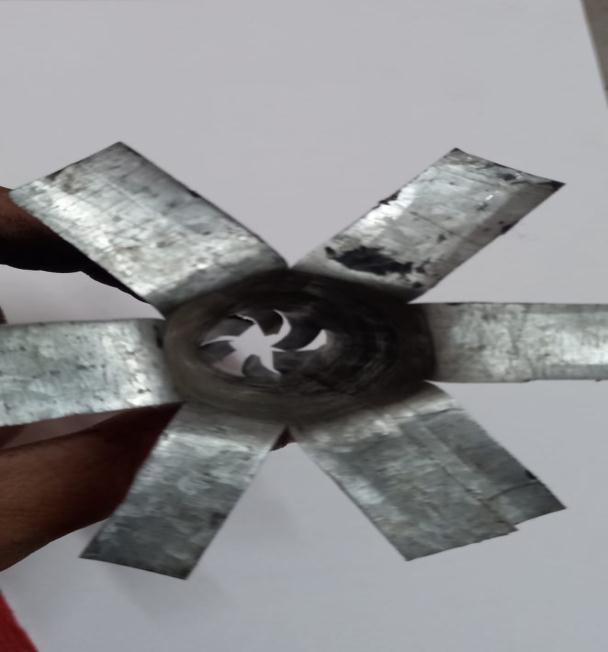

Swirl enhancer(Physical model)

Fig-2: Sideviewoftheswirlenhancer

Fig-3: Topviewoftheswirlenhancer

1. A 15x15mmsteelsheetmetalisselectedformakingtaperedswirlenhancer.

2. Asheetmetalisselectedbecauseitiseasytoperformoperationswhilemakingaswirlenhancer.

3. Sheetmetalworkingtoolsareusedformakingswirlenhancer.

4. AswirlenhancermadeupofsheetmetalcaneasilytaketheshapeoftheInletairport.

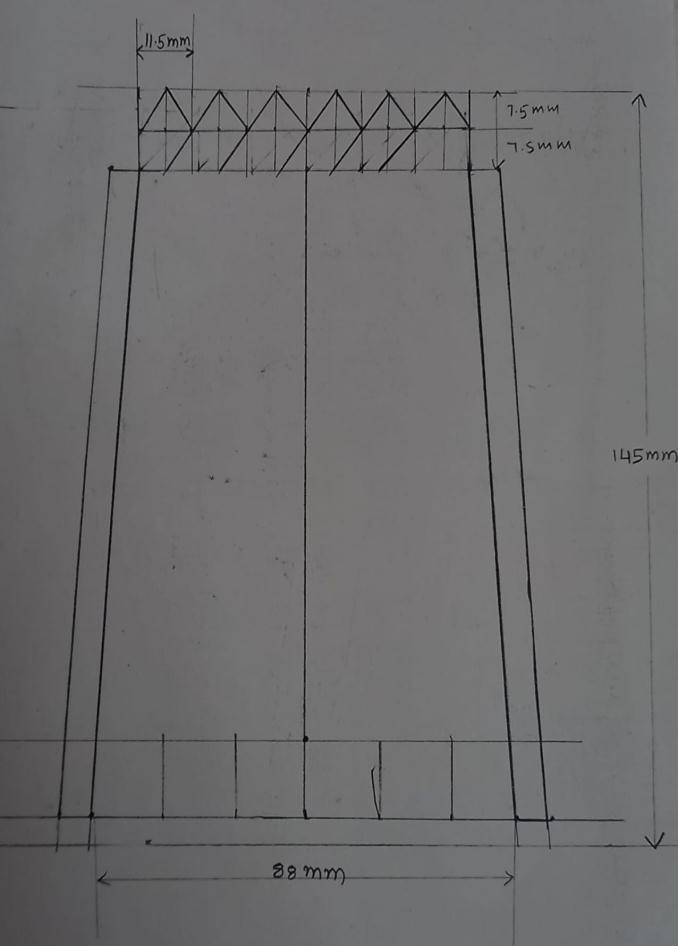

5. Initiallyadevelopmentofconemethodisusedtodrawthedevelopmentof taperedswirlenhancer.

6. Thedevelopmentispastedonsheetmetalandcuttedaccordingly

7. Thecuttedsheetmetalisrolledtoformataperedswirlbooster

8. Theswirlenhancerisinsertedinsidetheinletairportofthecylinderhead.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Fig-4: Devlopmentsketchofswirlenhancer Fig-5: Swirlenhancerinsertedinacylinderhead 3. EXPERIMENTAL SETUP

