International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

1 Student, Department of Construction Technology & Management, Dayananda Sagar College of Engineering, Bengaluru, Karnataka, India

2, Assistant Professor, Department of Civil Engineering, Dayananda Sagar College of Engineering, Bengaluru, Karnataka, India. ***

Abstract A pothole is a depression in a road surface, usually asphalt pavement, where traffic has removed broken pieces of the pavement. It is usually the result of water in the underlying soil structure and traffic passing overtheaffectedarea.Waterfirstweakenstheunderlying soil;traffic thenfatiguesandbreaksthe poorlysupported asphalt surface in the affected area. Continued traffic actionejectsbothasphaltandtheunderlyingsoilmaterial to create a hole in the pavement. Iron ore tailings (IOTs) are a form of solid waste produced during the beneficiation process of iron ore concentrate. Among all kinds of mining solid waste, IOTs are one of the most commonsolidwastesintheworldduetotheirhighoutput andlowutilizationratio.

These iron ore tailings can be used as a complete replacement for conventional aggregates in pothole patching mixtures. Using iron ore tailings in the synthesis ofpotholepatchingmixtureswill helpintheutilization of these wastes in great volume. The test which has been conductedforthepredictionofoptimumbindercontentis the Marshall stability test which includes the preparation of the mold and check the strength of the mold after 24 hoursofsettingtime.Theresultsthatwereobtainedfrom the tests are that the optimum binder content is about 5 percent of 1200 grams which is the total amount of aggregates taken. The cutback bitumen was made making themixofkeroseneandbitumenintheratioof30% 70% respectively.

Key Words: Cutback, Iron Ore Tailing, Zycotherm, Optimum Binder Content, Tensile Strength Ratio.

Apotholeisasmallareaofdistressinapavementwithan asphalt surface caused by the base course and asphalt surface being worn away. Usually made of asphalt, potholes are depressions in the road's surface where debris has been removed by forcing water into the subsurface soil structure and traffic in the affected area aretypicallythecausesofthis.Waterinitiallyweakensthe underlying soil.Theasphalt surfaceintheaffectedarea is thendestroyedasaresultofthetrafficbecomingfatigued

Pothole creation is primarily caused by two factors. Poor craftsmanship and mixed design are two of them. When heavy traffic passes over these areas, the asphalt deteriorates and materials are scraped from the surface, leavingthepotholesinitswake.Seepageofwaterthrough fractures and freezing conditions are two additional factors that contribute to pothole formation. When water freezes, it forces he top layer of asphalt and the stratum beneath it down, deteriorating the surfaces underneath the road surface that support it and forming a zone of weakstrains.

Potholes are created when the surface layer breaks up when the vehicle travels over it. As a result, materials becomefreeandescapethesurroundingpavement.Traffic congestion, fuel waste, and longer travel times are all caused by potholes. This ultimately contributes to air pollution, which affects people's health and causes many major issues. In addition, the presence of these potholes contributestonumerousaccidents.

Theformationofpotholeshasfourmainreasons:

1. Insufficient Road tightness to support traffic during snow/meltingseasonswithoutlocalfailure

2.Insufficientwaterflow

3.Failureofoperatingandsimulationchannels(holesand draincasings)

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p ISSN:2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page 69

4. Faults and cracks in paved roads left unattended and closed to allow moisture and jeopardize the integrity of thepavementstructure

When iron ore concentrate is beneficiated, a type of solid waste called iron ore tailings (IOTs) is created. IOTs are among the most widely dispersed solid wastes in the world among all types of mining solid waste because of they produce a lot, but use relatively little About 5% of the Earth's crust is made up of iron, the fourth most common element. Iron, which is frequently found as ore, has been utilized to make tools and weapons for almost 4,000 years. It is difficult to envision modern life without iron ore because it is a necessary component in the

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p ISSN:2395 0072

productionofsteel.SouthAfrica,Australia,Brazil,Canada, India, China, and Europe contain the majority of the world'sironorereserves.

The formation of iron ore concentrates from the iron ore in raw form and as the result there is the formation of tailingintheformoffinesaswellascoarseanditaccounts of total of 20 40% of total weight of iron ore used in raw form, which is a huge by product formed and need to be dumped or utilized in some way so that it does not form any kind of pollution and harm to the environment. As if notutilizedinanykindofworkitneedstobedumpedata placewhichwouldresultsinmanythingssuchaspolluting the groundwater underneath the dumping area, making the area barren and no more agricultural activity can be done as it makes the soil impervious so making it less fertile.

One of the most typical wastes produced worldwide is iron ore tailings. IOTs are a particular category of solid waste produced duringthebeneficiationofironoreconcentrate.

In pothole repair combinations, these iron ore tailings can completely substitute traditional aggregates. Iron ore tailings can be utilised in large quantities by creating pothole repair mixturesusingthem.

Potholes are prevalent all over the world. To use ironoretailingsasasubstitutetoothermaterials usedinpotholepatching.

These iron ore tailings can be utilised in pothole filling mixtures in place of traditional aggregates entirely. Utilizing these wastes in significant quantities will be made possible by making pothole fillingsolutionsoutofironoretailings.

Petrographic examination of iron ore tailings forutilizationinpotholepatchingmixtures.

Mix design of pothole patching mixtures utilizing iron ore tailings as a substitute to conventional aggregates with antistripping agents.

Laboratory evaluation of pothole patching mixtures with iron ore tailings and natural aggregate

Cutback Bitumen, Coarse Aggregate, Fine Aggregate, Iron Ore tailings and Zycotherm were employed in this experiment

The aggregates were obtained from the L.G BLUE METAL crusherinTamilNāduthecombinedgradationPercentage passingoftheAggregatebyJobMixFormula.Thequantity of aggregates was accurately measured to ±0.1 grams in accordancewithIndianStandards:2386(Part1) 1963

The petroleum product known as "cutback bitumen" is madebydilutionofbitumenwith petroleumhydrocarbon (Kerosene). In order to improve bitumen's penetration into asphalt surfaces, viscosity must be reduced. The cutback bitumen was made making the mix of kerosene andbitumenintheratioof30% 70%respectively

IOTs are one of the most prevalent solid wastes in the world among all types of mining solid waste because of their huge output and low usage ratio. Iron Ore Tailings were brought from the Kudremukh. They were sieved accordinglywiththesievesizesofaggregate.

Table 1: Properties of Iron Ore Tailings

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

ZycoTherm is a warm mix asphalt enhanced antistrip additive of the next generation (WMA). It works with every sort of aggregate. It enables increased bitumen adhesion to. An odourless nano organosilane ingredient called Zycotherm is utilised in bituminous mixes. Zycotherm provides improved chemical bonding for longermoistureresistanceandguaranteesthatbitumenis completelycoatedatlowtemperatures.

Various test needs to be performed on the samples and Firstly Marshal stability test need to be conducted to find outtheoptimumbindercontent.

Thefollowingtestneedtobeconductedontheaggregates.

SpecificGravity

WaterAbsorption

AbrasionValue

CrushingValue

ElongationIndex

Flakiness

BulkDensity

ThefollowingarethelistoftestsconductedonCutback

PenetrationTest

SofteningPointSpecificGravity

DuctilityTest

Flash&Fire

Viscositytest

The following are the list of tests conducted on Mix Specimen

MarshalStabilityTest

AdhesionTest

CohesionTest

IndirectTensileStrengthTest

TheMarshallmixdesignmethodconsists of6basicsteps:

1.Selectionofaggregates 2.Asphaltbinderselection 3.Samplepreparation(includingcompaction)

4. Stability determination using the Marshall Stability test Apparatus

5.Densityandvoidscalculations

6.Optimumasphaltbindercontentselection

3.3.1.1 MIX DESIGN

Table 2: Marshall Mix Proportions

PROPORTIONS

Optimum binder contentbyweightmix 5 % by weight of mix 60Gms (9.5mm 4.75mm) 40 % by weight of Aggregate 480 Gms (4.75mm 2.36mm) 35 % by weight of Aggregate 420 Gms (2.36mm 1.18mm) 20 % by weight of Aggregate 240 Gms (1.18mm 0.075mm) 5% by weight of Aggregate 60Gms

Table 2 depicts the proportions for marshall specimen preparationbasedonMORTHtable500 17,aswell asthe jobmixformularestrictions.