Fig-6: Computeriseddieselenginetestrig

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

Testrigconsistsof 1. Singlecylinderfourstrokedieselengine(computerised). 2. Fueltankandfuelmeasuringunit. 3. Rotametersforcoolingmeasurement. 4. Transmittersforfuelflowandairflowmeasurementnts. 5. Eddycurrentdynamometerforloading 6. Emissiontestingequipment.

1. Initiallyengineisfueledwithdiesel. 2. Engineischeckedforcoolingwaterflow. 3. Ensuringitisat0kgload. 4. Ensurepowersupplymainsareon. 5. Ensureenginetestrigisconnectedcomputerandemissioncheckingdevice 6. Starttheenginewith0kgloadandrunfor20minutesand slowlyrisetheload 7. Loadisincreasedby2kg,4kg.6kg,8kgand12kgandreadingsaretabulated

1. Load vs Brake thermal efficiency

20.00

15.00

10.00

5.00

BTHE in % Load in Kg

25.00 0 2 4 6 8 12

BTHE 1(%) BTHE 2(%)

0.00

Chart-1: LoadvsBrakethermalefficiency

Brake thermal efficiency depends on Brake power and specific fuel consumption. Here Specific fuel consumption is increasinginanenginewithmodifiedinletmanifoldastheflowoffuelismorethanair.Hencebrakethermalefficiencyis increasingwithincreasingloadBrakethermal efficiencyof anenginewithanmodified inetmanifoldisslightylessthan conventionadieselengine

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

2. Load vs Specific fuel consumption

SFC in Kg/kWh

0 0.2 0.4 0.6 0.8 1 1.2 1.4 0 2 4 6 8 12

Load in kg

Chart-2:LoadvsSFC

Thespecificfuelconsumptionofconventionaldieselengineislowerthanthatofenginewithmodifiedinletmanifold.This isbecauseofthedisturbedairpassageintheairinletport.

3. Load vs Indicated thermal efficiency

100

80

60

40

120 0 2 4 6 8 12

ITHE in % Load in Kg

20

ITHE 1(%)

ITHE 2(%)

SFC 1 SFC 2 0

Chart-3: LoadvsITHE

Indicated thermal efficiency depends on the indicated power which inturn depends on the indicated mean effective pressure.Indicated mean effective pressure is the average pressure in the cylinder for a complete engine cycle. As indicated mean effective pressure is increasing for diesel engine with modified inlet manifold .The ITHE of diesel engine withmodifiedinetmanifoldhasslightyhigherthanconventionadieseengine.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

4. Load vs Mechanical efficiency

50

40

A/F Ratio

70

60

50

40

30

20

10

30

20

60 0 2 4 6 8 12

mech eff in % Load in Kg

10

0

Chart-4: LoadvsMechanicalefficiency

Mechanicalefficiencyisobtainedbytheratioofbrakepowertotheindicatedpower.Astheindicatedpowerisincreasing inanenginewithmodifiedinletmanifoldhencemechanicalefficienyisdecreasing

5. Load vs A/F Ratio

80 0 2 4 6 8 12

Mech eff 1 Mech eff 2 Mech eff 3 Mech eff 4 0

Load in Kg

Chart-5: LoadvsA/FRatio

Conventional Modified inet manifold

Theairfuelratioismoreinconventionaldieselengineanditisreducinginanenginewithmodifiedinletmanifoldbecause oflessairflowresultinginrichmixture.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