Table 3: Combined Gradation of Aggregate Combined Gradation of Aggregate IS Sieve (mm) Job Mix formula combined gradation Percentagepassing

MORTH Specified Limits table500 10 19 100 100 13.2 99.08 90 100 9.5 85.99 70 88 4.75 58.74 53 71 2.36 46.47 42 58 1.18 38.43 34 48 0.6 31.43 26 38 0.3 22.37 18 28 0.15 15.52 12 20 0.075 6.42 6.42

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p ISSN:2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

Table3depictsthejobmixformulaofcombinedgradation percentage passing as per MORTH (table 500 10) specifiedlimits

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p ISSN:2395 0072

Inthelaboratory,Intheprocessofsamplepreparation,we should have an idea of the range in which the optimum binder content will fall and make a certain number of samples mix with 3 number of blends and mix the aggregates and the chosen amount of bitumen content thoroughly and place the mix in the oven at 135 C for 24 hours.Onthenextday,themixcanbetakenoutandmade intothesamplewiththehelpofMarshallHammerwith75 number blows on either side of the mold once placed in the metallic cylindrical mold. Then marshall stability test isperformedonthespecimeninaccordancewithASTM D 1559 76. Then the marshall load & flow values are note downed. Then Bulk Volume, Bulk Specific Gravity, % Air Voids, % VMA, % VFB, are determined using below equations mentioned. Then based on test results graphs areplotted.

The compacted sample was extruded and the sample was inverted. The adhesion of the mixture was measured by the amount of time it took for the specimen to drop from the substrate asphalt. Two groups of materials were tested,includingtheoriginalandoven aged(608Cfor4h) group. The test was conducted at room temperature (258C).

•

• Determinationofthecohesivenessofsample

3.3.3.1

MarshallStabilityLoad,(KN)=AppliedloadinDivision* CorrectionFactor*ProvingRingFactor.

Bulk Volume (cc) = (Mass of Saturated Surface dry SpecimeninAir) (MassofSpecimeninwater)

Bulk Specific Gravity (Gmb) (gm/cc) = (Mass of SpecimeninAir)/(BulkVolume)

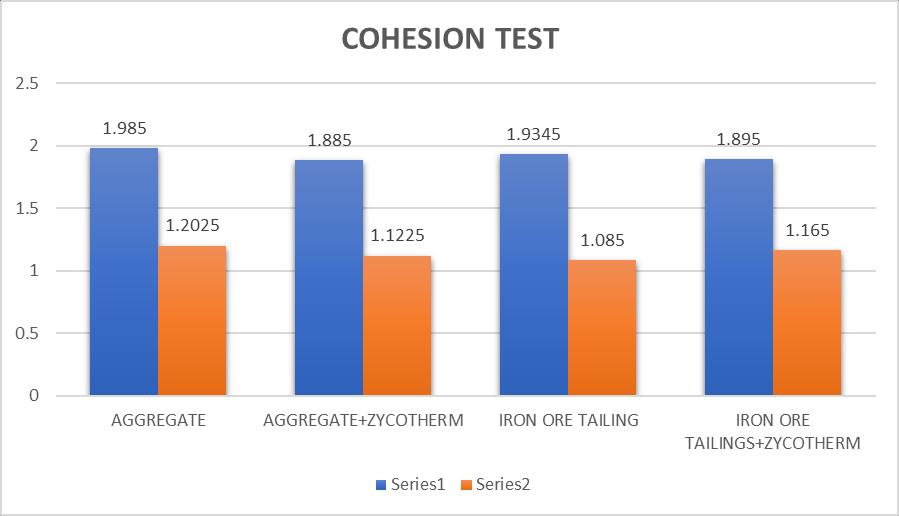

Cohesion test, also named as rolling sieve test, measures the cohesion or the bonding inside the materials. Sealed loosecoldmixesandtheMarshallmouldwereplacedina refrigerator at 48C for 12 h. Thousand grams of cold mix were then placed in the mould and compacted five times on each side with the Marshall hammer. The extruded samplewasplacedina 30.5 cmdiameterfull heightsieve with25.4mmopenings.

% Air Voids = ((Max SG of loose Mixture) Bulk SG Specimen))/(MaxSGofLooseMixture)*100

3.3.3.2 Determination of the cohesiveness of sample

% Voids in Mineral Aggregate = 100 ((Bulk SG of Specimen * Percentage of Aggregates)) / (Bulk SG of Aggregate)

%VoidFilledwithBitumen=100*((%VoidsinMineral Aggregate %AirVoids))/(%VoidsinMineralAggregate)

• Preparationofthesample

• DeterminationOfAdhesivenessofsample

3.3.2.1

500 grams of lose asphalt mixtures were placed in a 100 mmdiameterMarshallmouldontopofa75 mmsampleof compacted HMA and compacted with10 blows of a standardMarshallhammer

A cover was placed on the sieve and the sieve was rolled back and forth on its side approximately. Then, the material loss was calculated by weighing the material retainedonthesieve.Thepercentageofmaterialsretained onthesievewascalculatedasameasureofcohesionofthe mixture higher percentage indicates a more cohesive material.

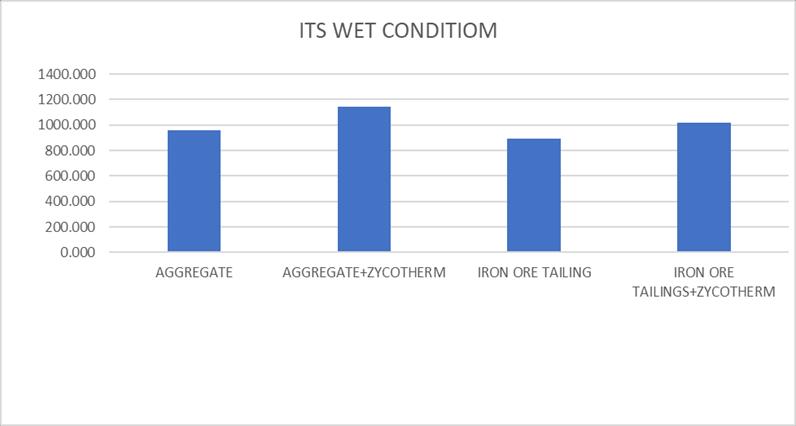

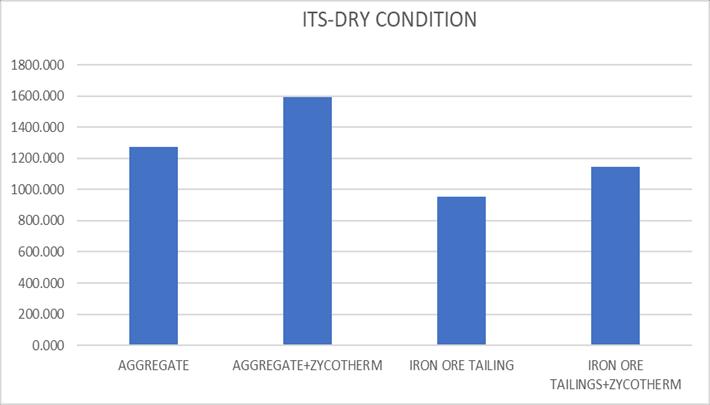

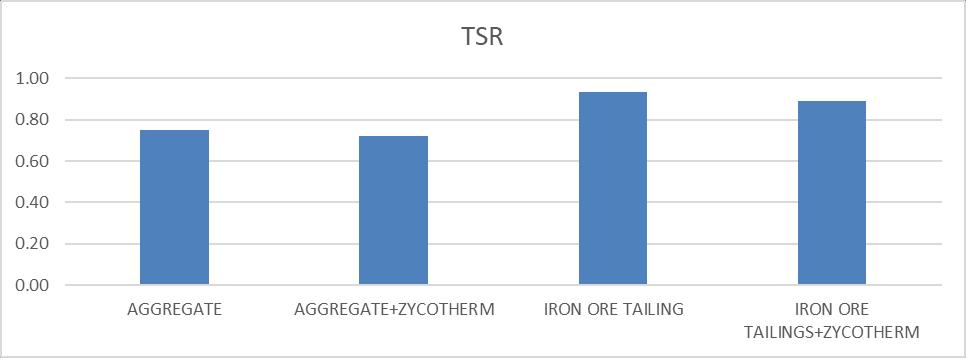

Tensile Strength Ratio is used to assess the moisture susceptibility of a cold mix asphalt mixture. The Marshall specimenwassubjectedtoanindirecttensilestrengthtest in order to compute the tensile strength ratio in accordance with MORTH (table500 13) and AASHTO T283.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p ISSN:2395 0072