1. Load vs CO emission

0 0.5 1 1.5 2 2.5 3 3.5 4

CO in % Load in Kg

Conventional diesel engine

2. Load vs HC emission

160

140

120

100

80

60

40

20

0kg 2kg 4kg 6kg 8kg 12kg

Chart-6: LoadvsCOemission

HC in PPM Load in Kg

Modified inlet manifold with diesel 0

0kg 2kg 4kg 6kg 8kg 12kg

Chart-7: LoadvsHCemission

Conventional diesel engine Modified inlet manifold with diesel

Higher fuel/air ratio causes the emission of HC and CO. During the initial loads the CO and HC emissions are comparativelysmallandthereisslightdifferencebetweendifferencebetweenthetwoButathigherloadsitisincreasing becausewithincreaseintheloadthefuel/airratioincreasesandalsothereisdisturbanceforairflowduetomodification ifaninletmanifold.Thiscausesrichfuel/airmixturehenceresultinginCarbonmonoxideandhydrocarbonemissions.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

3. Load vs CO2 emission

0 1 2 3 4 5 6 7 8 9

CO 2 in % Load in Kg

Conventional diesel engine

0kg 2kg 4kg 6kg 8kg 12kg

Chart-8: LoadvsCO2 emissions

Thecombustionprocesscausesamixingofcarbonwithoxygeninairresultingintheformationofcarbondioxide.The changeofCO2emissionisslightyreducedinanenginewithmodifiedinletmanifoldatmaximumload.

4. Load vs NOx emission

NOx in PPM Load in Kg

Conventional diesel engine

Modified inlet manifold with diesel

Modified inlet manifold with diesel 0 100 200 300 400 500 600 700 800 0kg 2kg 4kg 6kg 8kg 12kg

Chart-9: LoadvsNOxemission

NOx emissions increases with increase in load because it causes increased fuel supply resulting in longer combustion durationcausingincreasein temperaturehenceitcausesNOxformation.TheNOxemissionsare decreasinginanengine withmodifiedinletmanifoldbecauseofrichmixtureburning.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

5. Load vs O2 emission

0 2 4 6 8 10 12 14 16 18 20 0 2 4 6 8 12

O2 in % Load in Kg

Conventional diesel engine

Chart-10: LoadvsO2 emission

WithincreasingloadoxygenemissionisreducingindifferentsetupswhichresultsingoodcombustionoffuelO2emission isalsonearlysamefordifferentsetupsandfuels.

6. Load vs smoke emission

50

40

30

20

60 0 2 4 6 8 12

Smoke in PPM load in Kg

10

Conventional diesel engine

Modified inlet manifold with diesel

Modified inlet manifold with diesel 0

Chart-11: LoadvsSmokeemission

Smoke emission is the part of combustion process.Smoke is increasing with increasing load because of rich fuel mixture burning

1. Inletairswirliscreatedbyusingmodifiedinletmanifold.

2. It concludes that small reduction in Brake thermal efficiency and sight increase in specific fuel consumption.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p-ISSN: 2395-0072

3. Carbonmonoxideandhydrocarbonemissionsareslightydecreasingatthe initialloadsandincreasingat thehigherloadsduetorichmixture.

4. Nitrogenoxide,carbondioxideandoxygenaredecresinginanenginewithmodifiedinletmanifold.

1. T. Shimadev, K.Sakai and S Kurihara, Variable swirl inlet and its effect on diesel engine performance and emissions SAEVol 95,section4(1986).

2. Himegoudar Yerranna Goudaru & Shiva Prasad Desai. Effect of intake air swirl on single cylinder four stroke dieselengineperformance.Vol11,Version iv(July-August2014).

3. Vinod Kumar Sharma, Man Mohan and Chandra Mouli, Effect of inlet swirl on performance of single cylinder directinjectiondieselengine.2017IOPConf.

4. Mahmut KAPLAN, Influence of swirl tumble and squish flows on combustion characterstics and emissions in in ternulcombustionengine–Review .

5. InternalcombustionenginesbyVganesan4th edition.

6. InternalcombustionenginesfundamentalsbyJohnBHeywood.