Theindirecttensilestrengthtesthasthesamemixdesign as the Marshall mix design. Eight moulds are created for each%.Fourofthemouldsarekeptconditioned,whilethe remaining four are unconditioned. The dry condition tensile strength of the first set of compacted samples was measured in an environmental chamber at 25 ℃ for two hours.Thesecondsetofcompactedsampleswasplacedin a 60 degreeCelsius water bath for 24 hours before conditioning in a 25 degree Celsius water bath for two hours.Thedryandwetspecimensweretestedforindirect tensilestrengthatadisplacementrateof50mm/minata temperature of 25 ℃. Then tensile strength ratio is determinedusingbelowmentionedequation,

Indirect TSR = (Average Indirect Tensile Strength Values of Conditioned Specimens) / (Average Indirect Tensile StrengthValuesofUnconditionedSpecimens)*100

ITSofSpecimen(2000*P)/(π*D*h)

Where,P=AppliedLoad@Failure,(KN).

D=DiameterofSpecimen,(CM).

t=HeightoftheSpecimen,(CM).

1Division=61.53Newton’s/6.27Kilograms

Table 4: Results obtained from Marshall Stability test

AsphaltContent(%) Description 4.5 5 Thickness (mm) 100.5 100.5

Height(mm) 80.50 80.50 Volume(cm3) 628.00 635.08 Weight in air (g) 1087 1147.5 Weight in water(g) 612.00 644 DialReading 113.00 151.50

Flow(mm) 7.25 6.30 StabilityValue (kN) 6.20 8.32

Bulk density (kg/m3) 2288.42 2279.04 Theoretical density (kg/m3)

2437.98 2421.90

Airvoids(%) 6.13 5.9

Volume of Asphalt(%) 16.798 17.633

Void Mineral Aggregates (VMA)(%)

Void Filled with Asphalt (VFA) (%)

16.798 17.633

63.479 66.538

The table shows results obtained in the marshal stability test for the Aggregates with cutback was tested for 4.5% and5%bindercontent.AccordingtoASTMD6927 06,the marshall stability value must be more than 8.0 kN to achieve the minimum standard for road pavement. Hence thestabilityat4.5%is6.20 kNand5%is8.32kNandthe maximumflowvalueis0.2%byweightofbitumenthatis 12mmsothevalueof4.5%is7.25mmand5%is6.30mm andhence5%reachedtheminimumrequirementanditis takenasoptimumbindercontentforthetest.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p ISSN:2395 0072

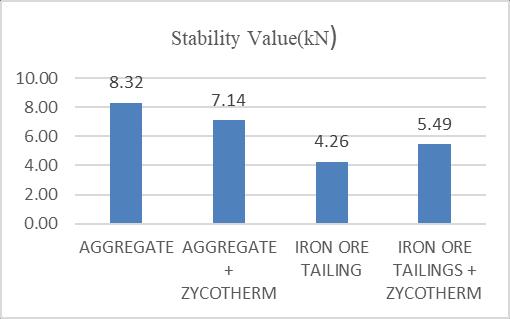

The graph depicts Marshall Stability value of Aggregate, Aggregate with Zycotherm, Iron ore tailing and zycotherm treated iron ore The stability value of aggregatesampleis8.32kN,AggregatewithZycothermis 7.14 k N, Iron ore tailing sample is 4.26 k N, Iron ore tailingwithZycothermsampleis5.49kN.

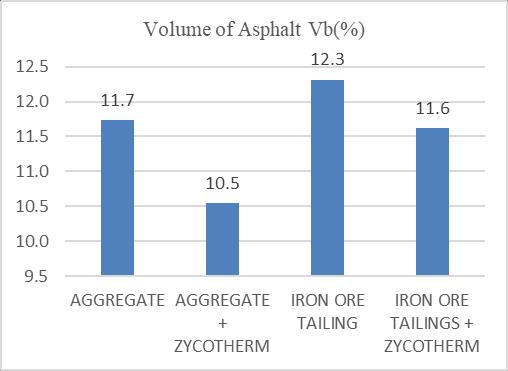

TheVoidsofAsphaltpresentinAggregate,Aggregatewith Zycotherm, Iron ore tailing and Zycotherm treated iron ore tailing sample. The Percentage of Air Voids value of aggregate sample is 11.7 % Aggregate with Zycotherm is 10.5 %, Iron ore tailing sample is 12.3 %, Zycotherm treatedironoretailingsampleis11.6%.

4.1.4

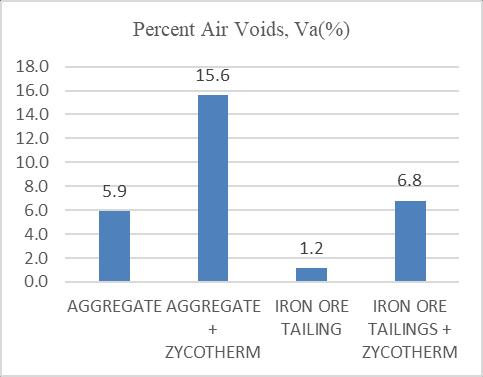

The percentage of aggregate air voids, Aggregate with Zycotherm, Iron ore tailing and Zycotherm treated iron ore tailing sample. The Percentage of Air Voids value of aggregate sample is 5.9 % Aggregate with Zycotherm is 15.6 %, Iron ore tailing sample is 1.2 %, Zycotherm treatedironoretailingsampleis6.8%.

Fig

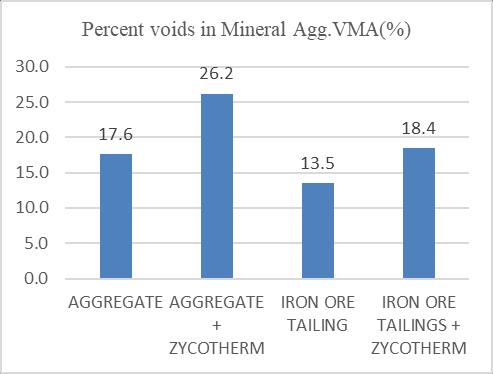

The Voids in Aggregate Minerals present in Aggregate, Aggregate with Zycotherm, Iron ore tailing and Zycotherm treated iron ore tailing. The Voids in Mineral Aggregate value of aggregate sample is 17.6 % Aggregate with Zycotherm is 26.2 %, Iron ore tailing sample is 13.5 %,Zycotherm treatedironoretailingsampleis18.4%

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p ISSN:2395 0072

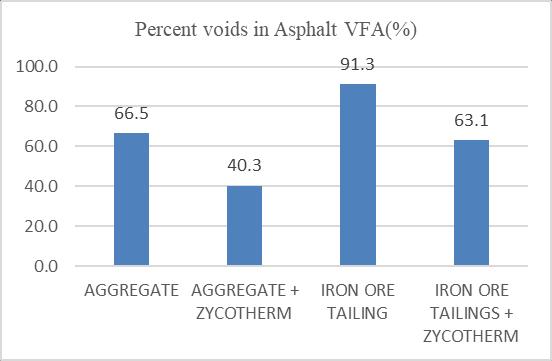

TheVoidsfilledinasphaltpresentinAggregate,Aggregate with Zycotherm, Iron ore tailing and Zycotherm treated iron ore tailing. The Voids filled in asphalt value of aggregate sample is 66.5 % Aggregate with Zycotherm is 40.3 %, Iron ore tailing sample is 91.3%, Zycotherm treatedironoretailingsampleis63.1%.

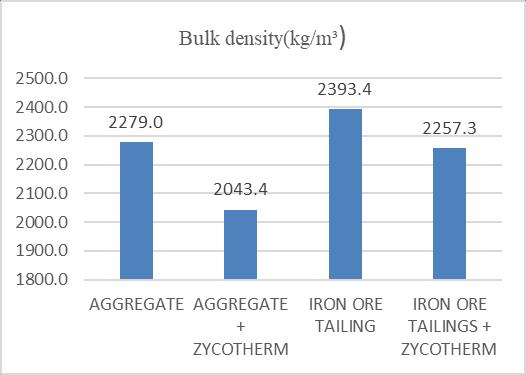

Volumetric properties such as bulk density for Aggregate, Aggregate with Zycotherm, Iron ore tailing and Zycotherm treated iron ore tailing are shown in the bar chart. The bulk density of Aggregate is 2279 kg/m3, Aggregate with Zycotherm is 2043.4 kg/m3, Iron ore tailings is 2393.4 kg/m3, Zycotherm treated iron ore tailingis2257.3kg/m3.

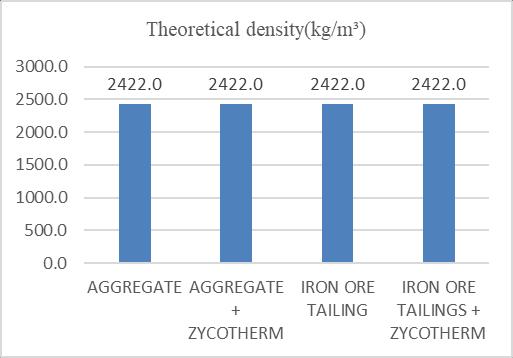

Volumetric properties such as theoretical density for Aggregate,AggregatewithZycotherm,Ironoretailingand Zycotherm treated iron ore tailing are shown in the bar chart. The bulk density of Aggregate is 2422 kg/m3 , AggregatewithZycothermis2422kg/m3,Ironoretailings is2422kg/m3, Zycotherm treatedironore tailing is2422 kg/m3 .

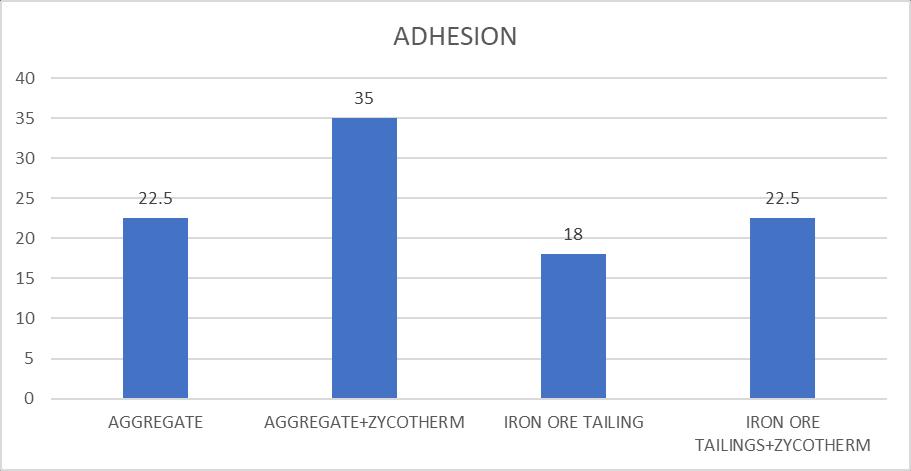

Adhesive Properties exhibited by Aggregate, Aggregate with Zycotherm, Iron ore tailing and Zycotherm treated iron ore tailing are shown in the bar chart. The AdhesivenessofAggregateis22.5seconds,Aggregatewith Zycotherm is 35 seconds, Iron ore tailings is 18 seconds, Zycotherm treatedironoretailingis22.5seconds.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p ISSN:2395 0072

Cohesiveness Properties exhibited by Aggregate, Aggregate with Zycotherm, Iron ore tailing and Zycotherm treated iron ore tailing are shown in the bar chart.TheWeightofAggregateis1.985kg,Aggregatewith Zycotherm is 1.885kg, Iron ore tailings is 1.9345kg , Iron ore tailing with Zycotherm is 1.895kg . The Weight retained after rolling of Aggregate is 1.202 kg, Aggregate with Zycotherm is 1.1225kg, Iron ore tailings is 1.08 kg, Zycotherm treatedironoretailingis1.165kg.

The moisture susceptibility may be determined using the tensile strength ratio. When testing moisture resistance, TSR alone was determined to be insufficient. To evaluate the moisture damage resistance of asphalt mixtures, it is recommendedtotestbothTSRandwetITSstrengthatthe same time. The TSR Value of Aggregate sample and Aggregate with zycotherm, Iron ore tailing and Zycotherm treated iron ore tailing is shown in the barchart. The value of TSR for the Aggregate is 0.75, AggregatewithZycothermis0.72,IronOreTailingis0.93 andZycotherm treatedironoretailingis0.89

The current study was primarily concerned with the utilization of Iron Ore Tailing as an alternative to conventional aggregate inasphaltmixtures.Thefollowing conclusions are reached based on the findings of experimentaltesting:

• It was investigated to see if iron ore tailings (IOTs) might replace traditional aggregates in pothole patching mixtures. It was discovered that doing so would help to significantly increase the amount of trash that could be used up. You can save 20 to 30 percent on pothole repair costs.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

• Since IOTs have a higher moisture content than aggregates, their inclusion reduces the mixture's workability. With the addition of IOTs, the cost strength increasealsorisesby20to30percent.

• A small number of samples of cutback bitumen were collected, and both ordinary aggregate and iron ore tailings were used to create the sample. The sample contained 30% kerosene and 70% bitumen. The Marshall Stability test was performed on each of them, and it was discovered that in order to obtain the necessary quantity offlowvalueandstability,wehadtoutilisearound5%of the cutback bitumen, or 60g, in the aggregate or iron ore tailingstotalquantity(i.e.,1200g).

• In a cohesion test, aggregates and iron ore tailings producedroughlythesameresultsatacutbackcontentof 5%; however, when zycothetrm was added, the cohesivenessvalueincreased.

• The specimens of aggregate, aggregate with Zycotherm, iron ore tailings, and iron ore tailings with Zycotherm underwent an adhesion test. The duration required by aggregate and iron ore tailings using the zycothermwasshowntobe22.5seconds.

• In both dry and wet conditions, loaded wheel tests were performed on specimens of aggregate, aggregate with zycotherm, iron ore tailings, and zycotherm treated iron ore tailings. When compared to aggregates, the iron ore tailings will be more resistant to temperature and load

[1] Ahmad and Jahangir Mirza, “Evaluation of iron ore tailings as replacement for finer aggregate in concrete”,ConstructionandBuildingMaterials

[2] H. Obaidi, B. Gomez Meijide, A. Garcia, “A fast pothole repair method using asphalt tiles and induction heating”,ConstructionandBuildingMaterials

[3] Hussain A. Khalid and Ormsby K. Monney, “Moisture damage potential of cold asphalt”, International JournalofPavementEngineering

[4] Matthew Sainz. “Pothole Patching: A Review on MaterialsandMethods”:IAPAScholarshipSubmission

[5] NyomanAryaThanaya,NyomanWidanaNegara,Putu Suarjana, “Properties of Cold Asphalt Emulsion Mixtures (CAEMs) using materials from old road pavementmilling”,ProcediaEngineering.

[6] Qiao Dong, Baoshan Huang & Sheng Zhao. “Field and laboratory evaluation of winter season pavement

pothole patching materials”: International Journal of PavementEngineering.

[7] Tanuj Parmar, Prof. C.B. Mishra, Dr. Sangita, Prof. N.F Umrigar, “Potholes Repair Technology A Review ” : International Journal for Scientific Research and Development

[8] Yang, Zhendong Qian , Xin Song,“A pothole patching materialforepoxyasphaltpavementonsteelbridges”, ConstructionandBuildingMaterial

Author 2ndAutho

DEEPTHI.C, M.techStudent,Departmentof Constructiontechnology& Management,DayanandaSagar College of Engineering, Bengaluru, Karnataka,India

Dr.SHIVAKUMARG, AssociateProfessor, DepartmentofcivilEngineering, DayanandaSagarCollegeof Engineering,Bengaluru, Karnataka,India

Volume: 09 Issue: 08 | Aug 2022 www.irjet.net p ISSN:2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal